Horizontally feeding type packing machine

A technology of packaging machine and feeding device, which is applied in the direction of packaging and can solve research and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

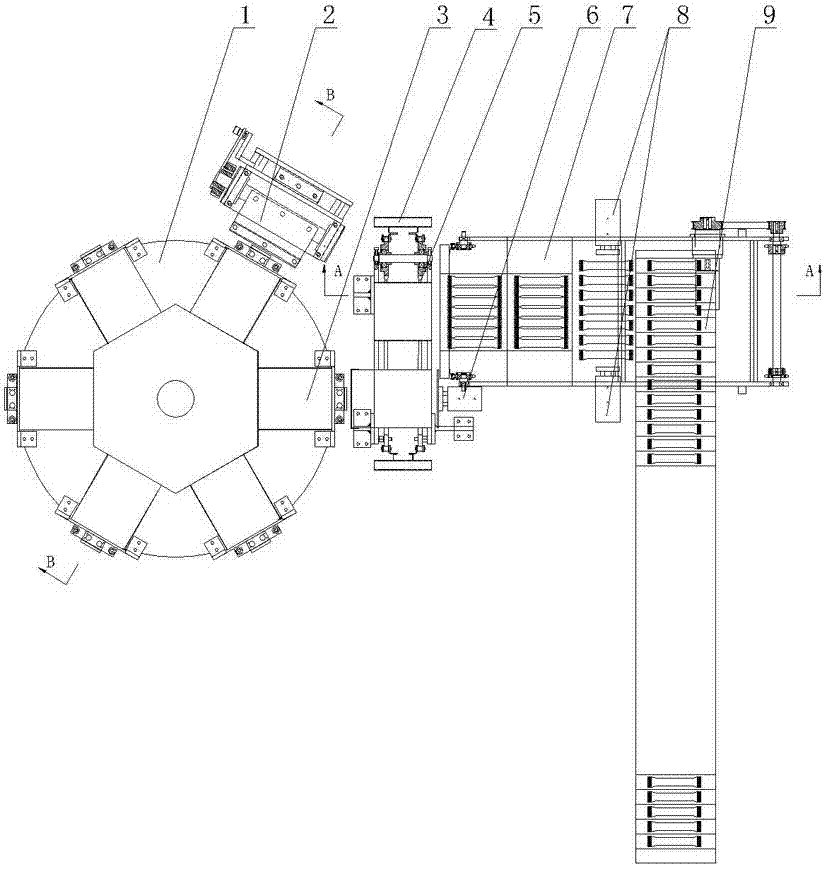

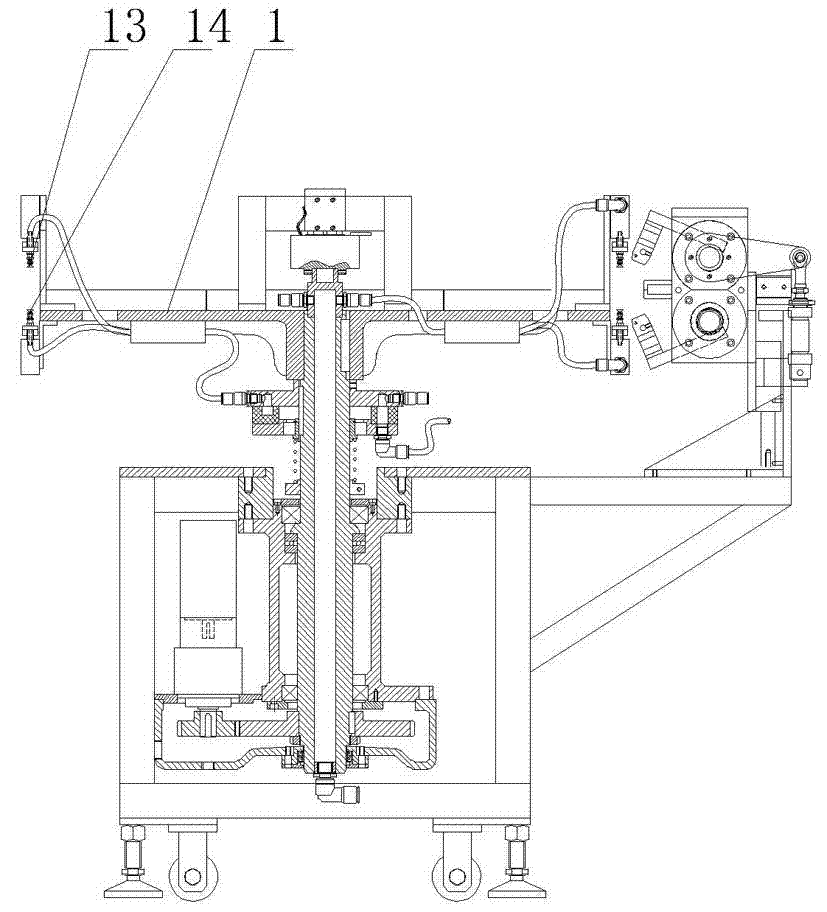

[0017] Embodiment one: refer to figure 1 , image 3 , Figure 4 , the parts involved in the present embodiment are the first feeding chain 5, the first motor and the first charging box 4 such as the feeding chain, the motor, and the charging box. Therefore, the following feeding chains, the first charging box and its The corresponding labels are 5 and 4 respectively. This horizontal feeding packaging machine has a rotatable turntable 1, on which a bag opening device and a heat-sealing device 2 are arranged, wherein the heat-sealing device 2 belongs to the prior art, and will not be repeated here. The bag opening device includes upper and lower suction cups 13, 14 installed on the turntable 1, and the upper and lower suction cups 13, 14 are respectively communicated with the vacuum pump. When the packaging bag is between the upper and lower suction cups 13, 14, the upper and lower suction cups 13, 14 move closer , after the vacuum pump works, the upper and lower suction cups...

