Preparation of high closeness polyacrylacid ester dispersion

A polyacrylate and acrylate technology, applied in the coating and other directions, can solve the problems of easy adhesion, yellowing, color bleeding, etc., and achieve the effects of low gel rate, small amount of emulsifier, and fast drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

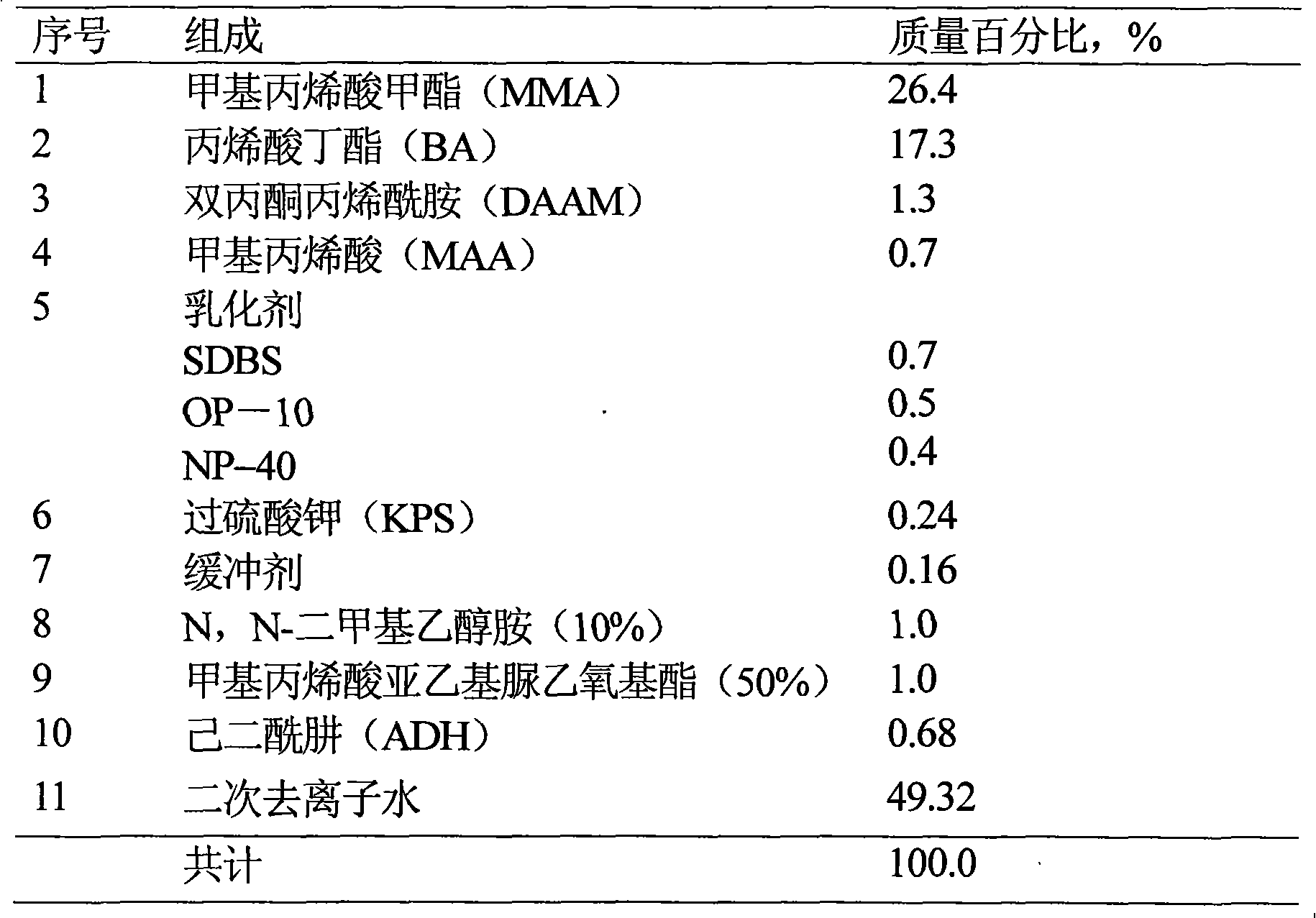

[0063] The monomer composition is butyl acrylate, methyl methacrylate, methacrylic acid, diacetone acrylamide, ethylene urea ethoxy methacrylate, and its components are listed in Table 1.

