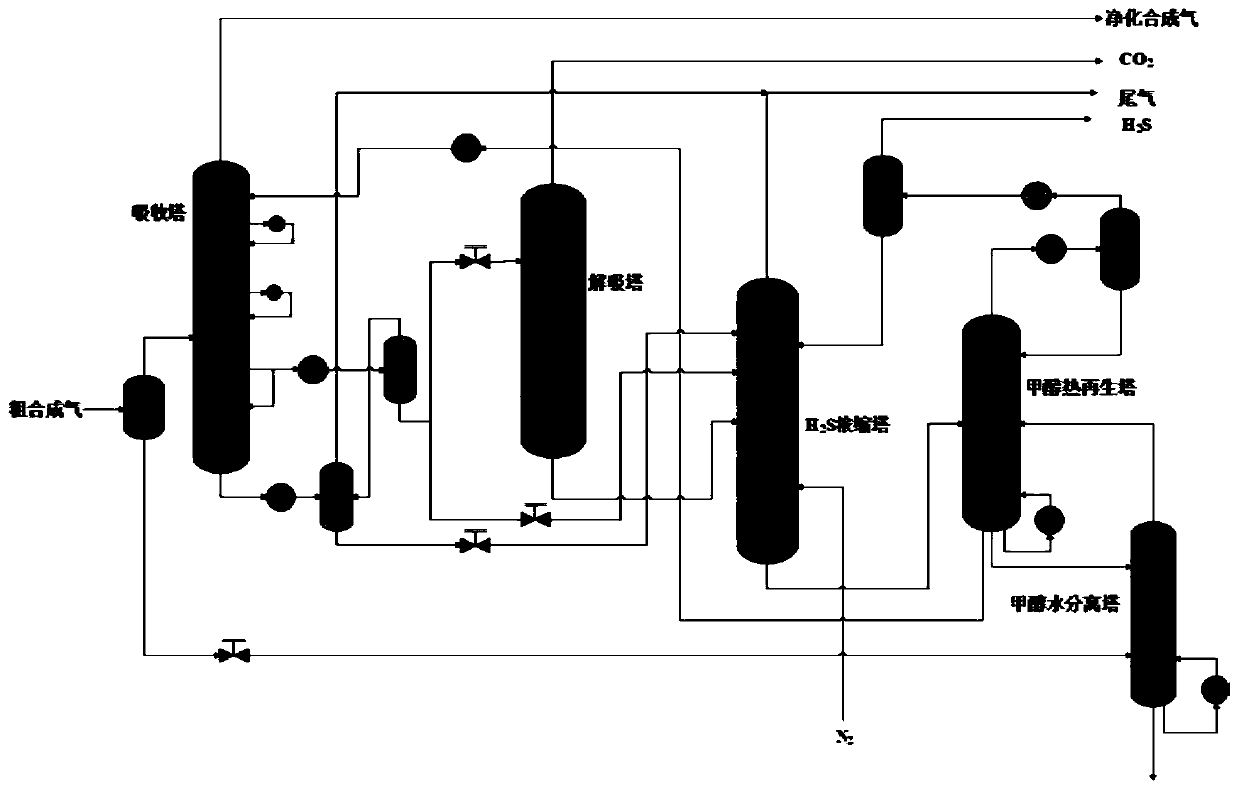

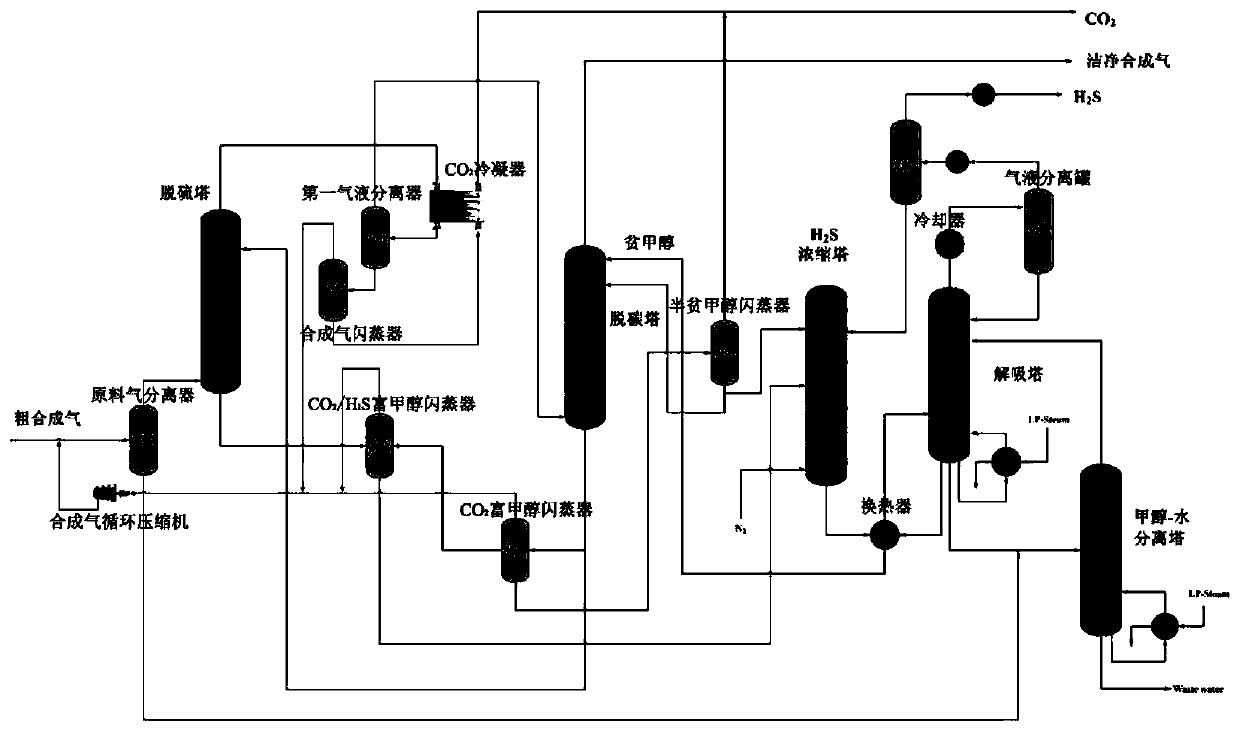

Low-temperature methanol washing process method and device with low energy consumption and high carbon capture rate

A low-temperature methanol washing and capture rate technology, applied in the field of coal chemical industry, can solve the problems of high energy consumption and low carbon capture rate, and achieve high energy consumption, high resource utilization, reduced cooling capacity and compression power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a process method for low-temperature methanol washing using the above-mentioned device.

