Methanol dynamic device and work done method by methanol pyrolysis

A power plant, methanol cracking technology, applied to engine components, combustion engines, machines/engines, etc., to achieve the effect of improving thermal efficiency and reducing compression power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

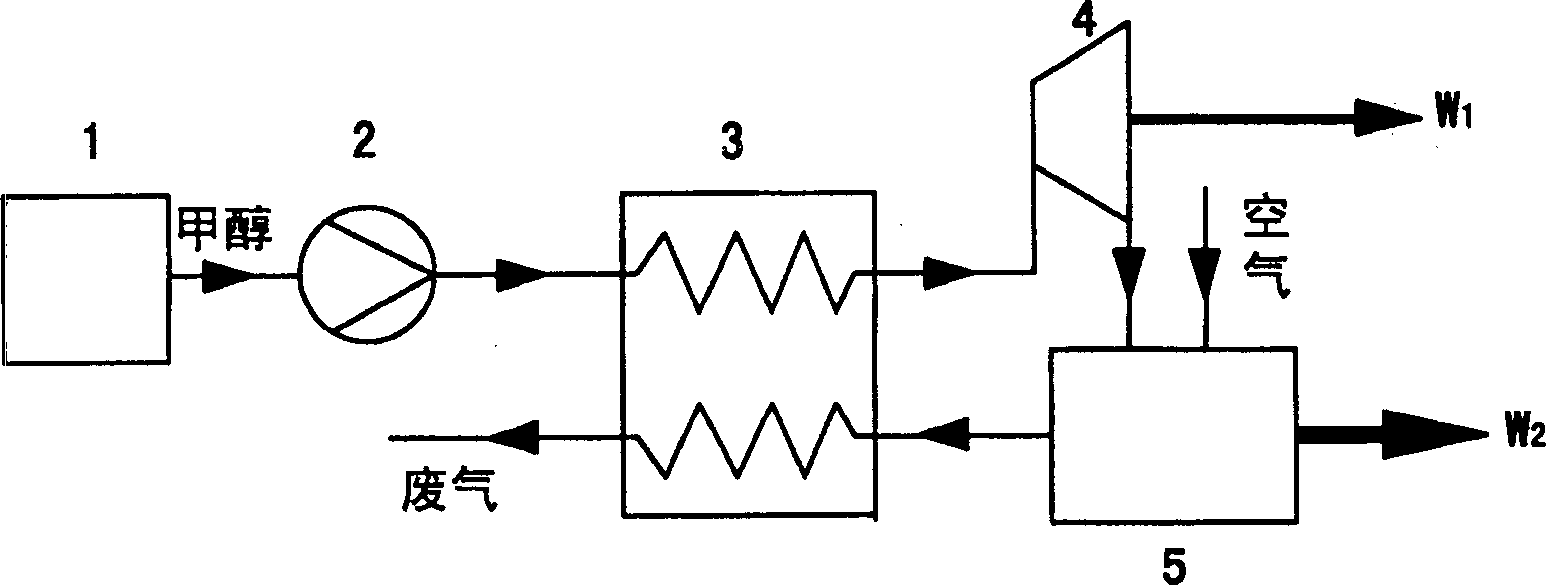

[0022] Combine below figure 1 Describe in detail the details and working conditions of the specific device proposed according to the present invention.

[0023] Such as figure 1 As shown, the methanol power plant of the present invention is composed of a methanol tank 1, a methanol pump 2, a heat exchanger / cracker 3, a turbine 4 and an internal combustion engine 5. Catalyst is accommodated in heat exchanger / cracker 3, such as supported molten salt catalyst CuCl-KCl / SiO 2 . Wherein the internal combustion engine 5 is provided with an air inlet for introducing air.

[0024] Methanol is stored in the methanol tank 1, and the liquid methanol from the methanol tank 1 is pressurized by the methanol pump 2 to a corresponding pressure and then enters the heat exchange / cracker 3, where the waste heat from the exhaust of the internal combustion engine 5 is received in the heat exchange / cracker 3. Vaporization and cracking under the action of catalyst. The cracked mixed gas enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com