[0064] Table 1 polyacrylate dispersion formula

[0065]

[0066] Add 2.7 parts of compound emulsifier, buffer, and 32.92 parts of deionized water into the reaction kettle, stir at high speed for 20 minutes, and raise the temperature to 55°C, add 0.4 parts of methacrylic acid, 8.4 parts of butyl acrylate, 16 Mixed monomers of methyl methacrylate, raise the temperature of the reactor to 82°C, slowly add part of the initiator solution dropwise, wait until the seed dispersion is in a blue phase and stabilize for half an hour, add the pre-emulsified dropwise within 1.5 hours For the core monomer, continue to drop the pre-emulsified shell monomer within 2 hours after an interval of 20 minutes. After adding all the monomers, add 4 parts of 10% aqueous initiator solution, raise the temperature t...

Embodiment 2

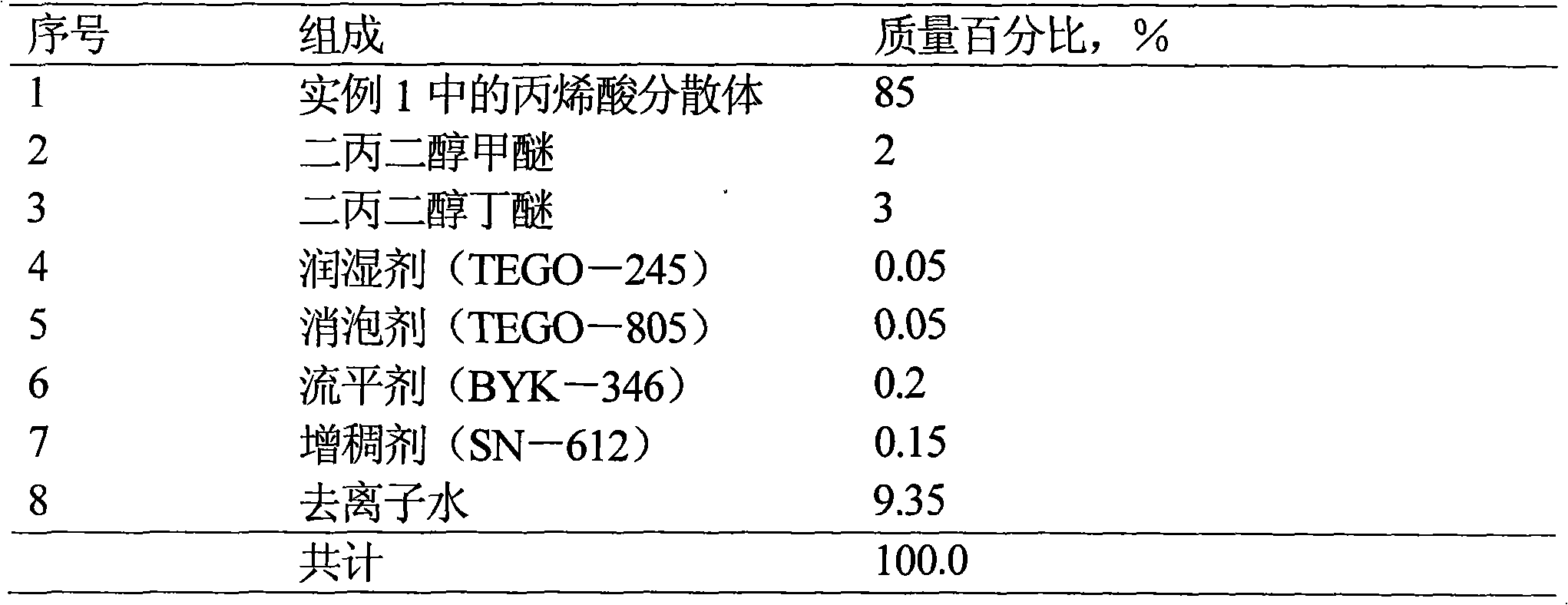

[0071] Using the acrylate dispersion prepared in Example 1, the wood coating formulation was prepared as shown in Table 2.

[0072] Table 2 Waterborne Wood Coating Formulation

[0073]

[0074] The preparation method is as follows: firstly add raw materials No. 2-8 into the stirring tank, disperse with a high-speed disperser for 10-30 minutes, then slowly add the acrylic acid dispersion into the stirring tank, stir at a medium speed for 30-60 minutes, adjust with ammonia water The pH value of the paint, when the pH value is qualified, it is filtered, discharged and packaged. Properties of the prepared wood coating: Appearance: milky white slightly transparent liquid without mechanical impurities; pH=7-9; solid content 35-40%, viscosity 30-200cps. Wood coating film performance: Pencil hardness of coating film: HB; water resistance: no obvious change after soaking in water for 48 hours; adhesion: level 1; flexibility: level 1; excellent sealing; anti-adhesion: level A.

