Macromolecular adhesive coating device for waterproof coiled material processing

A polymer adhesive and waterproof membrane technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problem that the power consumption of the equipment cannot be matched with the adhesive, and the range of the adhesive cannot be controlled , increased workload and other issues, to achieve the effect of easy winding and storage, easy heating treatment, and reduced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

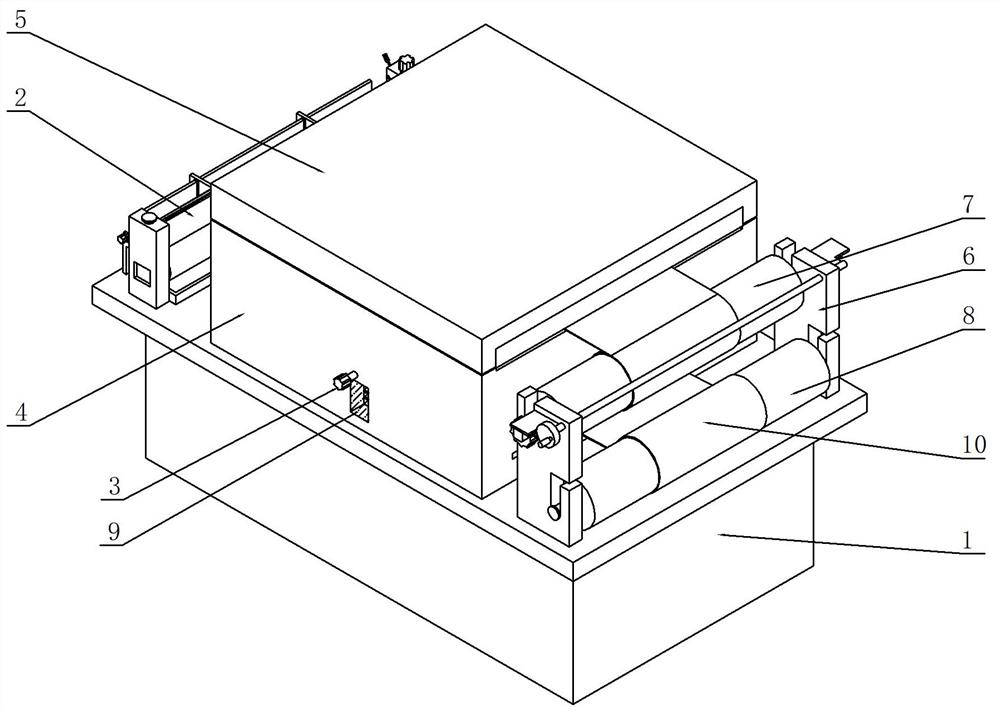

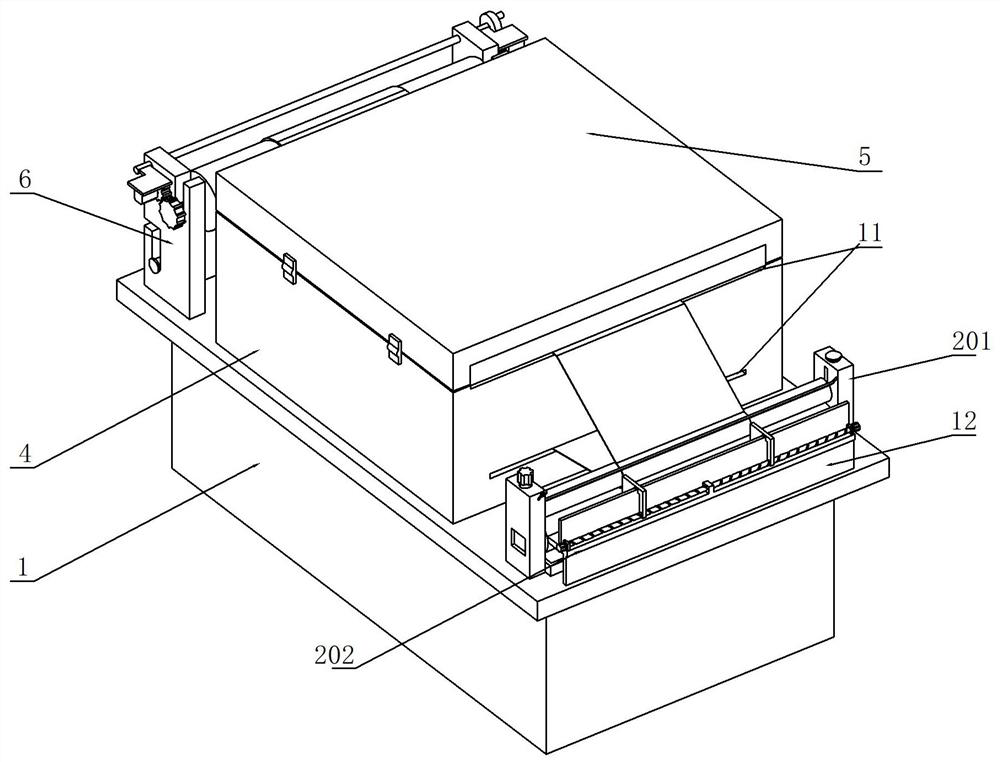

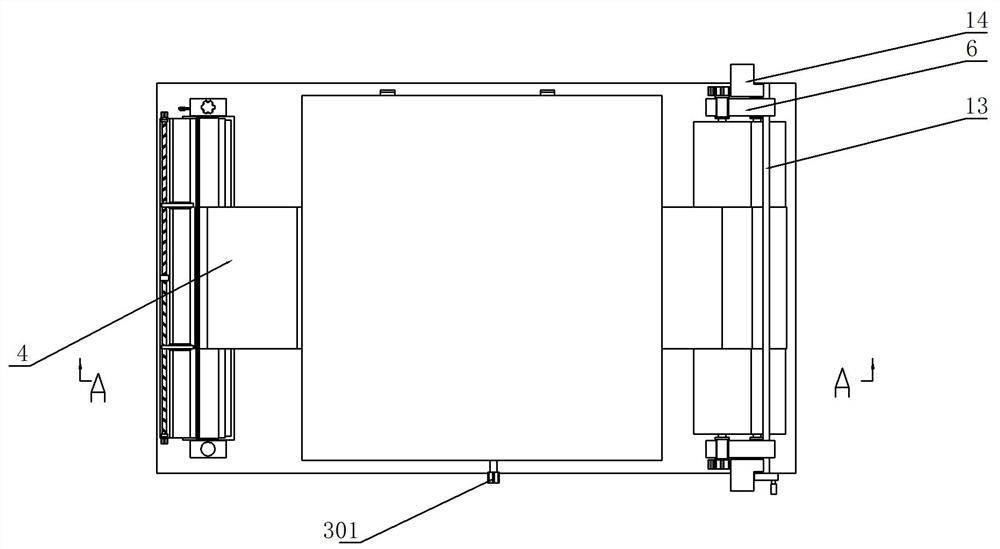

[0036] Example: such as Figure 1-13 As shown, a polymer adhesive coating device for waterproof coil processing includes a workbench 1, a heating shell 4 is fixedly installed in the middle of the upper surface of the workbench 1, and a heating shell 4 is installed on the two sides of the heating shell 4 respectively. Two interspersed through holes 11, two intersected through holes 11 are set up and down correspondingly, the upper end of the heating shell 4 is hinged with a flip cover 5, and the two ends on one side of the upper surface of the workbench 1 are fixedly installed with side mounting plates 6. A component mounting plate 12 is fixedly installed on the side of the upper surface of the workbench 1 away from the side mounting plate 6, a through window 9 is provided on one side of the heating shell 4, and a side of the heating shell 4 close to the through window 9 The second coating assembly 3 is fixedly installed on the side, and the first coating assembly 2 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com