Quality control product shaking-up device

A technology of quality control products and storage trays, applied in the field of medical devices, can solve problems such as unsatisfactory use requirements, long time consumption, and low efficiency, and achieve the effects of shortening the time of shaking, improving efficiency, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

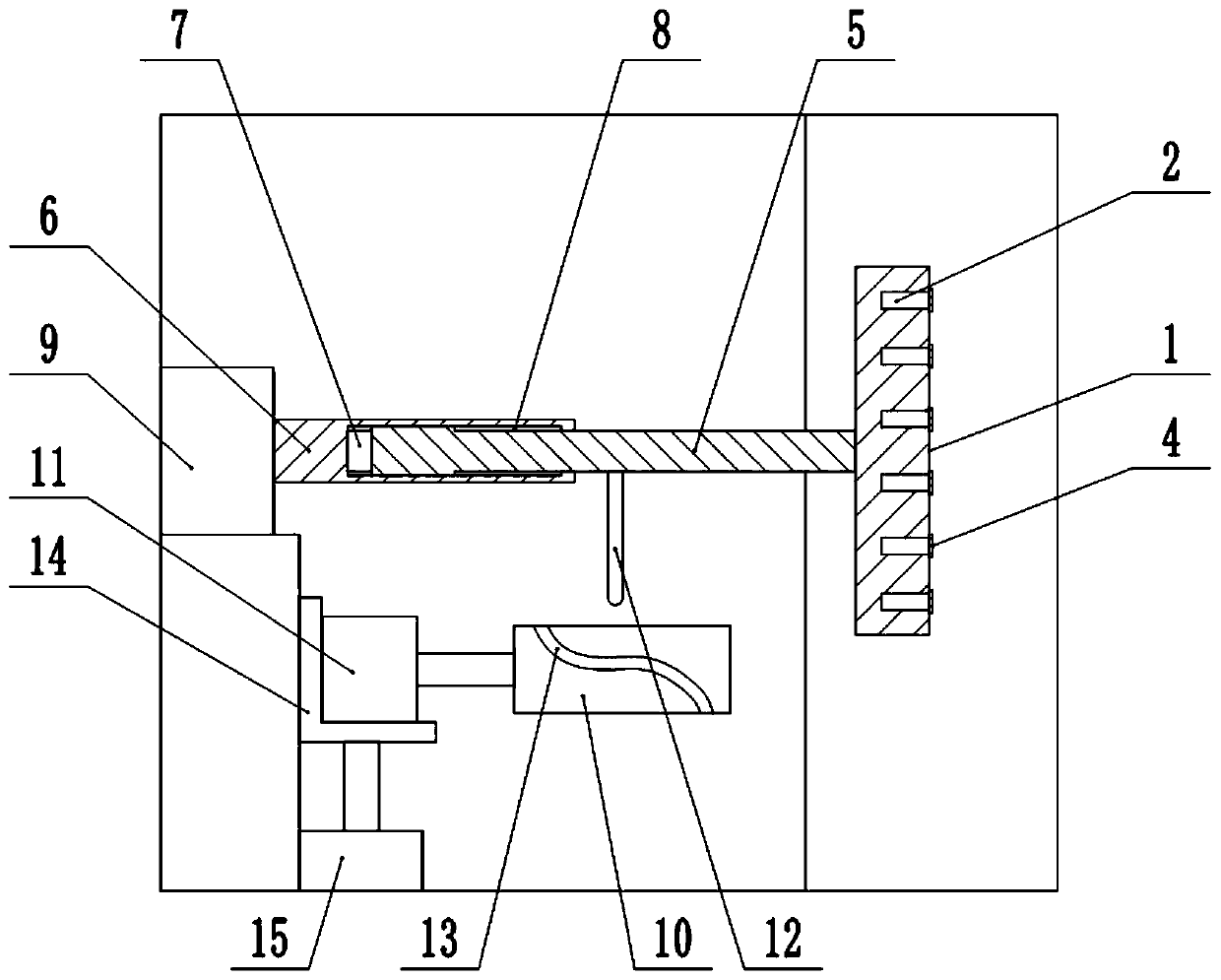

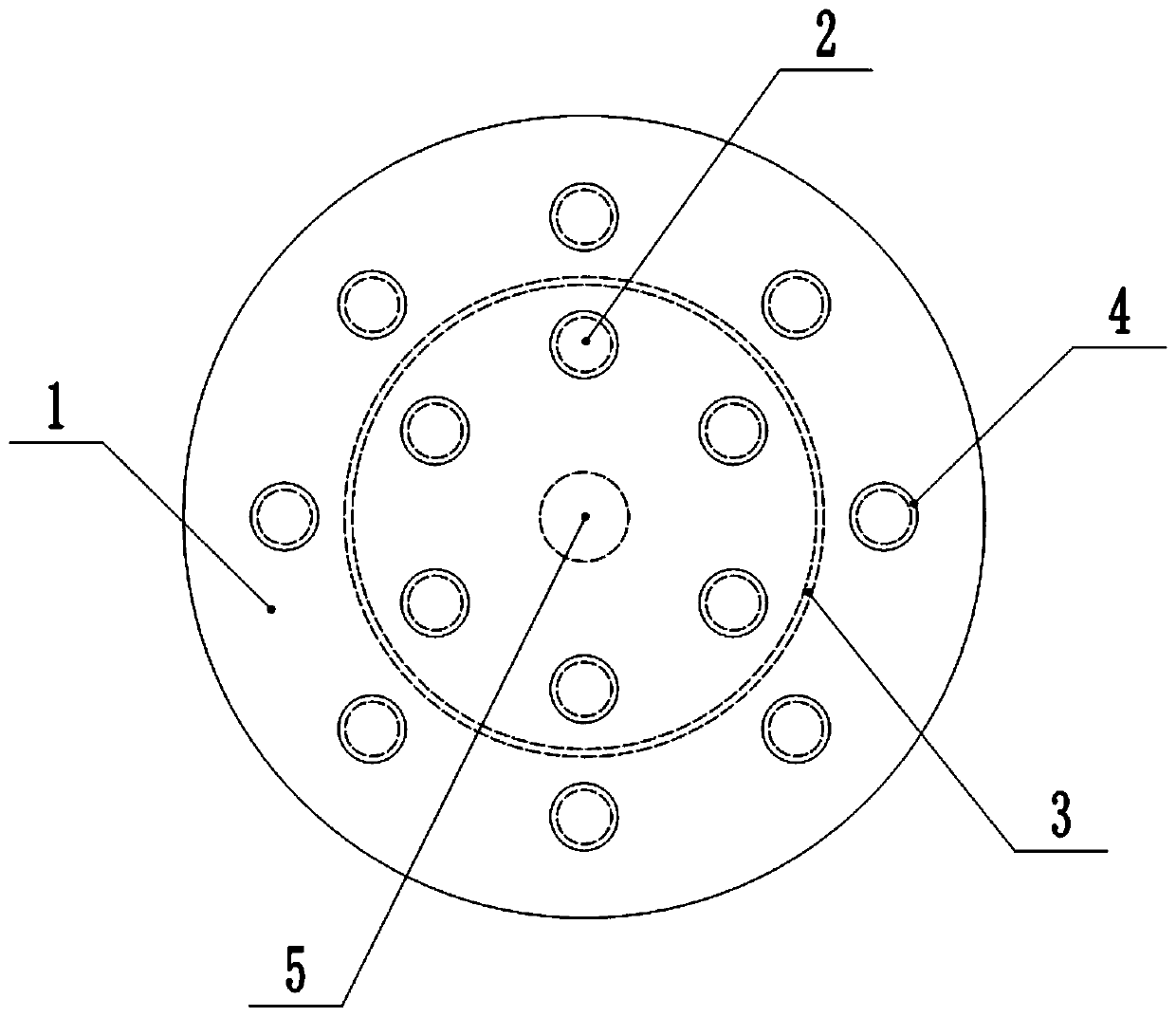

[0026] Embodiment one is basically as attached figure 1 , figure 2 Shown:

[0027] A shaking device for quality control products, including a frame, on which a storage tray 1 is provided, and on the storage tray 1, grooves 2 for placing quality control products and fixing parts for fixing quality control products, the grooves are provided The directions of 2 are parallel to the axis of the turntable, and are all arranged along the horizontal direction. The number of grooves 2 is at least four, and the grooves 2 are distributed on the storage tray 1 with the center of the storage tray 1 as the axis at multiple circles at equal intervals, and the grooves 2 on each circle are distributed in a circular array. The storage tray 1 is embedded with a cylindrical heating net 3 , the heating net 3 is a resistance wire, and the heating net 3 is located between two adjacent grooves 2 . A buffer layer is bonded on the inner wall of the groove 2, and the buffer layer is a foam layer or ...

