Automatic truck loading management system

A management system and automatic technology, applied in the direction of inspection devices, instruments, time registers, etc., can solve the problems of inaccurate position and start-stop point, falling on the weighbridge, affecting the loading speed, etc., so as to avoid excessive installation position High, improve the loading speed and reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

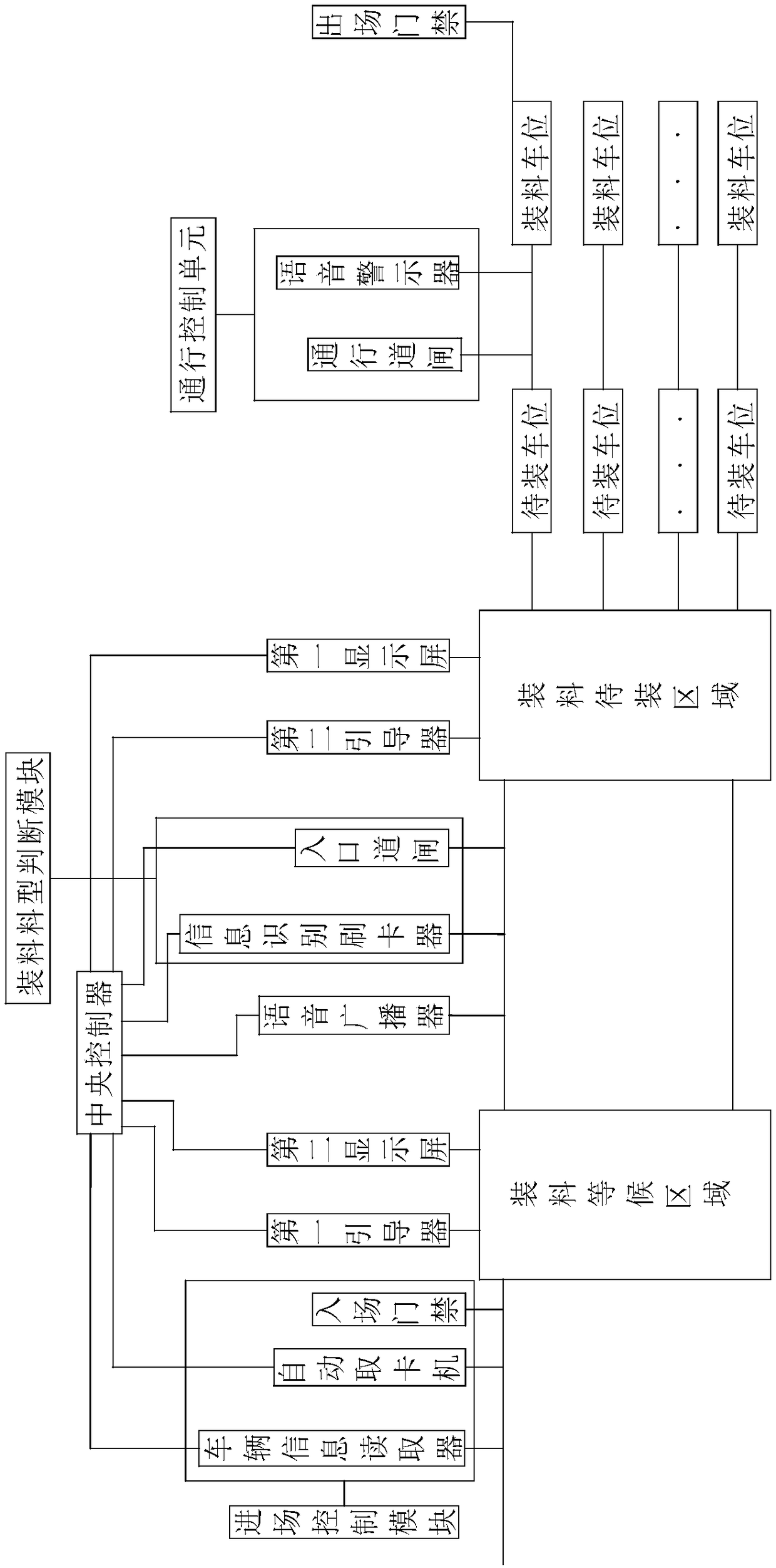

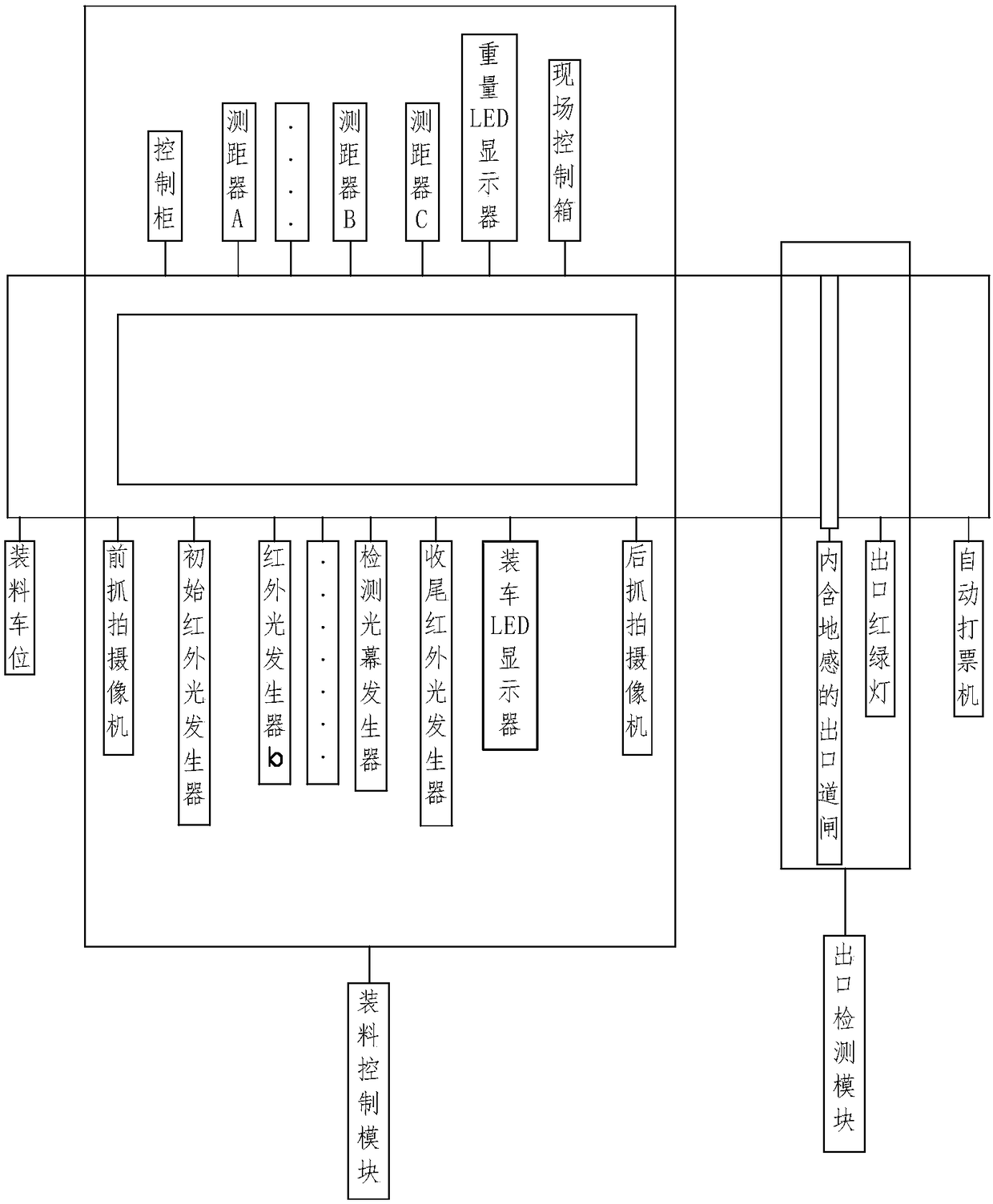

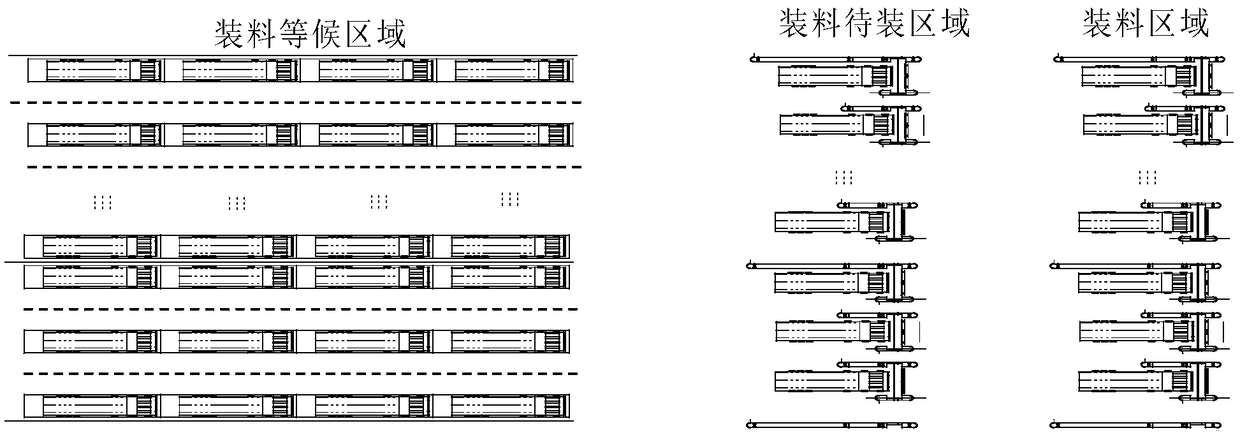

[0026] refer to Figure 1 to Figure 8Shown: an automatic loading management system, including an entry queuing and waiting unit, the entry queuing and waiting unit includes a central controller, an entry control module, a loading waiting area, a loading waiting area, and a loading area; the entry control The module includes a vehicle information reader, an automatic card reader electrically connected to the vehicle information reader, and access control. Both the automatic card reader and the access control are electrically connected to the central controller, and the central controller is connected to the driver of the entering vehicle 8. The mobile communication device is connected by communication, and the automatic card reader is equipped with a card outlet and a ticket outlet for loading information; the waiting area for loading includes multiple waiting areas for different material types, and each material type waiting area includes multiple queuing parking spaces. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com