Non-concentric variable cross section GWF device

A non-concentric, variable-section technology, used in gas fuel, gas treatment, vapor condensation, etc., can solve the problems of small centrifugal force, complex structure and process flow, high manufacturing and operating costs, and achieve improved recovery rate, efficient separation or liquefaction. effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

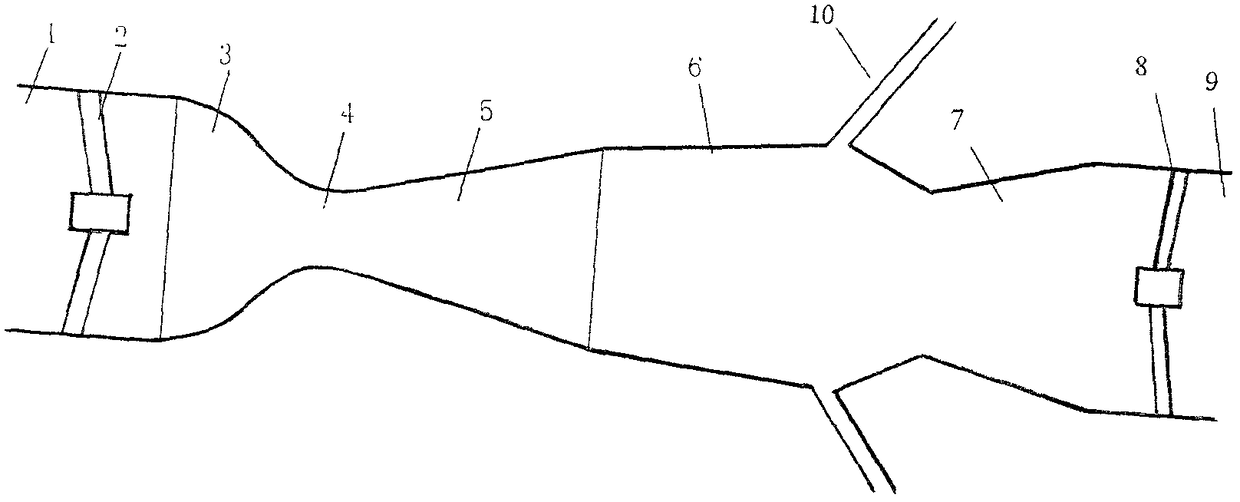

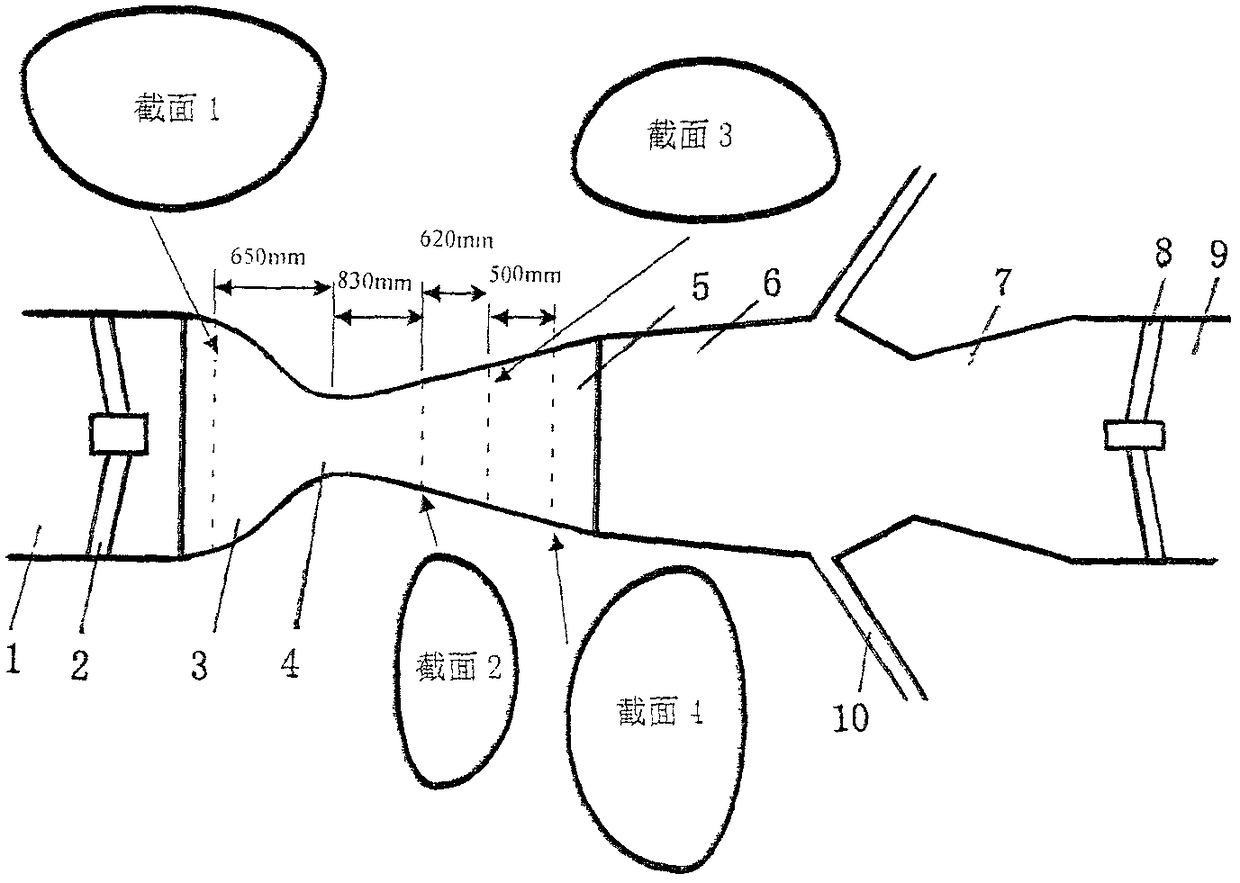

[0048] Embodiment Non-concentric variable section GWF device ( Figure 12 , image 3 shown)

[0049] Location of use: A gas gathering station in Kuqa, southern Xinjiang

[0050] Operation time: October 1, 2012

[0051] Raw gas initial conditions and requirements:

[0052] 1. Entry pressure: 2.0~2.2MPa.g

[0053] 2. Entry temperature (T0): ≤30°C

[0054] 3. Capacity: 6~15×10 4 N m 3 / day (0.1MPa, at 20°C)

[0055] 4. Water dew point (under outlet pressure): ≤-15°C

[0056] 5. Feed gas components (the sum of carbon-3 and above components is 5.52%)

[0057] components

[0058] Set device design parameters (with a processing capacity of 13×10 4 N m 3 / day is set for standard working conditions)

[0059] 1. Device import parameters:

[0060] Inlet flow (G1): 15.3×10 4 N m 3 / day (0.1MPa, at 20°C)

[0061] Inlet temperature (T1): 10~0℃

[0062] Inlet pressure (P1): 3.65MPa.g

[0063] 2. Device export parameters:

[0064] Outlet pressure (P2): 2.17MPa.g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com