Patents

Literature

107results about How to "Guaranteed linear motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

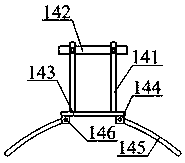

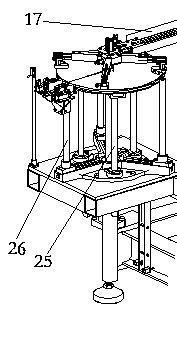

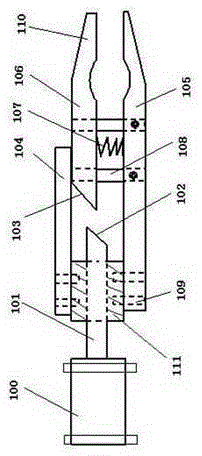

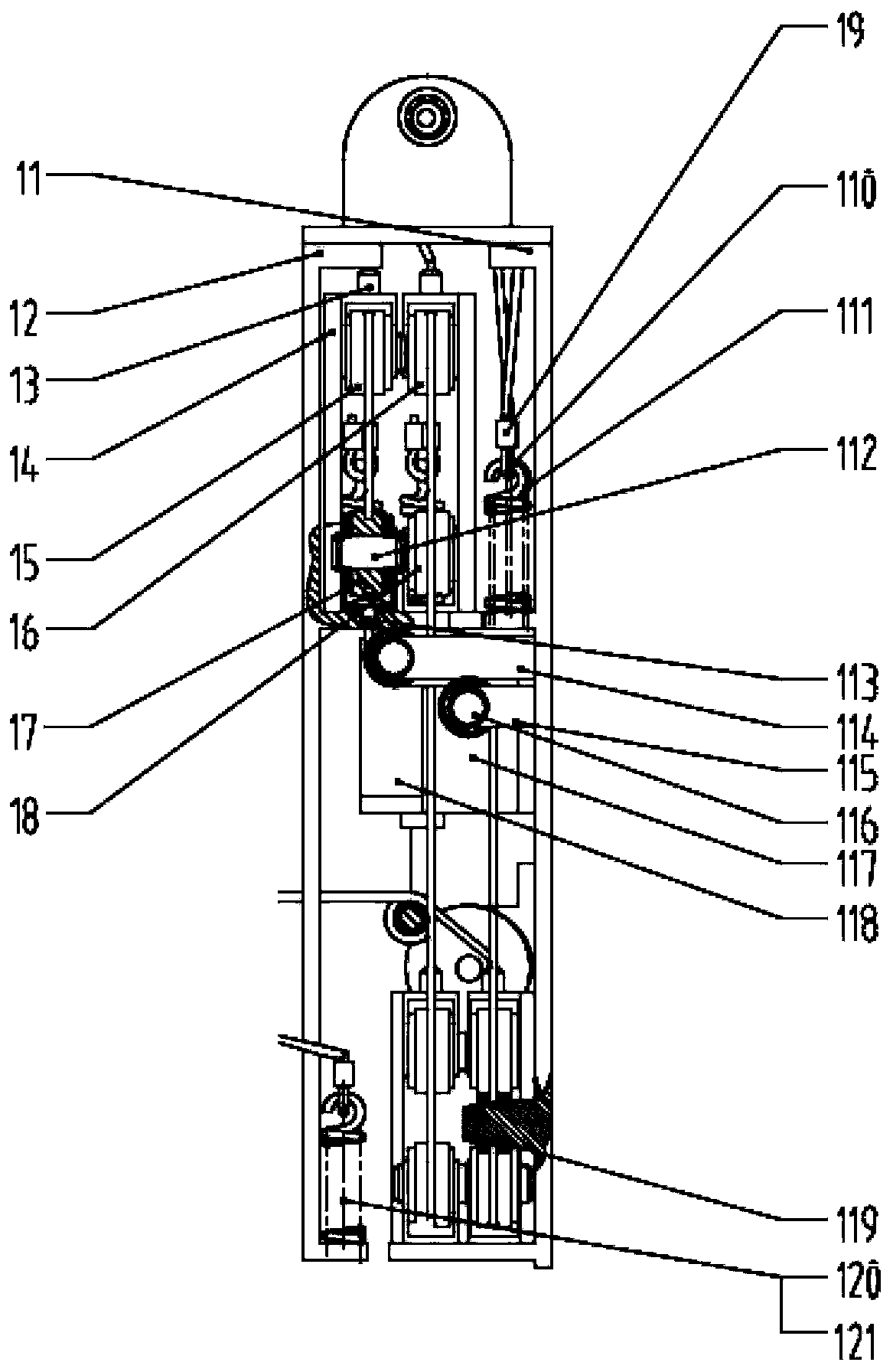

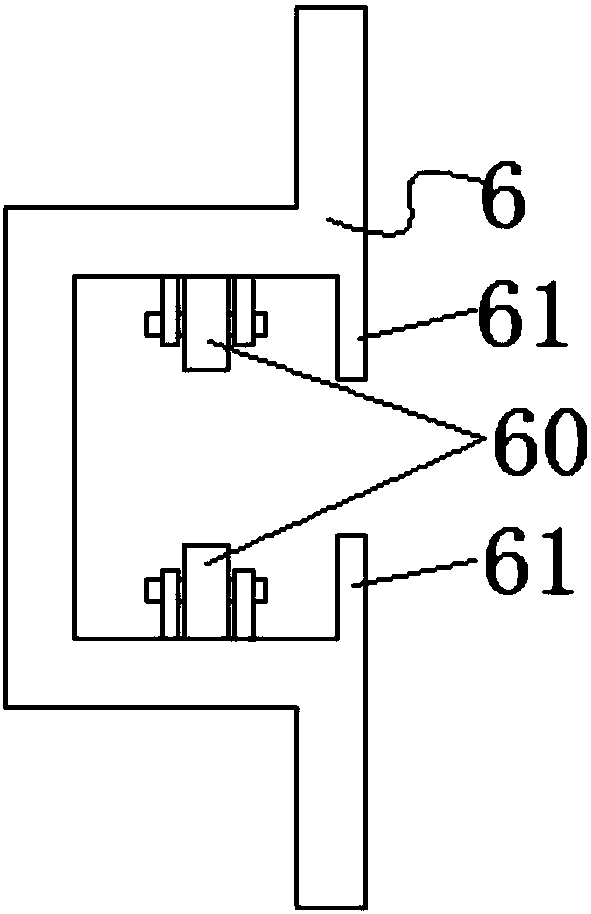

Hose cleaning robot

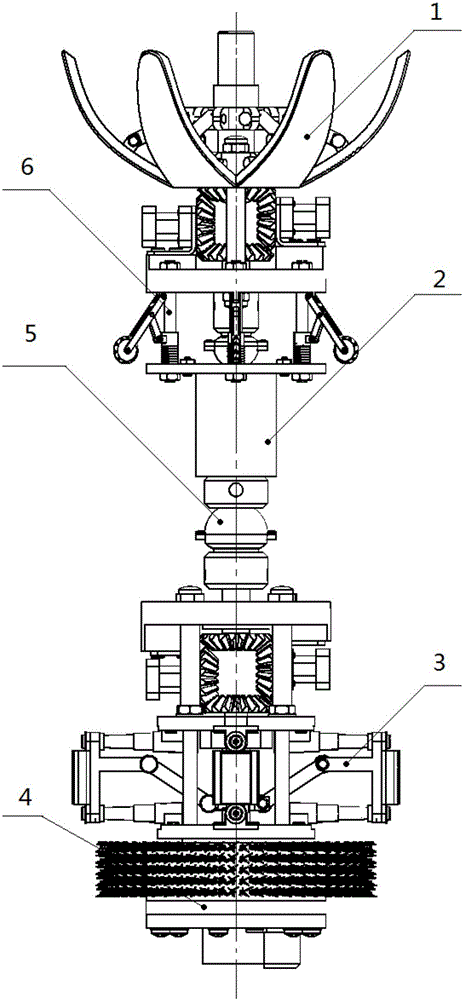

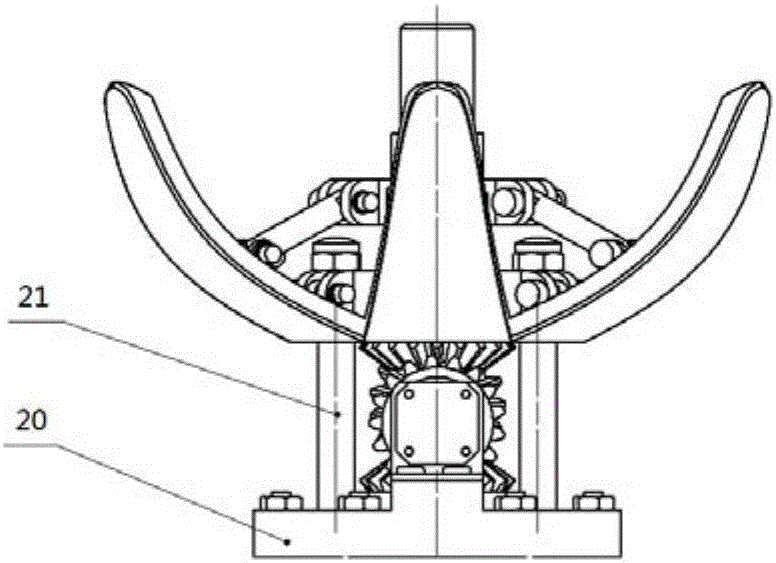

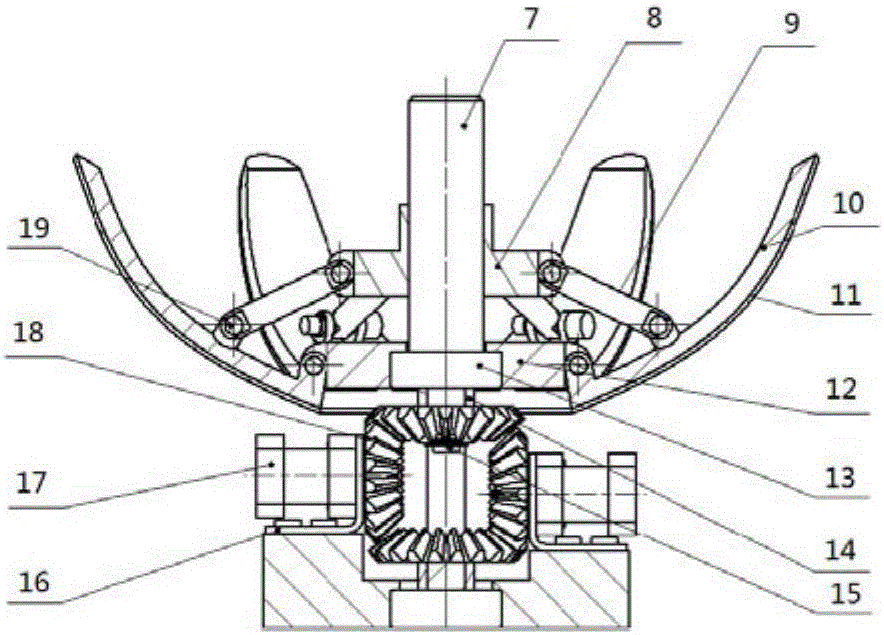

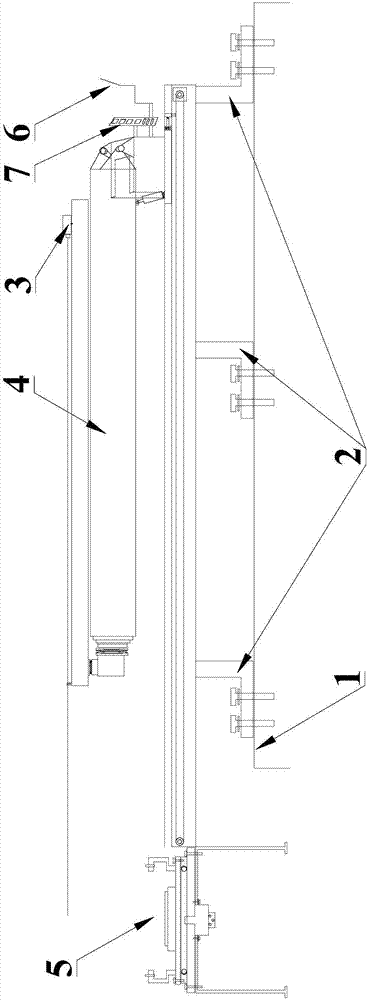

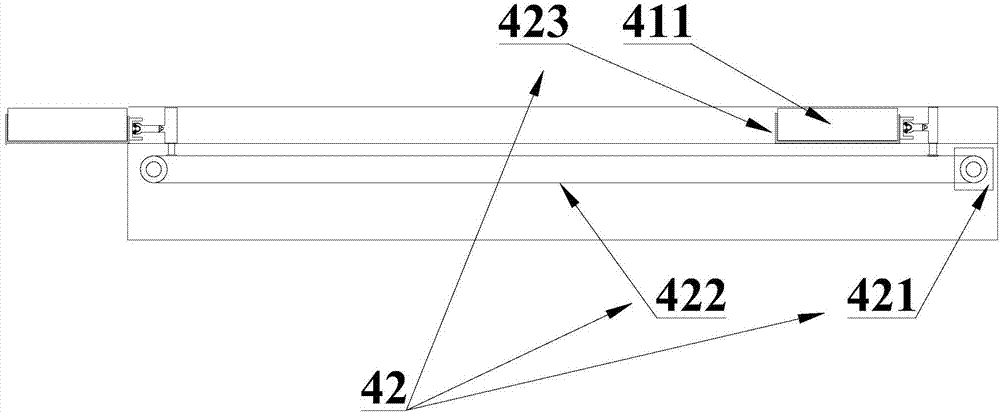

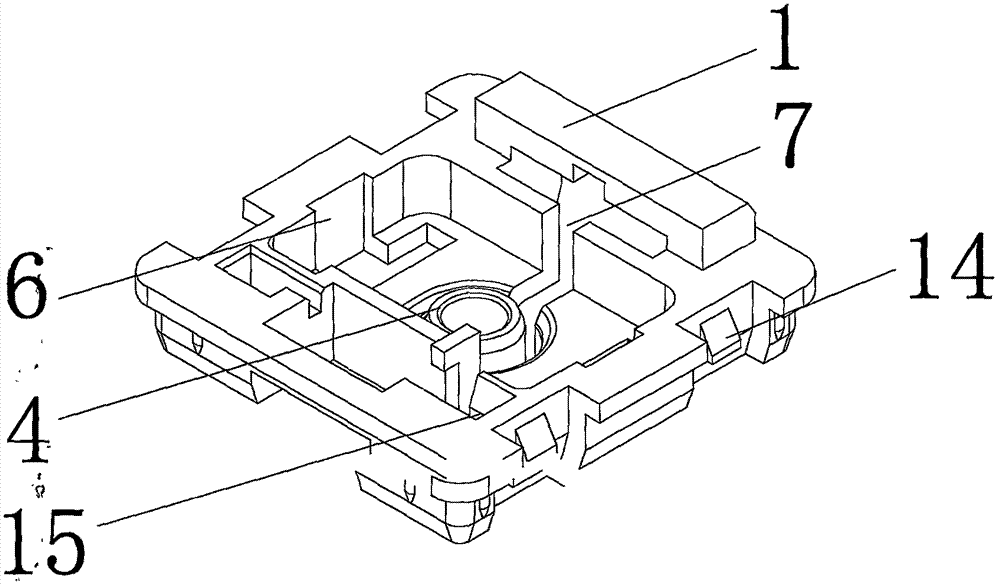

The invention provides a hose cleaning robot and relates to the field of pipeline inner wall crawling robots. In order to meet the requirements for crawling and cleaning of the inner wall of a hose, the robot for crawling on and cleaning the inner wall of the hose is designed. The robot comprises an upper fixing mechanism, a lower fixing mechanism and a middle heading mechanism. The two fixing mechanisms are located at the two ends of the middle heading mechanism respectively to achieve the fixing effect. The middle heading mechanism is in charge of connecting a whole machine, pushes the upper fixing mechanism to move forwards and pulls the lower fixing mechanism to ascend. Both the upper fixing mechanism and the lower fixing mechanism are designed as slider crank mechanisms to achieve the expanding, fixing, shrinking and separating functions. Curved face supporting boards driven by the upper fixing mechanism form a bud shape when folded, so that a road is opened; and when unfolded, the curved face supporting boards make tight contact with the inner wall of the hose to achieve the fixing effect. The two ends of a supporting board of the lower fixing mechanism are provided with telescopic rods, so that linear motion of the supporting board is guaranteed, and the supporting board is supported stably when fixed. A lead screw slider module is adopted for designing the middle heading mechanism, so that the heading function is achieved.

Owner:BEIJING UNIV OF TECH

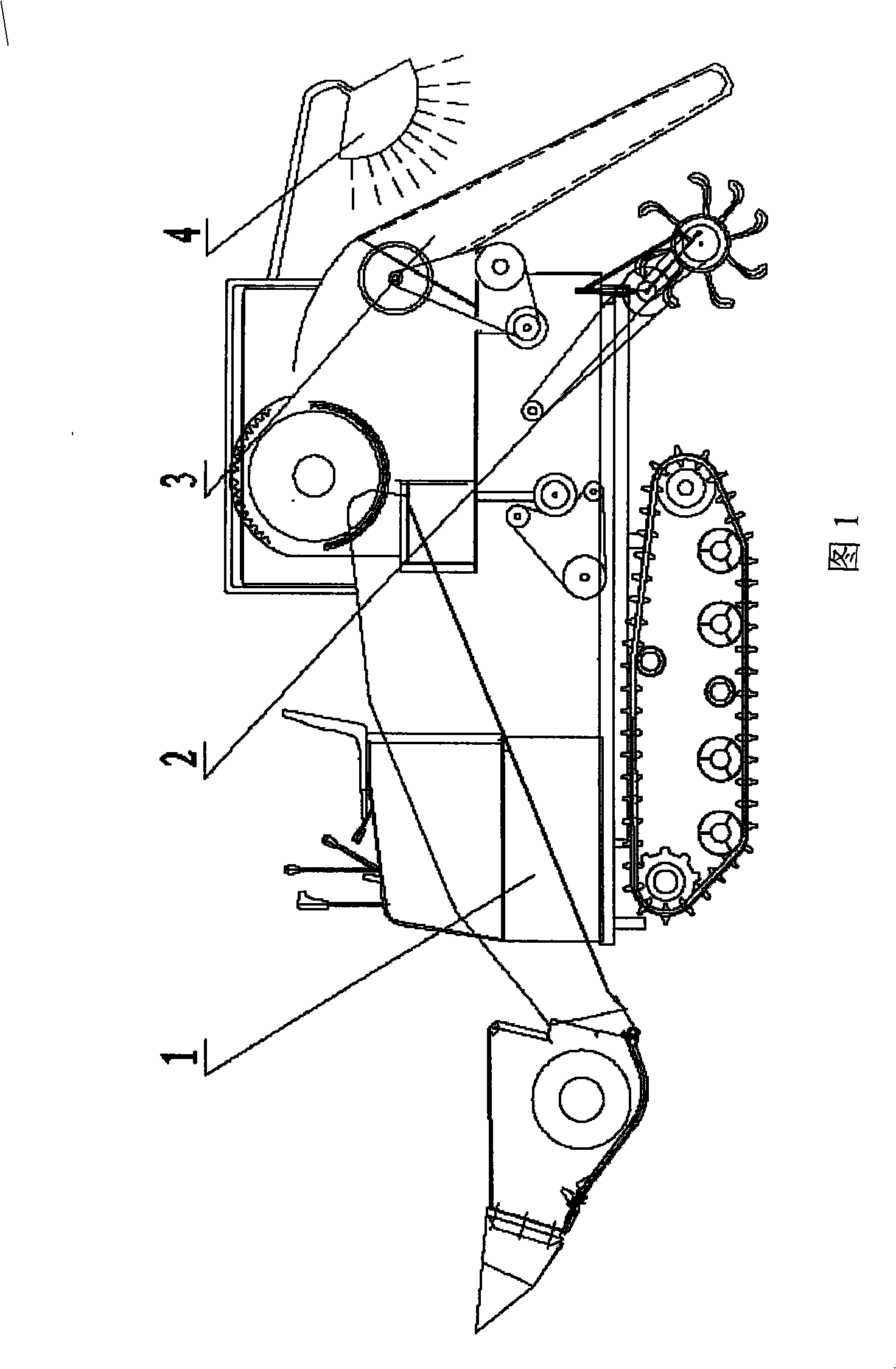

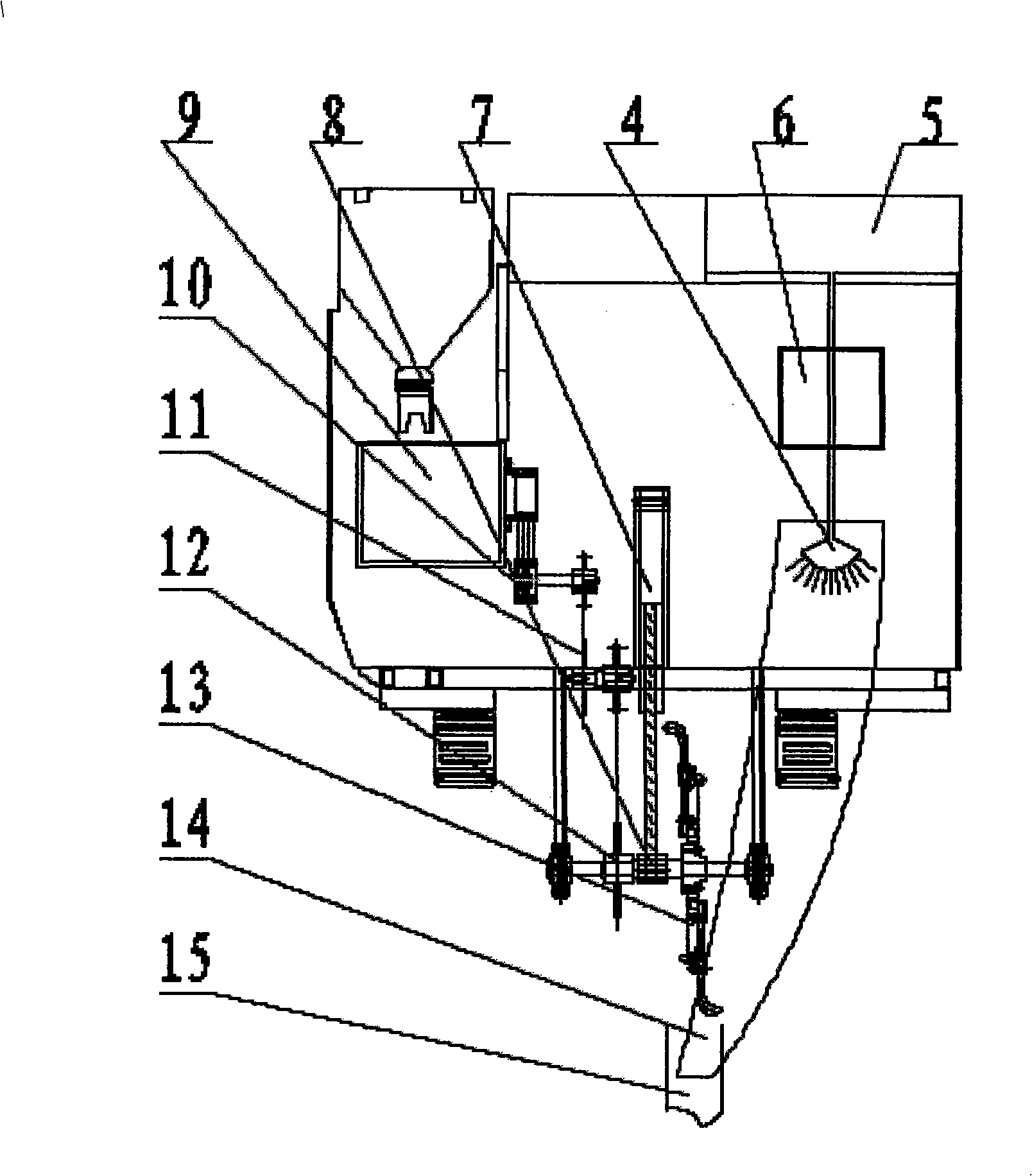

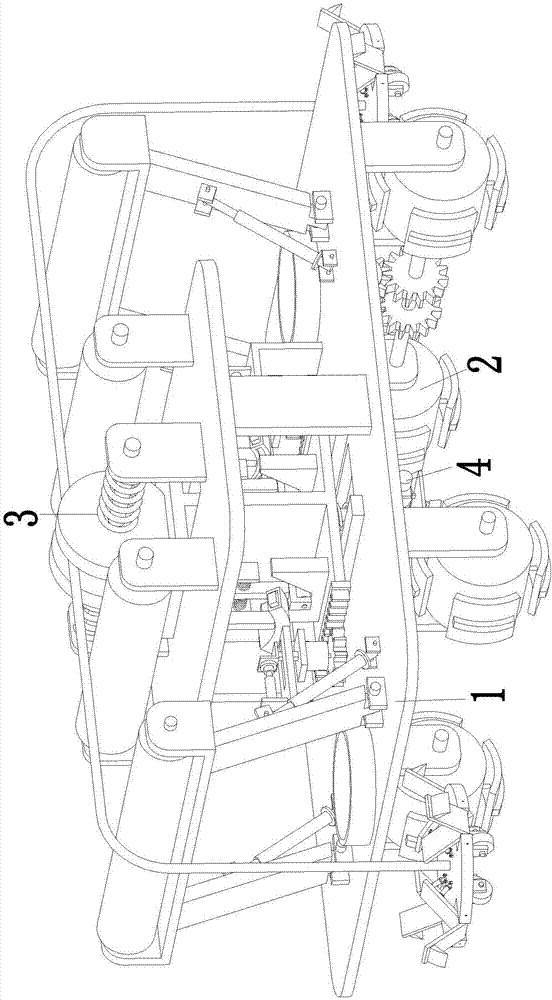

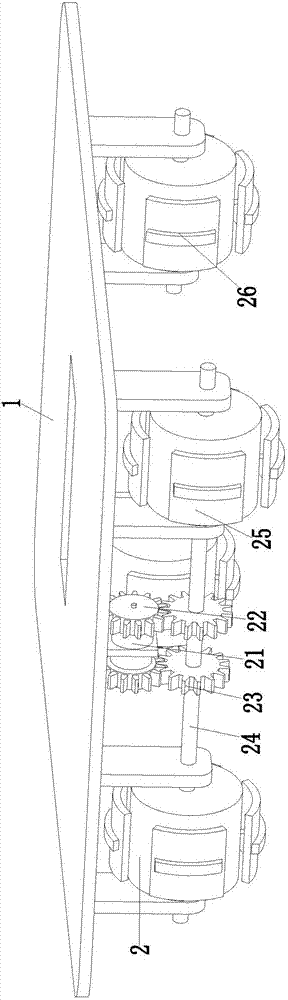

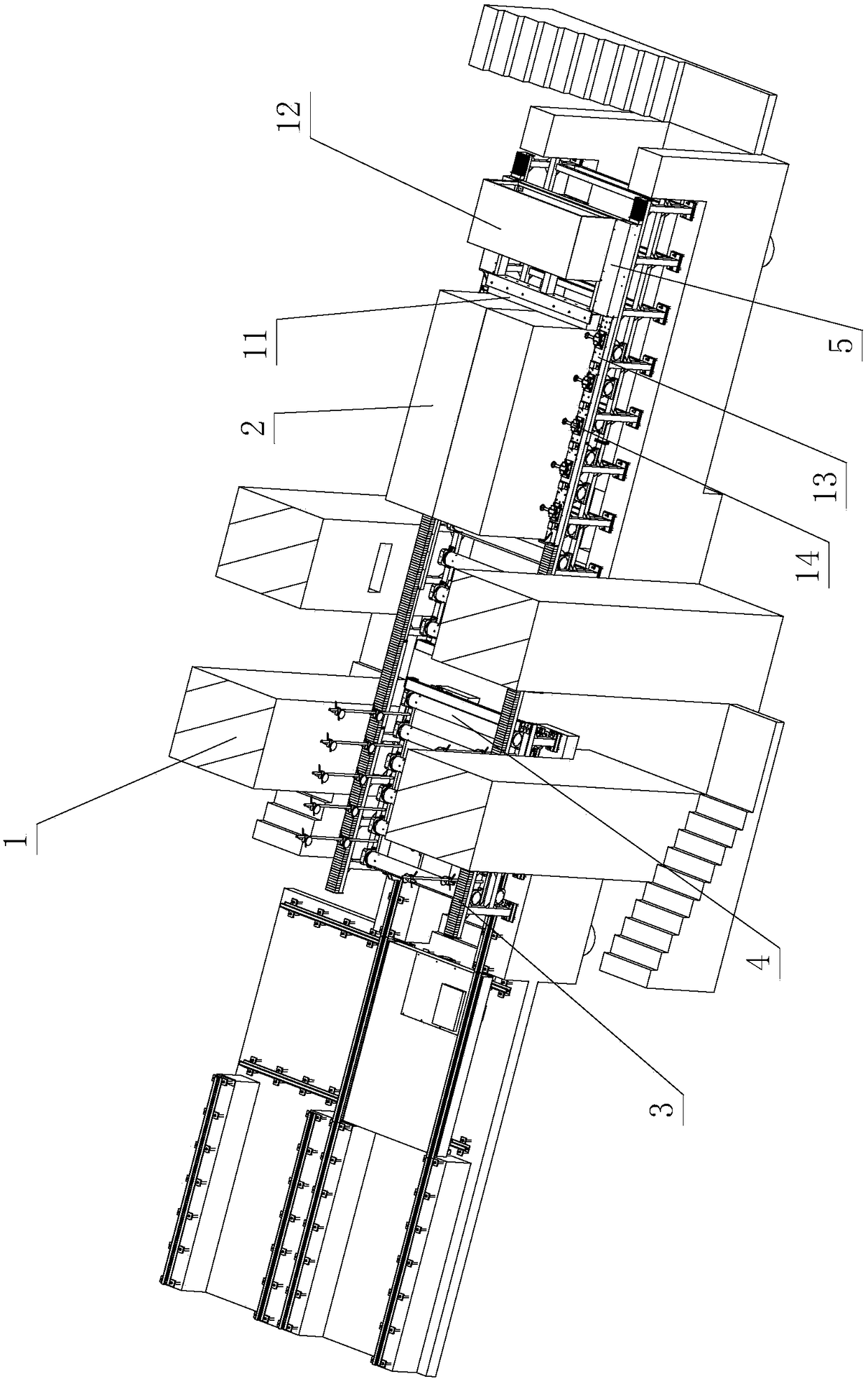

Rice-wheat combined multifunctional one-piece device of harvesting, ditching, covering grass and spraying

The invention relates to an all-in-one multifunctional machine for combined reaping, ditching, burying and spraying for rice and wheat, which comprises a ditching device, a straw guide device and a spraying device, wherein the ditching device is connected with a tail beam of a combined harvester through a movable bracket; the straw guide device is hinged with a straw discharge opening of a threshing separating device of the combined harvester through a pin shaft; the ditching device comprises a gear box, a ditching cutter head and a hydraulic oil cylinder; the ditching cutter head of the ditching device is arranged on the resistance central line of the tail of the machine through the movable bracket; and the spraying device is also arranged, and a spraying nozzle of the spraying device is positioned at an inlet of the straw guide device or the ditching surface of the ploughed ditch. The all-in-one multifunctional machine has the advantages that: the ditching cutter head of the ditching device is arranged on the resistance central line of the machine through the movable bracket, so that the machine cannot bear the push force action of sides when carrying out operation, and the machine can maintain rectilinear motion; and the spraying device sprays biological bacterial fertilizer (decay agent) on the straws at the inlet of the straw guide device or the plugged ditch surface, and can promote the straw to return to the filed and decay as soon as possible.

