Automatic loading device for sheet materials

A technology of automatic feeding and sheet material, applied in the directions of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of low efficiency, affecting the pace, limiting the automation and continuity of the glass plate grinding process, and reducing costs and speed. Efficient, streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

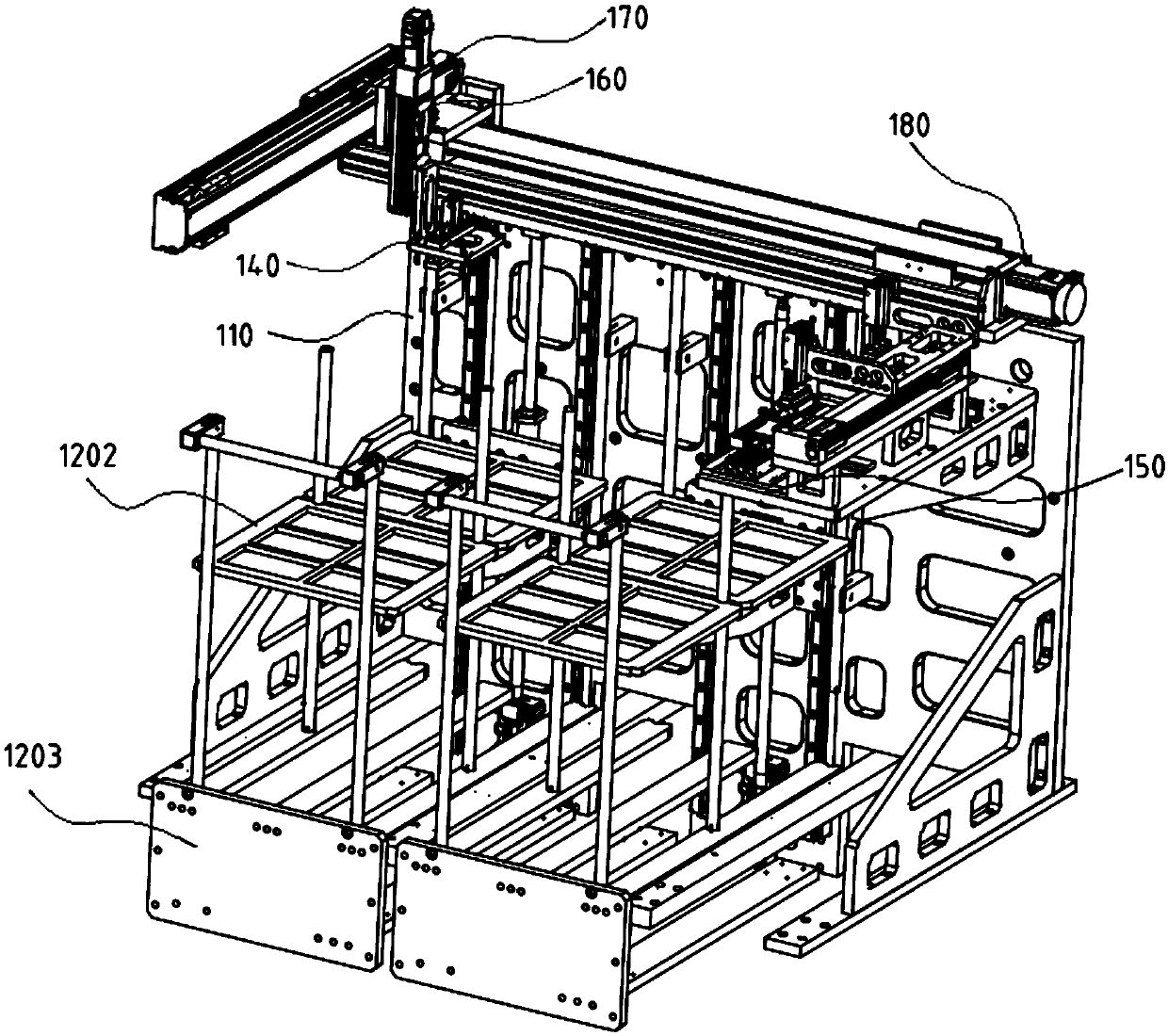

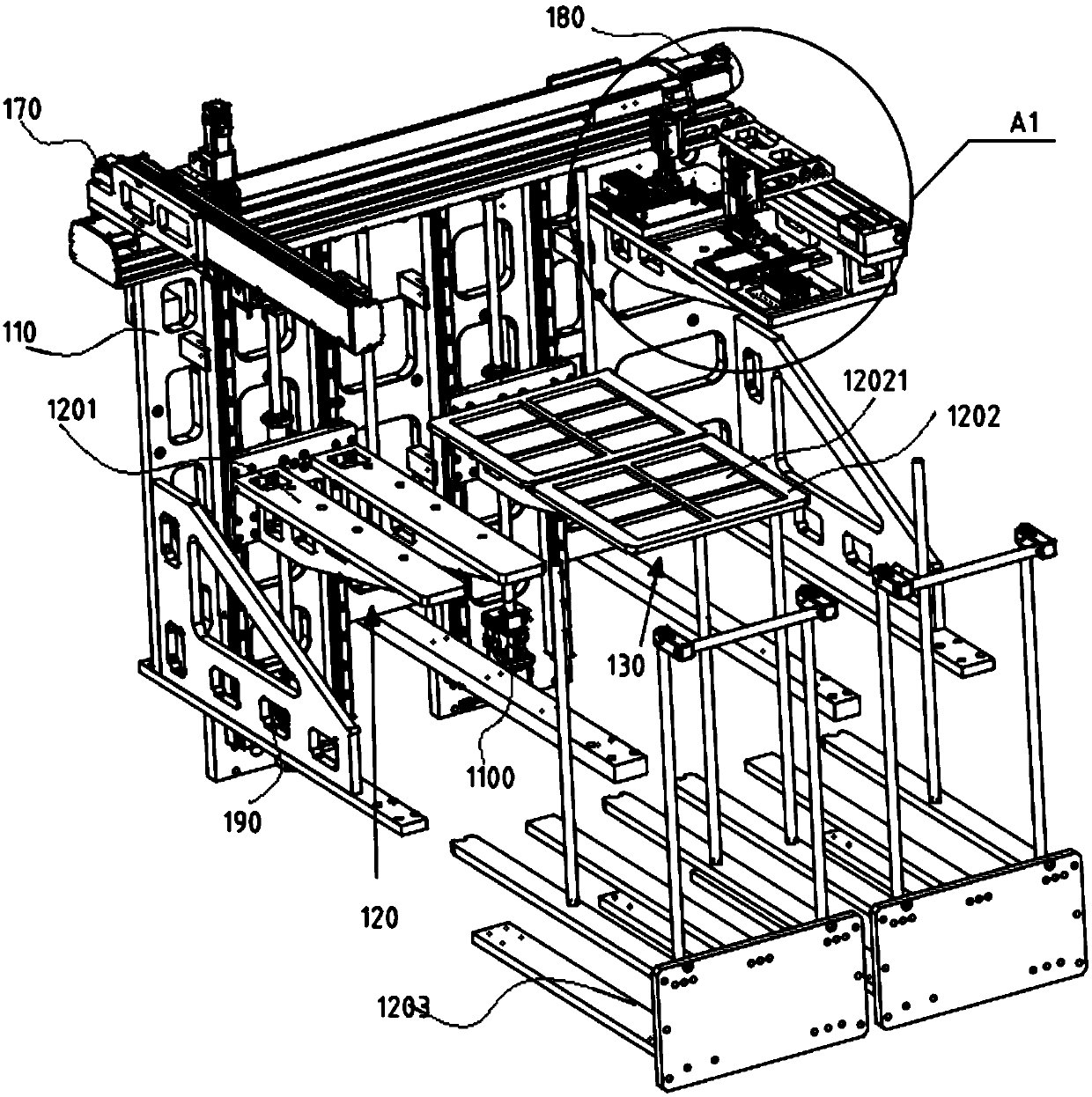

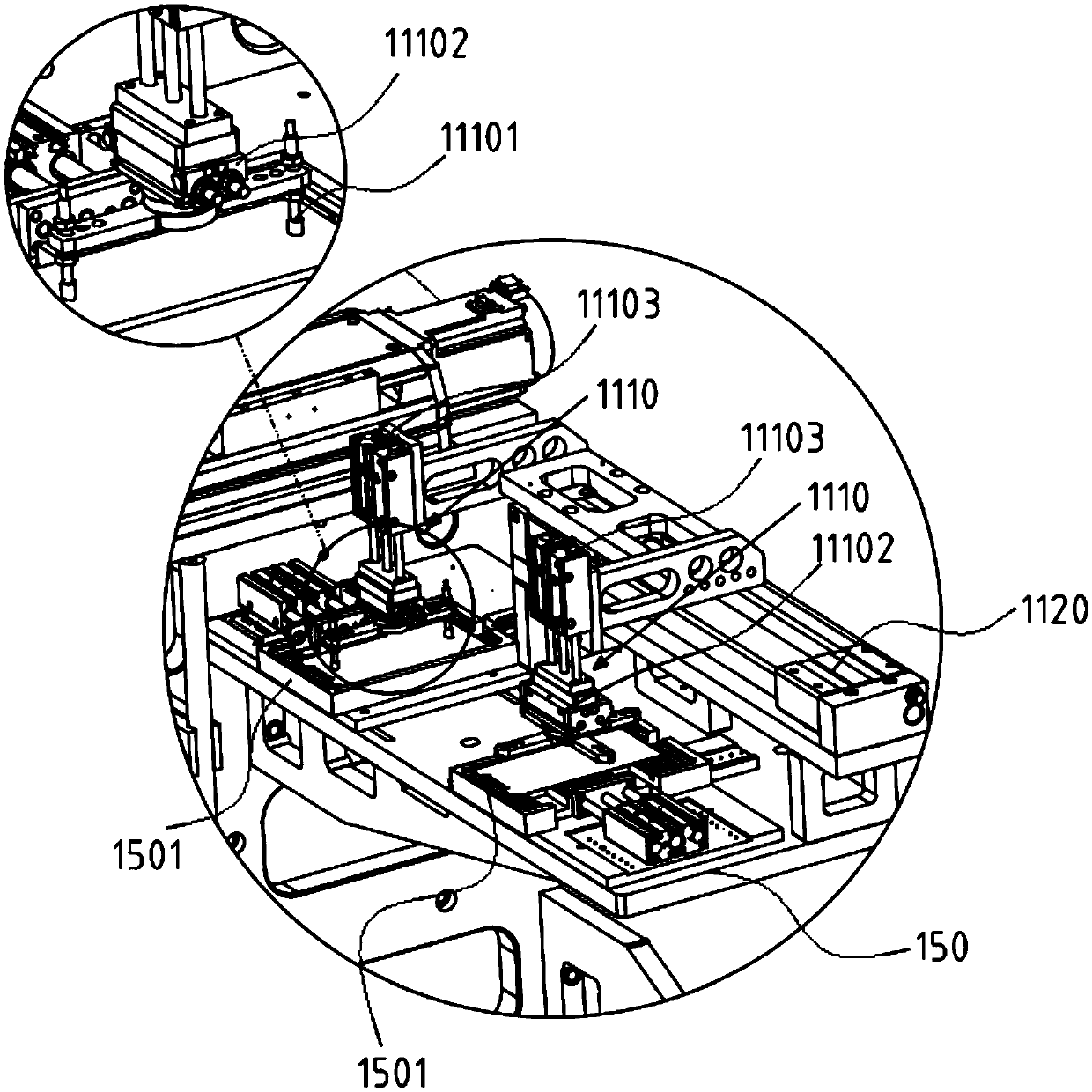

[0030] Embodiment: a kind of sheet material automatic feeding device, such as Figure 1 to Figure 5 As shown, it includes a frame 110 and a fetching and feeding mechanism 120 installed on the frame, a tray placement mechanism 130, a fetching mechanism 140 and a discharging platform 150;

[0031] Such as figure 1 with Figure 4 As shown, the frame is also provided with a first Z-direction drive mechanism 160 capable of driving the Z-direction translation of the reclaiming mechanism, a first X-direction drive mechanism 170 capable of driving the X-direction translation of the reclaimer mechanism, and a first X-direction drive mechanism 170 capable of driving The Y-direction driving mechanism 180 for the Y-direction translation of the reclaiming mechanism;

[0032] The frame is also provided with a second Z-direction drive mechanism 190 capable of driving the Z-direction translation of the fetching and feeding mechanism and a third Z-direction drive mechanism 1100 capable of dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com