A method of distributing ultra-fine ore for composite agglomeration process

A technology of composite agglomeration and concentrate, applied in the field of metallurgy, can solve the problems of over-melting layer, affecting the normal progress of sintering, etc., and achieve the effect of increasing the application ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

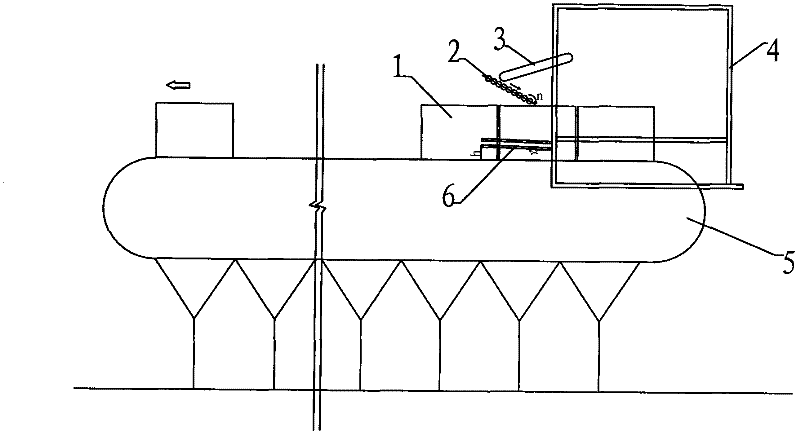

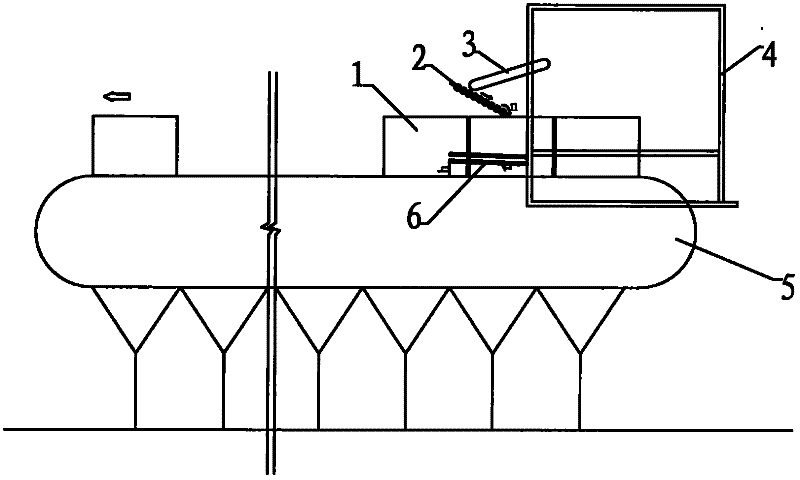

Image

Examples

Embodiment 1

[0019] Test on a 265m 2 On the sintering machine. The proportion of fine ore in the reference period and the test period is 15wt% (to account for iron material). In the test period, 30-50wt% ultra-fine concentrate is used instead of Baotou's self-produced iron concentrate. At the same time, the thickness of the material layer in the test period is lower than that in the reference period. Increase by 100mm. During the test, 5-30wt% of superfine concentrate was pelletized, the particle size of the green pellets was stable, and the original cloth was still used for the cloth, namely, swing belt→wide belt→nine-roll distributor, only adjusting the speed of the multi-roll distributor and The number and location of the looser. The speed of the multi-roll distributor is increased by 6-8r / min compared with the reference period, the number of looseners is reduced to a single row, and the air permeability of the material layer is obviously improved.

[0020] The results showed that the pr...

Embodiment 2

[0022] Under the conditions of the same type and proportion of iron materials, using the same material layer thickness and the same technology, the green ball proportion has been increased from 5wt% to 18wt%, which means that the proportion of ultrafine concentrate has increased by about 14%. On the basis of the distributing device, only the rotation speed of the multi-roll distributing device is adjusted to 2~4r / min, and the particle size of the green balls remains stable at 4~12mm. The results show that due to the improved material layer permeability, the pressure of the main pipe of the sintering machine is reduced by 0.2kPa, and the speed of the sintering machine is increased by 0.02m / min. At the same time, due to the reasonable distribution of green pellets and fuel, the sintering fuel consumption is reduced by about 2kg / t, and the quality of the finished ore Maintained stability, and did not deteriorate with the increase in the proportion of self-produced ultra-fine concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com