Energy self-feed type fluidized bed sludge incineration and tail gas pollution control system

A technology for sludge incineration and pollution control, applied in dehydration/drying/concentrated sludge treatment, incinerators, combustion methods, etc., can solve uneven heat transfer between partitions, uneconomical energy saving, and limited heating effect of wet sludge and other issues to achieve the effect of harmless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

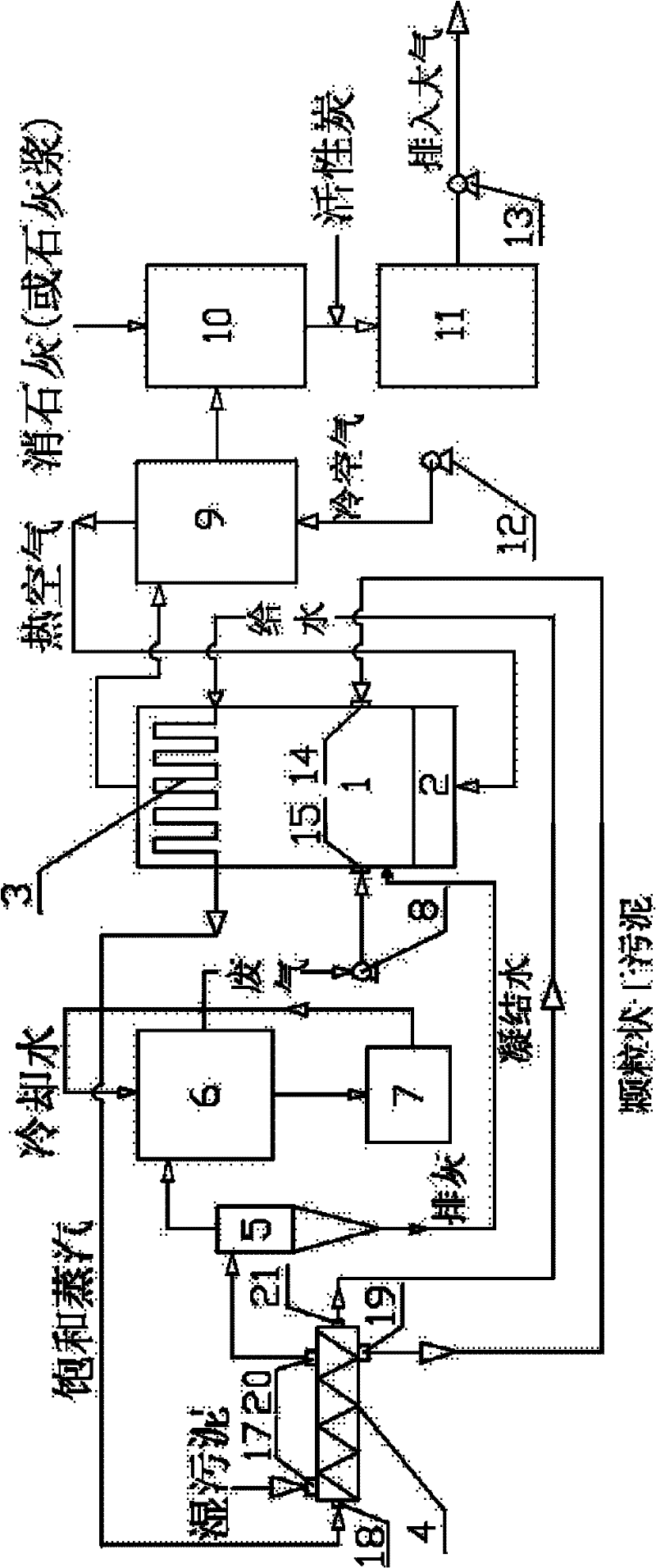

[0026] Example 1: see figure 1 , the control system includes fluidized bed incinerator 1, air chamber 2, waste heat boiler 3, sludge dryer 4, separator 5, spray dehydration tower 6, sewage treatment tank 7, fan 8, air preheater 9, acid Gas absorption tower 10, bag filter 11, blower 12 and induced draft fan 13. The fluidized bed incinerator 1 is equipped with a dry sludge feed port, the upper part is arranged with a waste heat boiler 3, and the lower part is arranged with an air chamber 2. The hot air from the air preheater enters the air chamber 2, and then enters the incinerator to participate in combustion. The steam generated by the waste heat boiler 3 is connected to the steam inlet 18 of the sludge dryer 4 through pipelines. The sludge dryer 4 is a paddle dryer, which is provided with a wet sludge inlet 17, a steam inlet 18, a dry sludge outlet 19 and Exhaust gas outlet 20 and condensed water outlet 21, the water content of the wet sludge after drying drops from 80% to a...

