A double-series series combined slide table

A tandem, sliding table technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem that there is no sliding table body beyond the control stroke of the oil cylinder itself, and achieve low manufacturing cost and high transmission accuracy. , the effect of easy processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

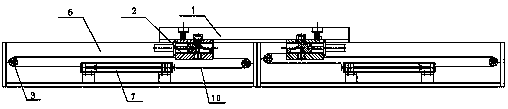

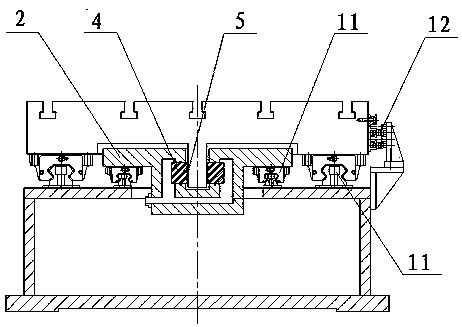

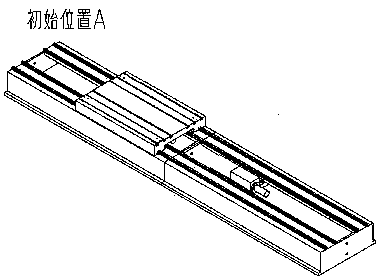

[0035] Such as figure 1 , figure 2 , image 3 As shown, the double-station series combined sliding table of this patent includes a controller, a sliding table body 1, a first sliding table mechanism, and a second sliding table mechanism, and both the first sliding table mechanism and the second sliding table mechanism include a drive Block 2, sliding table body position sensing device 12, sliding platform seat 6, linear guide rail 11, drive oil cylinder 7, left transmission mechanism, right transmission mechanism; Linear guide rail 11 is a plurality of, and each linear guide rail 11 is distributed in parallel.

[0036] Wherein, the controller is used to receive the signal from the position sensing device 12 of the sliding table body, and control the action of the driving cylinder 7 .

[0037] Drive oil cylinder 7, linear guide rail 11 are all arranged on the bottom of slide table seat 6, and left transmission mechanism, right transmission mechanism are respectively fixed on...

Embodiment 2

[0045]Double-series combined sliding table, including controller, sliding table body 1, first sliding table mechanism, second sliding table mechanism, both first sliding table mechanism and second sliding table mechanism include driving block 2, sliding table body Position induction device 12, sliding platform seat 6, linear guide rail 11, drive oil cylinder 7, left transmission mechanism, right transmission mechanism; Linear guide rail 11 is a plurality of, and each linear guide rail 11 is distributed in parallel.

[0046] Wherein, the controller is used to receive the signal from the position sensing device 12 of the sliding table body, and control the action of the driving cylinder 7 .

[0047] Drive oil cylinder 7, linear guide rail 11 are all arranged on the bottom of slide table seat 6, and left transmission mechanism, right transmission mechanism are respectively fixed on the left and right sides of slide table seat 6; Drive oil cylinder 7 is left and right two-way outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com