Owner:NANJING AGRICULTURAL UNIVERSITY

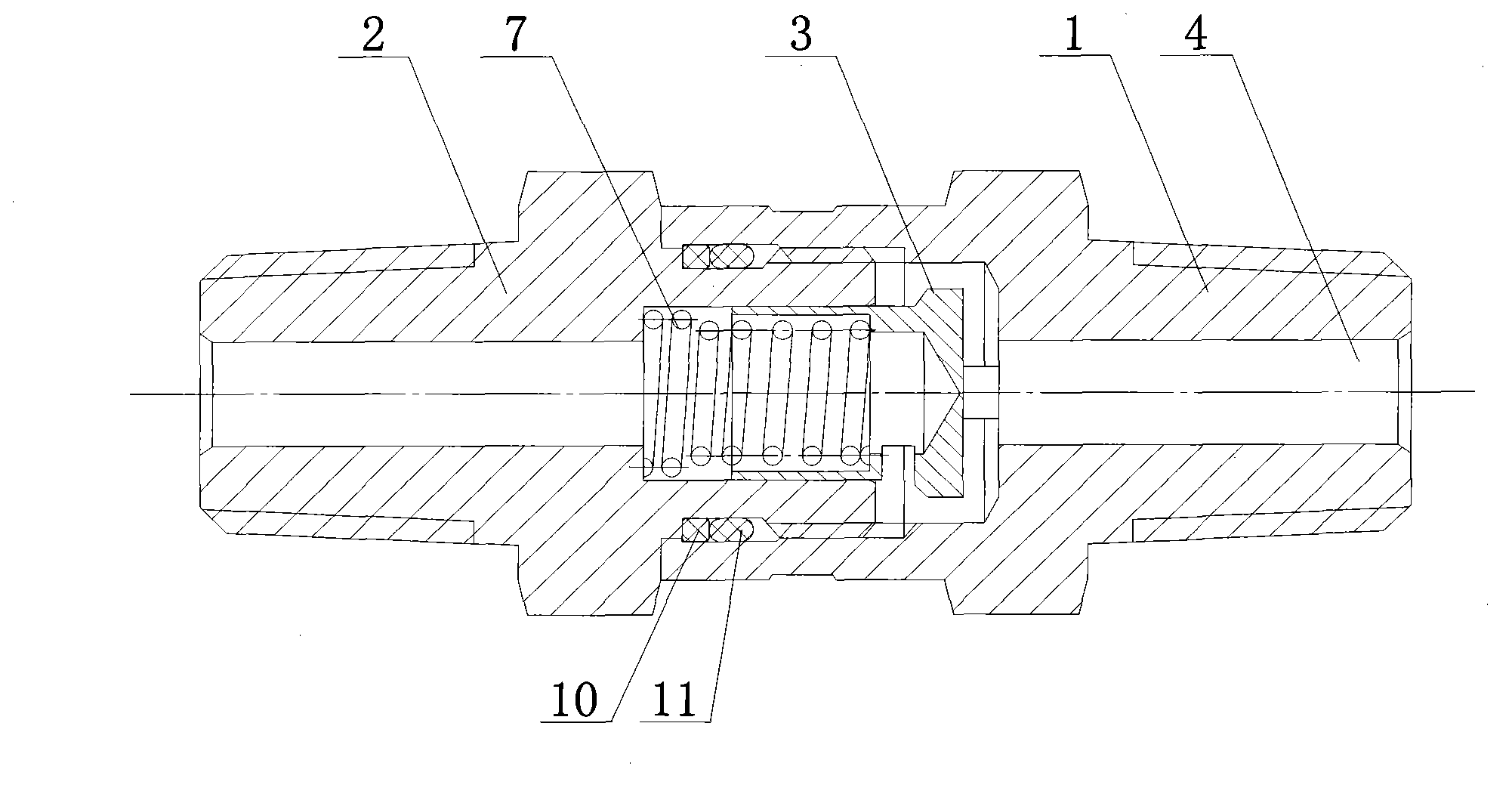

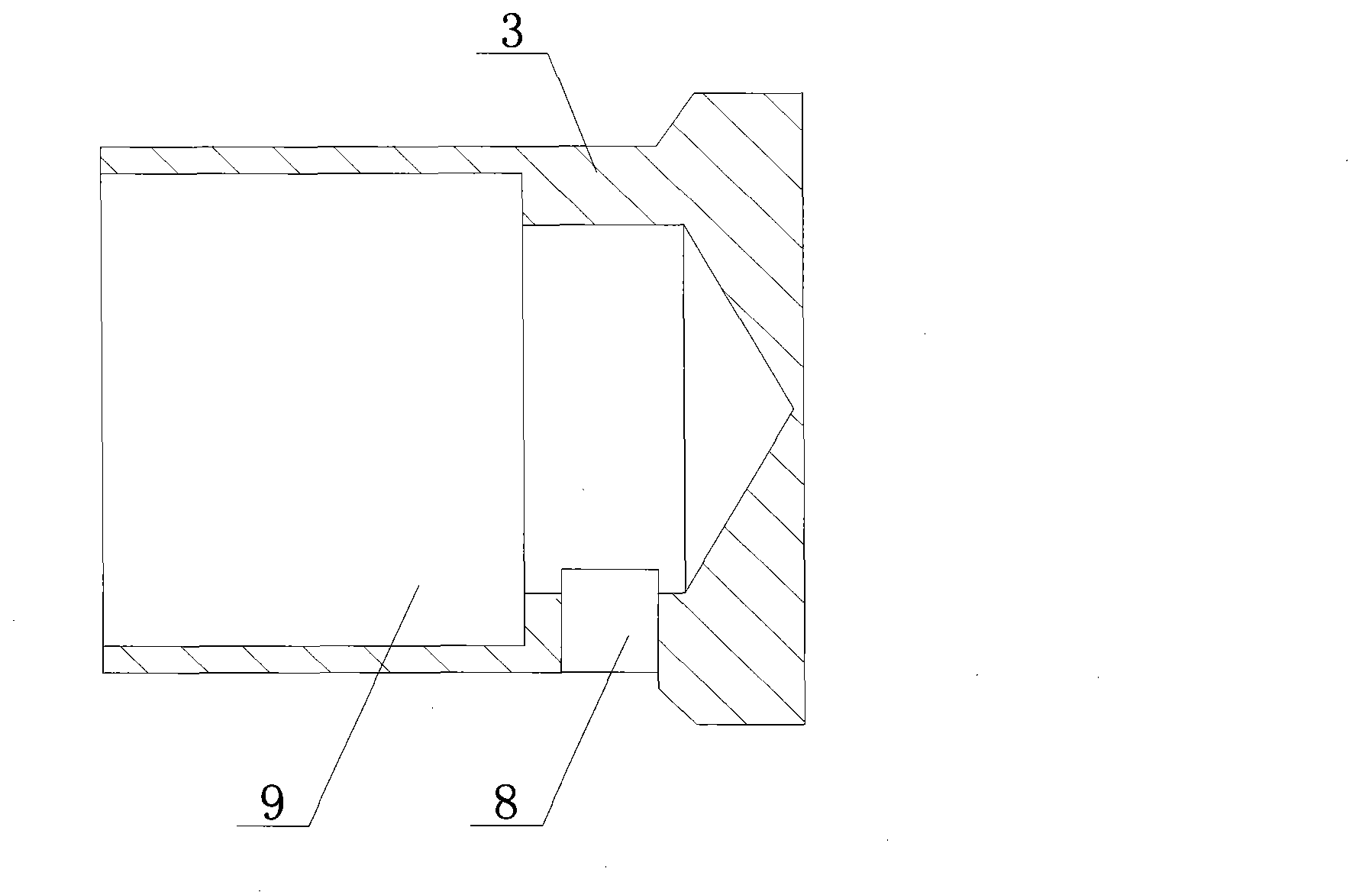

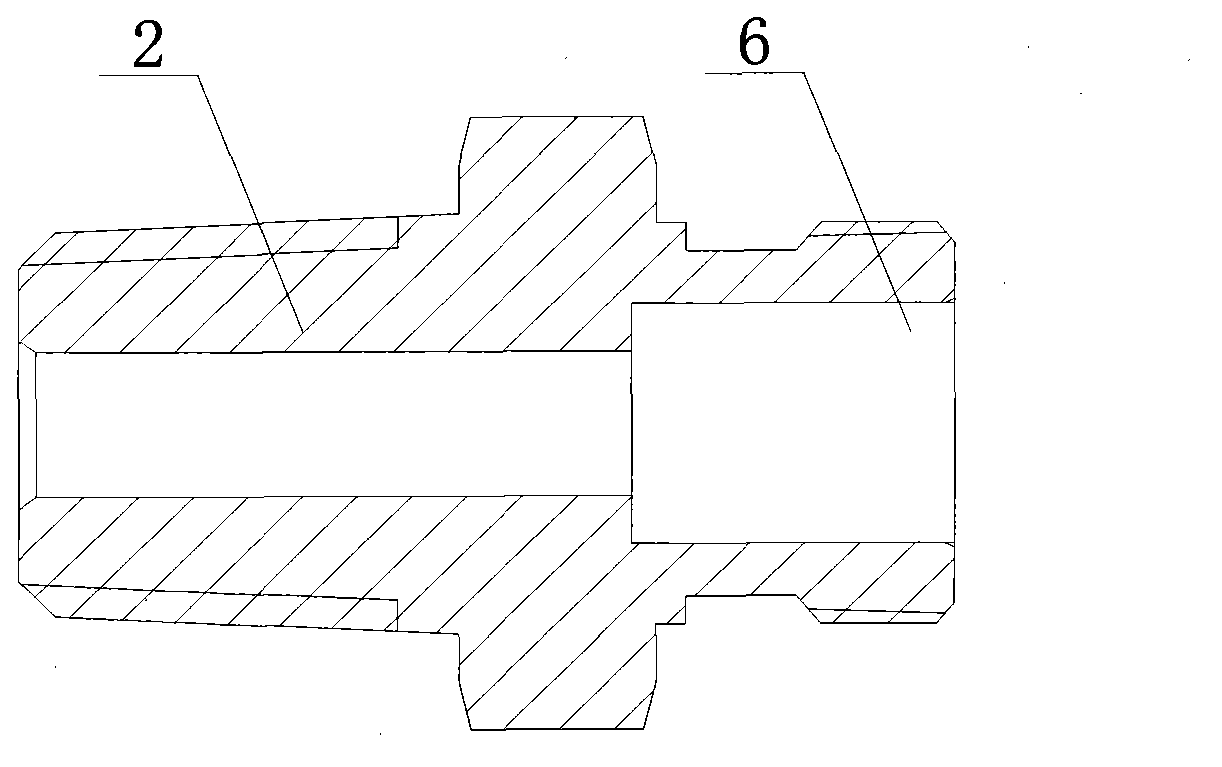

Electric screw overtravel automatic safe protective device

The invention relates to a safety protection device for engineering parts. An over-stroke automatic safety protection device for electric screw rod comprises a screw rod, a screw nut and a guide key. The invention is characterized in that an elastic screwed damping body is respectively equipped at two ends of the screw rod, a screw nut anchor ear is fixed on the screw nut and connected with the flange of a expansion rod, and a one-way stopping spacing pin is disposed on the housing and respectively corresponding to the two ends of the screw rod; when the screw nut locates at the limiting positions on the two ends of the screw rod and is stopped by the elastic screwed damping body so as to be in locking state, the screw nut anchor ear contacts with the guide key, and the screw nut and screw nut anchor ear rotate together with a screw mandrel; when the screw mandrel reversely rotates into a positioning groove on the circumferential surface of the screw nut anchor ear in which the one-way stopping spacing pin at this end is embedded, the locking state of the screw nut and screw rod is released, and a guide groove or guide notch on the circumferential surface of the screw nut is just flush with the guide key or a guide bulge. The invention solves can effectively prevent rapid abrasion of parts due to continuous trackslip without using conventional stroke switch, sensor and other electrical devices and elements.

Owner:上海久能机电制造有限公司

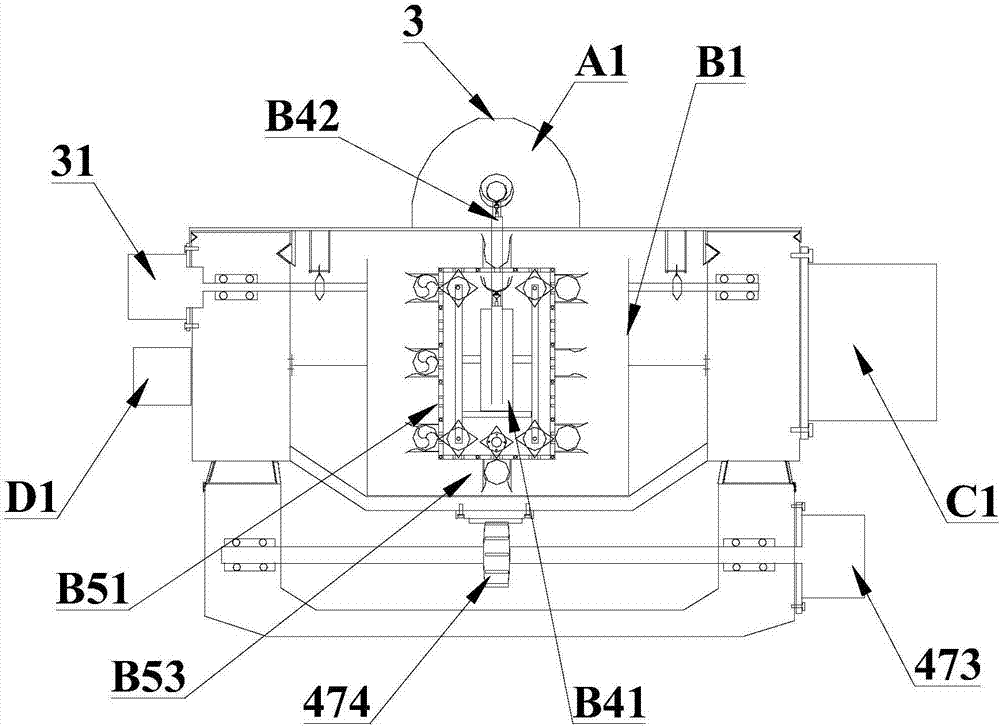

Multicolour screen printing machine

The present invention discloses a multicolour silk-screen printing machine, including machine frame, several printer heads mounted on the machine frame, drying equipment placed among the several printed heads, drive device, transfer device and final drying device. Said transfer device includes driving roller, driven roller, metal conveyer belt and stock fixing device, the driving roller or / and drive roller is equipped with driving pin which can be combined with pin hole on the metal conveyer belt, two sides of machine frame are equipped with spacing guideway respectively for preventing metal conveyer belt from producing jump and leftward and rightward displacement and ensusing striaght movement of the conveyer belt. Said invention is suitable for screen printing various materials.

Owner:安旭 +3

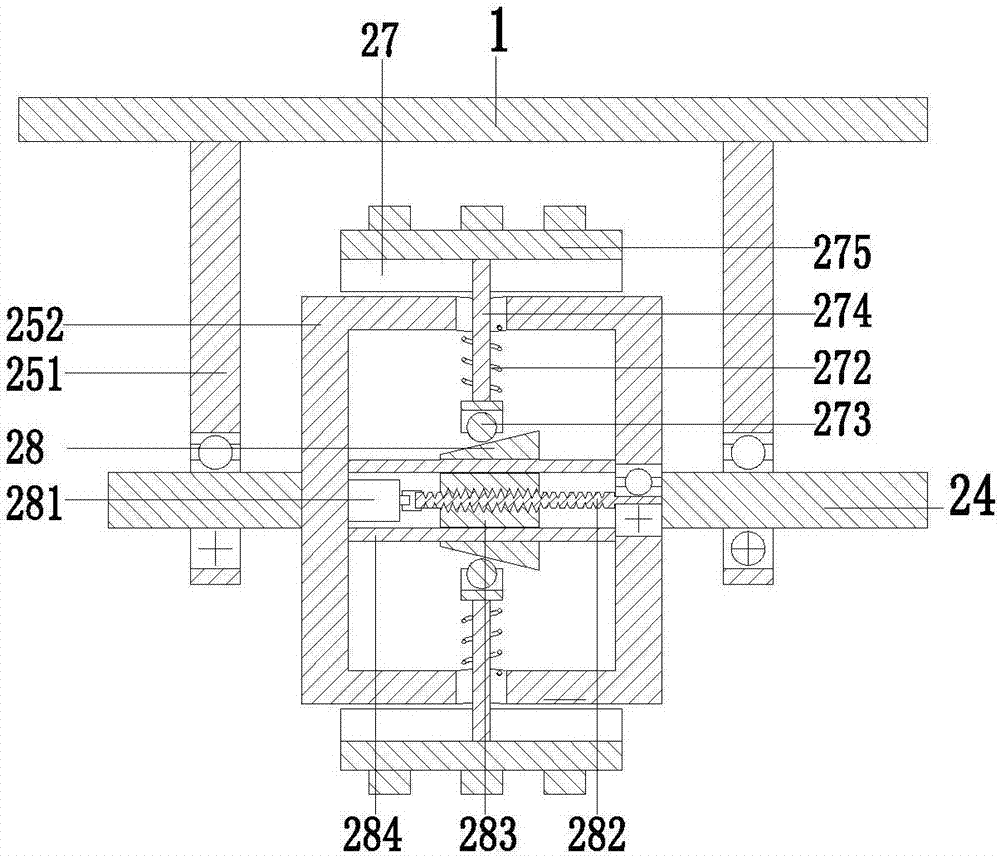

Anchoring agent automatic filling device

ActiveCN107044294AThe filling process is stableFor lateral movementAnchoring boltsBiomedical engineeringFill device

Owner:刘军

Multifunctional welding robot

InactiveCN109262168ARealize self-moving functionGuaranteed welding requirementsWelding/cutting auxillary devicesAuxillary welding devicesPush and pullEngineering

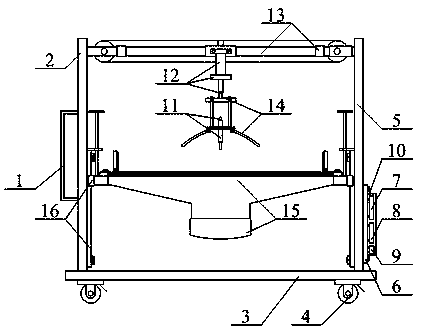

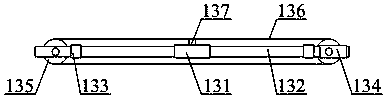

The invention provides a multifunctional welding robot. The multifunctional welding robot comprises a U-shaped push handle, a main supporting seat, a movable base, universal wheels with brake pads, anauxiliary supporting seat, a circuit board, a host, a control screen, a master control switch, a dustproof shield, a welding gun, a lifting cylinder, a self-movement type robot moving machine, a liftable adjusting light-proof shield structure, a push-and-pull type waste cleaning and collecting hopper structure and a liftable adjusting rod structure, wherein the U-shaped push handle is mounted inthe middle of the left side of the main supporting seat by a bolt; and the longitudinal lower end of the main supporting seat is mounted on the left upper portion of the movable base through a bolt. By arrangement of a self-moving slider, a stainless steel sliding track, a limiting switch, a self-moving type motor, a belt pulley, a synchronous belt and a connecting plate, a self-moving function ofthe robot is fulfilled favorably to meet welding requirements of the robot; and by arrangement of the limiting switch, a good limiting effect is achieved favorably.

Owner:青岛泽丰汽车零部件有限公司

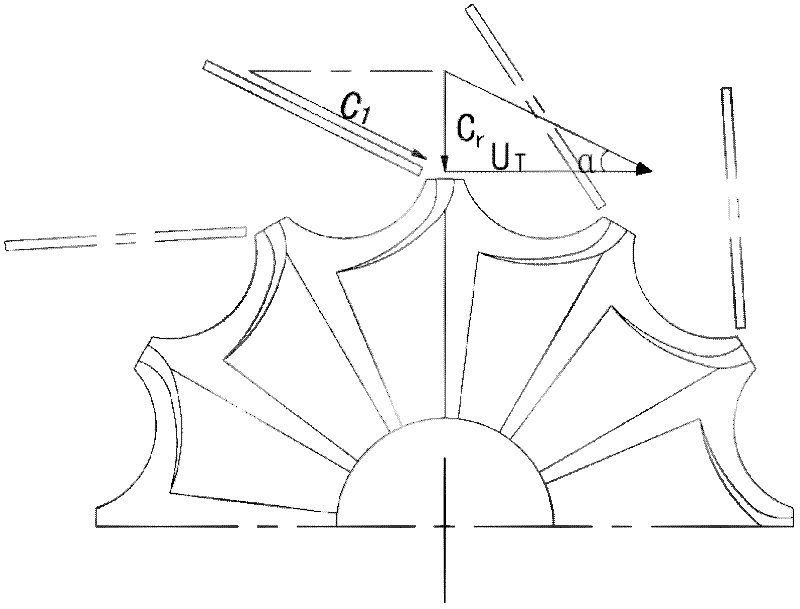

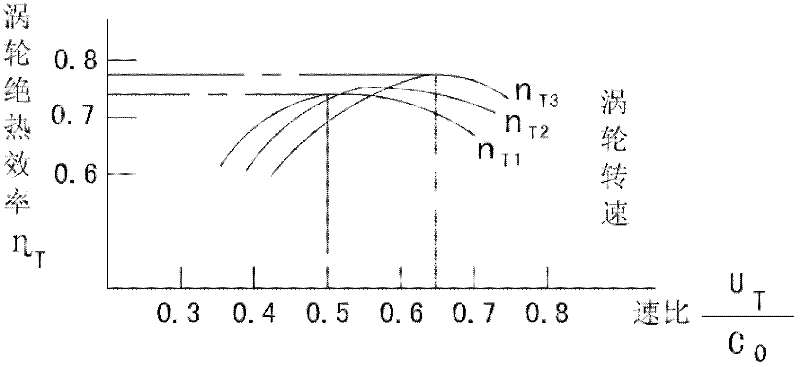

Turbocharger and working method thereof

InactiveCN102383871AImprove efficiencyChanging the cross-sectional area of the nozzleMachines/enginesEngine componentsImpellerTurbine wheel

The invention relates to a turbocharger and a working method thereof. The turbocharger comprises a volute arranged in a turbine casing body and a jet nozzle ring assembly which is fixed in the volute and sleeve on the periphery of an impeller of a turbine; the jet nozzle ring assembly comprises a jet nozzle ring, a plurality of long jet-nozzle blades distributed on the outer side face of the jet nozzle ring, a chute arranged between every two adjacent long jet-nozzle blades, short movable blades arranged in the chutes, linked rings concentrically arranged at the inner side surface of the jet nozzle ring, chute holes which are distributed on the linked rings and correspond to the corresponding chutes, a plurality of arc-shaped guide grooves which are distributed on the linked rings and are arranged concentrically to the linked rings, and a straight bolt arranged on the inner side surface of the jet nozzle ring; and a crank in transmission connection with a driving mechanism is arranged on an intermediate shell of the turbine and is connected with a pin hole in the linked rings through a crank shifting fork so as to drive the linked rings to rotate along a center and make the short movable blades displace in a linear reciprocating manner along a jet-nozzle airflow direction, and thus, the cross section of a jet nozzle is further controlled.