Embodiment 2

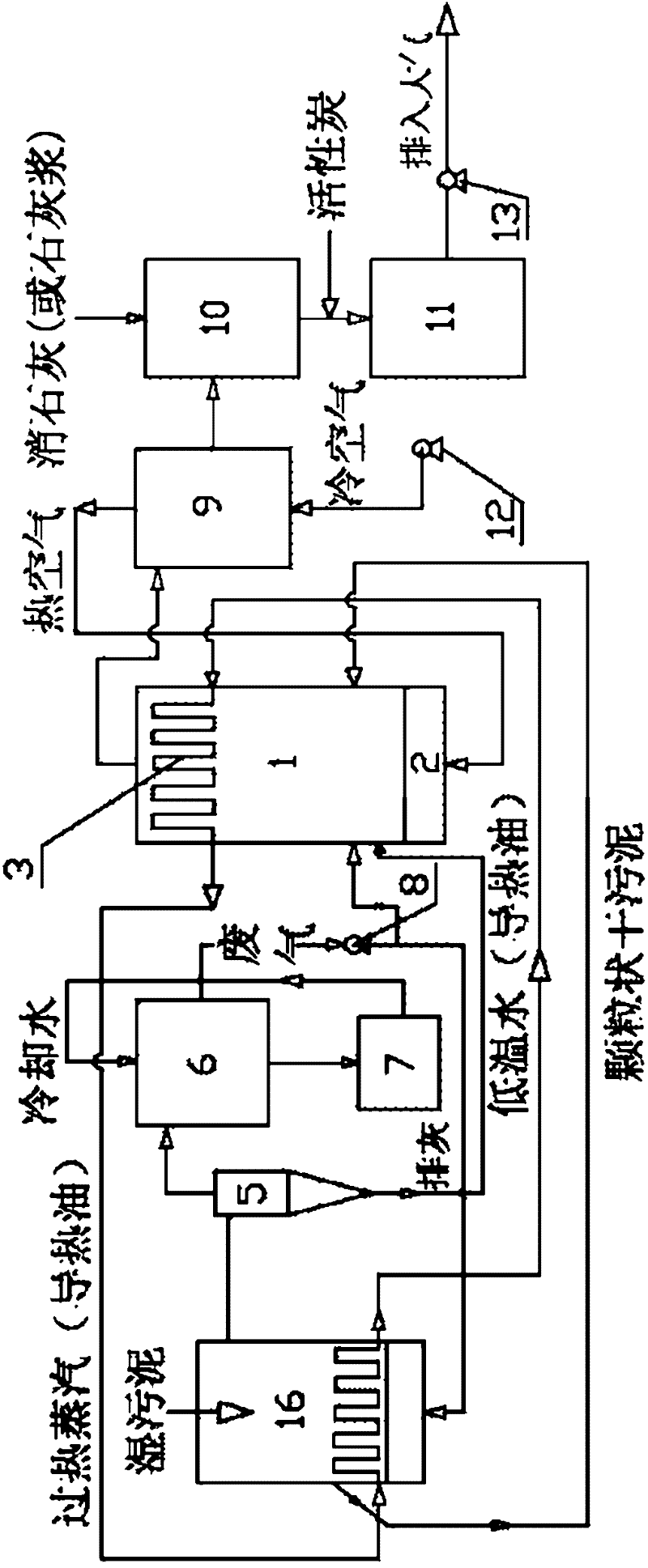

[0028] Example 2: see figure 2 , In this embodiment, the sludge dryer 4 for drying wet sludge can also be replaced by a fluidized bed dryer 16, and the fluidized bed sludge drying technology is a mature technology in the present. In this embodiment, the circulating working fluid used to dry the wet sludge can be superheated steam (temperature greater than 300° C.) or heat transfer oil. The fluidized medium of the fluidized bed dryer 16 is dehydrated waste gas produced by drying wet sludge. When the dehydrated waste gas is more than the amount of gas required for fluidization, the excess can be sent to the incinerator for combustion and deodorization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com