Intercooling type multistage axial flow air compressor and working method thereof

An axial flow compressor, cold type technology, applied in axial flow pumps, mechanical equipment, non-variable pumps, etc., can solve problems that cannot be used to reduce power consumption, complex structure, and pressure loss of low-pressure compressors, and achieve Effects of avoiding compression power consumption, avoiding pressure loss, and reducing compression power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

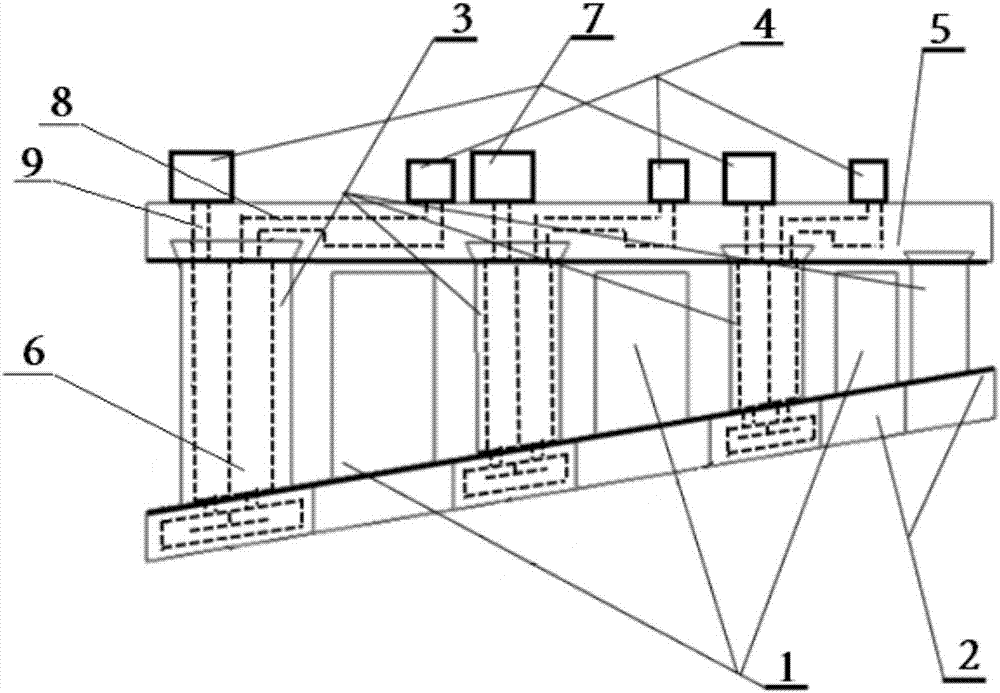

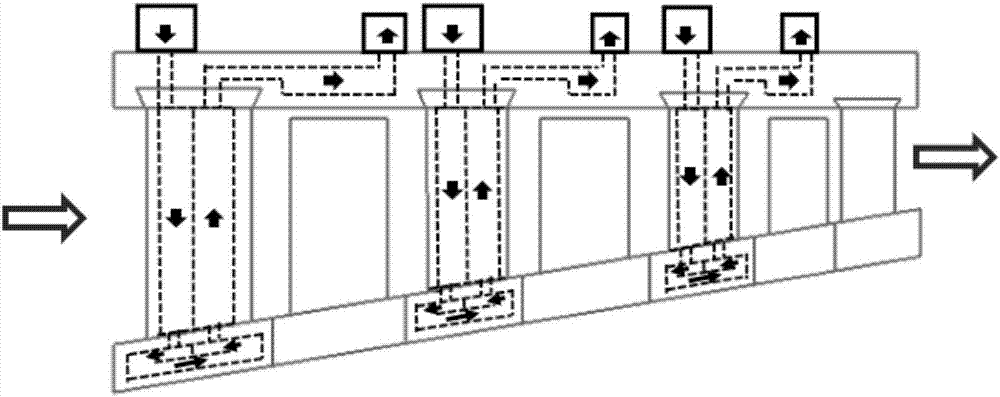

[0022] refer to figure 1 , the intercooled multi-stage axial flow compressor of the present invention includes a casing 5, a hub 2, a plurality of rotor blades 1 and a plurality of stator blades 3, and each rotor blade 1 and each stator blade 3 are sequentially staggered along the direction of flow of the working medium distribution, and the lower end of the rotor blade 1 is connected to the hub 2, the upper end of the stator blade 3 is connected to the casing 5, the lower end of the stator blade 3 is movably connected to the hub 2, and the casing 5 is provided with a number of cold air intake ring chambers 7 And some cold air exhaust ring chambers 4, a number of first internal cooling runners 8 and a number of second internal cooling runners 9 are opened in the casing 5, a third internal cooling runner 6 is provided in the 3 stator blades, a static The leaves 3 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com