Owner:CHANGZHOU XINRUI AUTO PARTS MFG

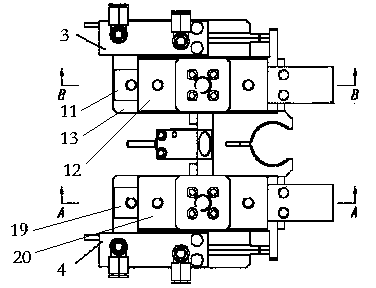

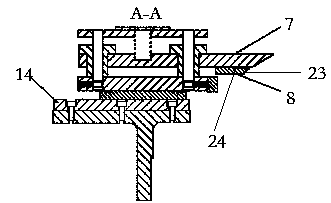

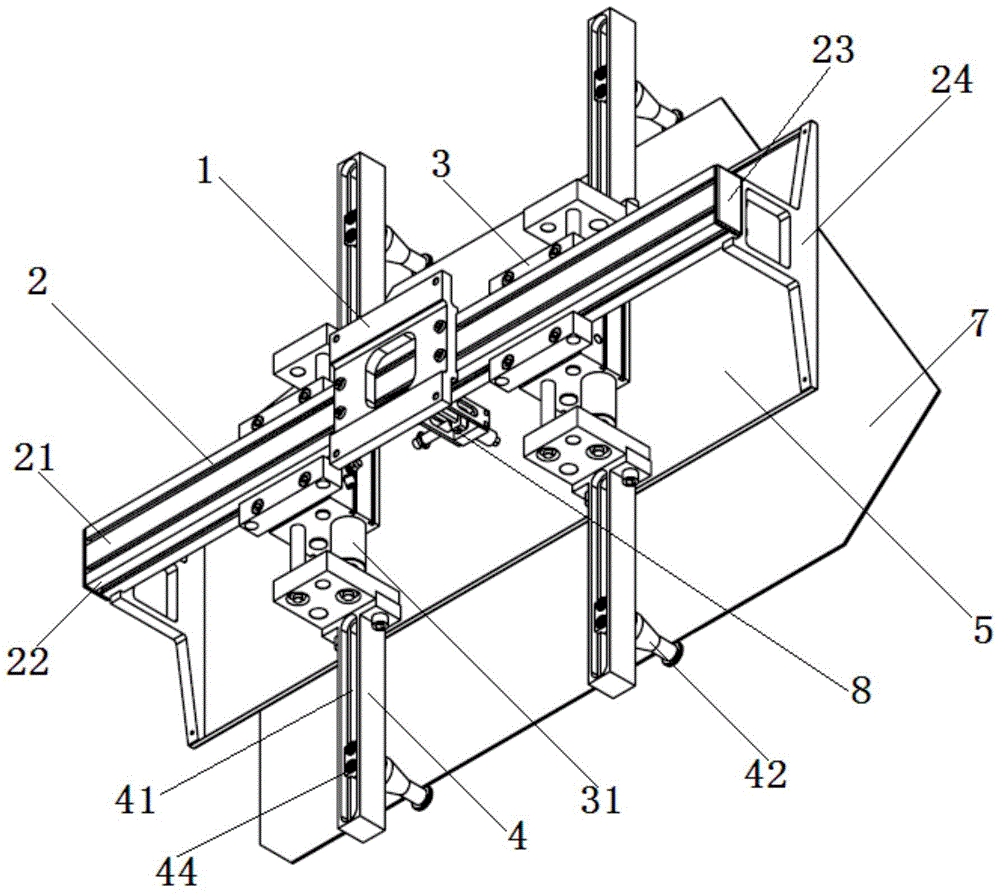

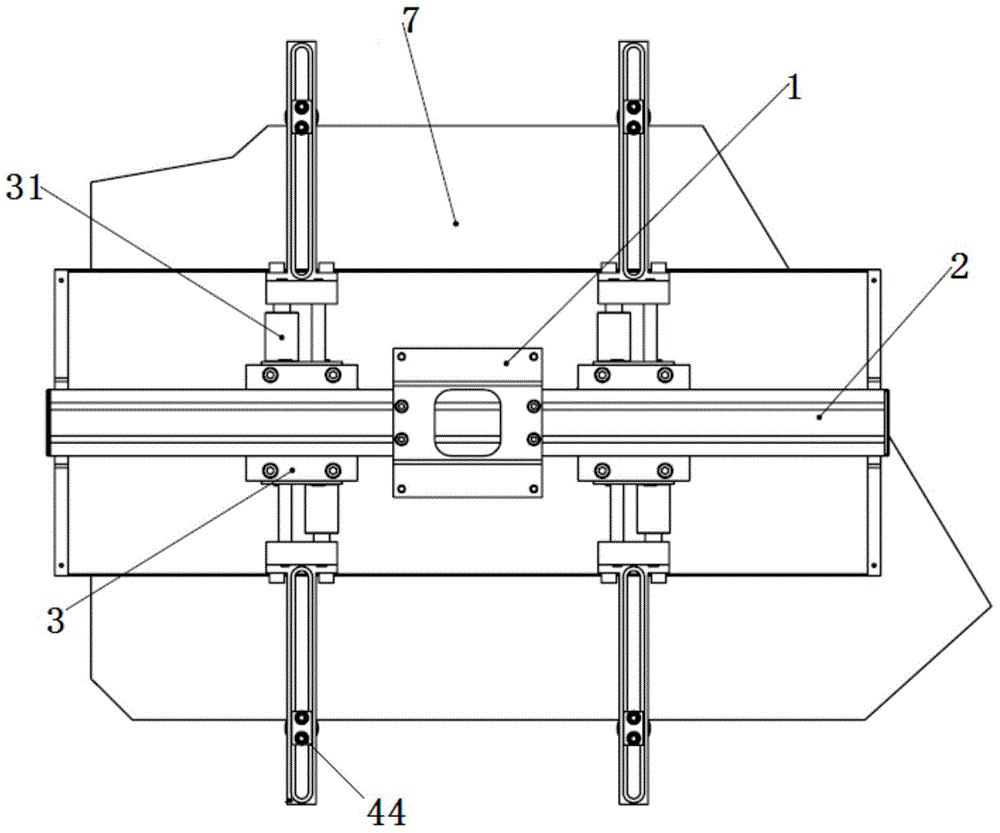

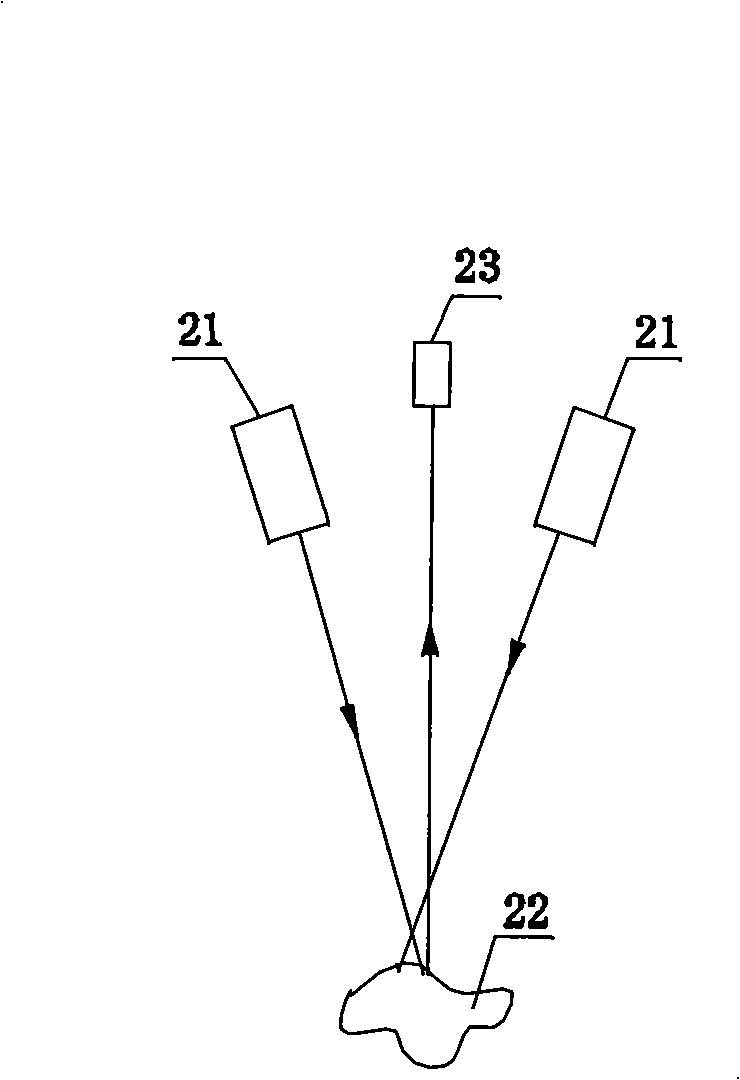

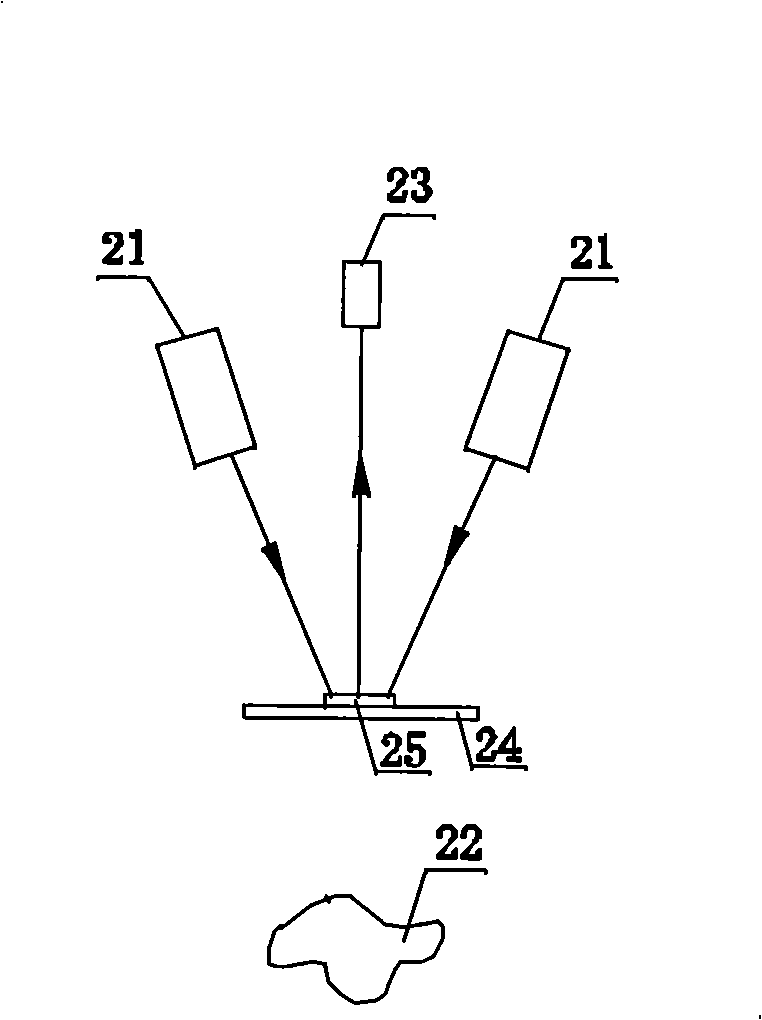

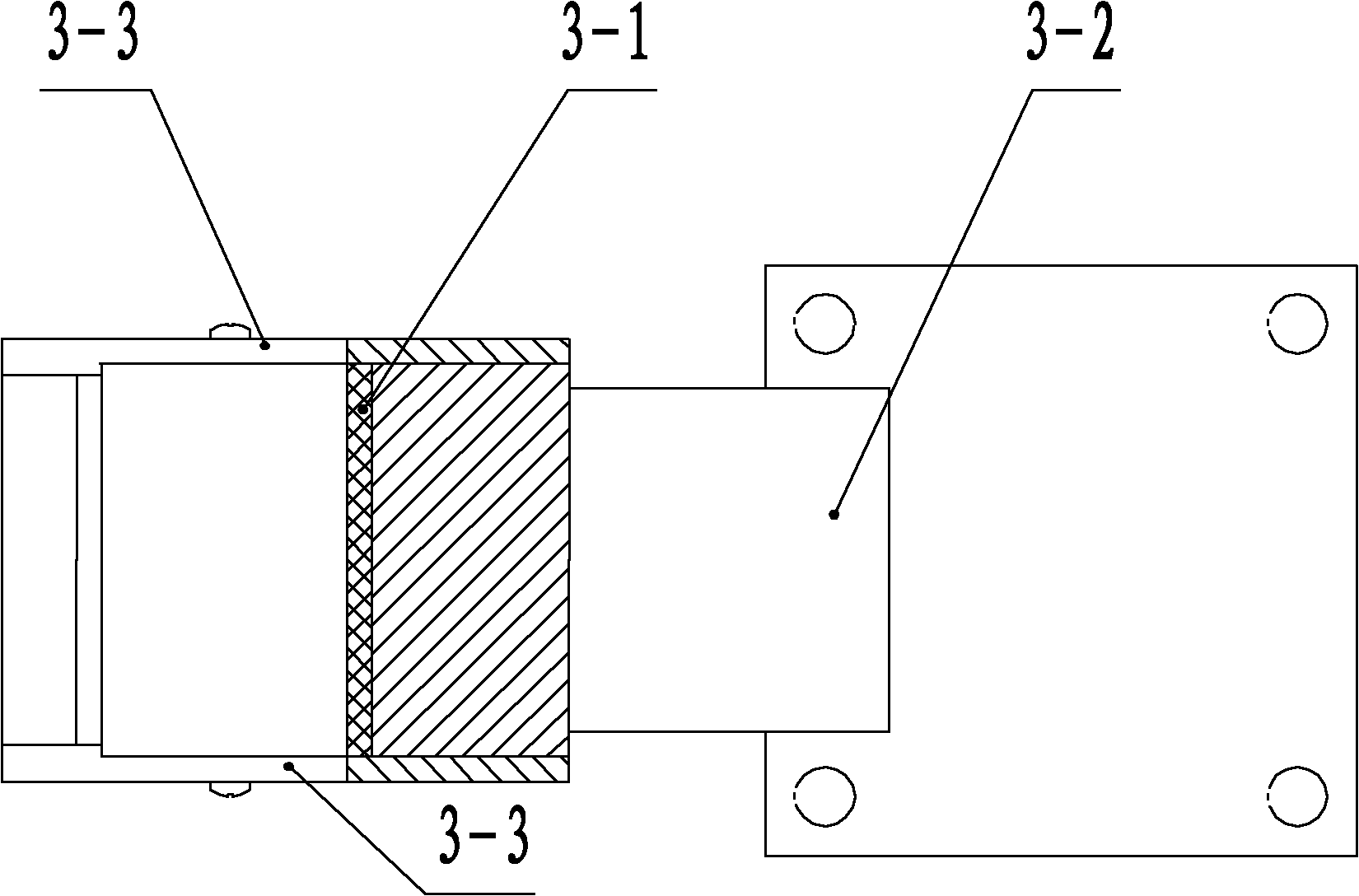

Detection device for material picking of mechanical arm

ActiveCN104002178AImprove loading and unloading efficiencyGuaranteed linear motionProgramme-controlled manipulatorMeasurement/indication equipmentsEngineeringManipulator

Owner:GUANGZHOU DAZHENG ADVANCED MATERIAL TECH CO LTD

Intelligent garden greening construction equipment capable of conducting automatic deviation correction on paying-off mark

InactiveCN107984457AReduce labor intensityNo manual adjustment requiredOther workshop equipmentMarking outArchitectural engineering

The invention relates to intelligent garden greening construction equipment capable of conducting automatic deviation correction on a paying-off mark. The intelligent garden greening construction equipment comprises a bottom plate. A lifting containing groove is formed in the middle portion of the bottom plate. A walking device is arranged at the lower end of the bottom plate. The bottom plate isprovided with a deviation correcting adjusting device. A mark adjusting device is arranged at the lower end of the deviation correcting adjusting device and located in the lifting containing groove. The deviation correcting adjusting device comprises a deviation correcting adjusting mechanism arranged on the bottom plate, the bottom plate is provided with two rotation auxiliary mechanisms, the tworotation auxiliary mechanisms are symmetrically located at the front end and the rear end of the bottom plate, the deviation correcting adjusting mechanism is provided with a mark line, and positioning mechanisms are symmetrically arranged at the front end and the rear end of the mark line. The intelligent garden greening construction equipment can solve the problems that in the existing garden construction line drawing work process, deviation is likely to happen due to manual line drawing work, time and labor are wasted during manual deviation correcting, and real-time monitoring cannot be conducted; and line drawing tools can be manually selected according to the actual operation environment, and sunstroke is likely to happen during manual outdoor operation in summer.

Owner:范满香

A high temperature pickup manipulator

InactiveCN105364920AWon't burnImprove reliabilityProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention provides a high temperature pickup manipulator with fingers. The positions of the fingers are adjustable; the finger feed is controlled by air cylinders. The fingers are used for clamping and fetching work pieces. The fingers are provided with gaskets used for lifting the work pieces. A baffle plate is arranged between the work pieces and the air cylinders and the like. The baffle plate isolates the work pieces and the air cylinders and the like above the work pieces, so that high-temperature work pieces are prevented from burning upper members. The high temperature pickup manipulator is arranged on a telescopic arm which drives the manipulator to perform feed movement; the telescopic arm is a two-stage telescopic arm, wherein the first-stage telescopic arm drives the second-stage telescopic arm to move at higher speed via a belt. The telescopic arm is simple in structure, small in size and high in moving speed.

Owner:SHENYANG ZHONGTUO ROBOT EQUIP

Component clamping device

Owner:刘坤

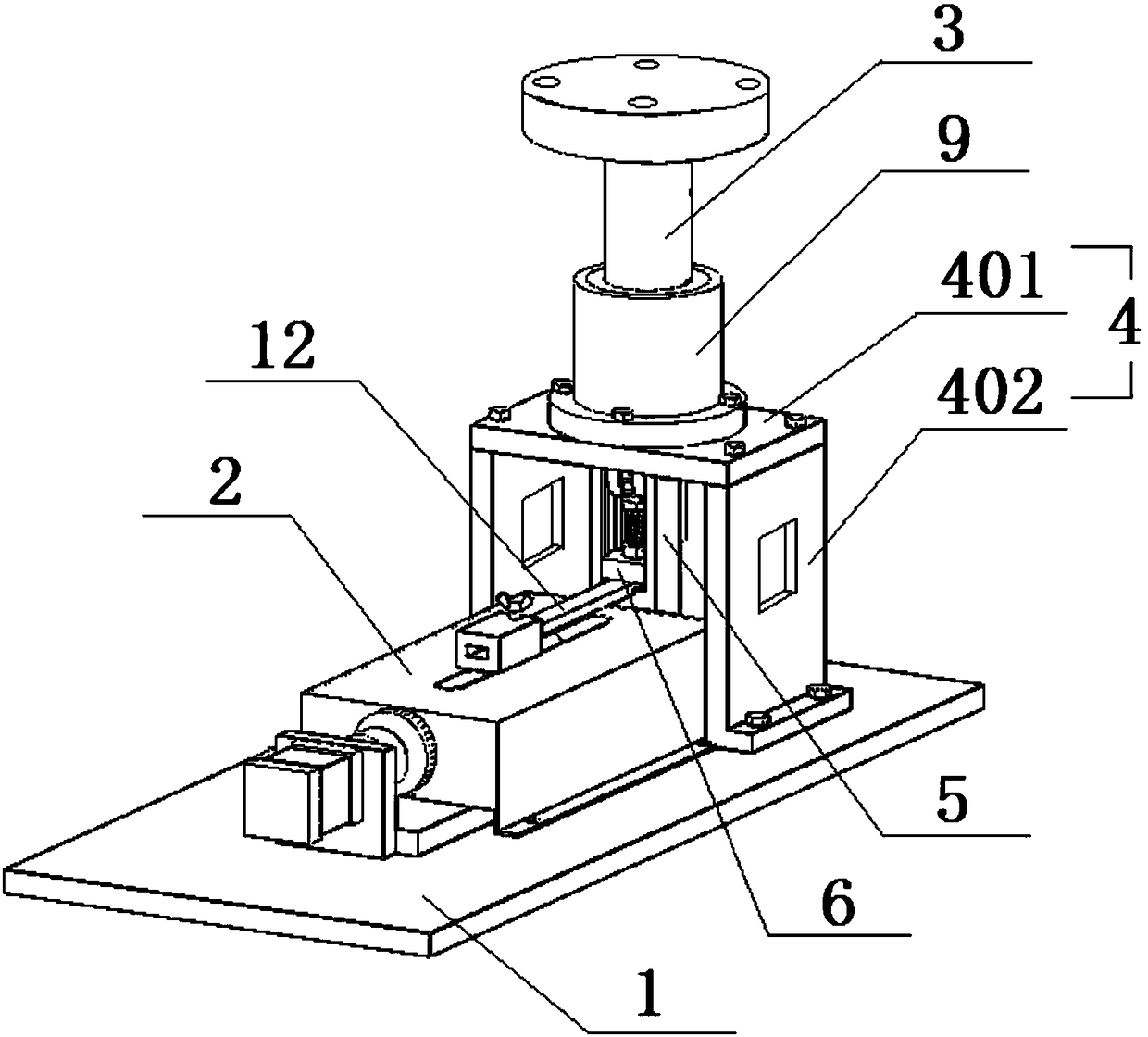

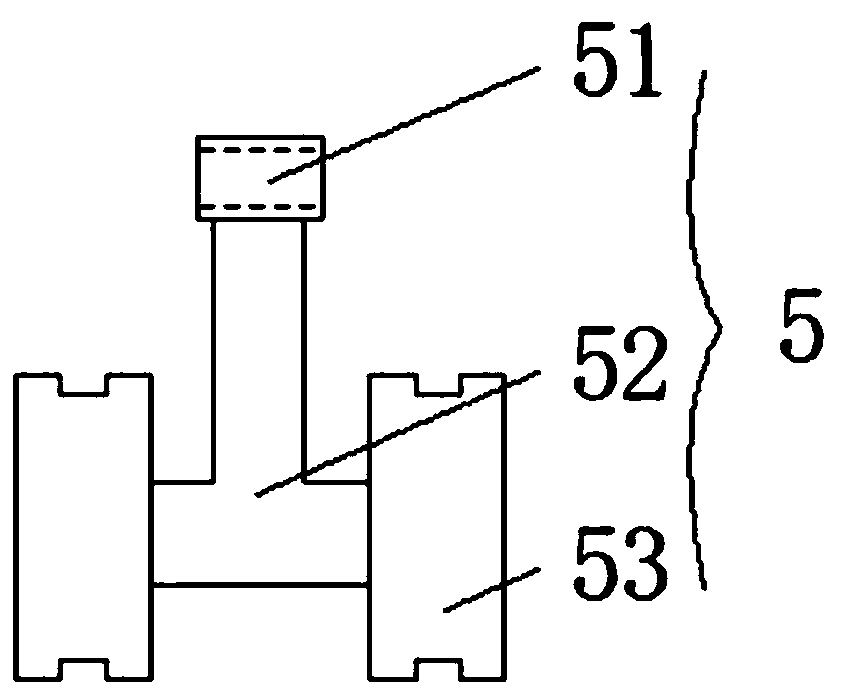

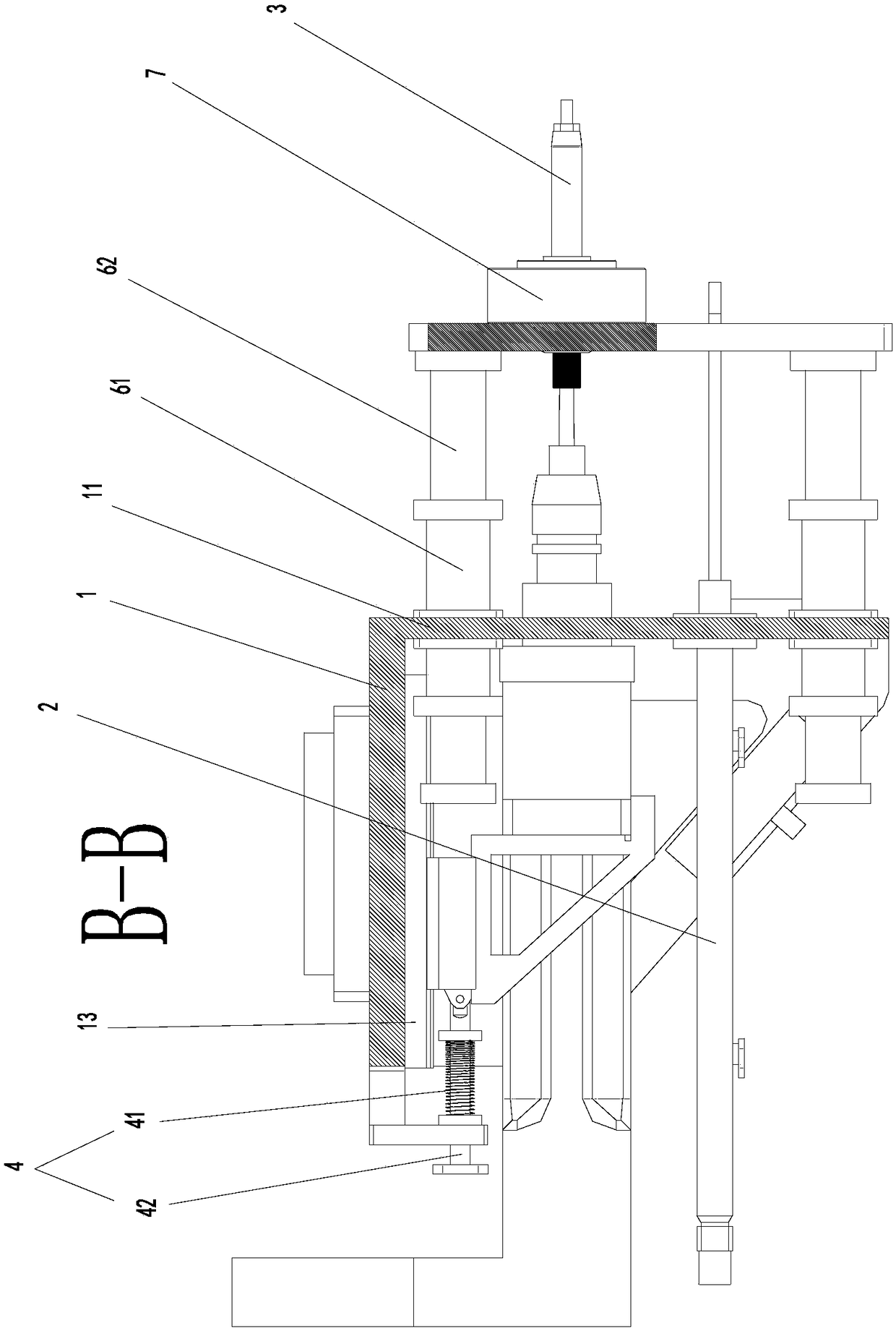

Micro-shearing testing apparatus

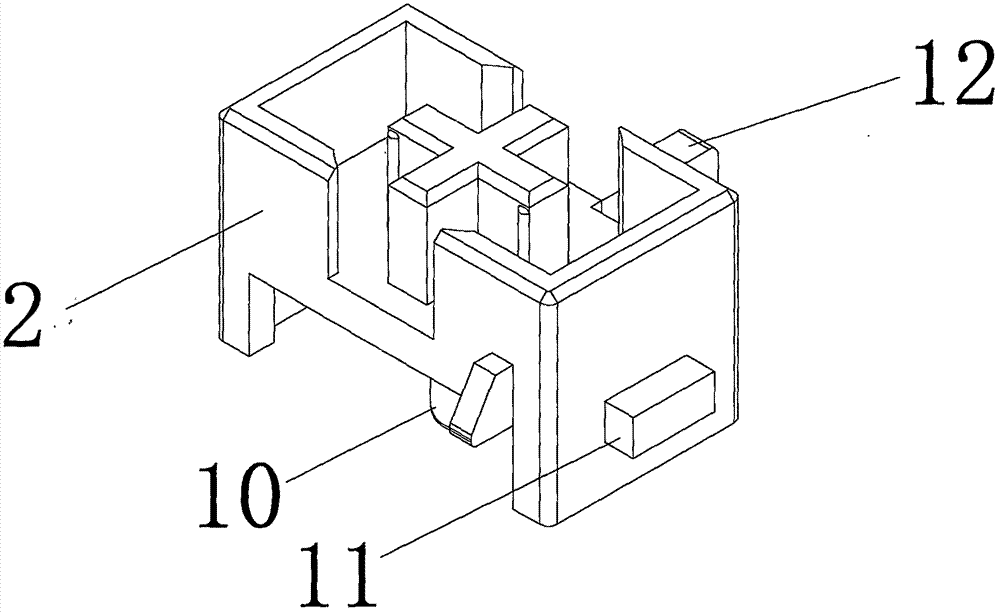

ActiveCN108426783AGuaranteed linear motionEasy to control the degree of compressionMaterial strength using steady shearing forcesInvestigating machinabilityEngineeringCam

The invention discloses a micro-shearing testing apparatus. The micro-shearing testing apparatus comprises a base; a sample fixing device on the base comprises a sample bearer, a front clamping blockand a rear clamping block; a cutter comprises a cutter handle connected with a tensile testing machine and a cutter head arranged on the bottom of the cutter handle; the base is provided with a hollowframework located at the front end of the sample fixing device; the hollow framework is provided with two face-to-face pressing-block support arms; a pressing block is slidably arranged between the two pressing-block support arms; a gear is arranged above the pressing block; both ends of the gear are axially provided with disc-shaped cams that rotate synchronously with the gear; the disc-shaped cams abut against the pressing block; the cutter handle longitudinally passes through the top of the framework, and the side wall of the lower part of the cutter handle is provided with a rack matchedwith the gear; and the front end of a to-be-measured sample extends into the hollow part of the framework and is located below the cutter head and the pressing block. The apparatus further comprises alinear bearing located on the top of the framework; the central part of the linear bearing is provided with an axial through hole; and the cutter handle can move up and down to pass through the axialthrough hole. The apparatus allows the cutter head to always realize vertical shearing of to-be-measured test pieces and is accurate in measurement.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

