Method for synthesizing low pressure ammonia

A low-pressure technology for ammonia synthesis, applied in the field of ammonia synthesis, can solve the problems of high energy consumption and high investment, and achieve the effects of reducing power consumption, simplifying equipment, and reducing hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

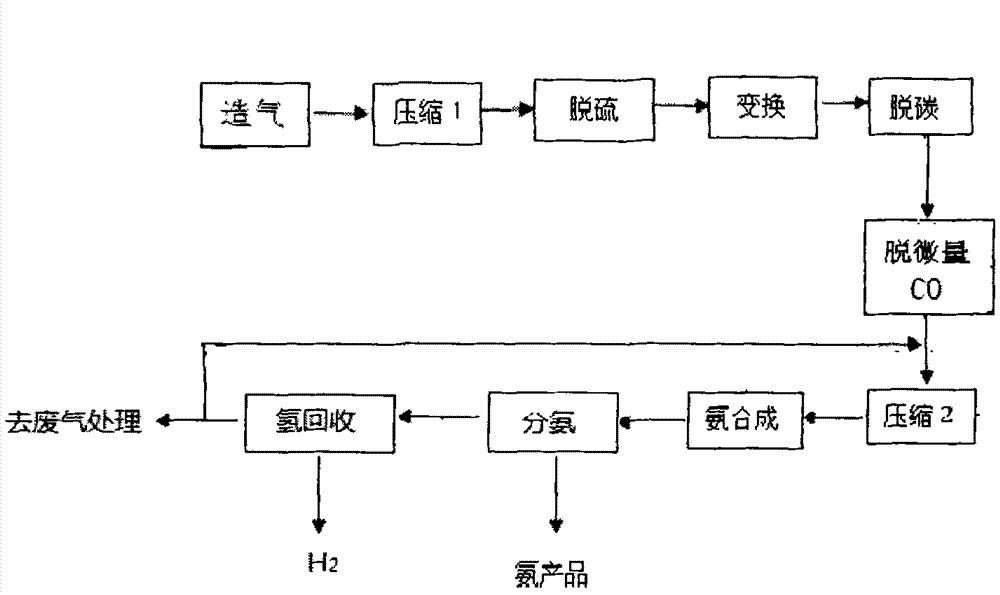

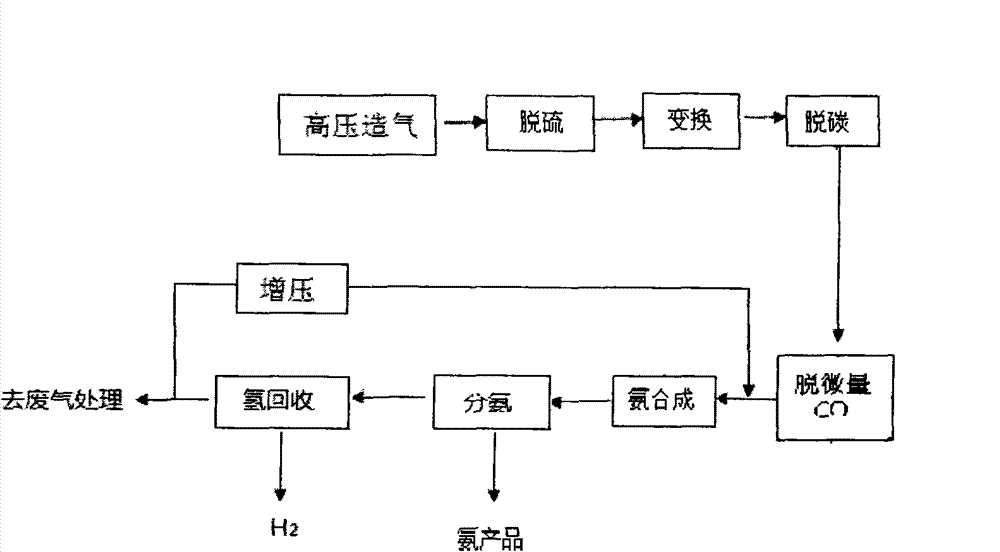

[0030] see figure 1 , the raw material gas obtained from coal gasification, or the tail gas produced by alcohol and ether, or the tail gas of coke oven, or the tail gas of steelmaking and the reformed natural gas with an operating pressure of 0.7-4.0MPa, is boosted by "compression 1" Finally, carry out desulfurization, conversion, decarburization, and then "compression 2" to raise the pressure to 10MPa and then enter the gas preheater, and exchange heat with the hot synthesis gas from the bottom of the synthesis tower before entering the synthesis tower. 10.0MPa, air speed 9000h -1 , the temperature is 300-400°C, and the hydrogen-nitrogen ratio of the feed gas is 0.55. The composition of gas entering and exiting the tower in the ammonia synthesis process is shown in Table 1.

[0031] Table 1

[0032] Composition / %

Embodiment 2

[0034] Repeat the process of Example 1, the feed gas hydrogen-nitrogen ratio is 1.11, space velocity 10000h -1 , temperature 300 ~ 400 ℃. The composition of gas entering and exiting the tower in the ammonia synthesis process is shown in Table 2.

[0035] Table 2

[0036] Composition / %

Embodiment 3

[0038] Repeat the process of Example 1, the feed gas hydrogen-nitrogen ratio is 1.46, space velocity 10000h -1 , temperature 300 ~ 400 ℃. The composition of gas entering and exiting the tower in the ammonia synthesis process is shown in Table 3.

[0039] table 3

[0040] Composition / %

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com