RFID-based dangerous and waste real-time risk early warning method and device

A technology of risk warning and RFID tag, applied in the field of real-time risk warning of hazardous waste based on RFID, can solve the problems of easy placement, difficulty, hidden danger, etc., and achieve the effect of convenient real-time monitoring, simple process and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

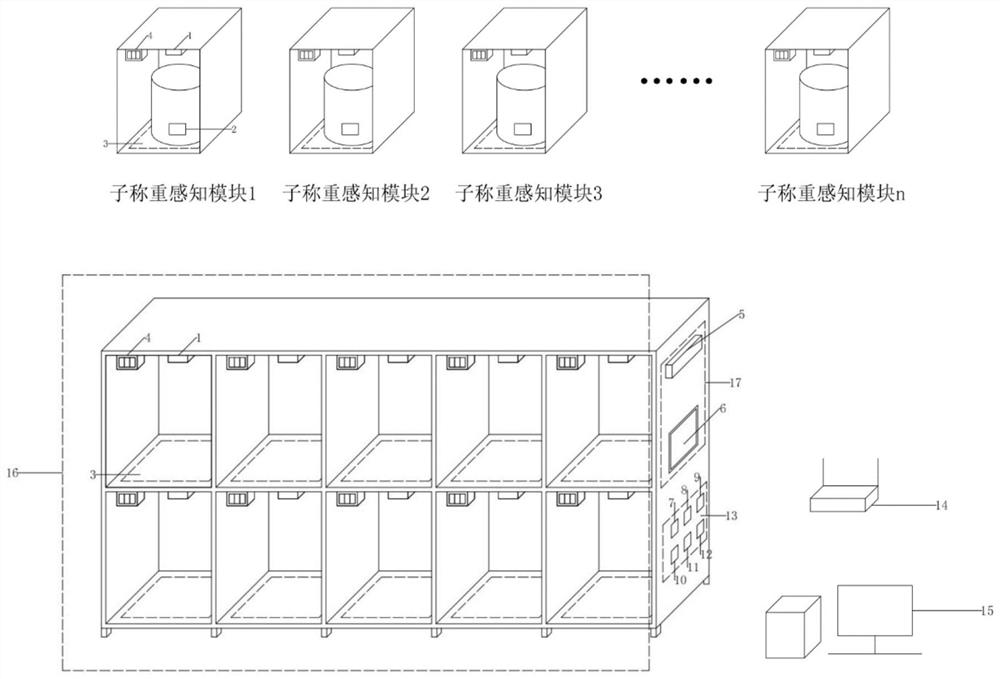

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

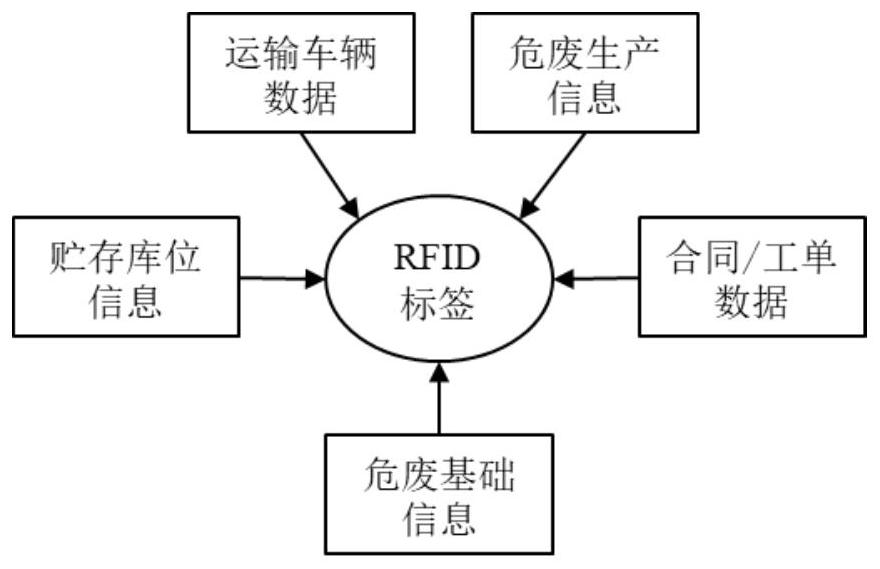

[0032] RFID technology consists of three parts: antenna, reader and RFID tag. The antenna queries the RFID tag by emitting a radio frequency signal. After the radio frequency signal reaches the RFID tag, it will be reflected back by the tag. The reader recognizes the RFID tag through the received reflected signal.

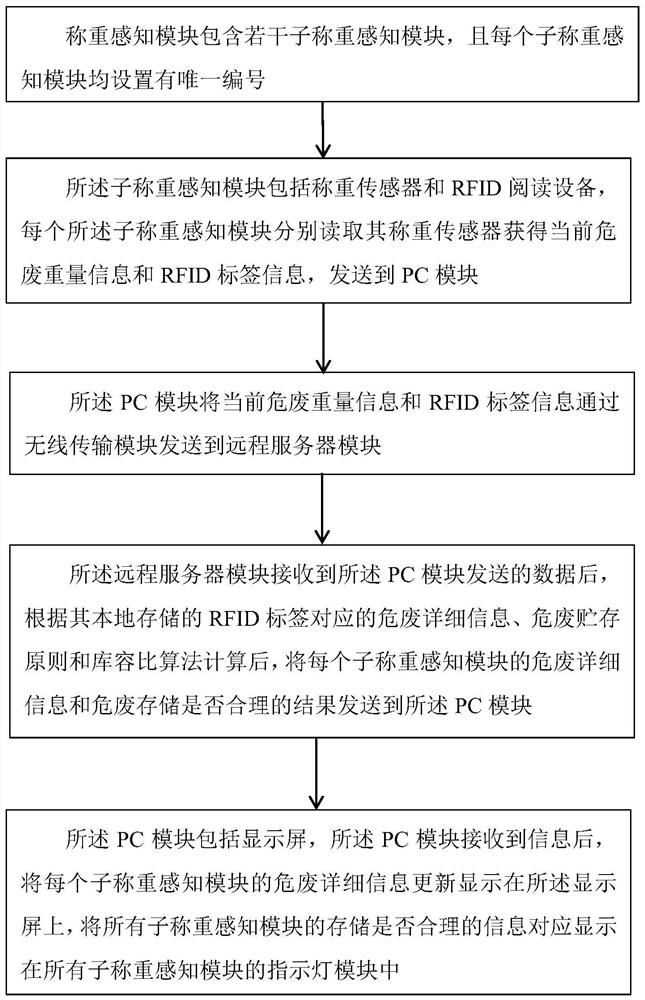

[0033] Such as figure 1 As shown, an embodiment of the present invention provides a real-time risk warning method for hazardous waste based on RFID, wherein an RFID label is pasted on each package of hazardous waste,

[0034] Step 1: The weighing sensing module includes several sub weighing sensing modules, and each sub weighing sensing module is provided with a unique number;

[0035] Step 2: The sub-weighing sensing module includes a weighing sensor and an RFID...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com