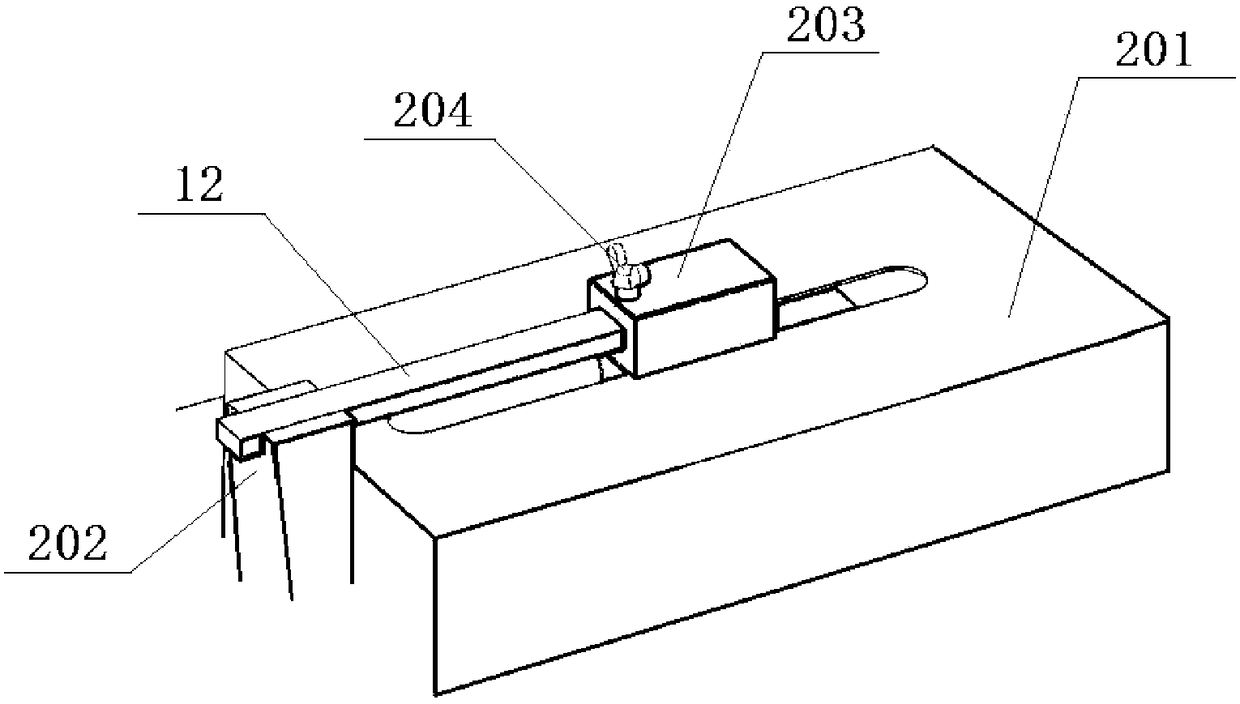

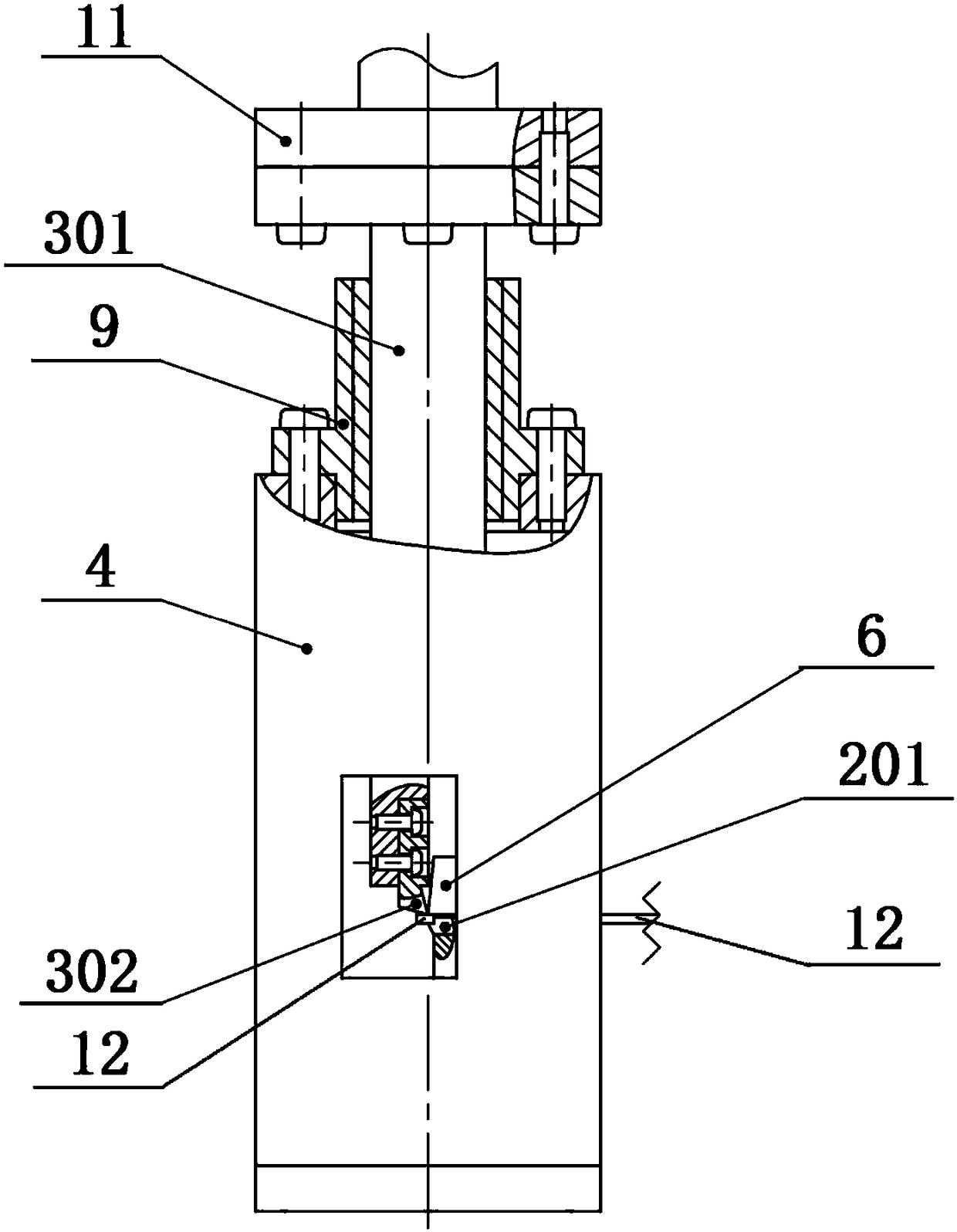

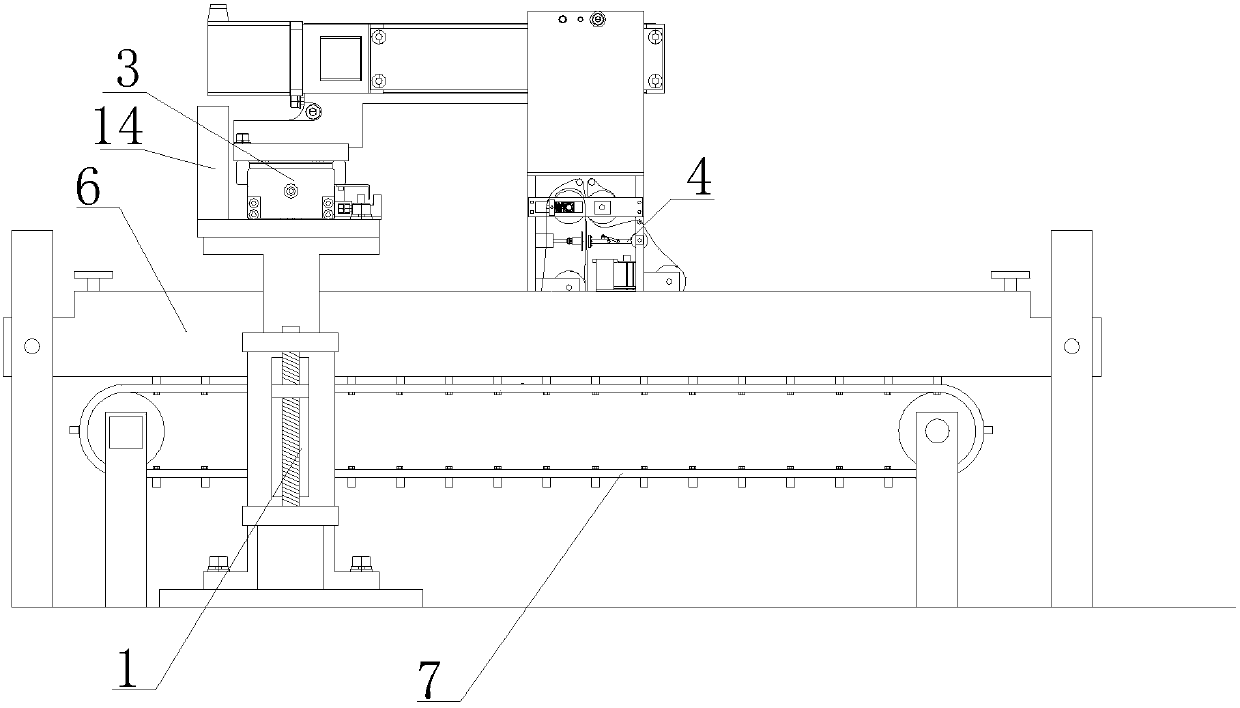

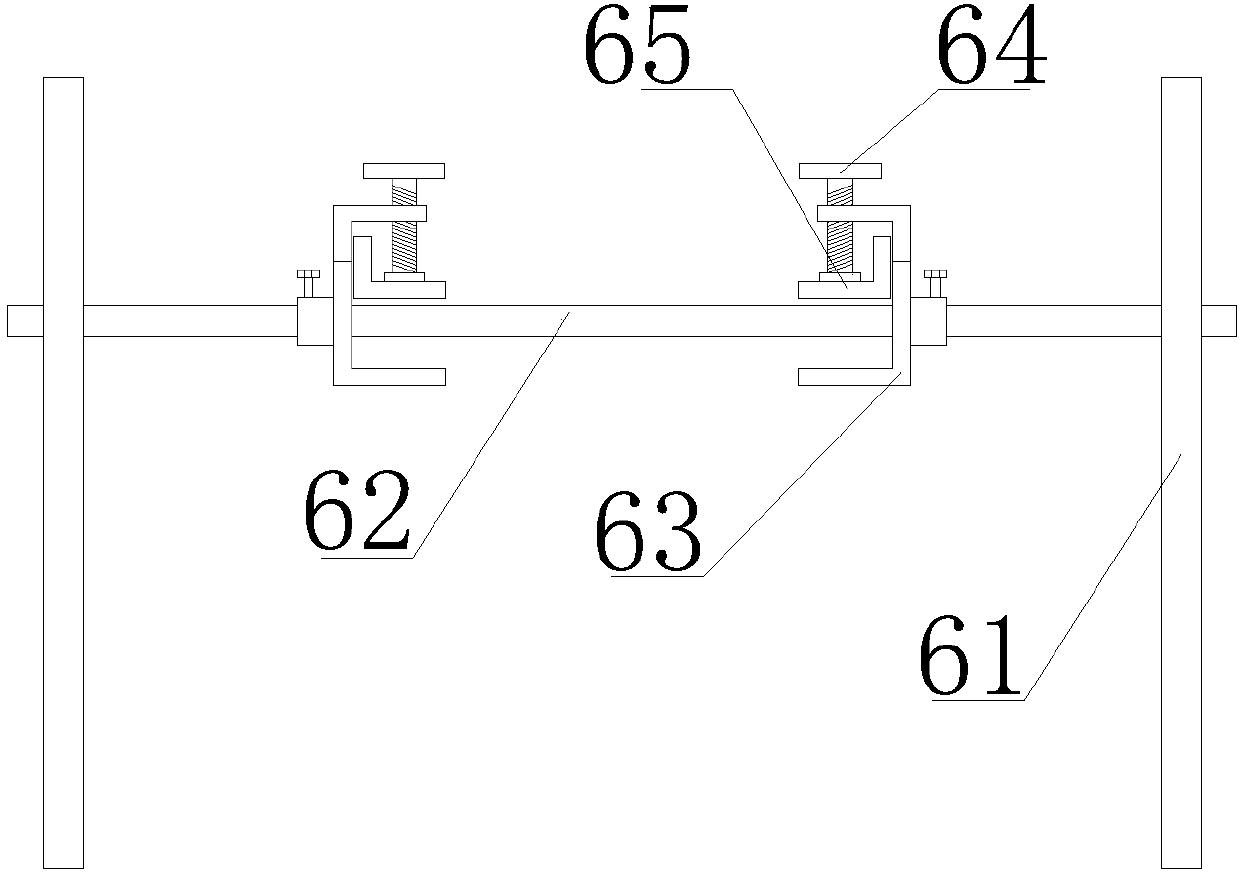

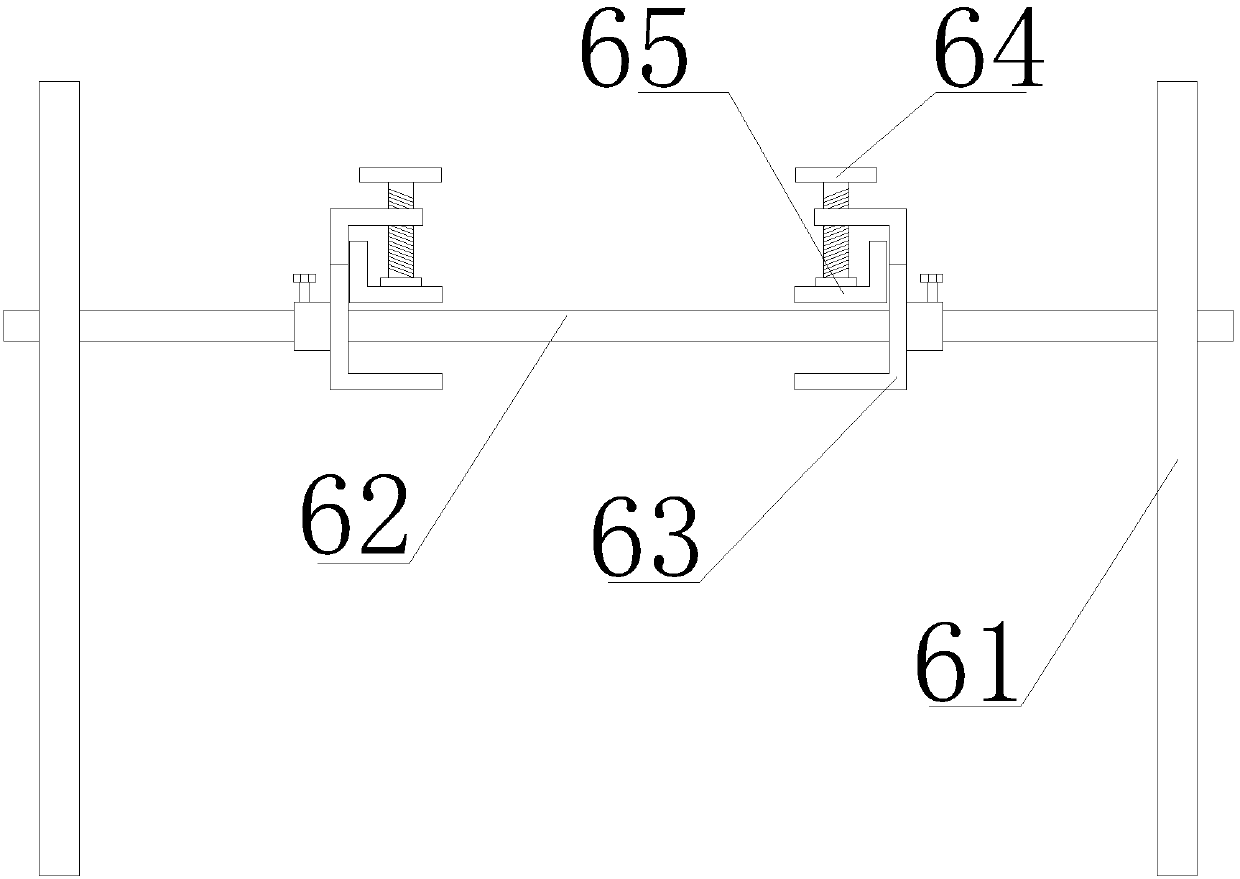

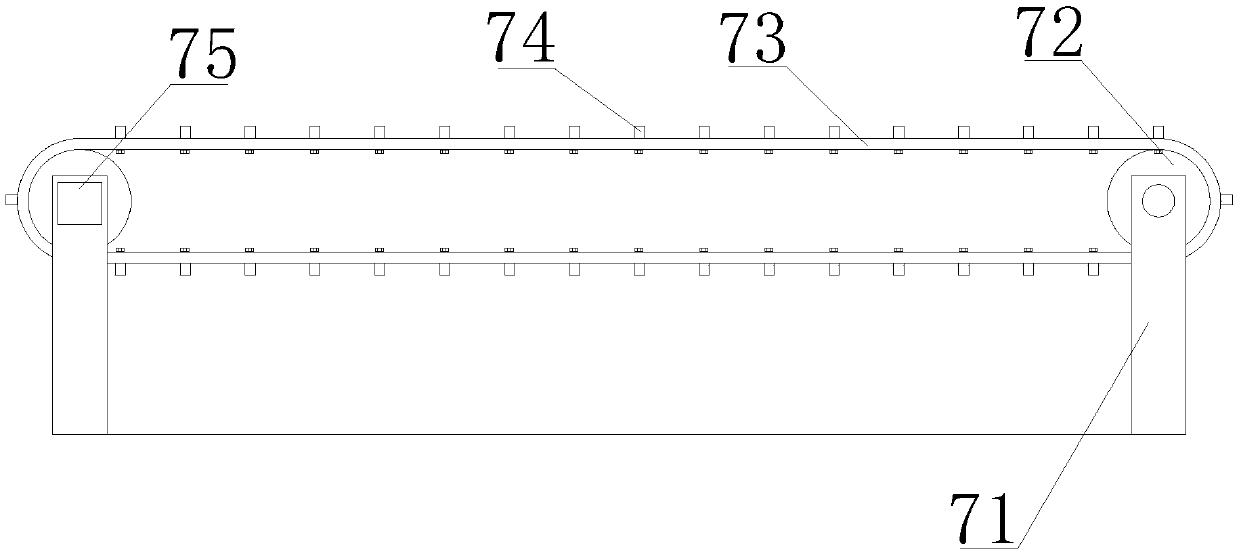

Labeling equipment capable of adjusting fixed width and for a packing box

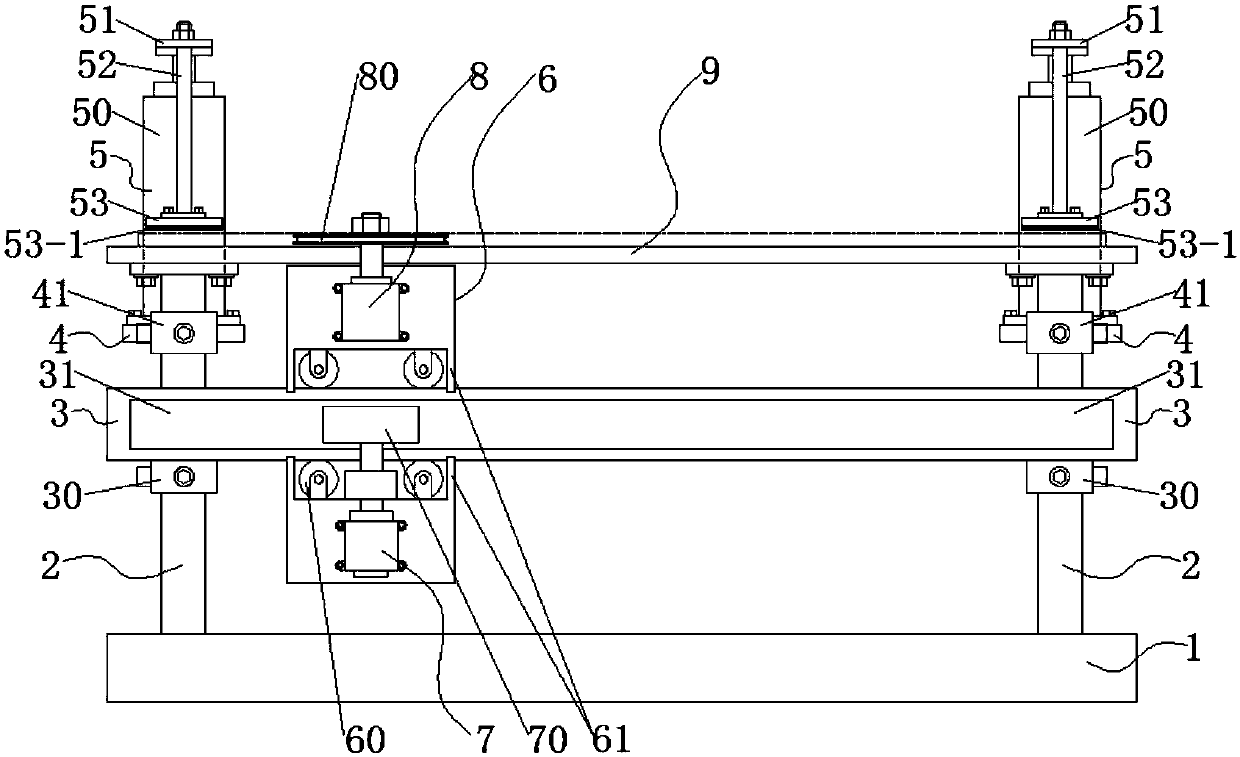

ActiveCN107600602AGuaranteed linear motionMeet labeling needsLabelling machinesControl equipmentFixed width

The invention discloses labeling equipment capable of adjusting fixed width for a packing box. Lifting and adjusting parts used for adjusting the height of the equipment are correspondingly arranged on the two sides of a material conveying power part. The upper part of each lifting and adjusting part is provided with a pasting left-right adjusting part used for driving labeling implementing partsto move left and right as well as back and forth. Each pasting left-right adjusting part is provided with one labeling implementing part use for labeling a label on a packing box. A switch control boxwhich controls an equipment working state is arranged at the side part of each pasting left-right adjusting part. The upper part of a material conveying power part is provided with a material guidingand conveying part which restrict the movement direction of materials. According to the labeling equipment, the equipment can paste the label on the packing box automatically, continuous working canbe achieved, the work efficiency is high, meanwhile, printing packing boxes of different heights can be adapted by adjusting, the equipment is high in adaptability, the labor cost of an enterprise canbe greatly reduced, the net profit of the enterprise is increased, and meanwhile, the equipment is easy to operate.

Owner:FUJIAN YILONG PACKING PROD CO LTD

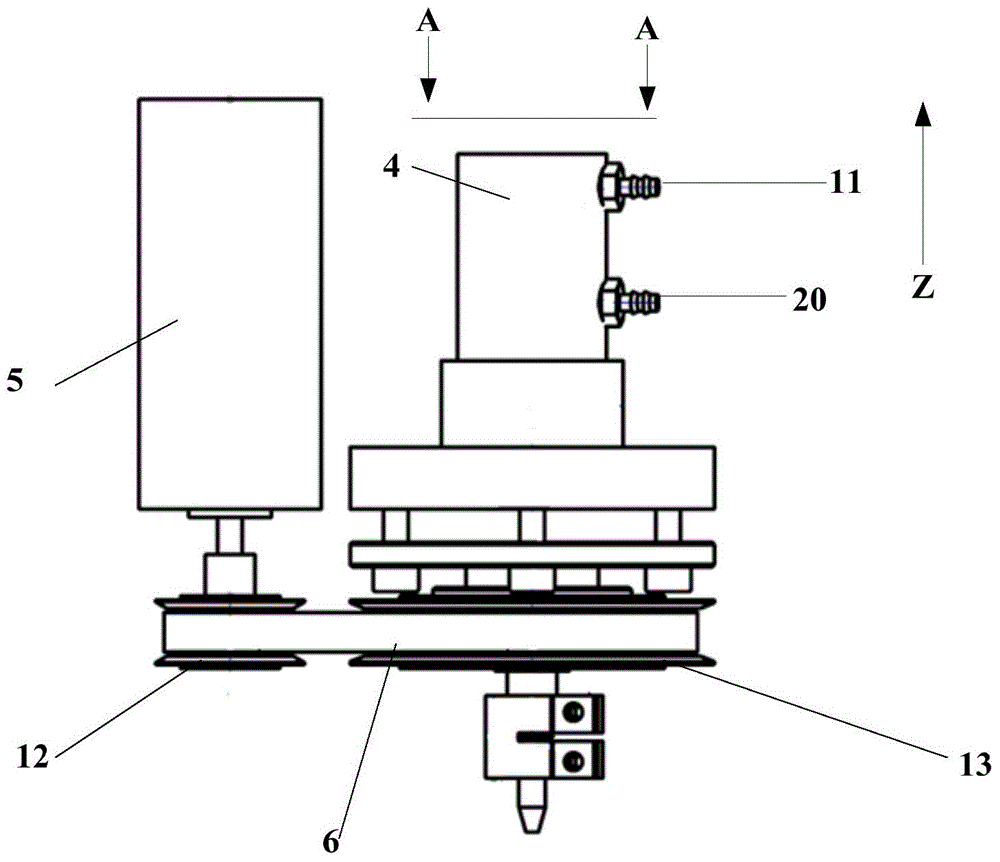

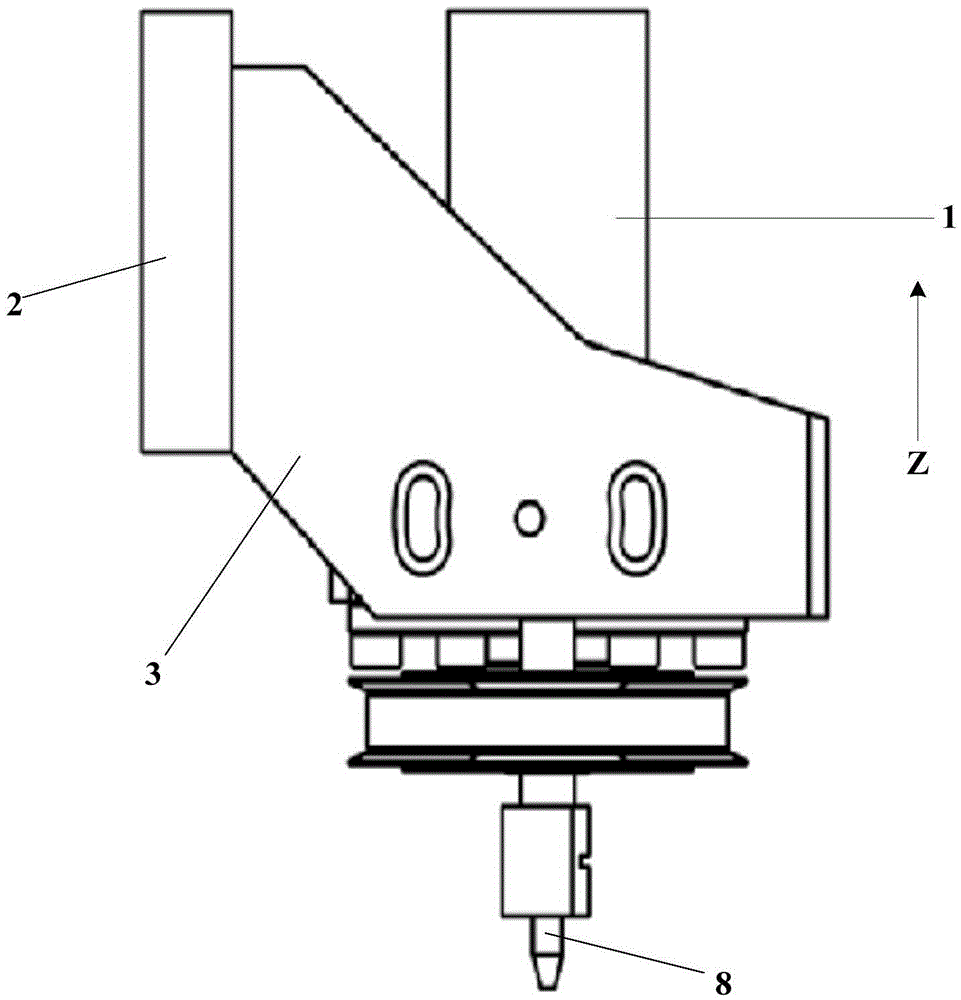

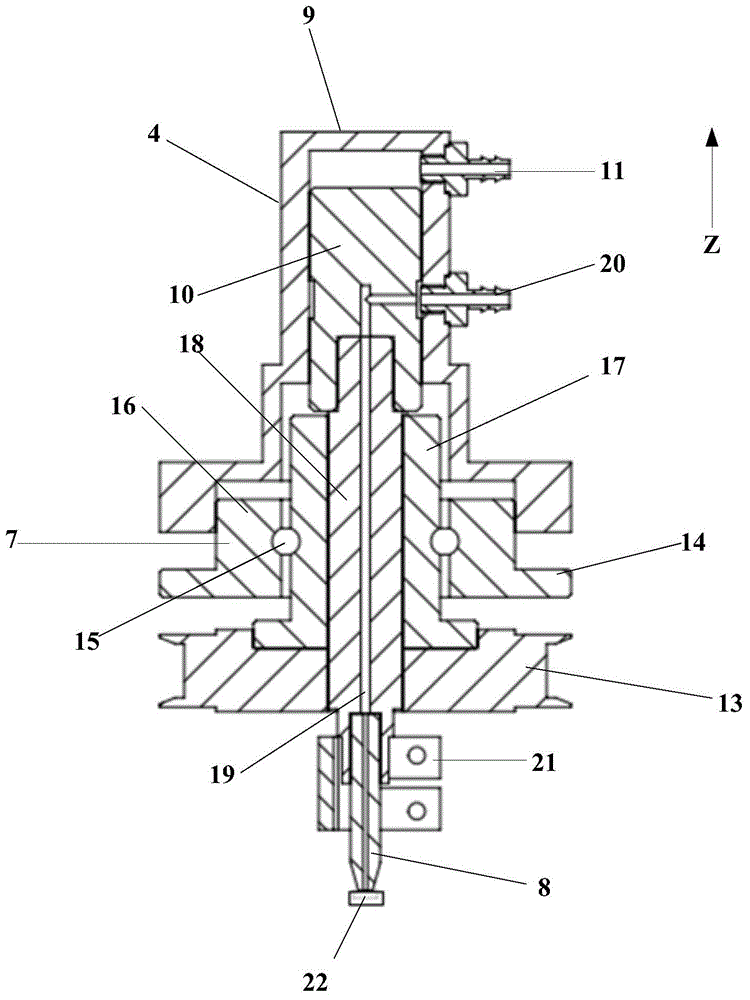

Bond head device

InactiveCN104966687AReduced size spaceReduced space required for installationSemiconductor/solid-state device manufacturingLinear motionDrive wheel

The invention provides a bond head device. The device comprises a device body, a linear slide block which is in drive connection with the outside, and a fixation bracket which is connected with the device body and the linear slide block. The device body comprises a cylinder structure, a servo motor under external drive control, a transmission structure, a spline shaft structure and a vacuum suction lever which is used for adsorbing chips. The spline shaft structure comprises a sleeve, a ball and a spline shaft which matches the sleeve. The output end of the servo motor is connected with a drive wheel of the transmission structure. A driven wheel of the transmission structure is connected with the spline shaft. The cylinder structure is fixed above the spline shaft structure and matches the spline shaft structure to form a closed structure. According to the invention, the Z direction size and the installation space of the bond head device are effectively reduced, which is important for optimizing the size of each component; the spline shaft structure is used as a guide system, which can ensure high-precision linear motion of the vacuum suction lever; and the chip operation precision can be effectively improved.