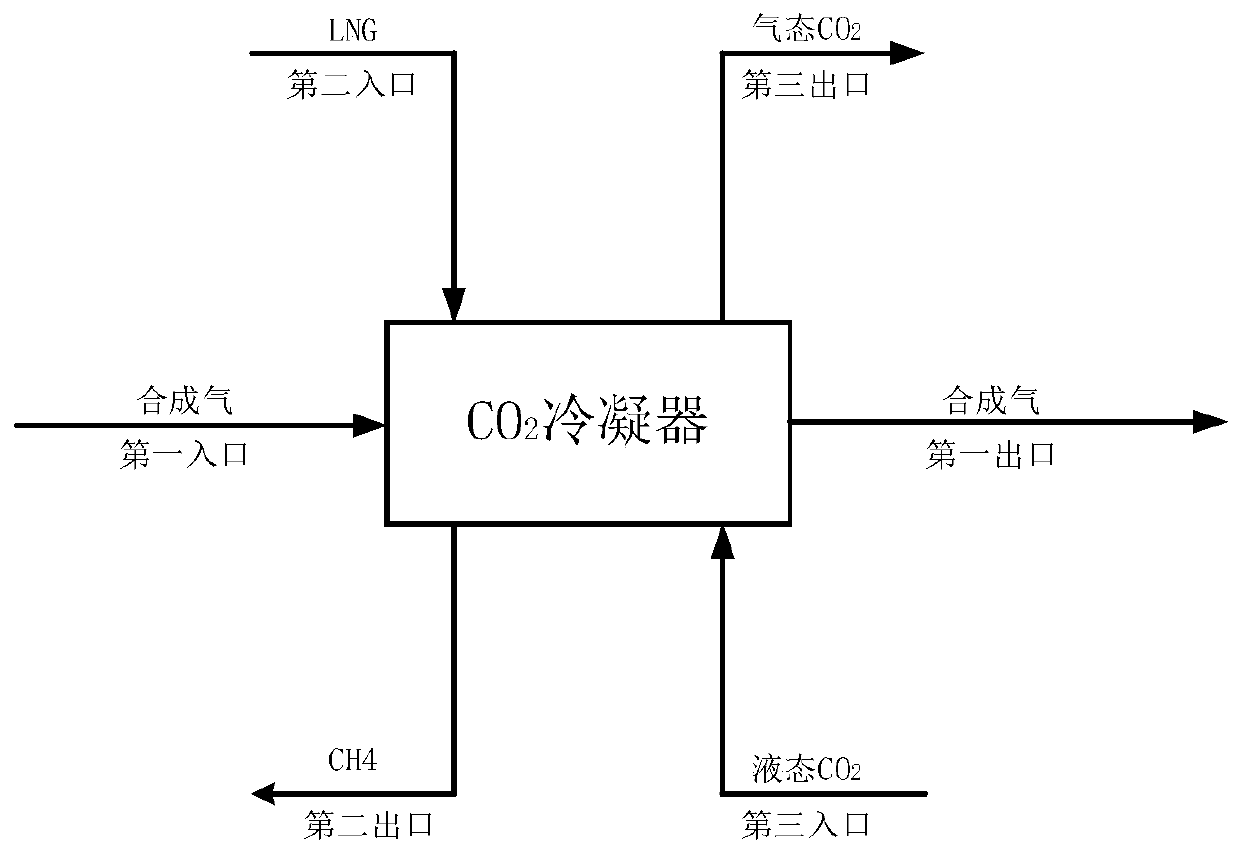

[0048] 40℃, 56bar, 17805kmol / h synthesis gas, containing 46.61% H 2 , 20.37% CO, 32.12% CO 2 , 0.3% N 2 , 0.1% Ar, 0.23% H 2 S and 0.27% H 2 O, through the gas-liquid separator, enters the desulfurization tower, and is enriched by CO 2 The methanol solution is absorbed and separated, and gas (CO 47.5%, H 2 21.2%, CO 2 30.8%, 0.5% N 2 and AR), overhead gas and CO 2 The first inlet of the condenser is connected and condensed to obtain 45.76kmol / h of CO and 159.9kmol / h of H 2 , 4451.27kmol / h of CO 2 Liquid carbon dioxide, and H containing 8253.27kmol / h 2 , 3502.21kmol / h of CO, 1739.44kmol / h of CO 2 , 52.1kmol / h of N 2 and 16.98 kmol / h of Ar synthesis gas. The temperature is 162°C, the pressure is 6.62bar, and the 6200kmol / h LNG is connected to the second inlet of the carbon dioxide condenser. Export sent. The synthesis gas containing condensate ...

Embodiment 2

[0051] This embodiment provides a process method for low-temperature methanol washing using the above-mentioned device.

[0052] 40℃, 56bar, 13353.75kmol / h synthesis gas, containing 46.61% H 2 , 20.37% CO, 32.12% CO 2 , 0.3% N 2 , 0.1% Ar, 0.23% H 2 S and 0.27% H 2 O, through the gas-liquid separator, enters the desulfurization tower, and is enriched by CO 2 The methanol solution is absorbed and separated, and the gas (CO47.5%, H 2 21.2%, CO 2 30.8%, 0.5% N 2 and AR), overhead gas and CO 2 The first inlet of the condenser is connected and condensed to obtain 