Embodiment 3

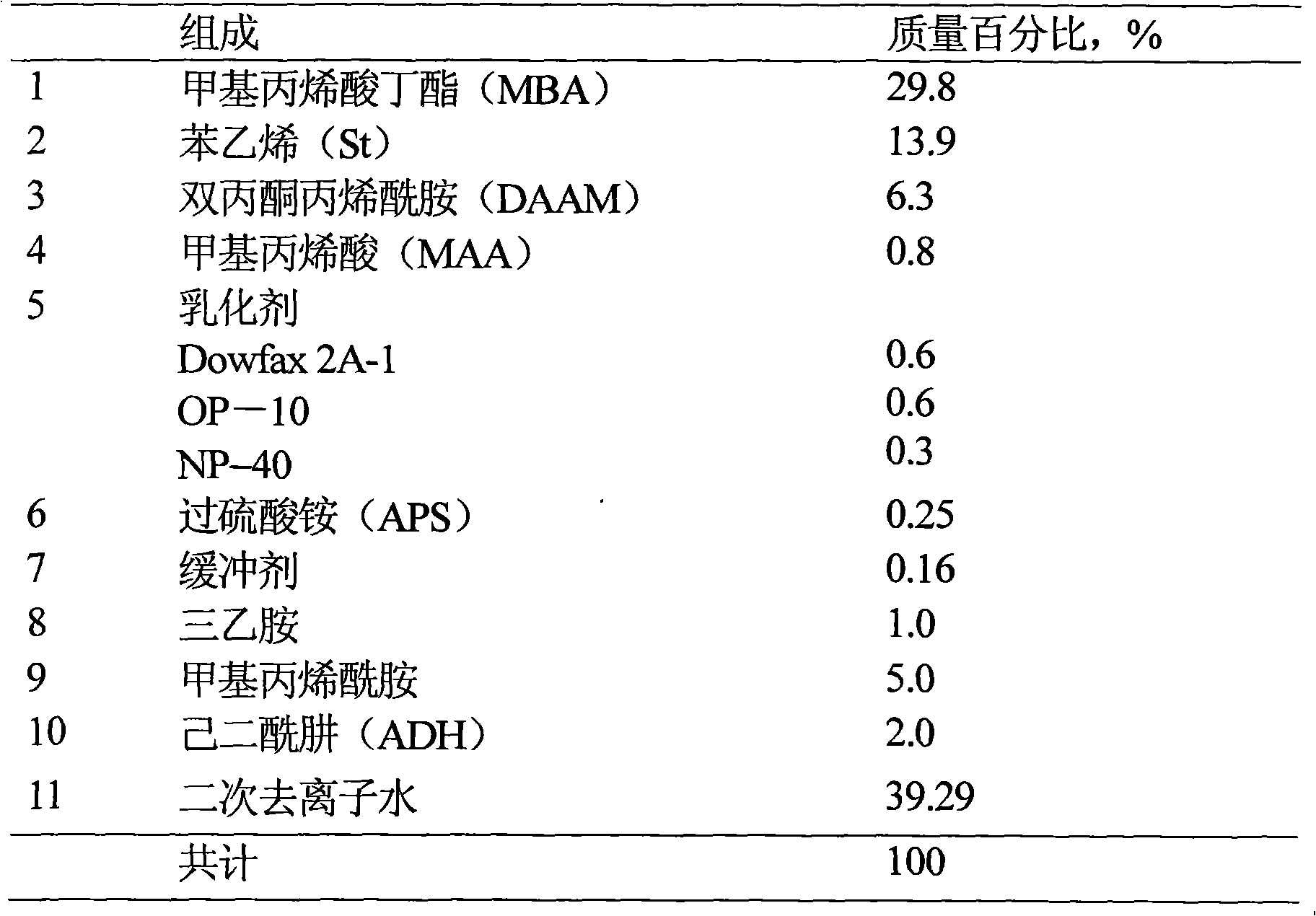

[0076] The monomer composition is butyl acrylate, methyl methacrylate, methacrylic acid, diacetone acrylamide, and methacrylamide, and its component formula is shown in Table 3:

[0077] Table 3 polyacrylate dispersion formula

[0078]

[0079] Add 4.0 parts of compound emulsifier, buffer, and 51.92 parts of deionized water into the reactor, stir at high speed for 20 minutes, and raise the temperature to 55°C. Within 20 minutes, 0.5 parts of methacrylic acid, 10.5 parts of styrene, 22.5 Part of butyl methacrylate mixed monomer, raise the temperature of the reactor to 82°C, slowly add part of the initiator solution dropwise, wait until the seed dispersion is in a blue phase and stabilize for half an hour, drop the pre-emulsified solution within 1.5 hours For the core monomer, continue to drop the pre-emulsified shell monomer within 2 hours after an interval of 20 minutes. After adding all the monomers, add 4 parts of 10% aqueous initiator solution, raise the temperature to 85°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com