Owner:CETC BEIJING ELECTRONICS EQUIP

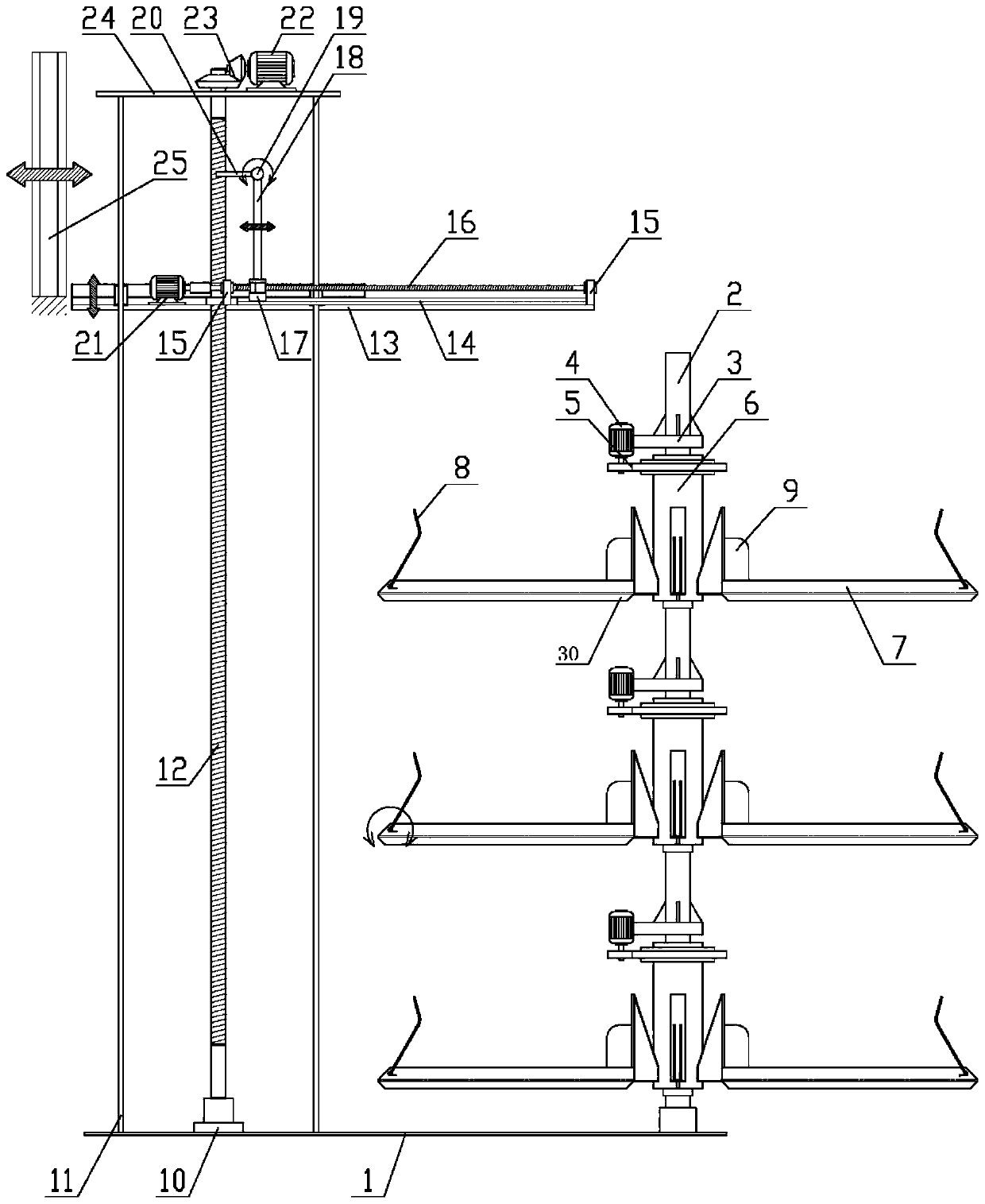

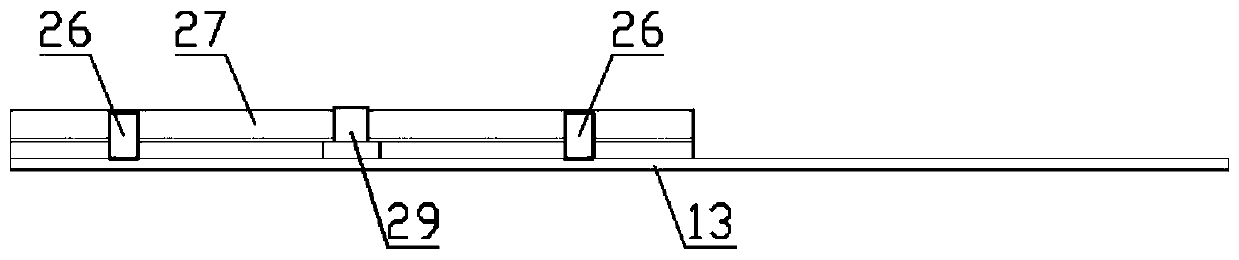

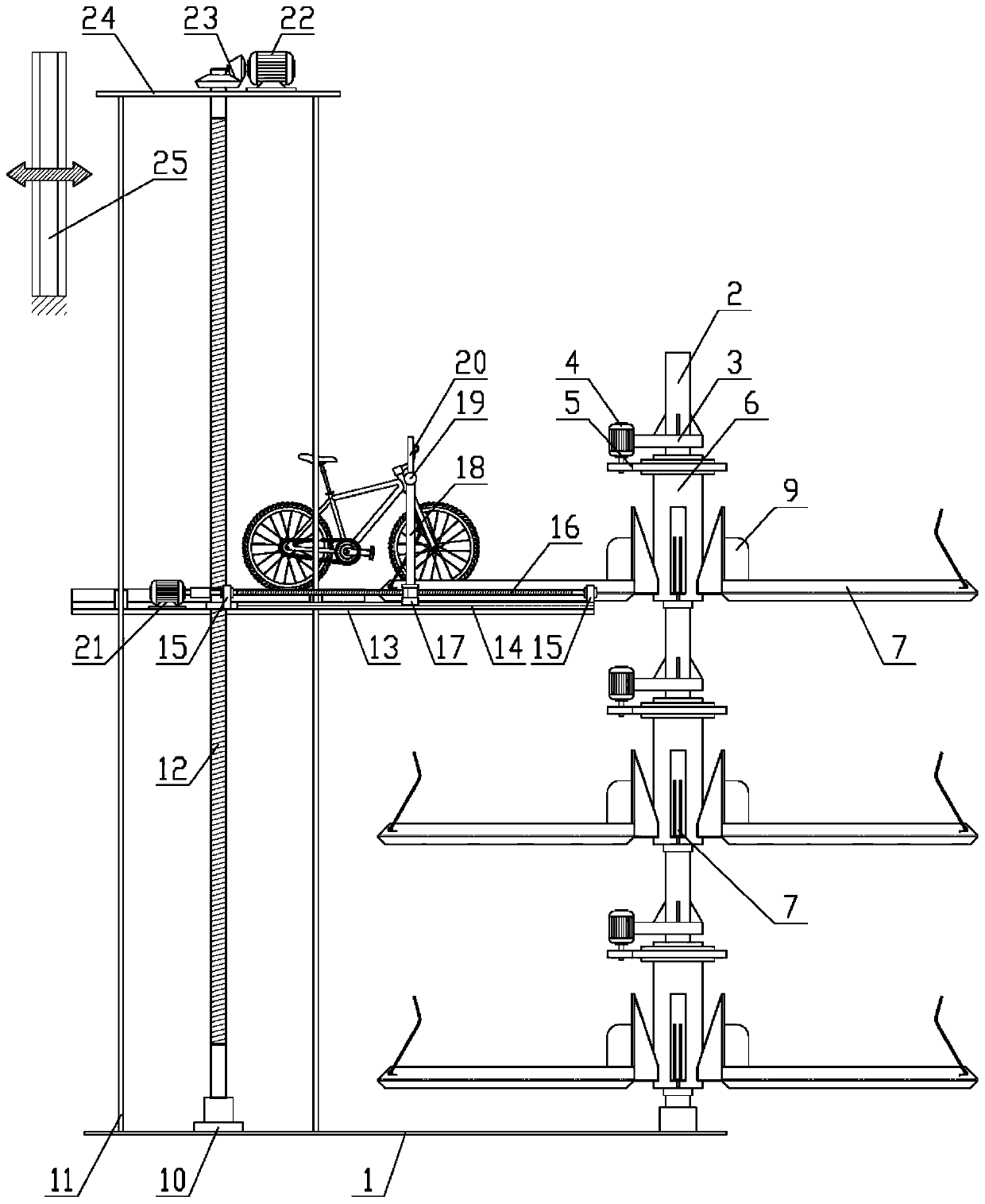

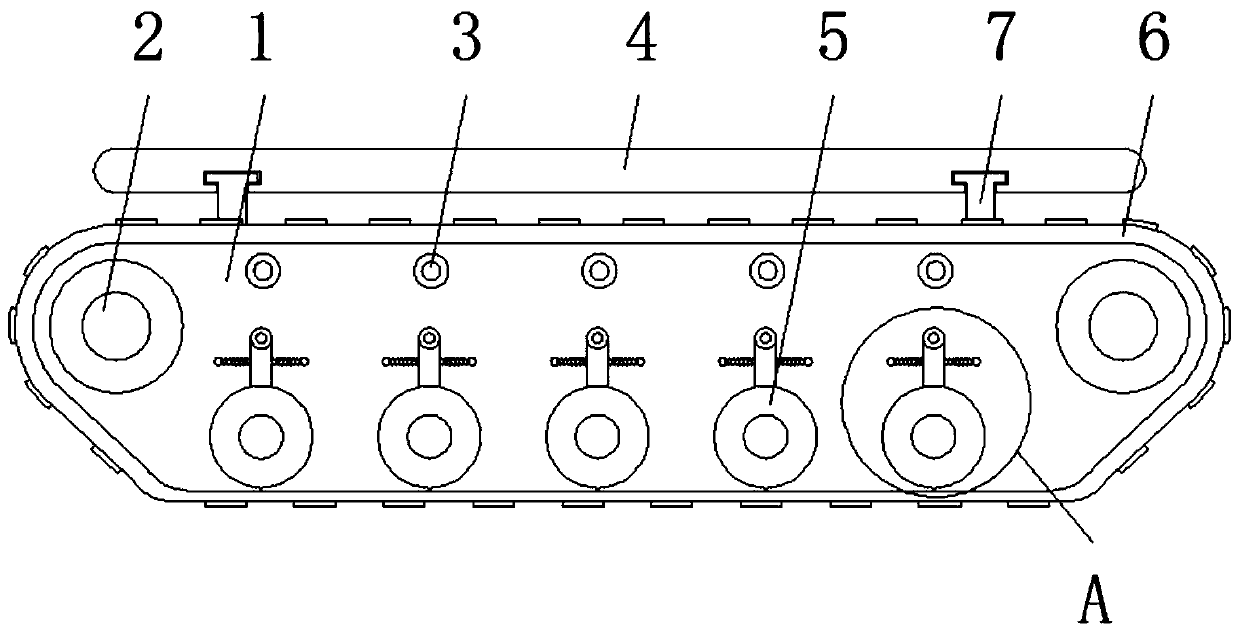

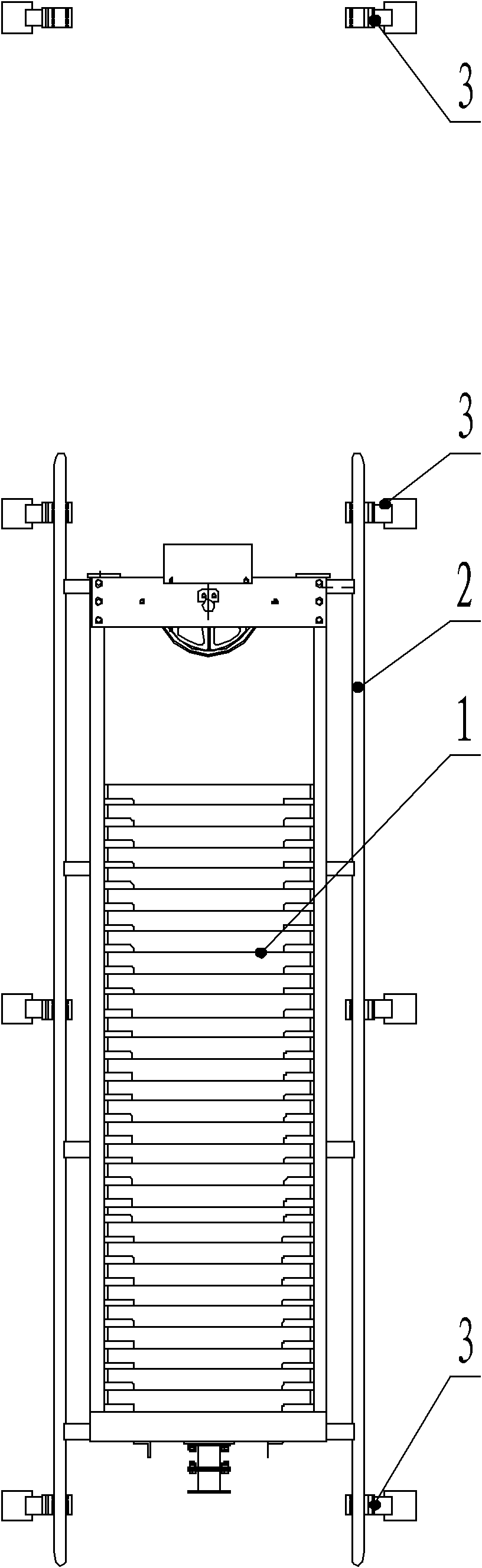

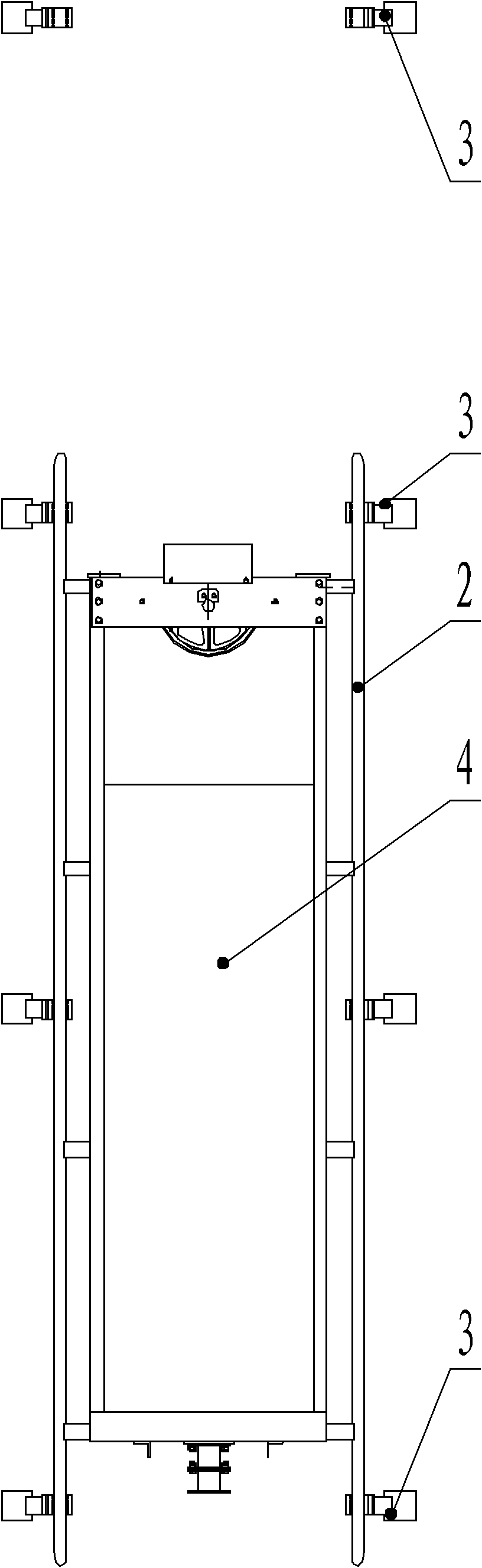

Bicycle underground three-dimensional storing and taking system

The invention discloses a bicycle underground three-dimensional storing and taking system. The bicycle underground three-dimensional storing and taking system comprises a base. A stand column and a lifting device are vertically arranged on the base. A plurality of rotating sleeves and a rotating motor for driving the rotating sleeves are arranged on the periphery of the stand column at intervals from top to bottom. A plurality of horizontal containers arranged along the circumference are arranged on each rotating sleeve. The movable portion of the lifting device is provided with a lifting platform. The lifting platform is provided with a guiding clamping groove and a horizontal driving device, wherein the horizontal driving device is used for driving a vehicle to move in the direction of the guiding clamping groove. The working portion of the whole system is arranged underground, and a garage door is arranged on the ground, so that the occupation of ground space is greatly reduced. Driving structures are dispersed on different parts to avoid the occasions that local parts are too heavy, the structure is too complex, and the energy loss of a driving power supply is therefore increased. Moreover, all layers of vehicles on the stand column independently rotate and do not interfere with each other, so that the working efficiency is improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

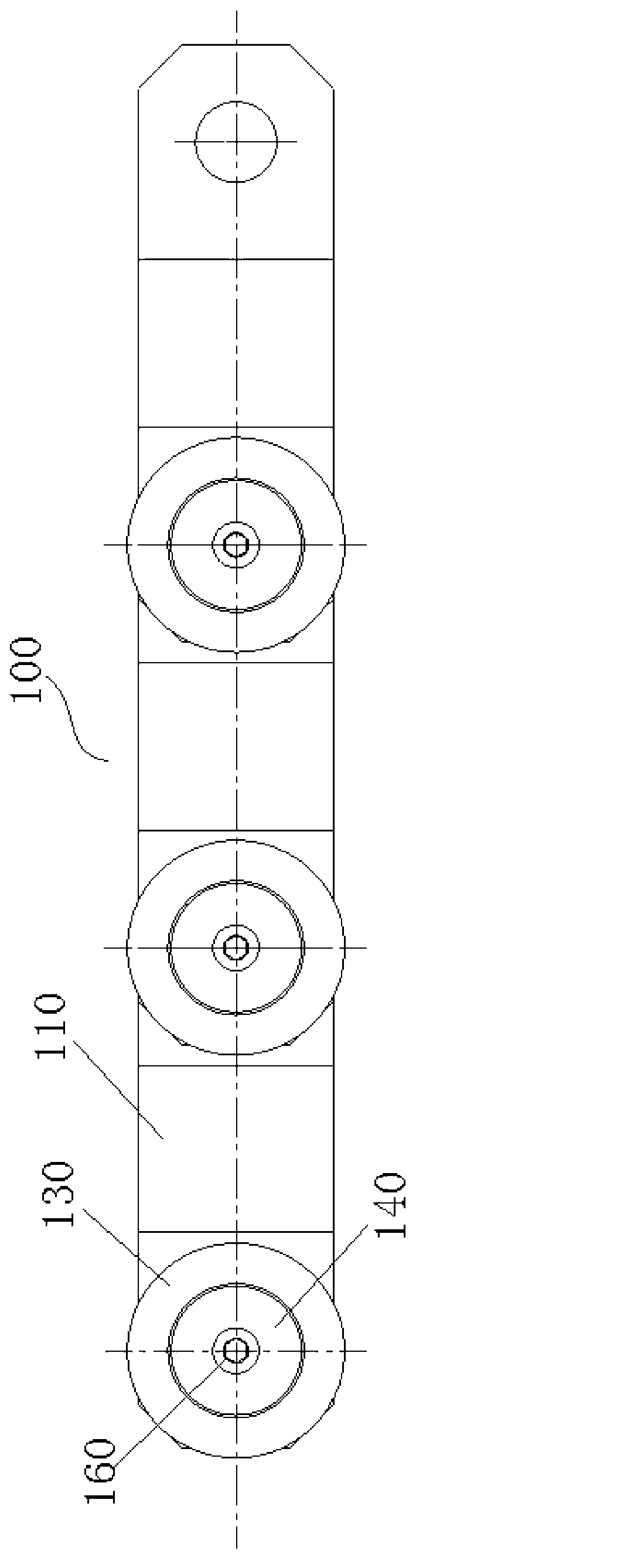

Y-shaped double-side-roller push and pull chain

The invention discloses a Y-shaped double-side-roller push and pull chain comprising a plurality of Y-shaped chain links. One end of each chain link is a projecting end, and the other end of the chain link is a socket end. The adjacent chain links are integrally connected in sequence and in series by mutual meshing of the projecting ends and the socket ends, the projecting ends are inserted into the socket ends, a central pin penetrates each two mutually meshed projecting and socket ends to fixedly connect the ends, and a roller for guidance and motion support is disposed at each end of the central pin, extending out of the chain link. The Y-shaped double-side-roller push and pull chain can transmit both pulling force and pushing force just under the restraint condition, meets the requirement of push and pull application, and has the advantages that the structure is simple, production is easy, assembly and adjustment are facilitated, the chain is simple to use and maintain, compact in structure, high in intensity and high in bearing capacity, the application requirement of heavy load in limited space can be met and the chain is applicable to different types of rollers for low-friction operation, effectively energy-saving and long in service life.

Owner:SHANGHAI SONCO QUICK CHANGE SYST

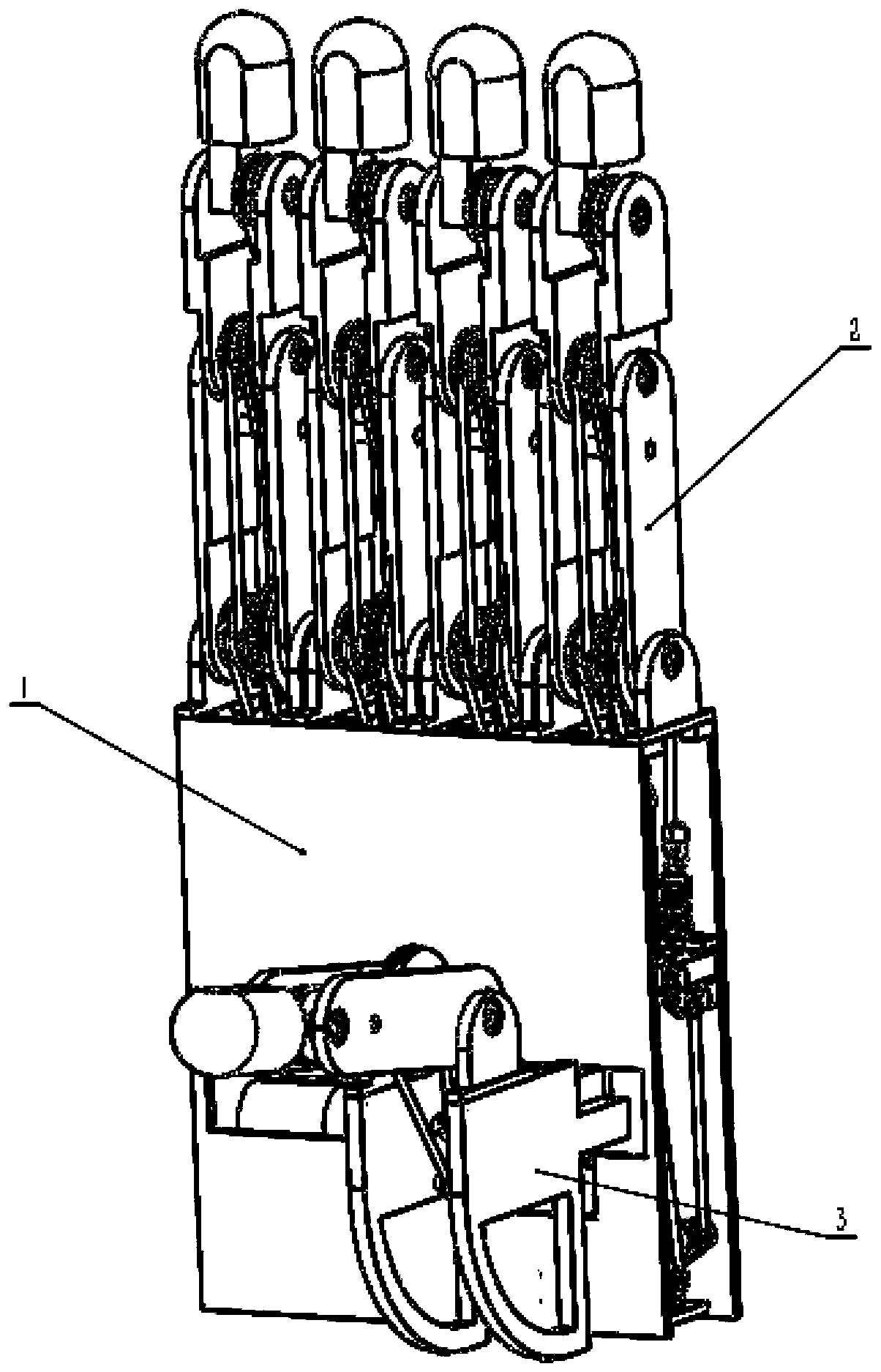

Rope-driven under-actuated five-finger manipulator

The invention relates to a rope-driven under-actuated five-finger manipulator. The rope-driven under-actuated five-finger manipulator comprises a palm assembly, and further comprises a thumb assembly,a four-finger assembly and a steel wire rope which installed on the palm assembly. According to the rope-driven under-actuated five-finger manipulator, through step-by-step work and synchronous workof the three rotating motors in the palm, the manipulator can grab an object in multiple modes; by adopting a rope-driven rope-pulley system structure, the number of finger driving motors is reduced on the premise that the daily life function of the manipulator is not affected, so that the manufacturing cost and weight of the manipulator are reduced, driving elements are compact in the palm, and fingers are lighter, more compact and more stable in movement; and through the manipulator, the object can be grabbed in a self-adaptive manner, and the postures of the fingers can be actively adjustedto a proper position for more accurate grabbing.