34.32kmol / h of CO and 119.925kmol / h of H 2 , 3338.4525kmol / h of CO 2 Liquid carbon dioxide, and H containing 6189.95kmol / h 2 , 2626.66kmol / h of CO, 1304.58kmol / h of CO 2 , 39.075kmol / h of N 2and 12.735 kmol / h of Ar synthesis gas. The temperature is 162°C, the pressure is 6.62bar, and the 4650kmol / h LNG is connected to the second inlet of the carbon dioxide condenser. Export sent. The synthesis gas containing...

Embodiment 3

[0055] This embodiment provides a process method for low-temperature methanol washing using the above-mentioned device.

[0056] 40℃, 56bar, 26707.5kmol / h synthesis gas, containing 46.61% H 2 , 20.37% CO, 32.12% CO 2 , 0.3% N 2 , 0.1% Ar, 0.23% H 2 S and 0.27% H 2 O, through the gas-liquid separator, enters the desulfurization tower, and is enriched by CO 2 The methanol solution is absorbed and separated, and the gas (CO47.5%, H 2 21.2%, CO 2 30.8%, 0.5% N 2 and AR), overhead gas and CO 2 The first inlet of the condenser is connected and condensed to obtain 68.64kmol / h of CO and 239.85kmol / h of H 2 , 6676.905kmol / h of CO 2 liquid carbon dioxide, and H containing 12379.905 kmol / h 2 , 5253.315kmol / h of CO, 2609.16kmol / h of CO 2 , 78.15kmol / h of N 2 and 25.47 kmol / h of Ar synthesis gas. The temperature is 162°C, the pressure is 6.62bar, and the 9300kmol / h LNG is connected to the second inlet of the carbon dioxide condenser. Export sent. The synthesis gas containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com