Combined use method of a combined multifunctional slide table

A multi-functional and combined technology, applied in the field of machinery, can solve the problems such as the control stroke of the sliding table body surpassing the oil cylinder itself, and the decline of the running accuracy of the sliding table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

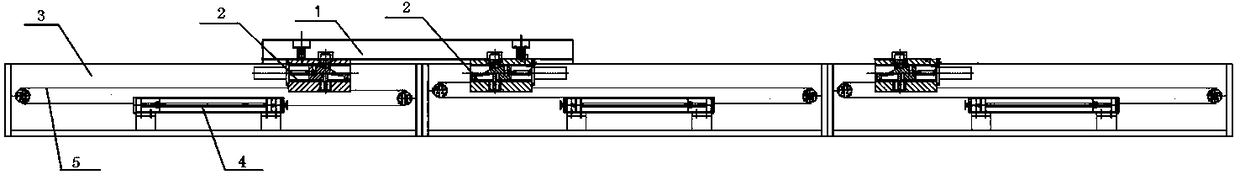

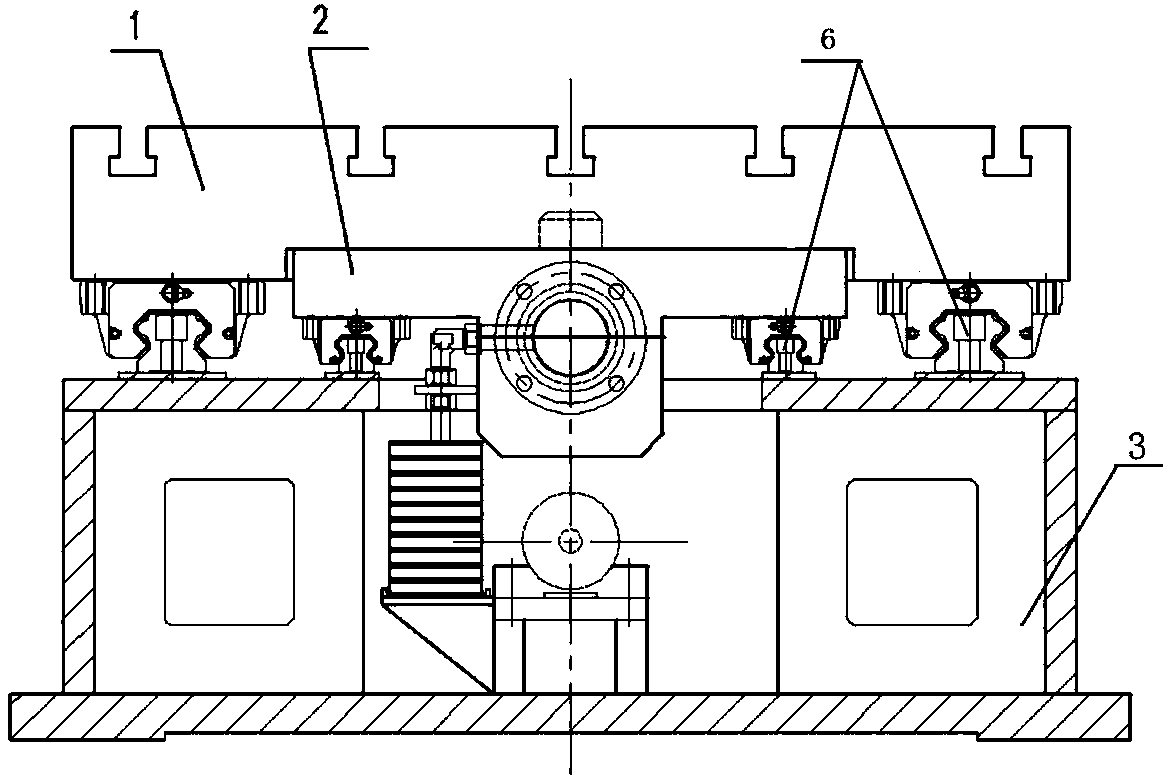

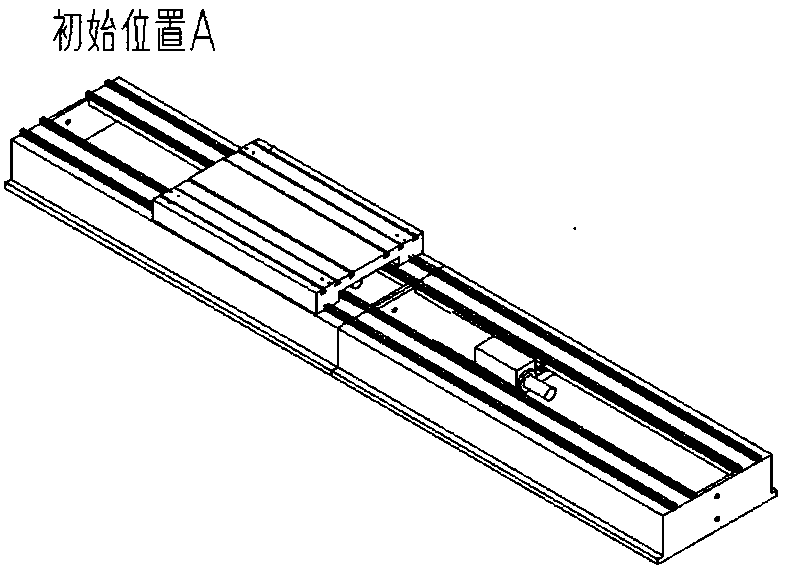

[0031] Such as Figure 1-5 As shown, the combined use method of the combined multifunctional slide table of this patent includes:

[0032] Make N sets of the same sliding table mechanism to be combined; N is the total number of sliding table mechanisms, and N is greater than or equal to three. A driving cylinder 4 is respectively installed at the bottom of the sliding table seat 3 of the sliding table mechanism, and a plurality of linear guide rails 6 are arranged at the upper end of the sliding table seat 3 , each linear guide rail 6 is distributed in parallel, and the supporting surface specifications of the linear guide rails 6 of each sliding table mechanism are the same; the driving cylinder 4 adopts left and right bidirectional output hydraulic cylinders; the sliding table seats 3 of the first sliding table mechanism to the Nth sliding table mechanism are connected in series , combined in the form of end-to-end connection; the linear guide rails 6 of the first slide mech...

Embodiment 2

[0041] The difference between the technical solution in embodiment 2 and the technical solution in embodiment 1 lies in the difference in the total number of slide tables and the difference in the specific structure of the telescopic fixing mechanism of the drive block and the docking mechanism of slide table body 1; the total number of slide tables is four Or more than four; the telescopic fixing mechanism is a clamping device, and the docking mechanism of the slide body 1 is a clamping surface corresponding to the clamping device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com