Owner:SICHUAN UNIV

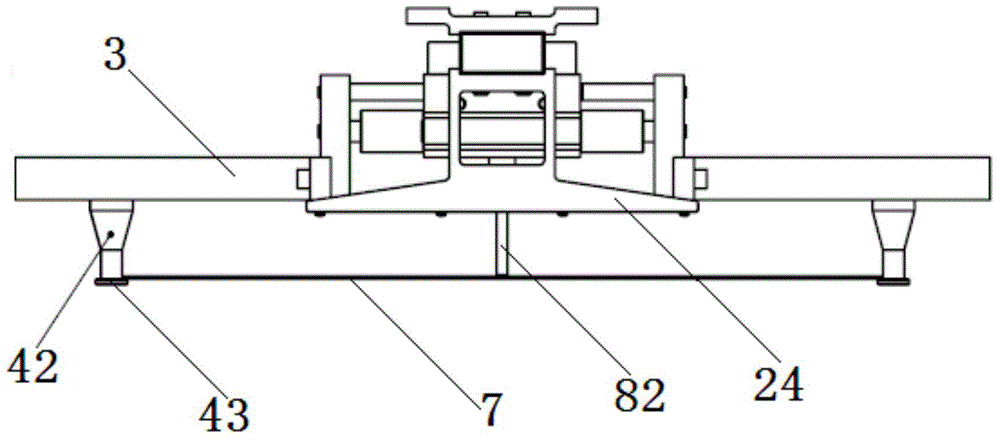

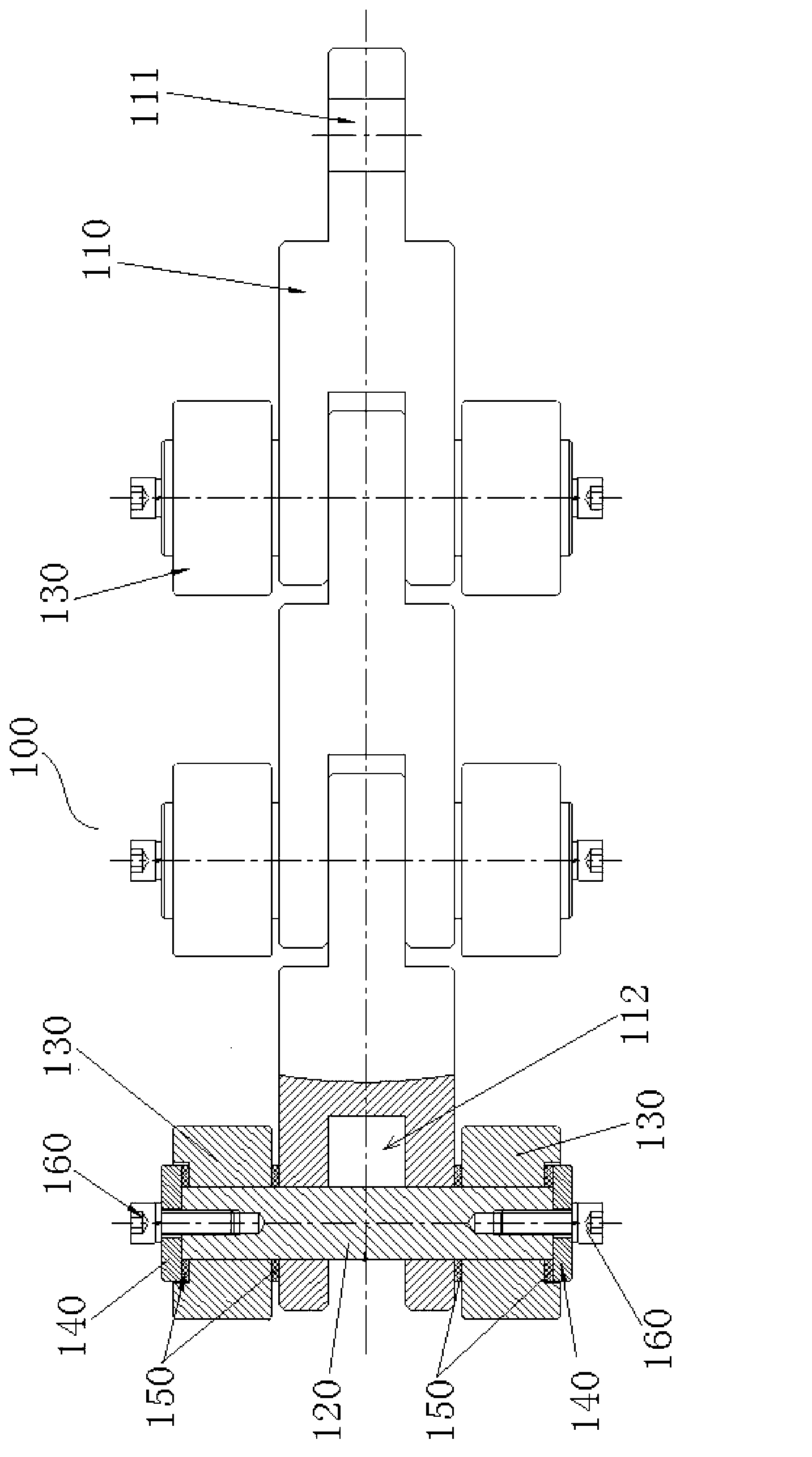

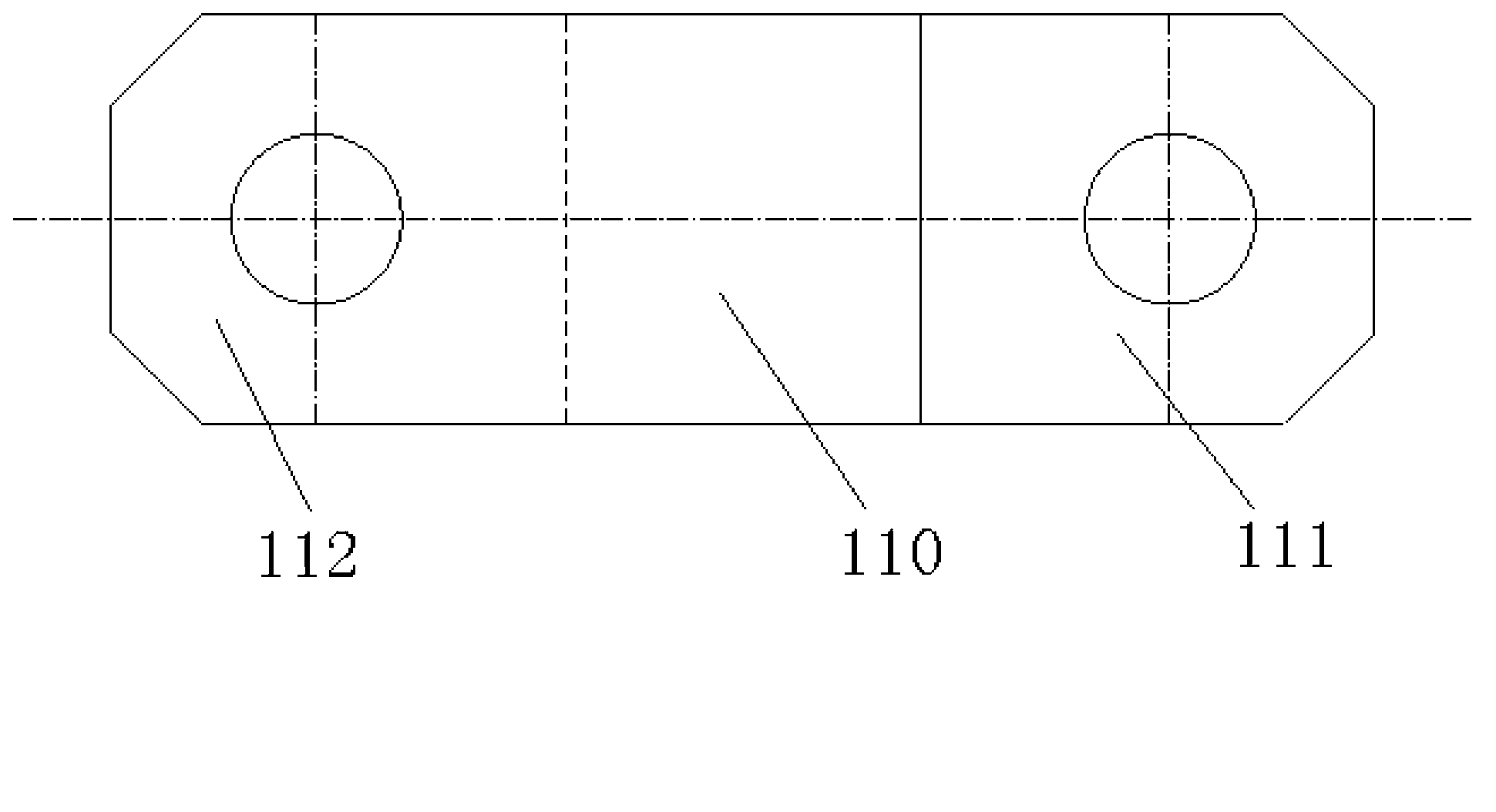

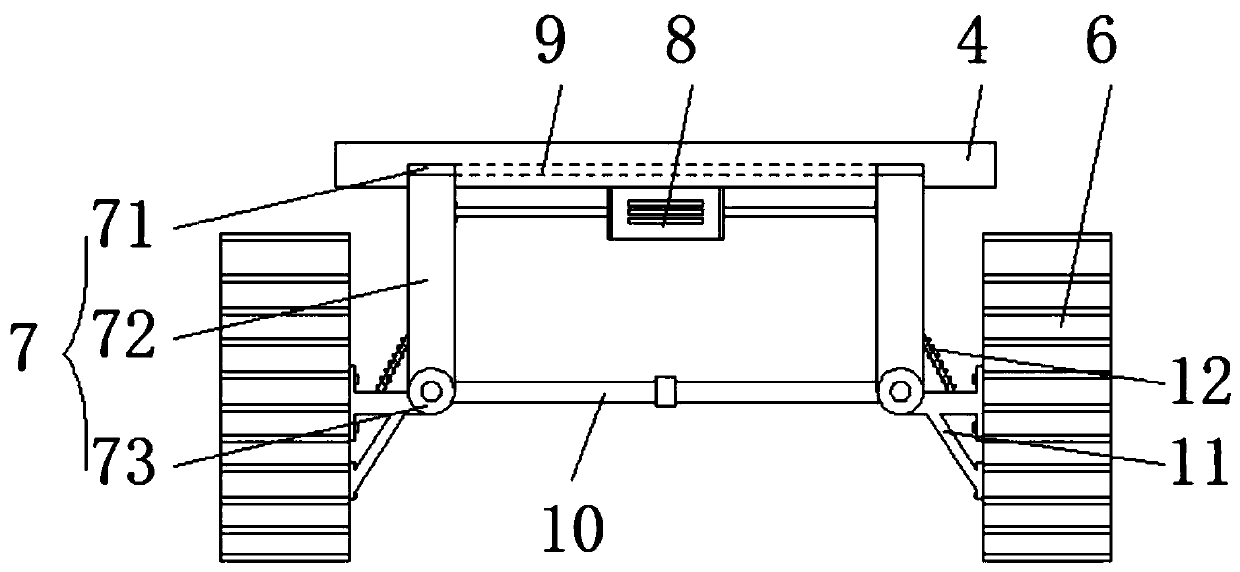

Crawler type walking mechanism supporting structure

InactiveCN110562339AWalking smoothlyPlay the role of cushioning and shock absorptionEndless track vehiclesRubber materialDrive wheel

The invention discloses a crawler type walking mechanism supporting structure which comprises two groups of frame plates, two groups of drive wheels, multiple supporting wheels and a supporting plate.One single drive wheel and the supporting wheels are movably arranged on one side of the corresponding frame plate; and drive motors are arranged on the positions, between the two groups of frame plates, on one sides of the drive wheels in a matched manner. According to the crawler type walking mechanism supporting structure provided by the invention, through arranging bearing structures, bearingwheels can deflect at a certain angles when driving on an irregular pavement, and second elastic elements are subjected to elastic deformation at the moment, so that a crawler belt is sunken so as tofurther ensure walking stability of the crawler belt; through arranging first elastic elements, each first elastic element, one support seat and one support rod form a triangular structure, so that the stability of the whole supporting plate is ensured; and the crawler belt is made of an elastic rubber material and can be deviated at a certain angle under the circumstance that the weight of an object on the upper surface of the supporting plate is gained, so that the contact area of the crawler belt and the ground is increased, and the road holding capacity of the crawler belt structure is improved.

Owner:安徽玄离智能科技股份有限公司

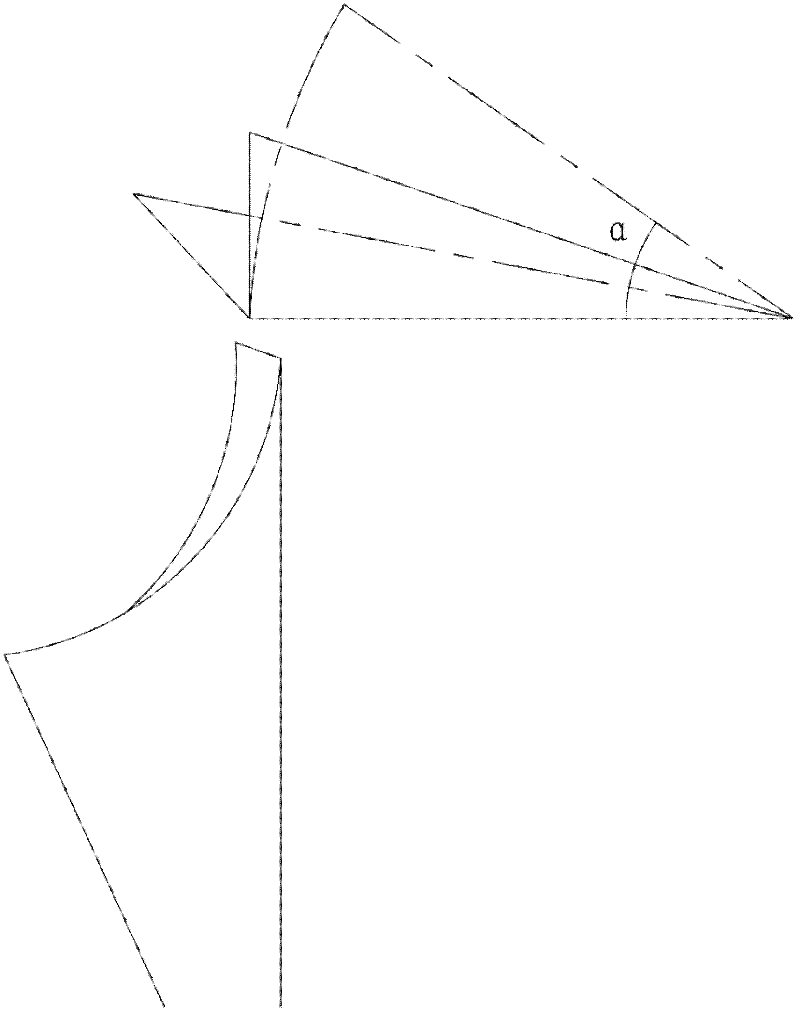

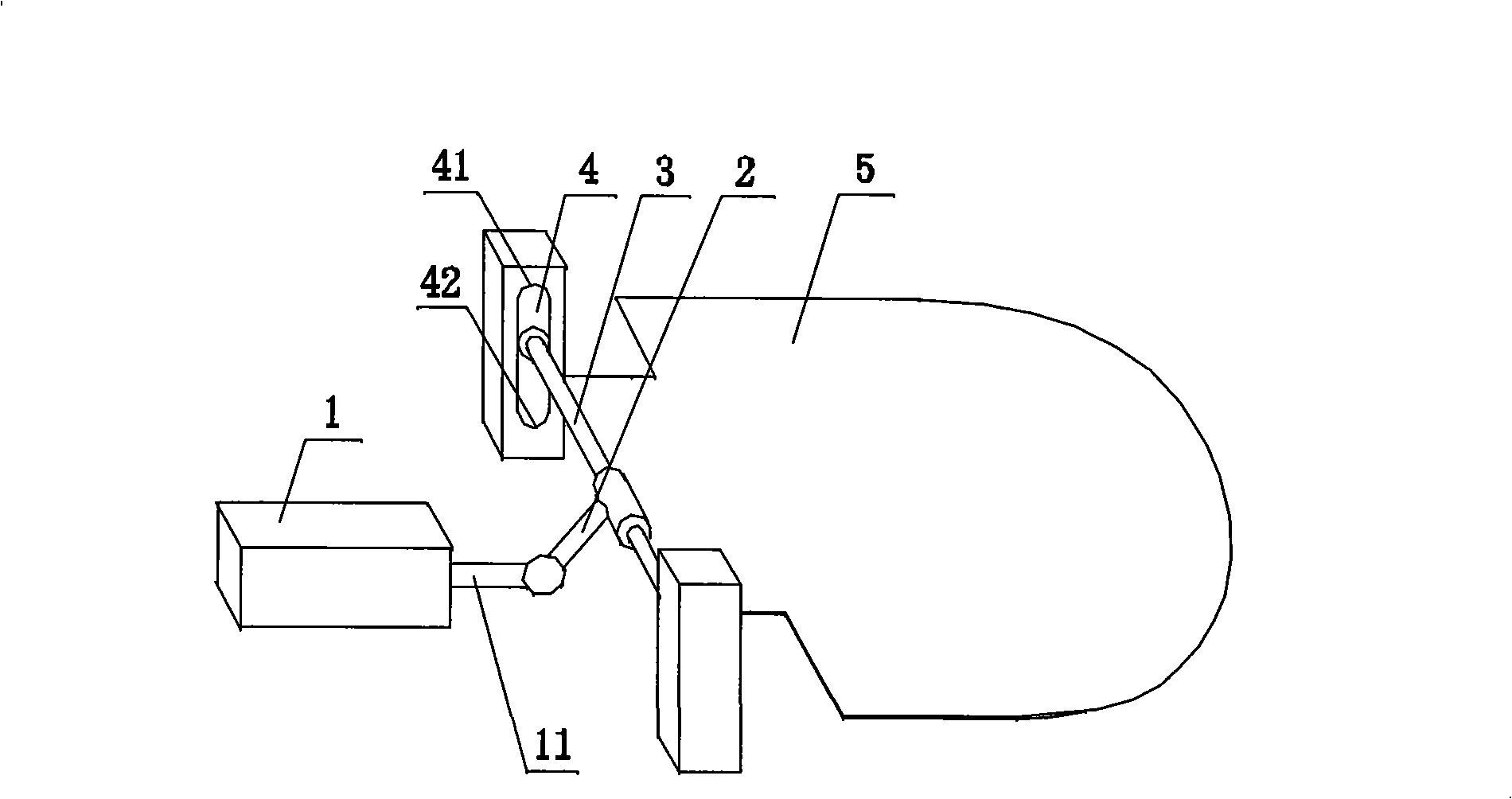

Turnover mechanism

InactiveCN101285761AGuaranteed linear motionGuaranteed uptimeMaterial analysis by optical meansControl theoryAngle alpha

The invention discloses a turnover mechanism, which comprises a drive set, a rotating device and a turnover piece, wherein, the rotating device consists of a rotary shaft, a rotary arm which is fixedly connected with the rotary shaft, and a first limit groove in which the rotary shaft performs translational motion and rotational motion; the turnover piece is arranged on the rotary shaft; a telescopic arm in the drive set is movably connected with one end of the rotary arm; the range of an included angle alpha between a plane in which the rotary arm and the rotary shaft are positioned and a plane in which the turnover piece and the rotary shaft are positioned is between 90 DEG and 180 DEG. The mechanism has the advantages of simple structure, stable operation, accurate positioning, high reliability, small volume, low cost and easy realization of the explosion prevention function.

Owner:FOCUSED PHOTONICS

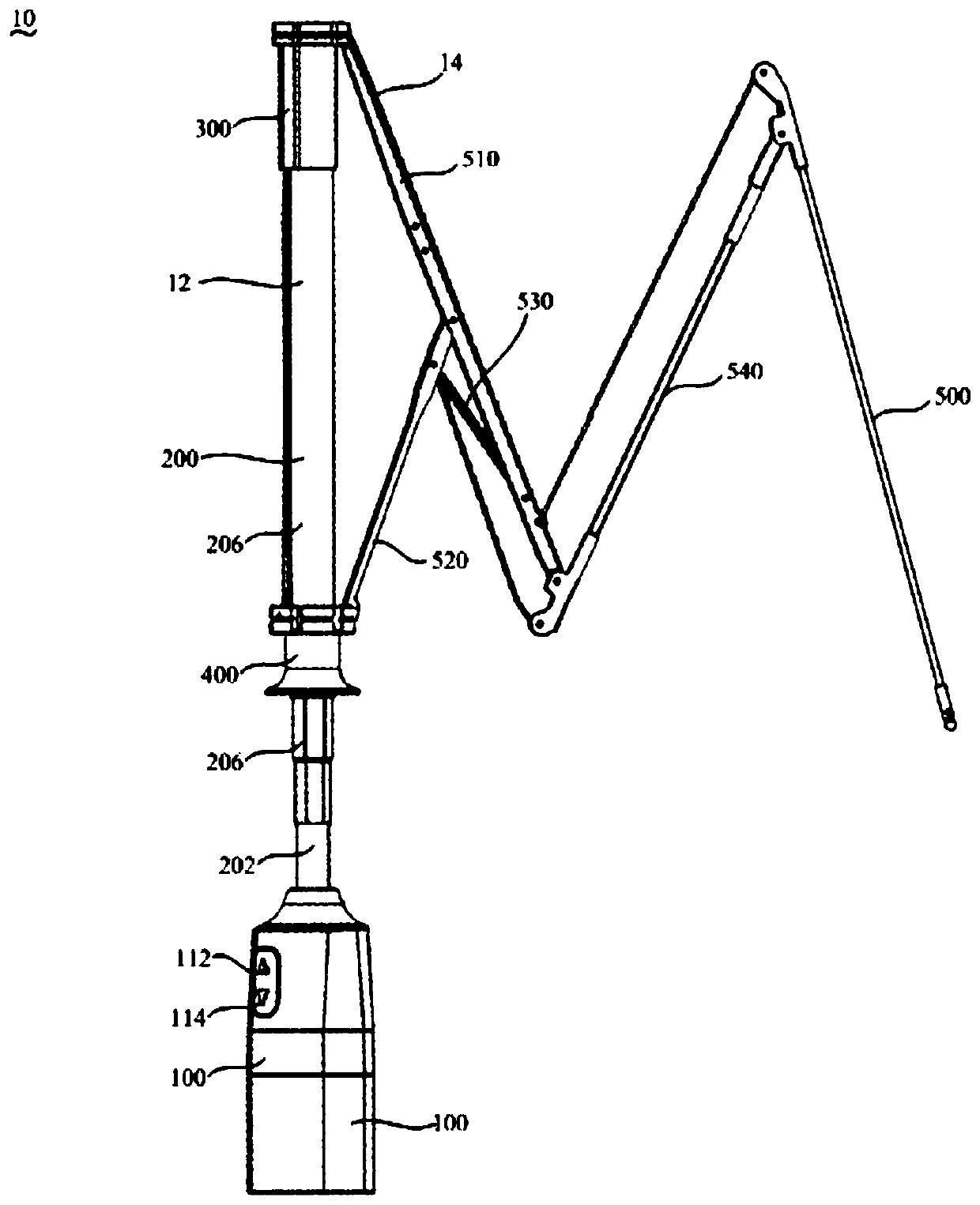

Umbrella rod device, umbrella rod transmission assembly thereof and electric umbrella

PendingCN110881760ASimple structureGuaranteed releaseWalking sticksUmbrellasEngineeringStructural engineering

The invention discloses an umbrella rod device, an umbrella rod transmission assembly thereof and an electric umbrella, the umbrella rod transmission assembly comprises a first rod structure, a secondrod structure and a spring, and the first rod structure comprises a first rod body and a rotation stopping part with a large outer diameter; the second rod structure comprises a second rod body and apressure spring part, the second rod body is inserted into the first rod structure, the pressure spring part is located outside the end, away from the first rod body, of the rotation stopping part, the end face, close to the second rod body, of the pressure spring part is a pressure spring face, and the pressure spring part is provided with a spring guide passage; the spring sleeves the first rodstructure, and at least part of the spring ring of the spring is arranged in the spring guide passage; when the second rod structure and the first rod structure rotate relatively, the spring compressed on the side, close to the second rod body, of the compressed spring face can be released, the spring stretches out from the end, away from the rotation stopping part, of the compressed spring partand applies force to the middle rod, the multiple sleeves of the middle rod are pulled open to form a long rod connected end to end, and the spring can be compressed to withdraw the force applied to the middle rod. The umbrella rod transmission assembly is simple in structure.