Embodiment 2

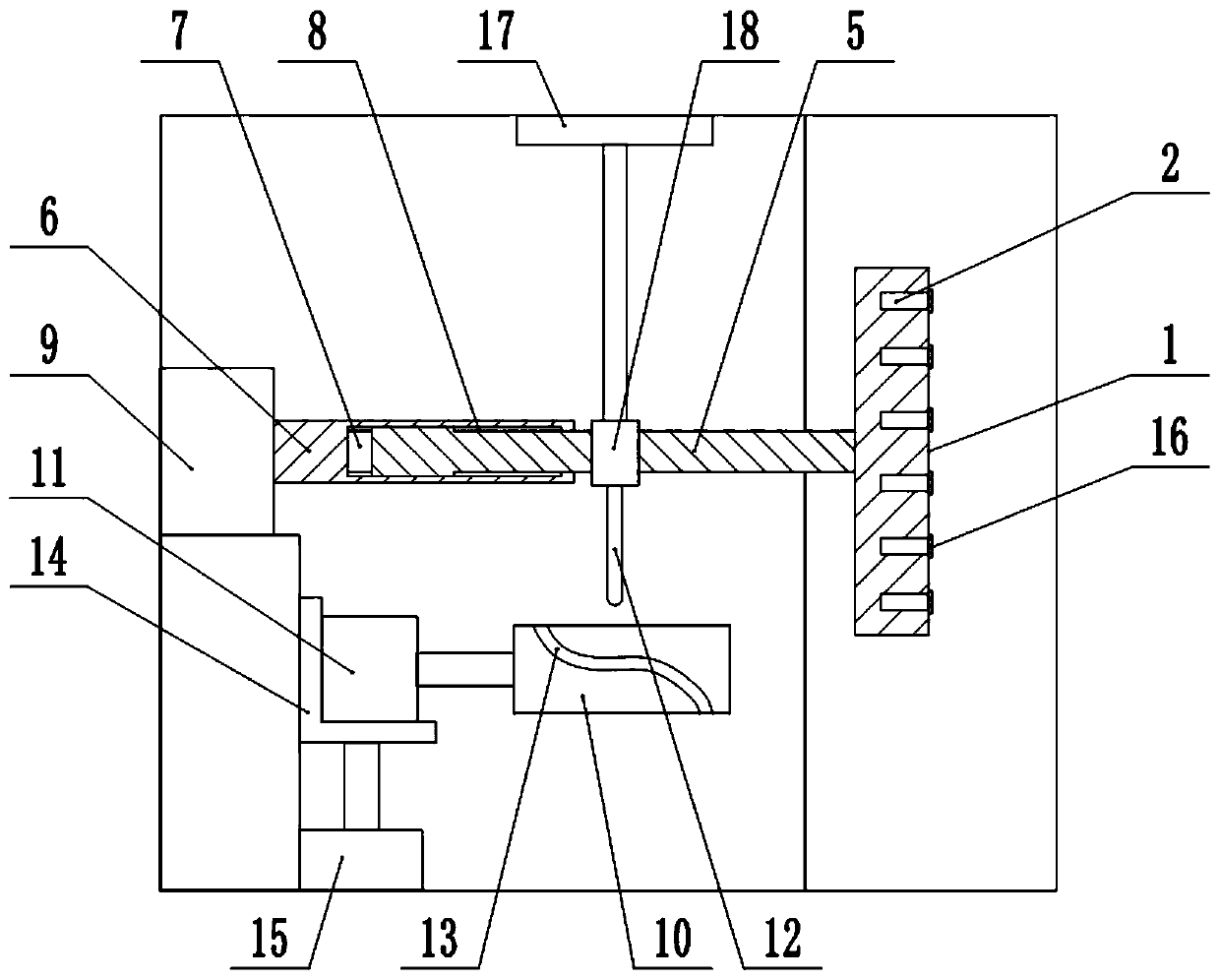

[0032] Embodiment two is basically as attached image 3 , Figure 4 Shown:

[0033] The difference between the present embodiment and the first embodiment is that the fixing member includes two arc-shaped snap rings 16 , one ends of the two snap rings 16 are hinged on the storage tray 1 , and the other ends of the two snap rings 16 are snapped together. The frame is horizontally slidably connected with a second slide plate 17, and the inner rod 5 is rotatably connected with a bearing 18. The bearing 18 is welded with the second slide plate 17, and the transmission rod 12 is fixedly connected with the inner rod 5 through the bearing 18.

[0034] When fixing the quality control product, the quality control product is located in the middle of the two snap rings 16, and then the two snap rings 16 are engaged with each other, and the quality control product is hugged and fastened, thereby fixing it. For quality control products whose length is greater than the depth of groove 2 o...

Embodiment 3

[0036] Embodiment three is basically as attached Figure 5 Shown:

[0037] The difference between this embodiment and Embodiment 1 is: a controller 19, an alarm 20, a timer 21 for recording quality control time, and a temperature sensor 22 for recording the temperature of the heating network 3 are installed on the frame, and the controller 19 is all electrically connected with the first motor 9, the second motor 11, the cylinder 15, the heating network 3, the alarm 20, the timer 21, and the temperature sensor 22. In this embodiment, the models of the controller 19 and the temperature sensor 22 are respectively PLC FX3GA-24MR-CM and LM35DZ.

[0038] During specific implementation, the opening and closing of the first motor 9 , the second motor 11 and the cylinder 15 are controlled by the controller 19 . When the heating temperature reaches the preset temperature, the temperature sensor 22 converts the temperature signal into an electrical signal and transmits it to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com