Roll paper cutting and unloading mechanism

A technology of roll paper and material shaft, which is applied in the field of roll paper cutting and blanking mechanism, can solve the problems of high manual work intensity, achieve stable and reliable blanking process, and reduce labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

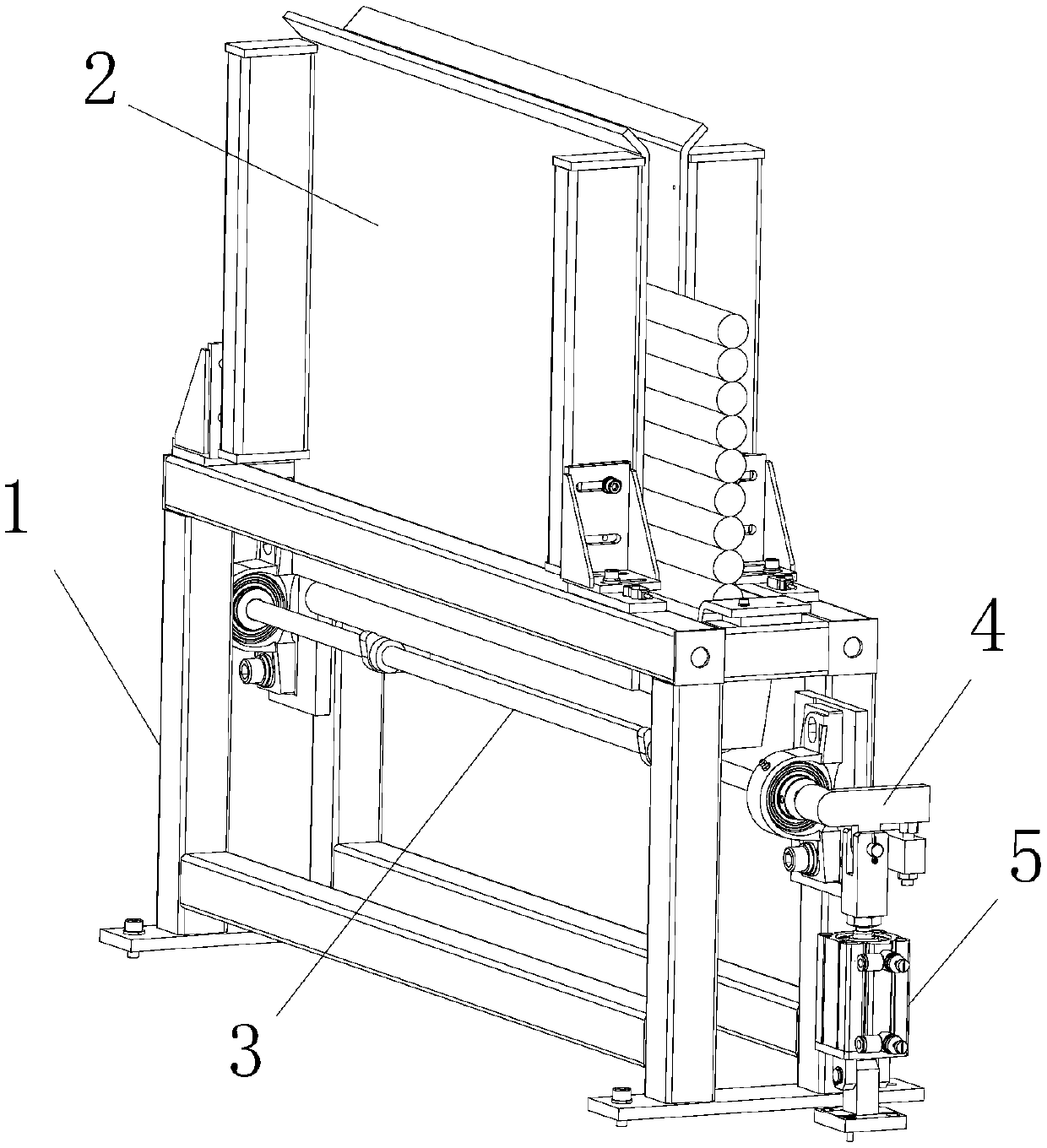

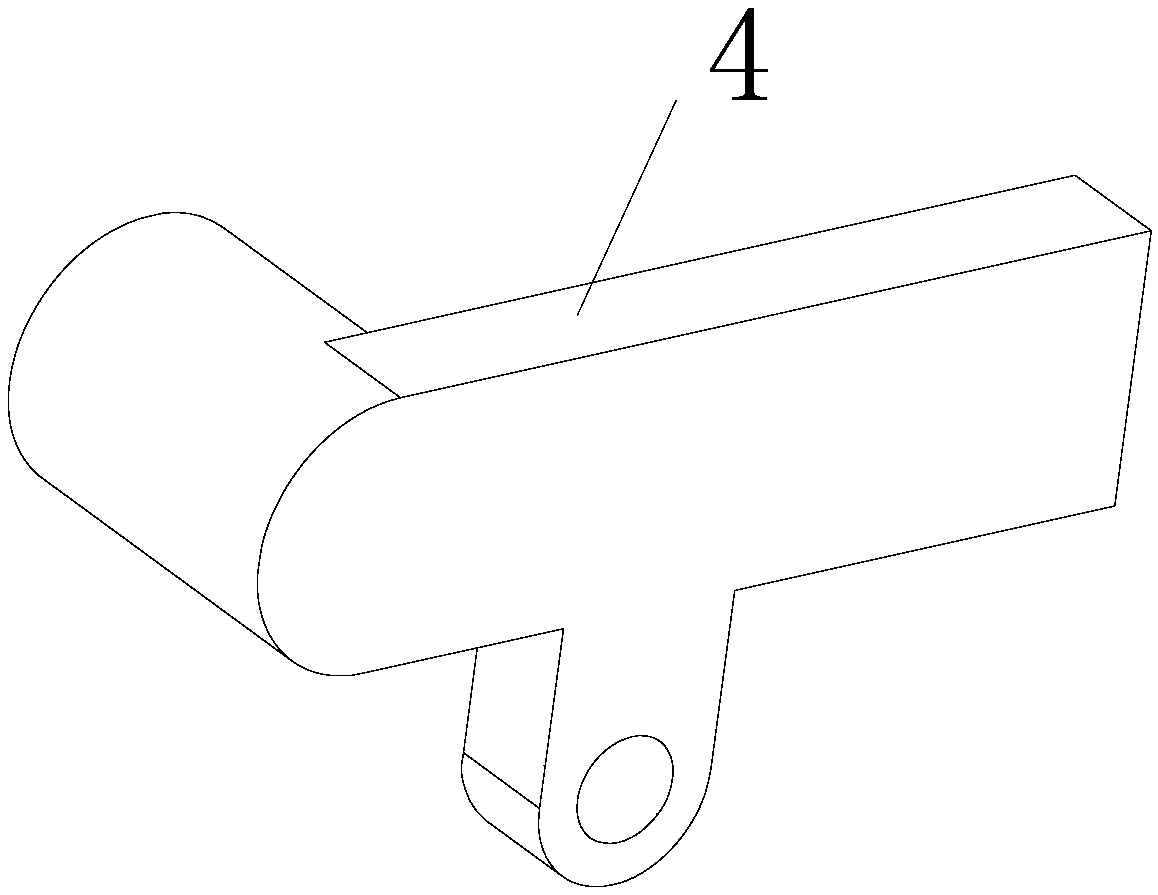

[0016] like figure 1 figure 2 As shown, a roll paper cutting and unloading mechanism includes a bracket 1, the upper end of the bracket 1 is provided with a roll paper unloading opening, two baffles 2 are respectively arranged on the brackets 1 on both sides of the unloading opening, and the two baffles 2 form Accommodating chamber for each roll to be cut.

[0017] There is a rotary discharge shaft 3 below the discharge port, and the two ends of the rotary discharge shaft 3 form a rotational connection with the bracket 1 respectively. There are 2 discharge plates on the rotary discharge shaft 3, and the discharge plates are fixed on the rotation shaft. .

[0018] When the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com