Owner:吕孙宝

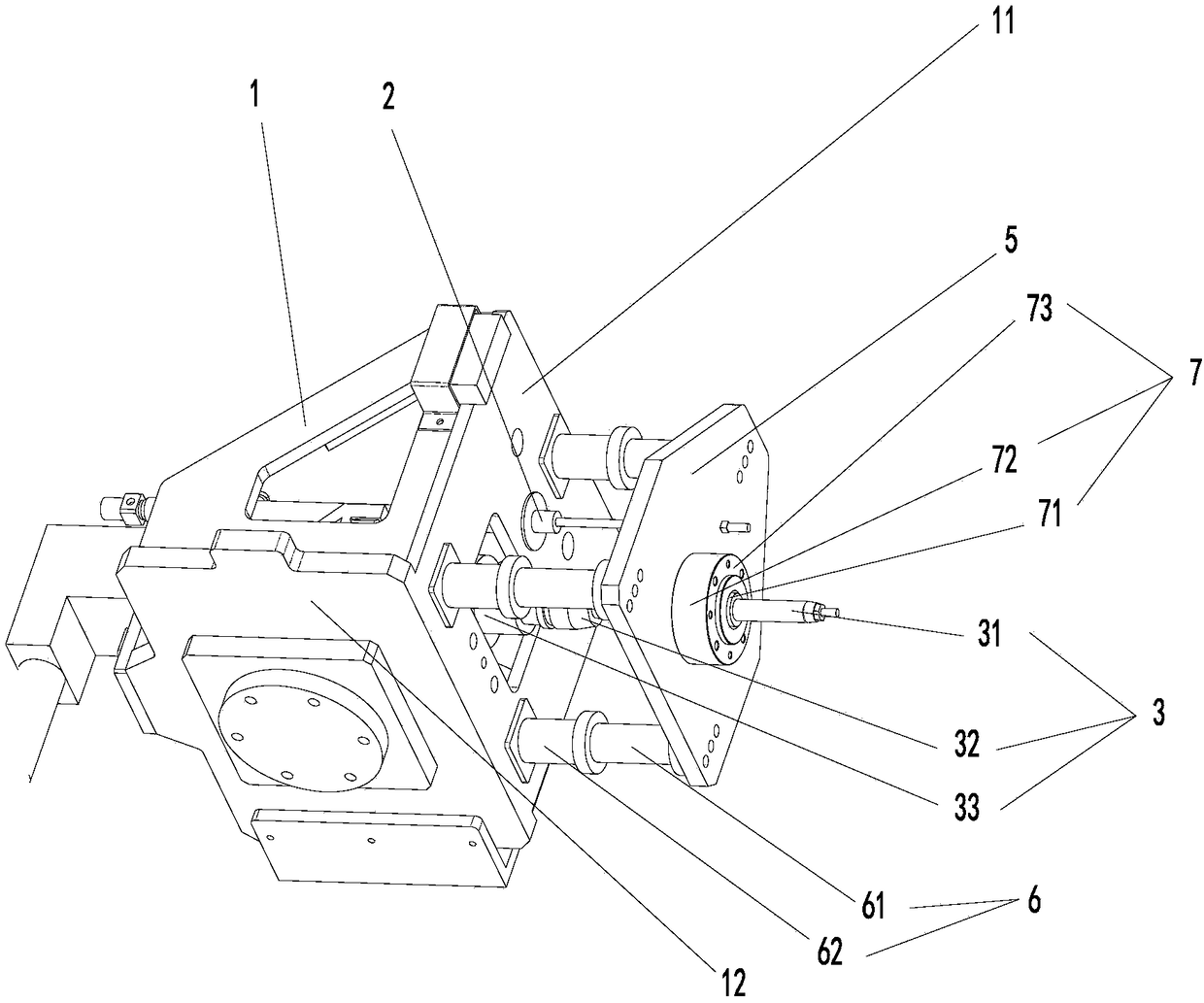

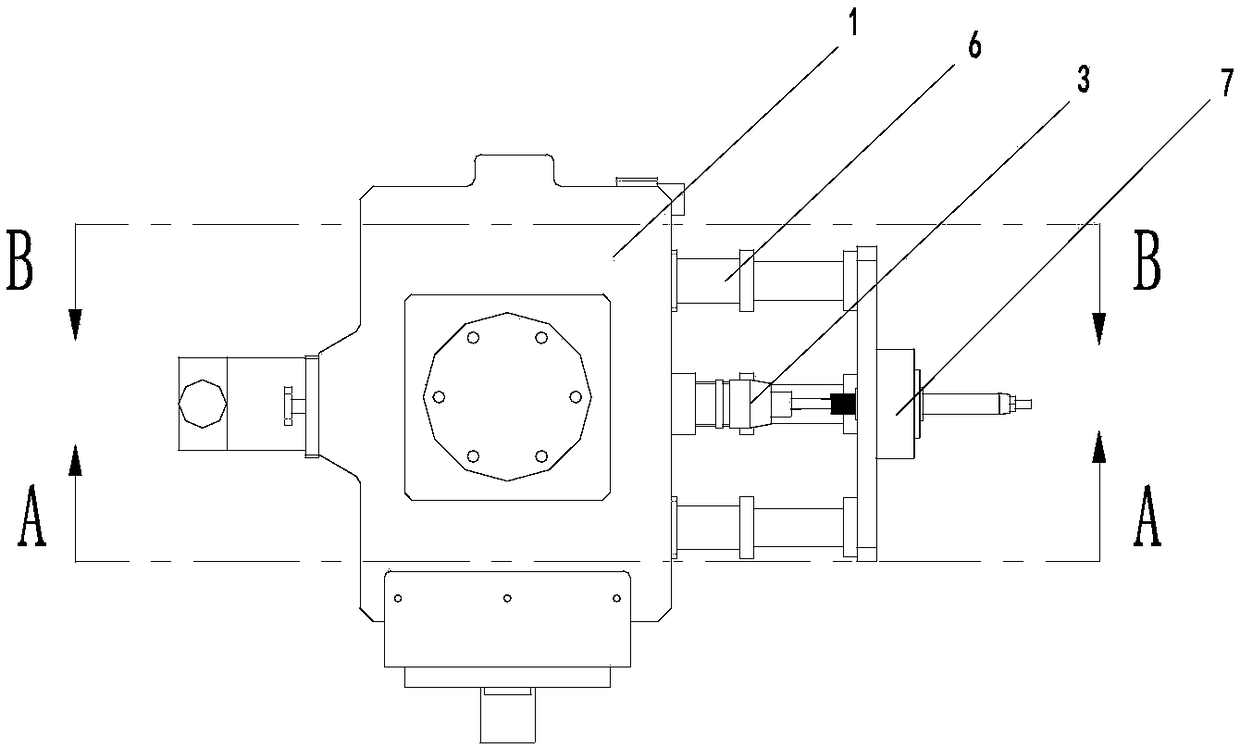

Expansion joint system and expansion joint method

PendingCN108500172AGuaranteed to stopFree expansion actionHeat exchange apparatusStart timeEngineering

The invention provides an expansion joint system and an expansion joint method. The expansion joint system comprises a connecting base and a telescopic drive mechanism. The telescopic drive mechanismis arranged on the connecting base. According to the expansion joint system and the expansion joint method, it can be ensured that an expansion joint mandrel and a pipe expansion head can freely perform expansion joint action and it also can ensured that the expansion joint mandrel stops at any position before entering a pipe to be expanded by using the interaction of the expansion drive mechanismand an elastic mechanism, the expansion joint thrust can be controlled by using the elastic mechanism, and the thrust of an industrial robot is effectively offset, so that the expansion joint systemcan achieve the purpose of simulating manual expansion joint, it can be ensured that a pipe expansion device can act to a certain extent, and it is ensured that the pipe expansion device smoothly enters the pipe to be expanded when the axis of the pipe to be expanded has a deviation from the axis of the pipe expansion head. The linear motion of the pipe expansion device can be ensured by a pipe expansion device extension and contraction device, the expansion joint start time of the pipe expansion device can be controlled by arranging a position sensor, and the controllable purpose of expansionjoint is realized.

Owner:GREE ELECTRIC APPLIANCES INC

Trackless counter weight assembly and trackless lift car

InactiveCN102126663ASimple structureReduce length dimensionElevatorsBuilding liftsEngineeringMechanical engineering

The invention discloses a trackless counter weight assembly and a trackless lift car. The trackless counter weight assembly comprises a counter weight housing assembly, wherein a guide rod used for guiding is respectively arranged at the two sides of the counter weight housing assembly, and a plurality of guide sleeve assemblies which are in a sliding fit with the guide rods are arranged on the side wall of an elevator. The trackless lift car comprises a lift car assembly, wherein the guide rod used for guiding is respectively arranged at the two sides of the lift car assembly, and a plurality of guide sleeve assemblies which are in a sliding fit with the guide rods are arranged on the side wall of the elevator. By adopting the trackless counter weight assembly and the trackless lift car in the technical scheme in the invention, a counter weight assembly and a lift car move up and down along a straight lie by utilizing the sliding fit between the guide rods and the guide sleeve assemblies, each guide rod is short, the processing process is simple, and linear error is small, thus bump and noise produced during the process that the counter weight assembly and the lift car are lifted as a track is long and joints are excessive can be avoided, the trackless counter weight assembly and the trackless lift car are convenient to transport and mount, components such as a special track, track support, special track pressure guide plate and the like can be saved, and the product cost can be reduced.

