Detection device applicable to axis part

A technology for shaft parts and detection devices, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve problems such as low efficiency, achieve high efficiency and improve detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

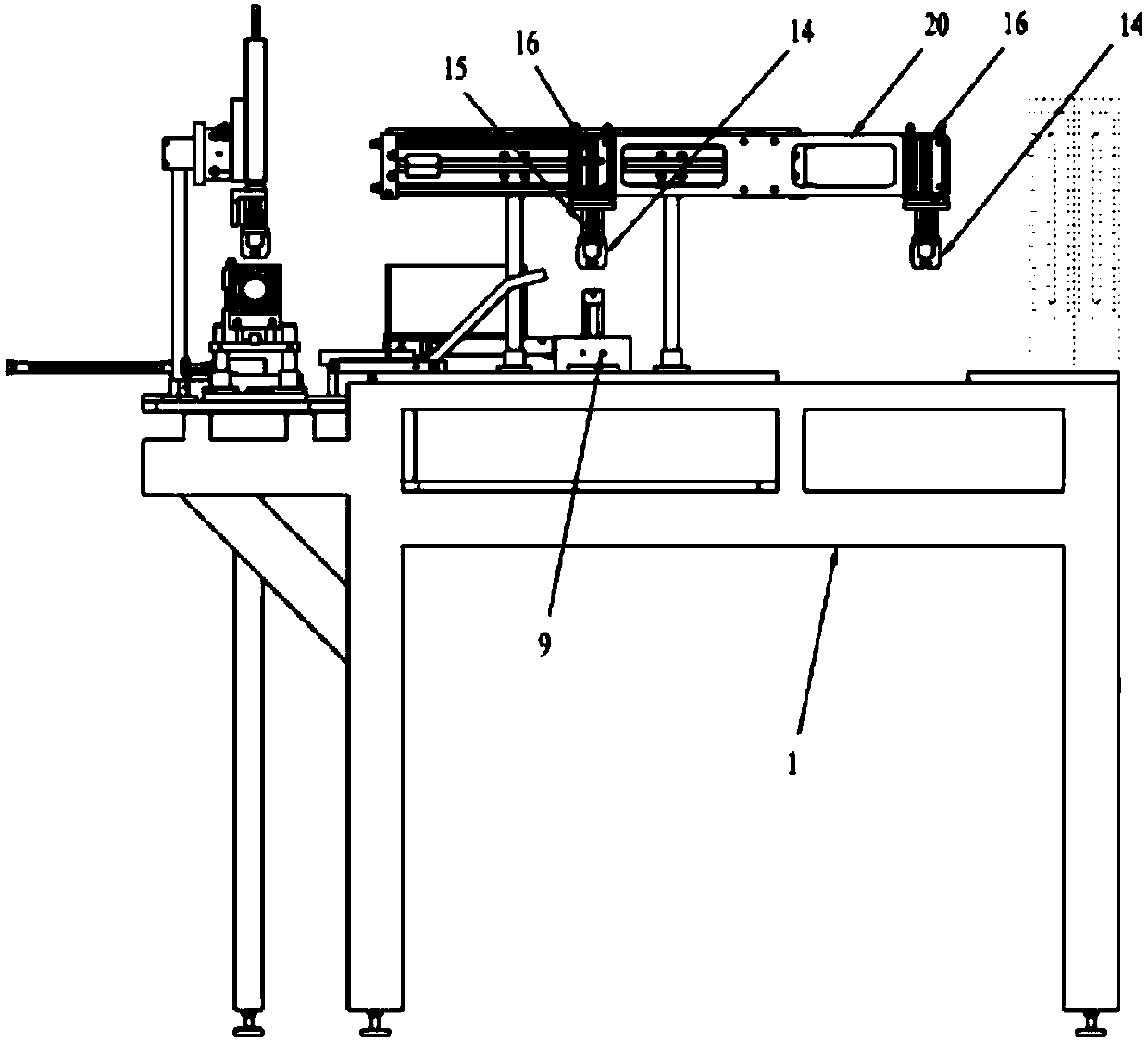

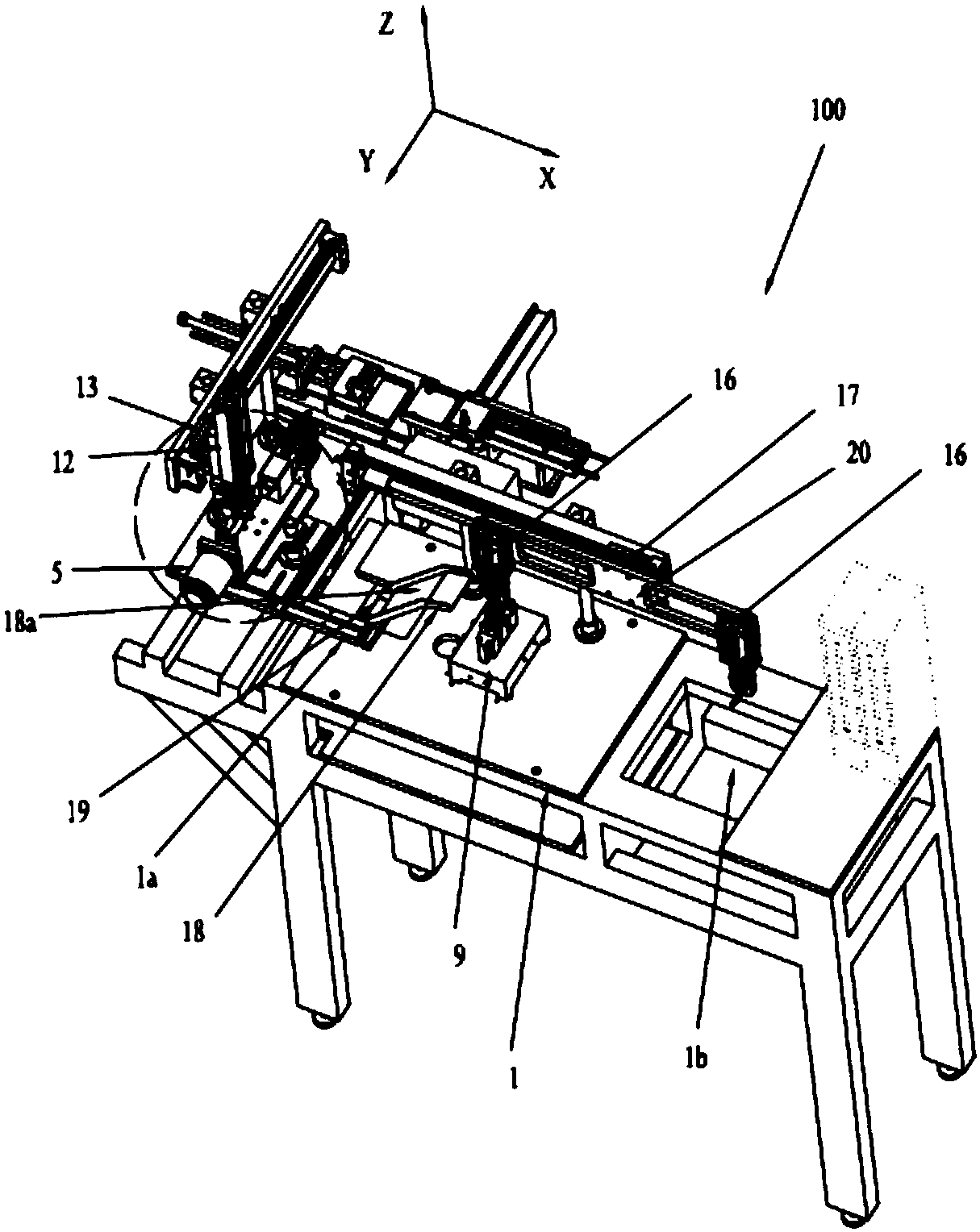

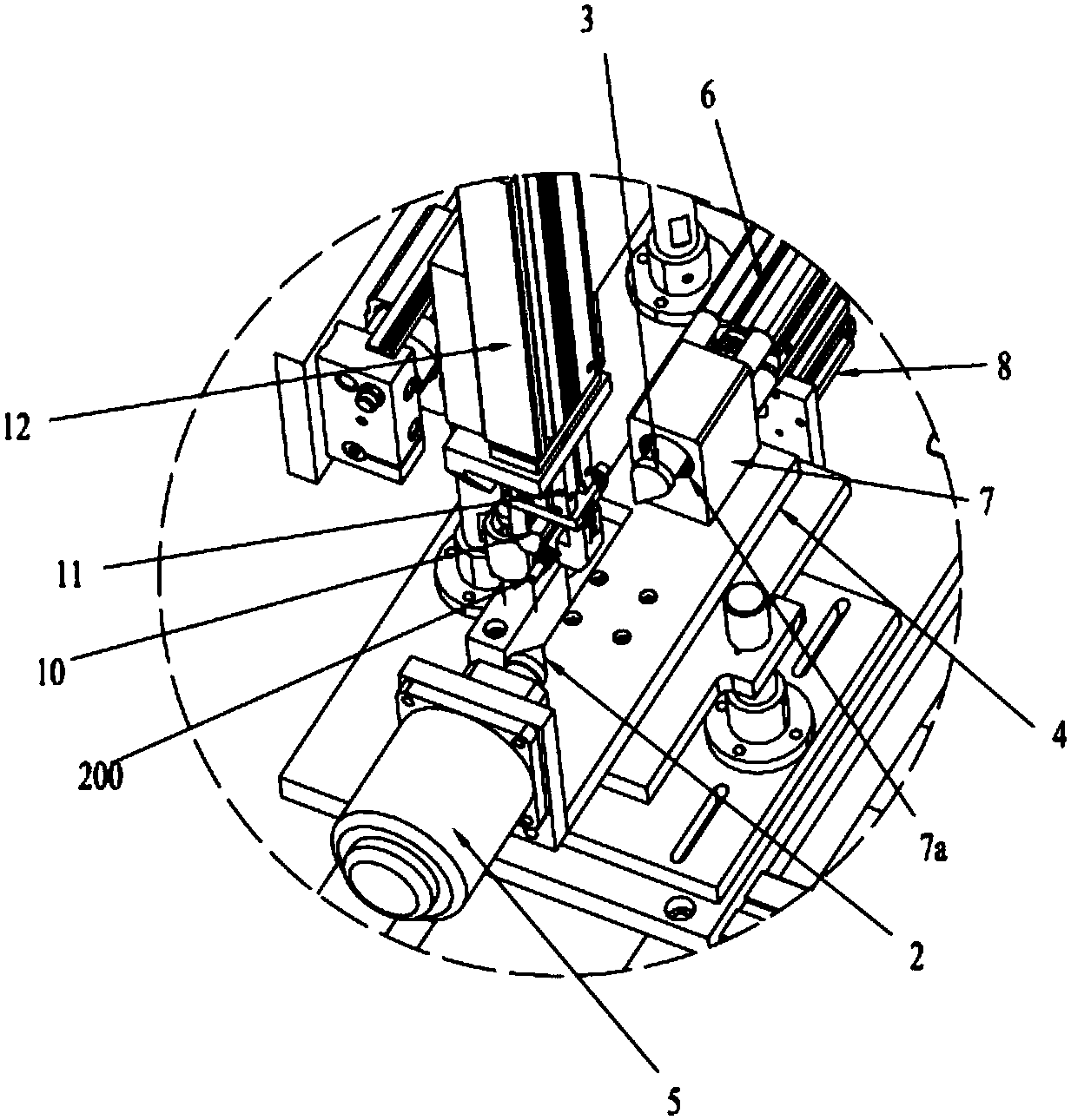

[0018] like Figure 1 to Figure 3 As shown, 1. A detection device 100 suitable for shaft parts 200, comprising: a frame 1, a first thimble 2, a second thimble 3, a movable frame 4, a thimble driving motor 5, a thimble driving cylinder 6, and a thimble seat 7. Moving frame movement cylinder 8, support platform for supporting shaft parts 200 9, feeding mechanical claw 10, feeding manipulator drive cylinder 11, feeding vertical moving cylinder 12, feeding vertical moving cylinder 13, unloading Mechanical claw 14, blanking mechanical claw drive cylinder 15, blanking vertically moving cylinder 16 and blanking laterally moving cylinder 17.

[0019] The thimble drive motor 5 drives the first thimble 2 to rotate; the thimble drive motor 5 is fixed to the movable frame 4; the thimble seat 7 is fixed to the movable frame 4; the thimble drive cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com