Embodiment 2

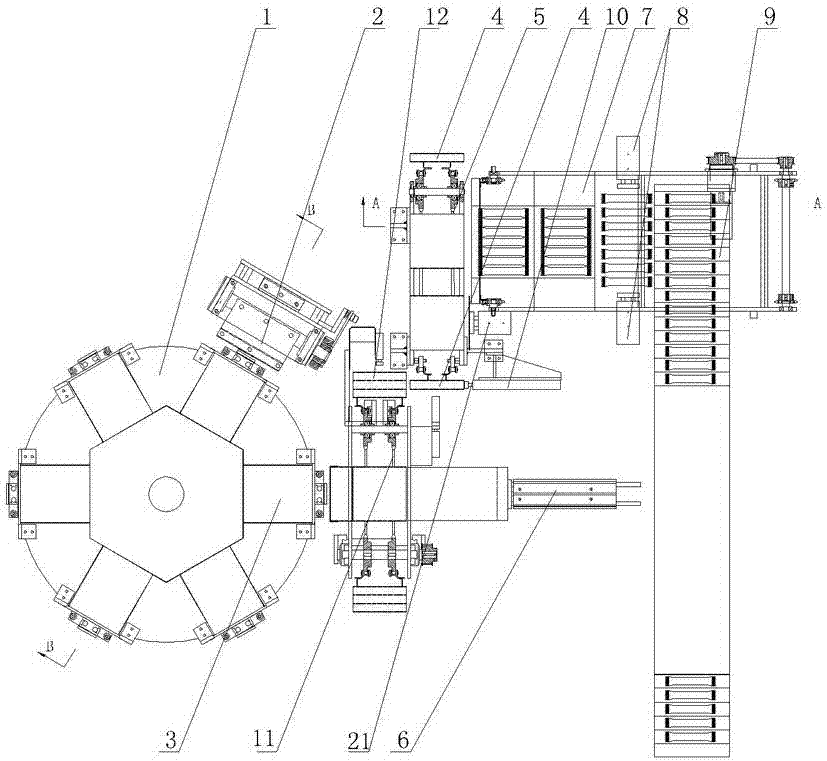

[0018] Embodiment two: refer to figure 2 , image 3 , Figure 4 , Figure 5, this embodiment is aimed at more than one row of article packaging, it is further improved on the basis of Embodiment 1, specifically, the feeding chain includes a first feeding chain 5 and a second feeding chain 11, so The first feeding chain 5 described above is perpendicular to the feeding belt 7, and the charging box includes a first charging box 4 and a second charging box 12, and the first charging box 4 and the second charging box 12 are correspondingly arranged on the first feeding chain 5 and the second feeding chain 11, and the motors include a first motor and a second motor (not shown in the figure), and the first motor and the second motor are correspondingly driven The first feeding chain 5 and the second feeding chain 11, the first feeding chain 5 and the second feeding chain 11 are arranged on the same side, and the dislocation is parallel, the afterbody of the first feeding chain 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com