Feeding and discharging device

A material and rotating arm technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of high cost and complex structure of the six-joint manipulator, and achieve the effect of low installation cost, low follow-up maintenance cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

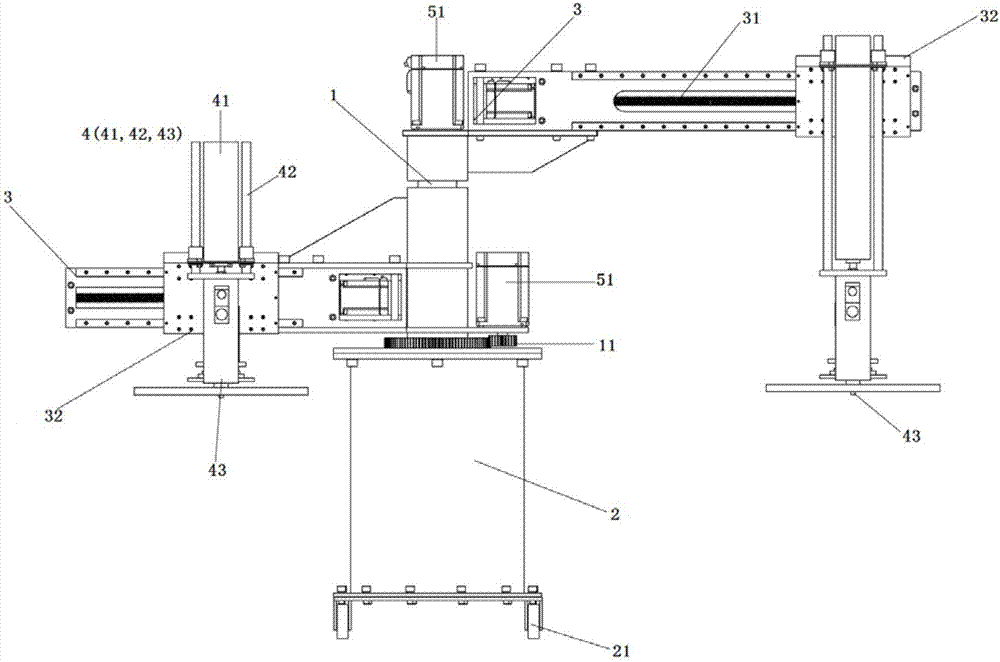

[0047] This embodiment provides a loading and unloading device, including a main shaft 1, a base 2, a rotating arm 3, a liftable adsorption component 4 and a control component, wherein,

[0048] The main shaft 1 is fixed on the base 2 . Generally, the connection between the main shaft 1 and the base 2 can be non-detachable or detachable, which can be determined according to the actual situation.

[0049] Preferably, universal wheels 21 are provided on the bottom of the base 2, so that the entire loading and unloading device can be easily moved, improving the convenience of use.

[0050] There is at least one rotating arm 3, and one end of the rotating arm 3 is fixedly connected to the main shaft 1, and the other end is suspended. The rotating arm 3 can rotate around the main shaft 1 as a central axis. Generally, the rotating arm 3 and the main shaft 1 are connected in a hinged manner, but other rotatable connections can also be used.

[0051] Preferably, the number of rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com