A microneedle patch transfer device

A microneedle patch and microneedle technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of objects, can solve problems such as low work efficiency, high labor intensity, and the impact of microneedle patch quality, and improve the efficiency of posting , Precise pasting, avoiding the effect of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

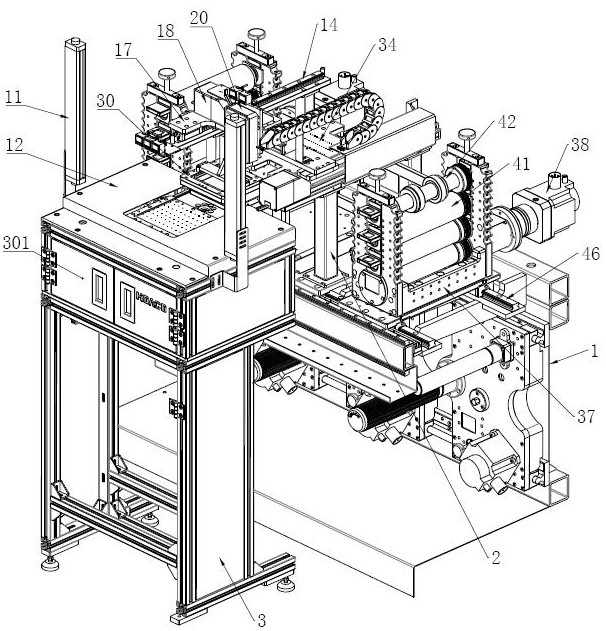

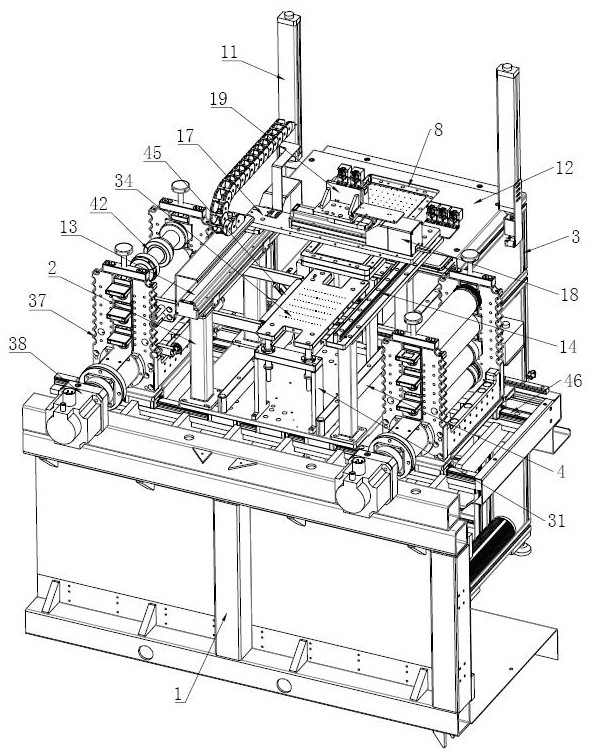

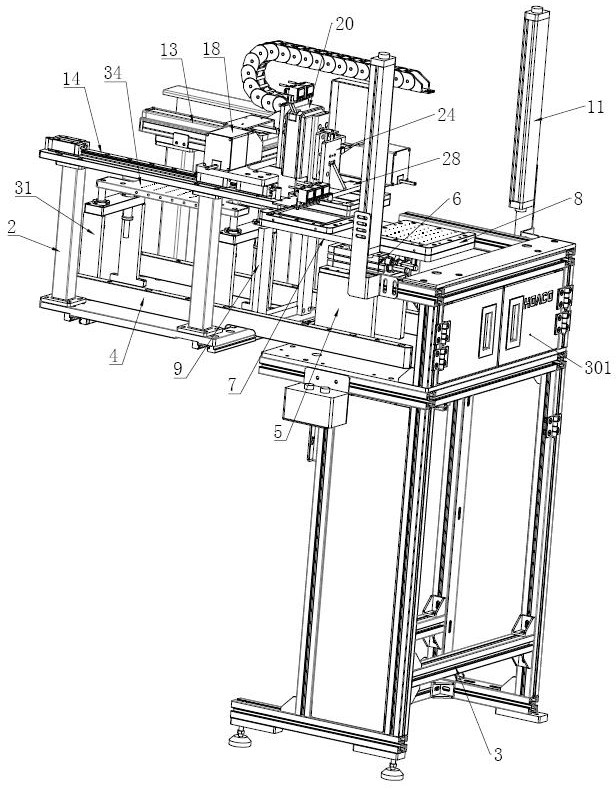

[0074] As shown in FIG. 1 to FIG. 6, the present embodiment provides a microneedle patch transfer device, including a rack 1, the rack 1

[0075] As shown in Figure 1 to Figure 4, Figure 7 to Figure 11, the material feeding mechanism includes a feeding rack body 3, and the feeding rack body 3 is on the upper

[0080] In the present embodiment, the sheet positioning tray 8 abuts against the material rotating plate 7 and is provided with a suction hole for the first sheet

[0095] The first buffer mechanism includes a second guide rail 22 vertically fixed on the third mounting plate 21, on the second guide rail 22

[0100] In this embodiment, the material suction plate 29 and the sealing cover plate 30 are annular structures, which saves materials.

[0105] The third material adsorption hole 3401 provided on the adhesive support plate 34 realizes the adsorption of the microneedle patch and ensures that the microneedle

[0106] As shown in FIG. 19, in the present embodiment, the adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com