Owner:邬建勋 +1

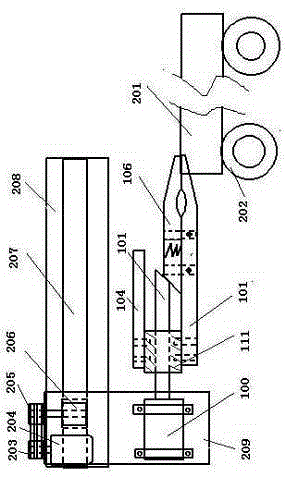

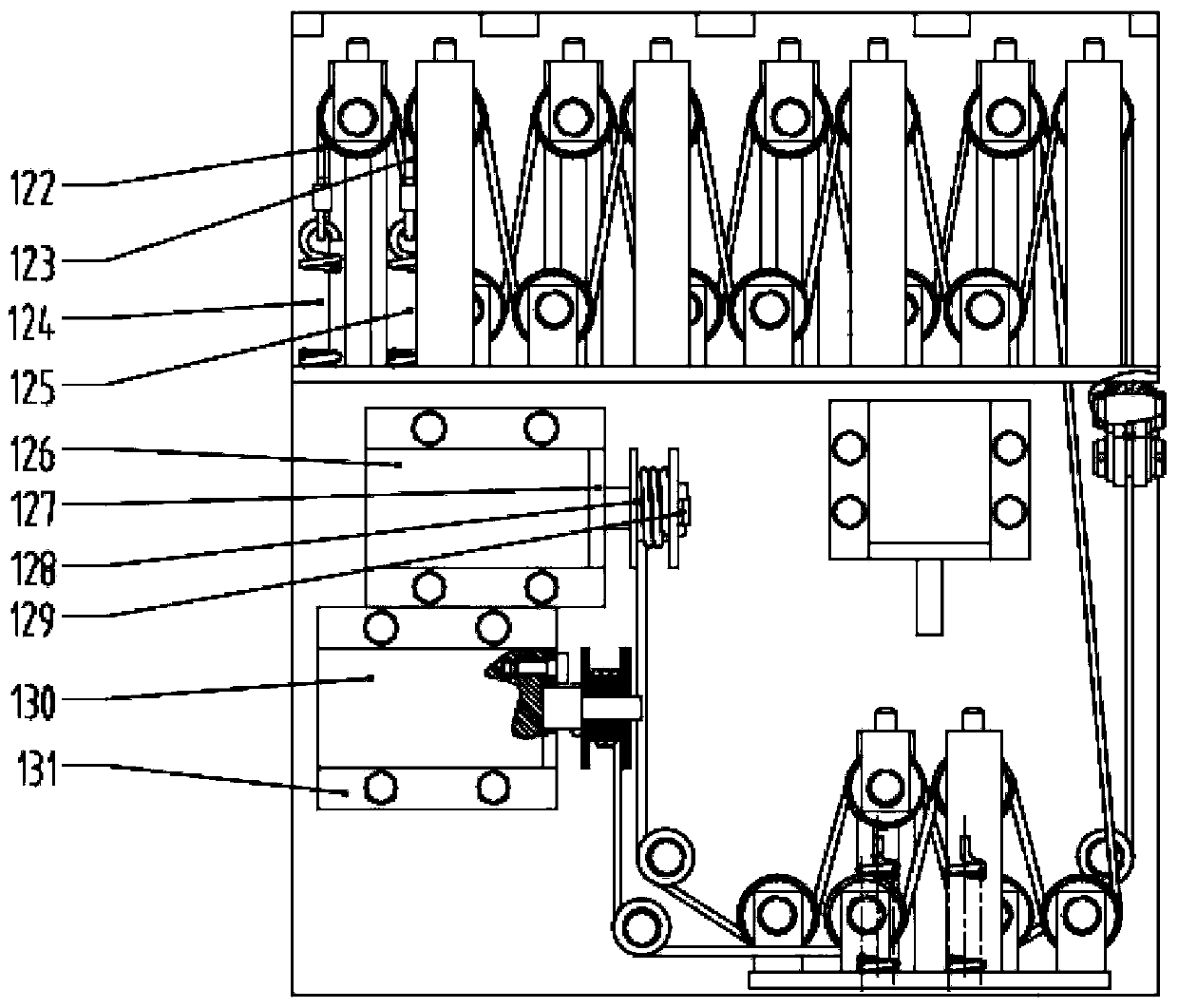

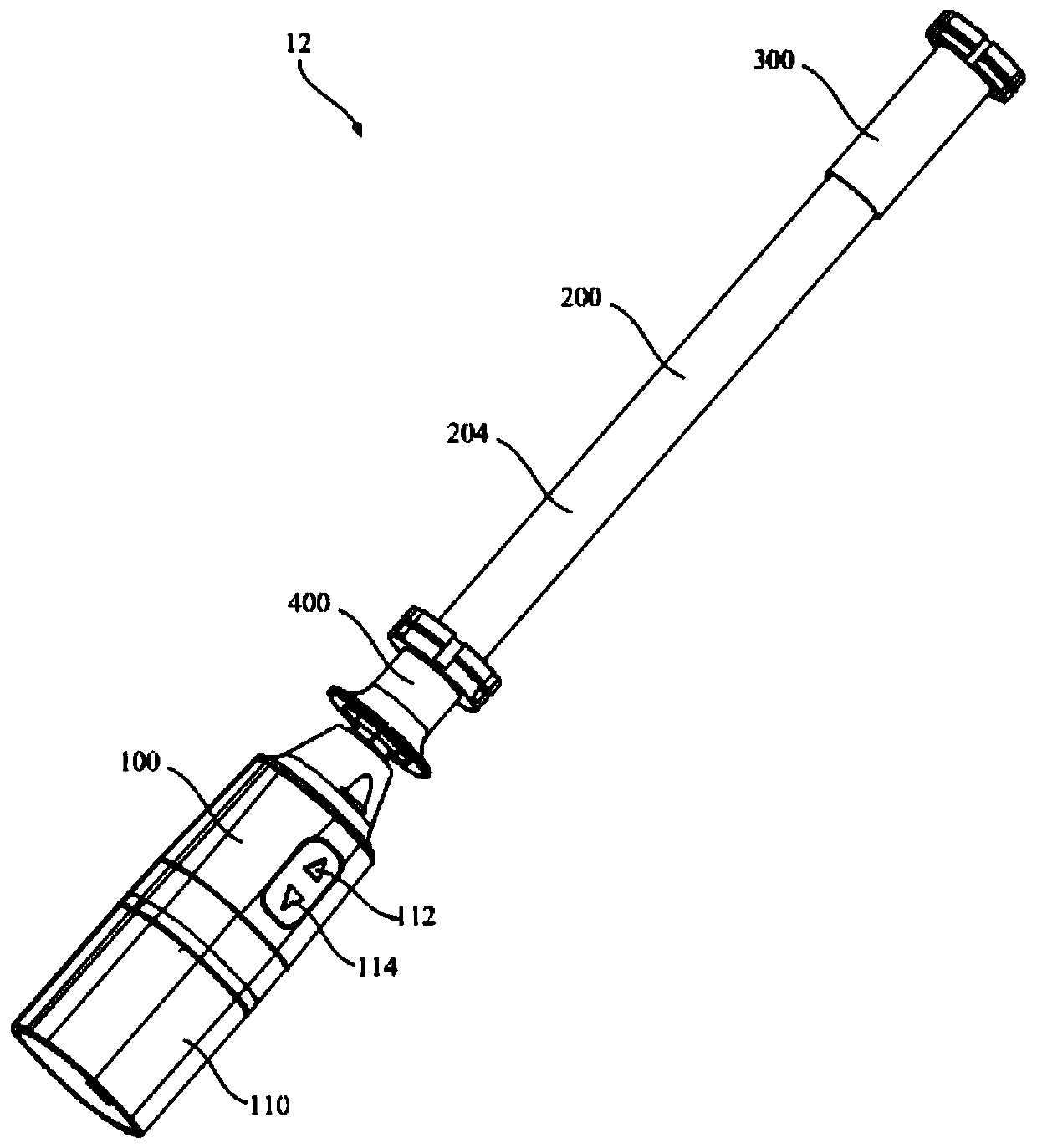

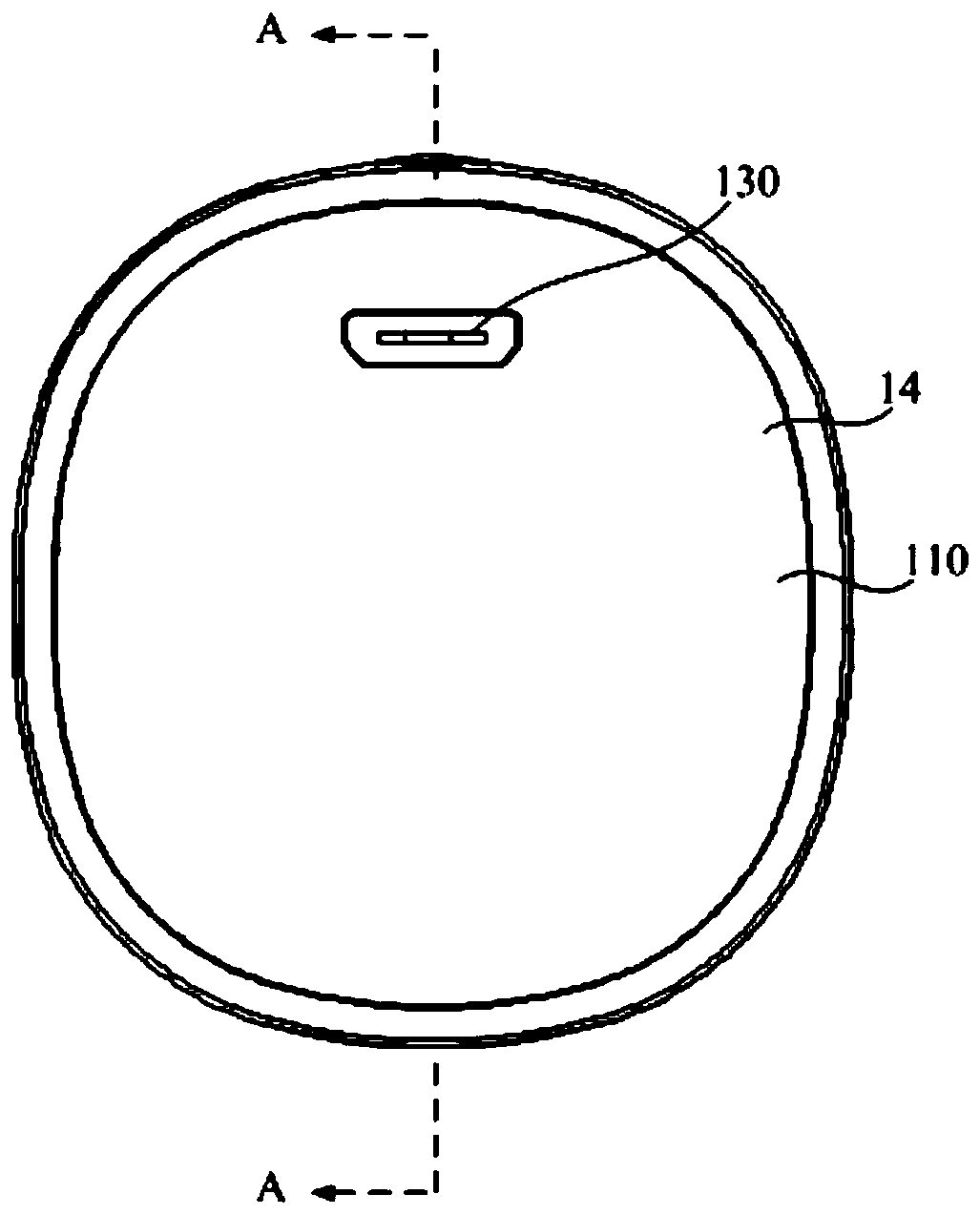

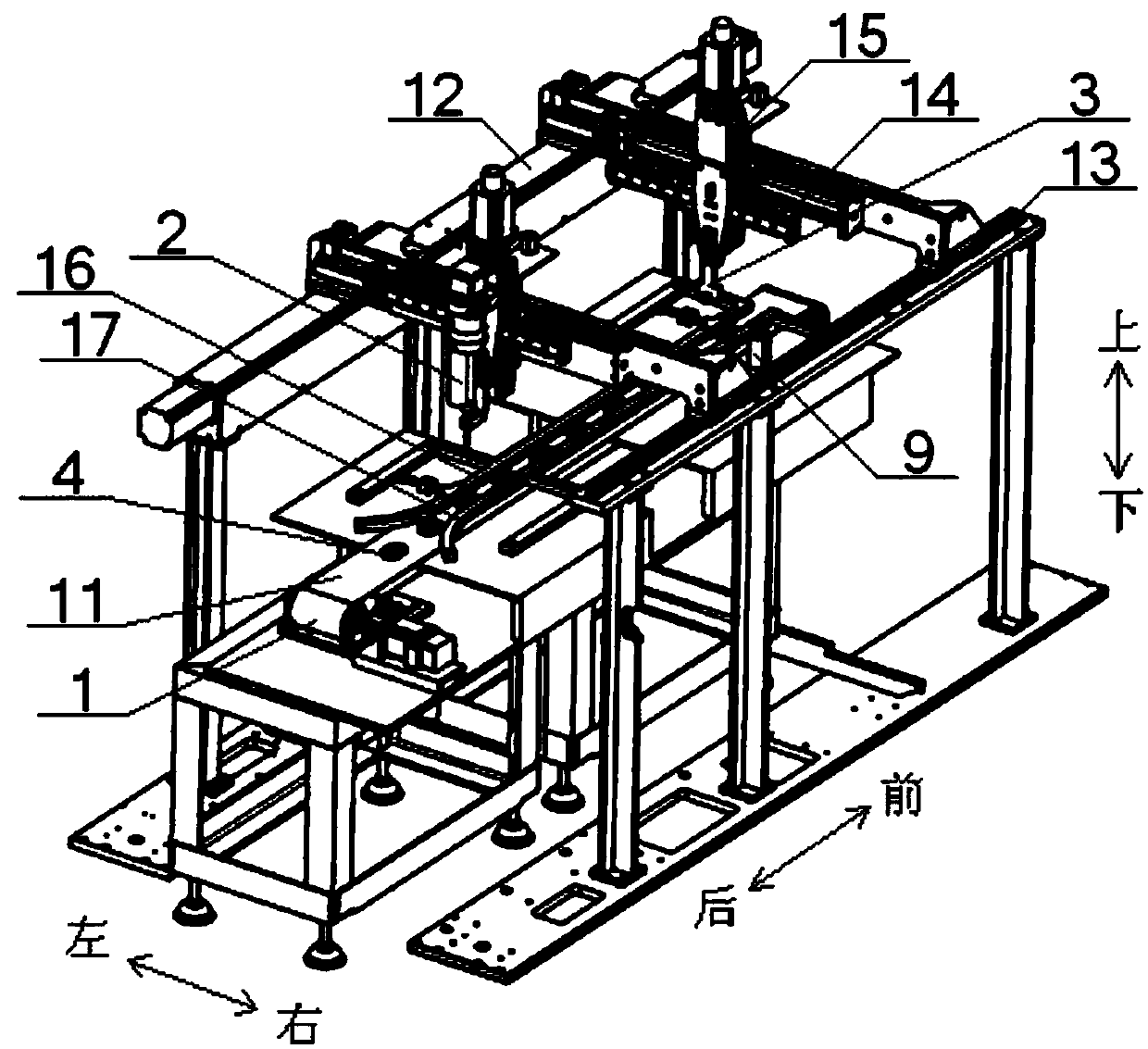

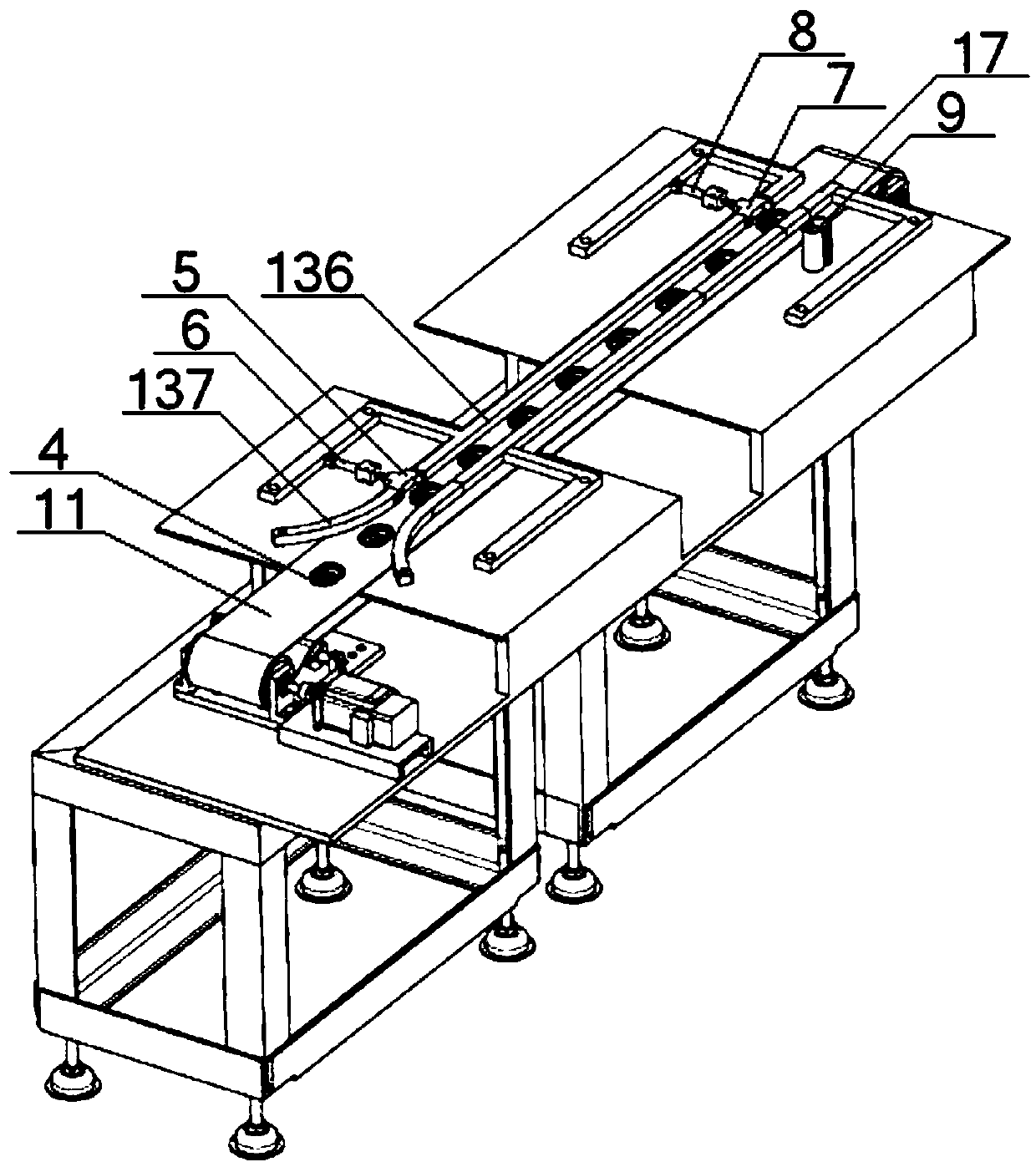

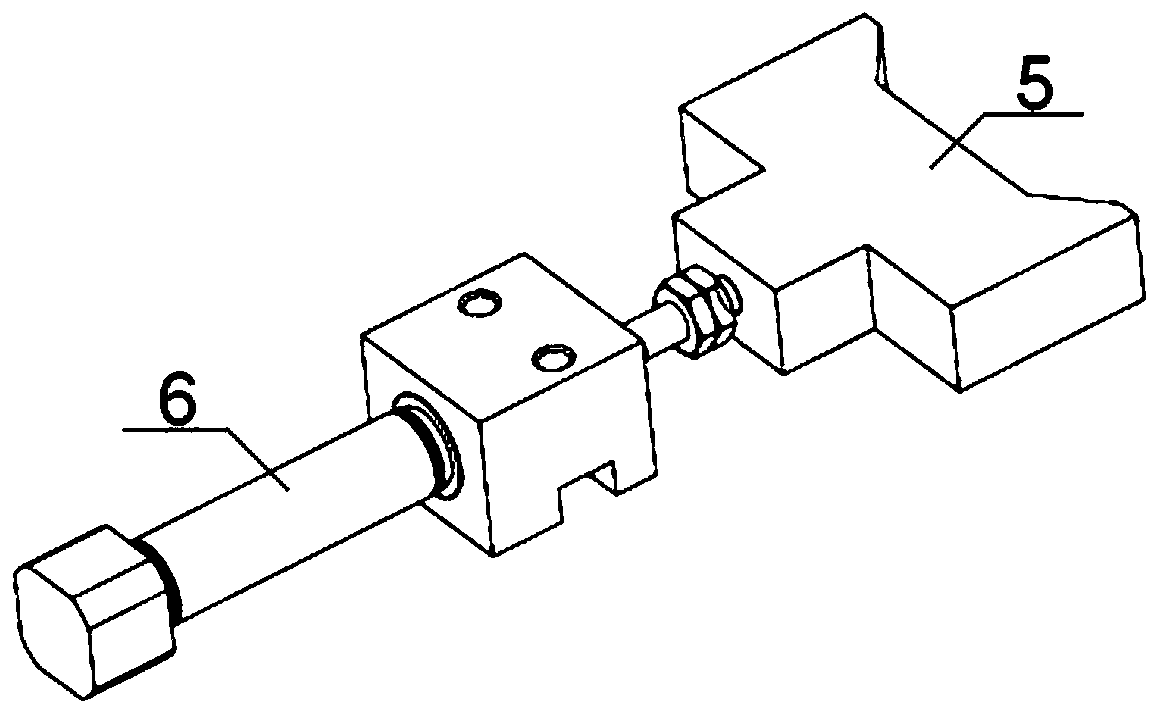

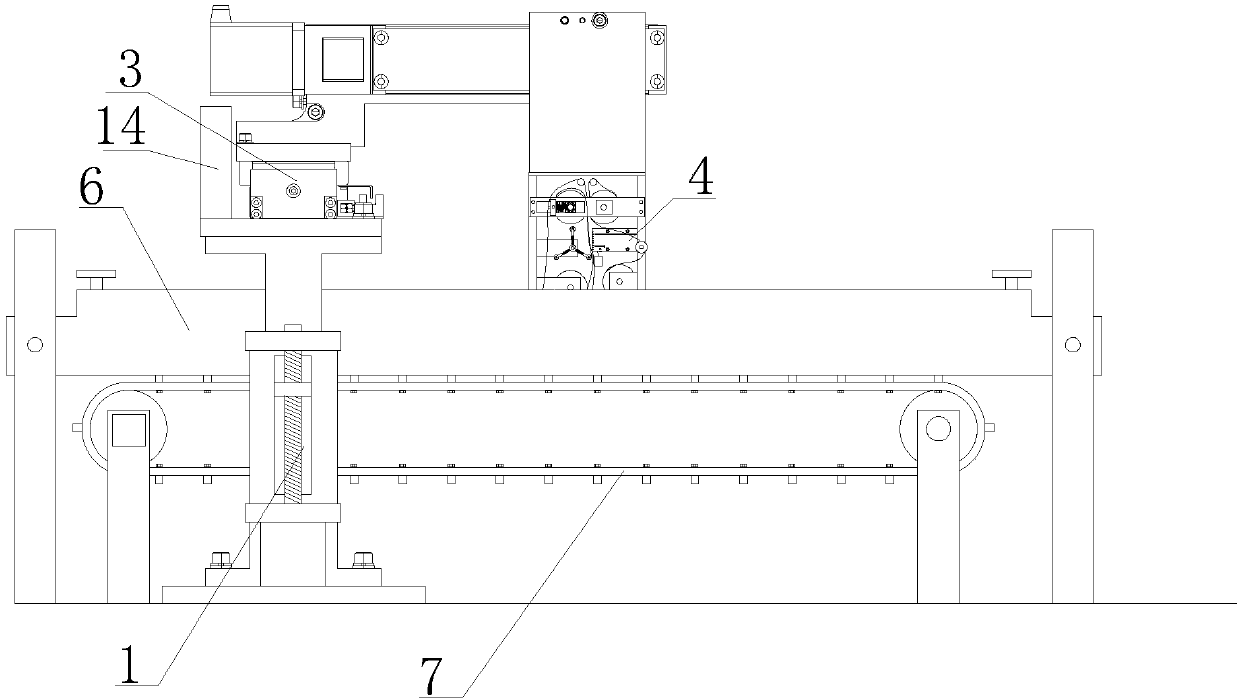

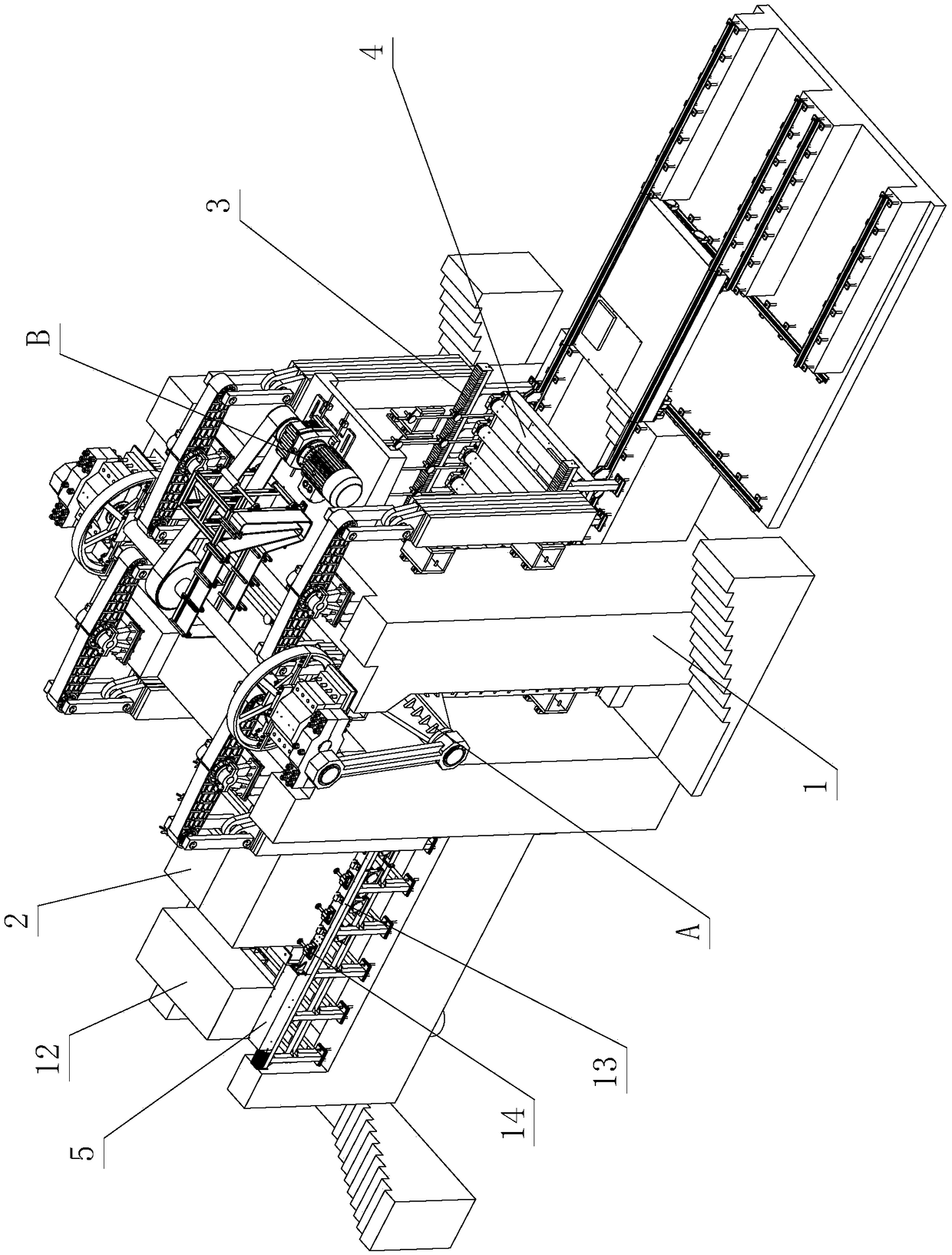

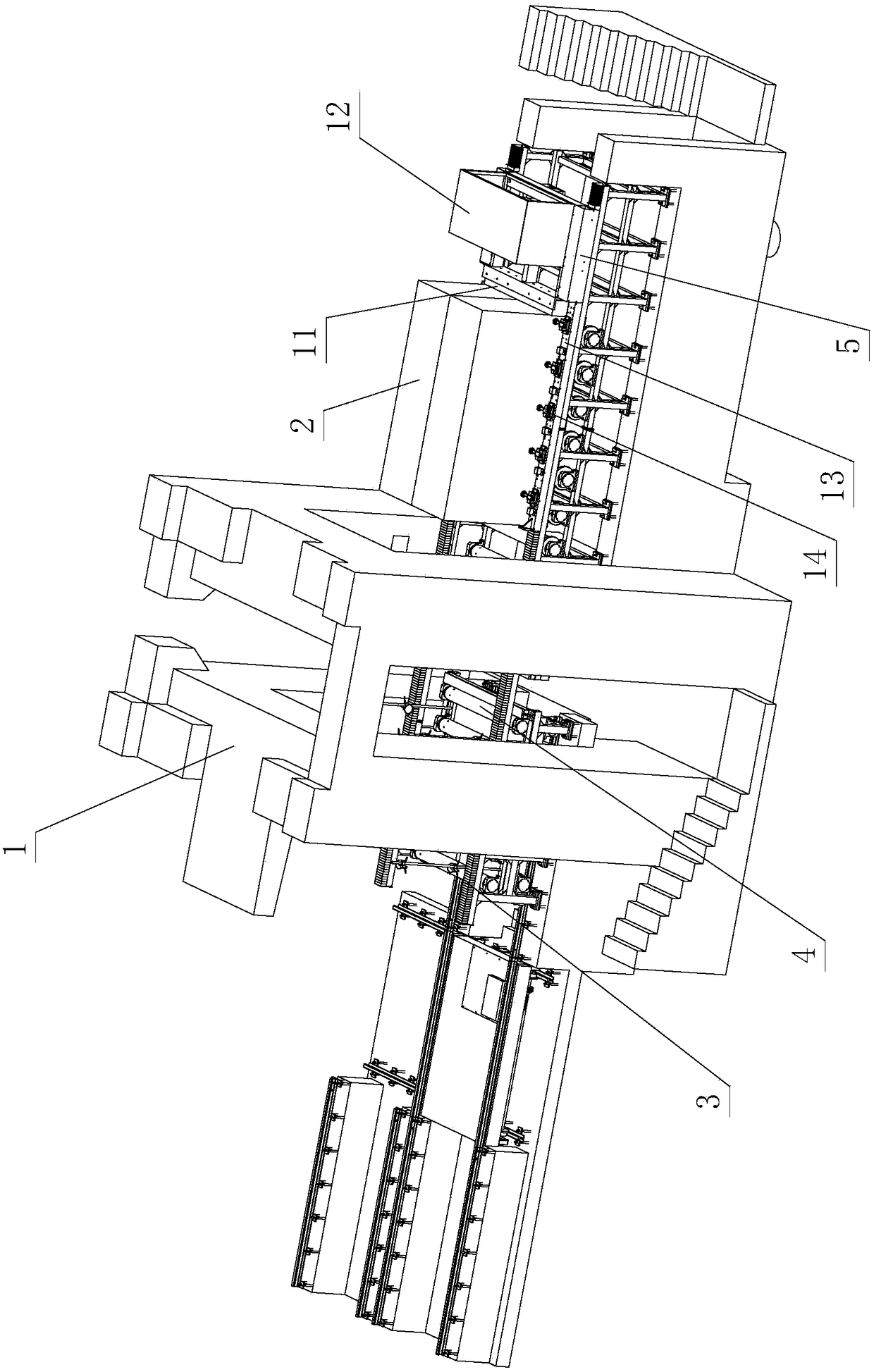

Ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine

ActiveCN109638150AHigh degree of automationPrecise Control of DisplacementPiezoelectric/electrostrictive device manufacture/assemblyLiquid surface applicatorsAtmospheric pressurePneumatic cylinder

Disclosed is an ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine. The ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine comprises a belt, a first guide rail and a second guide rail, wherein the first guide rail and the second guide rail are arranged on the two sides of the belt in parallel; two first guide columns are connected between the first guide rail and the second guide rail in a sliding mode, and the two first guide columns are connected with guiding-sliding columns in a sliding mode; a glue dispensing machine and a chip mounter are connected to the two guiding-sliding columns in a sliding mode respectively; two limiting guide rails are symmetrically arranged above the belt; a piezoelectric wafer shell is arranged on the part, located between the two limiting guide rails, of the belt; two movable blocks are arranged on one limiting guide rail, and the movable blocks are connected with a pneumatic cylinder, and the movable blocks are used for enabling the piezoelectric wafer shell to be abutted against the other limiting guide rail during glue dispensing and chip mounting; a piezoelectric wafer isarranged on the side of the belt; the glue dispensing machine is used for injecting glue liquid into the piezoelectric wafer shell; and the chip mounter is used for attaching the piezoelectric waferto the part, coated with the glue liquid, of the piezoelectric wafer shell. According to the design, the glue dispensing effect is good, the chip mounting effect is good, and the automation degree ishigh.

Owner:WUHAN TEXTILE UNIV

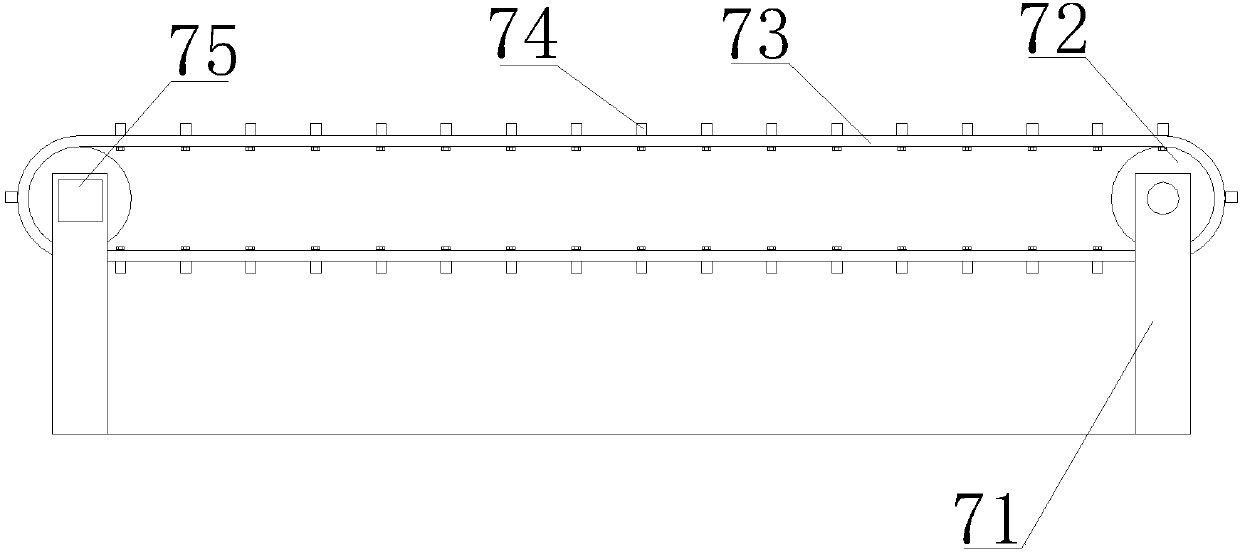

Carton printing single-rail adjustable labeling equipment

ActiveCN107792451AGuaranteed linear motionMeet labeling needsLabelling machinesControl equipmentEngineering

The invention discloses carton printing single-rail adjustable labeling equipment. Lifting adjusting parts for adjusting the height of the equipment are arranged on the two sides of a material conveying power part correspondingly. Bonding left-right adjusting parts for driving the tag executing parts to move left and right and front and back are arranged on the upper portions of the lifting adjusting parts, and the tag executing parts for pasting tags on printed cartons are arranged on the bonding left-right adjusting parts. Switching control boxes for controlling the work state of the equipment are arranged on the sides of the bonding left-right adjusting parts, and material guide conveying parts for limiting the movement direction of materials are arranged on the upper portions of material conveying power parts. The equipment can be adjusted to adapt to printed packaging boxes with different thicknesses, is high in adaptability, flexible in application, can automatically complete supply and bonding of the tags, and is high in automation degree, labor cost can be greatly reduced for enterprises, and the economic benefits of the enterprises can be increased. Meanwhile, the equipment is easy to operate and convenient to use.

Owner:嘉亿(邵阳)机械有限公司

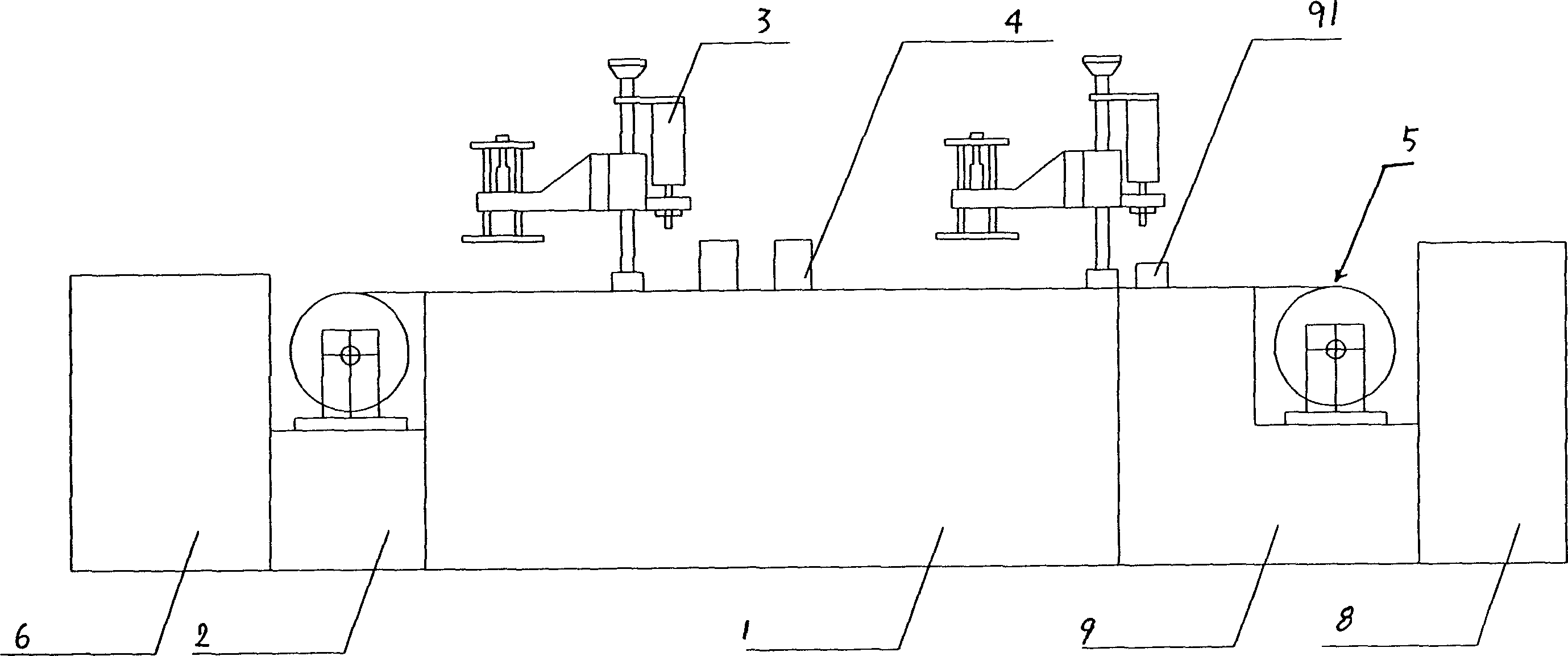

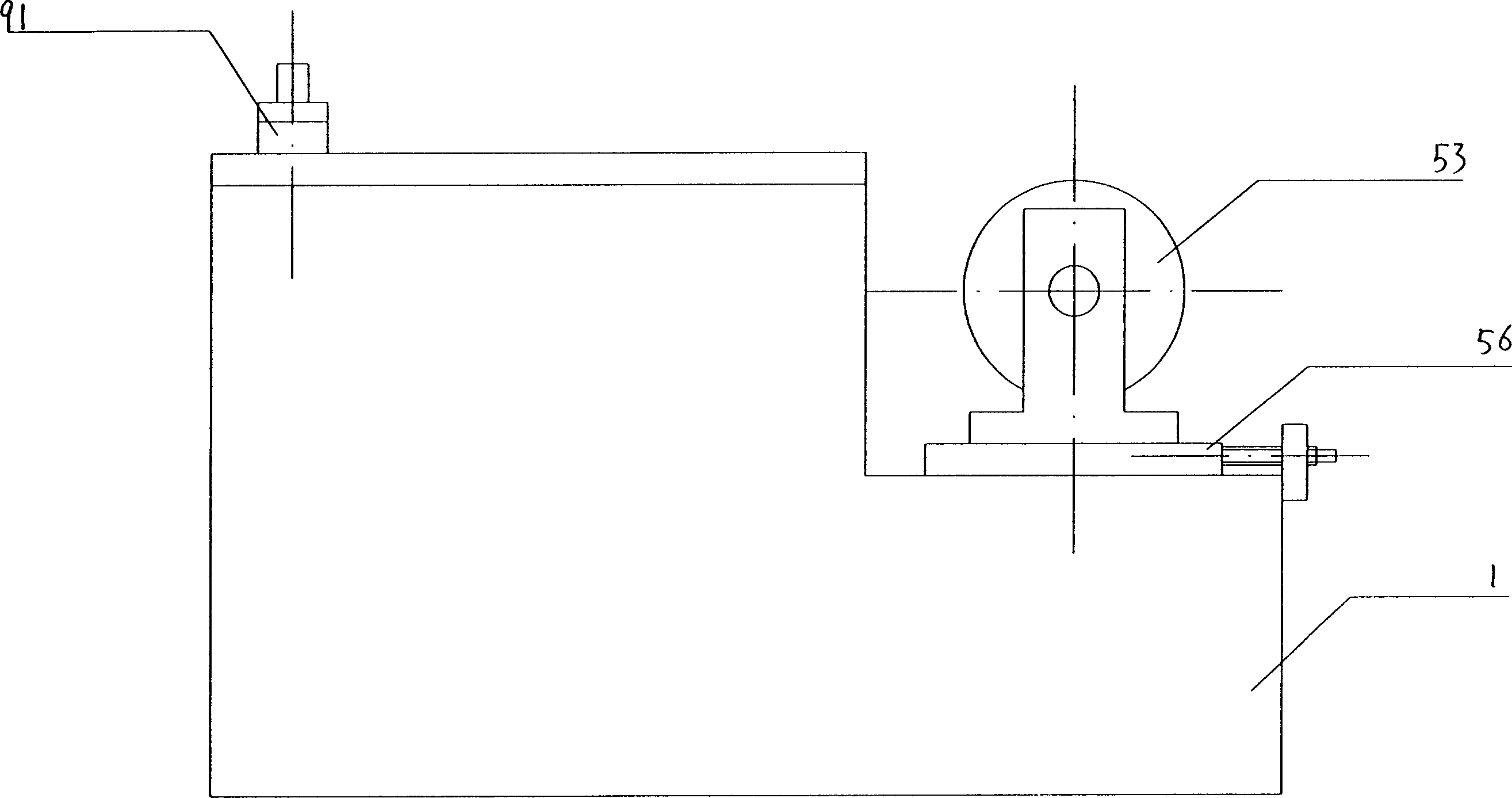

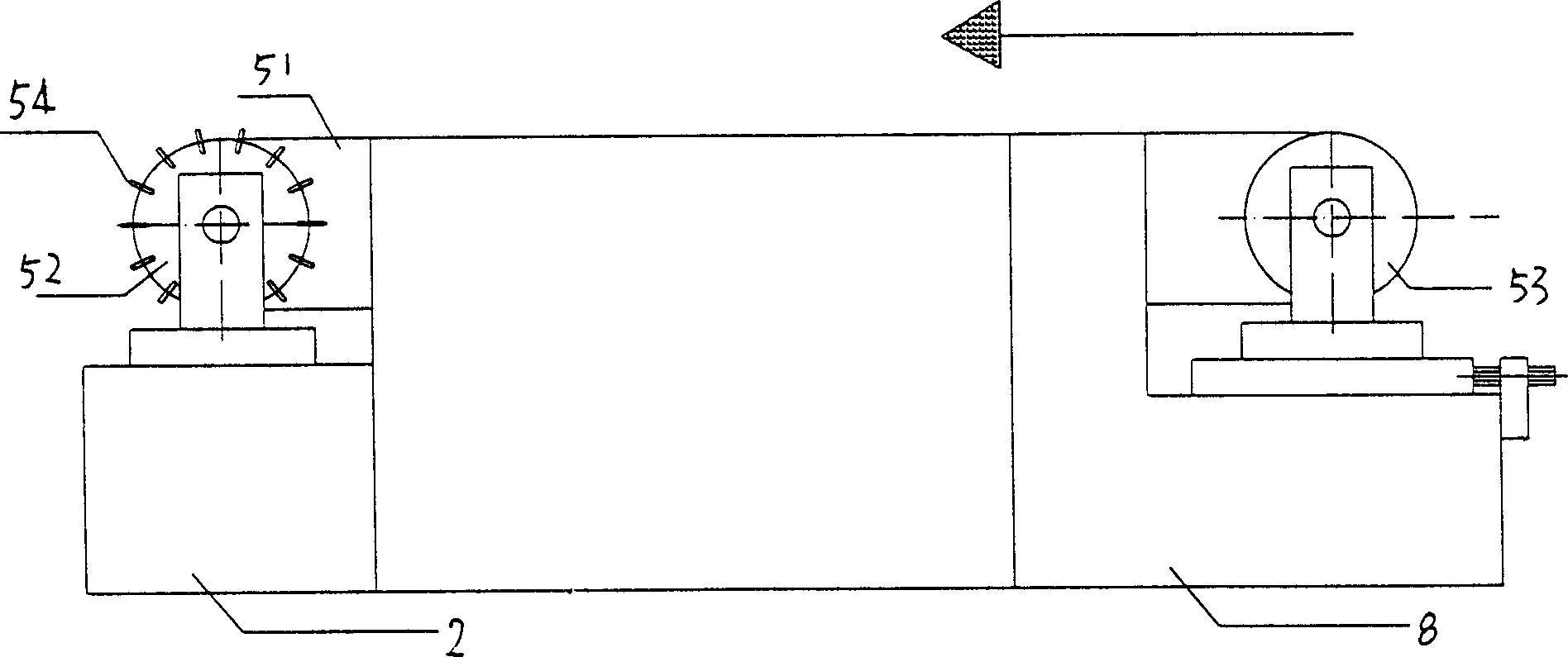

Back-and-forth movement thrust structure of stone sawing machine

PendingCN108544678ASimple and reasonable structureImprove performanceWorking accessoriesAerospace engineering

The invention discloses a back-and-forth movement thrust structure of a stone sawing machine. The structure comprises a foundation, stone to be sawn, a stone sawing device, a stone sawing driving device, a back-and-forth movement type thrust device, a linear guide rail and a rolling body. The thrust device comprises a thrust support, a push motor and a transmission assembly, the push motor is in driving connection with the transmission assembly and drives the thrust support to linearly slide on the linear guide rail, the thrust support linearly slides to drive the stone to be sawn to enter thestone sawing device through the rolling body, and the stone sawing device is in driving connection with the stone sawing driving device and saws the stone to be sawn. When stone sawing operation is completed for the stone to be sawn, the thrust support carries out blanking operation on stone through the cooperation of the push motor and the transmission assembly, and is returned to the initial position through the cooperation of the push motor and the transmission assembly after blanking operation is completed for the stone to be sawn. By means of the structural improvement, the practicability is high.

Owner:佛山市顺德区悍天睿数控机械有限公司 +1

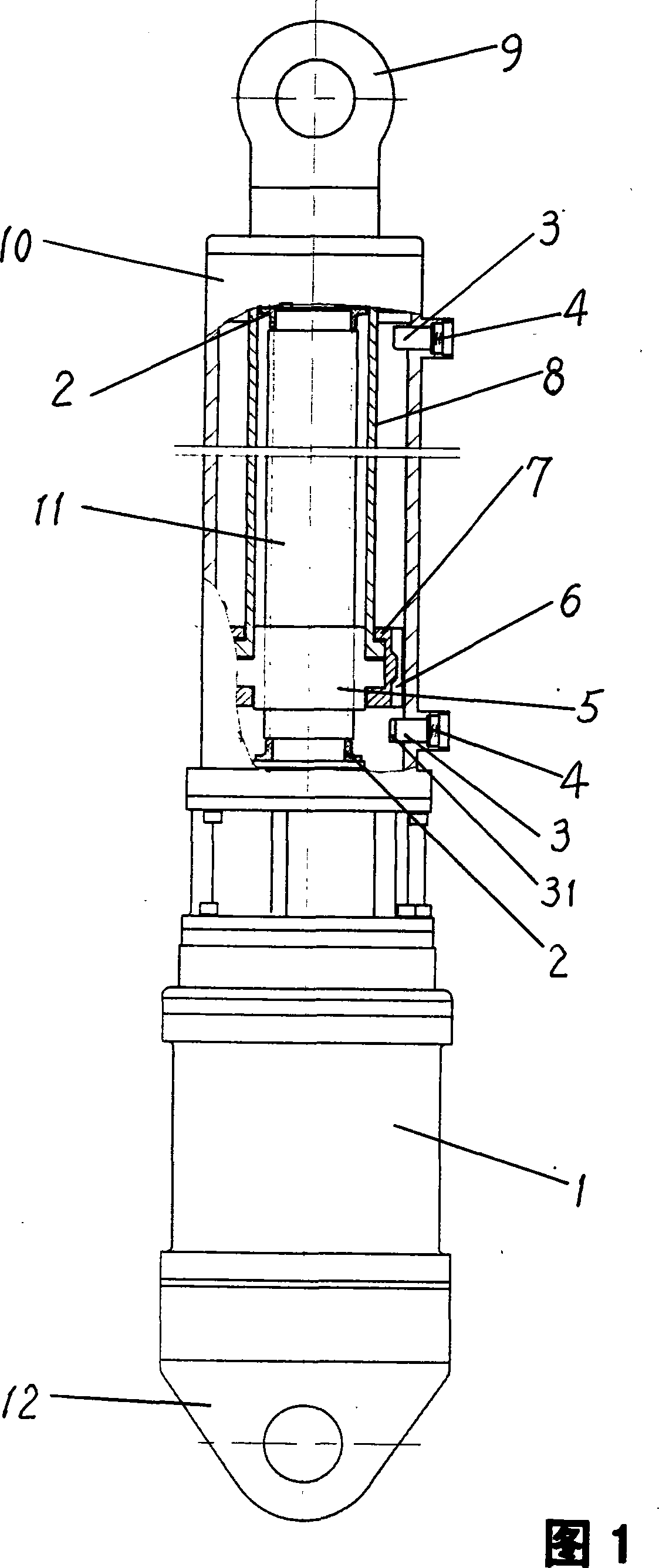

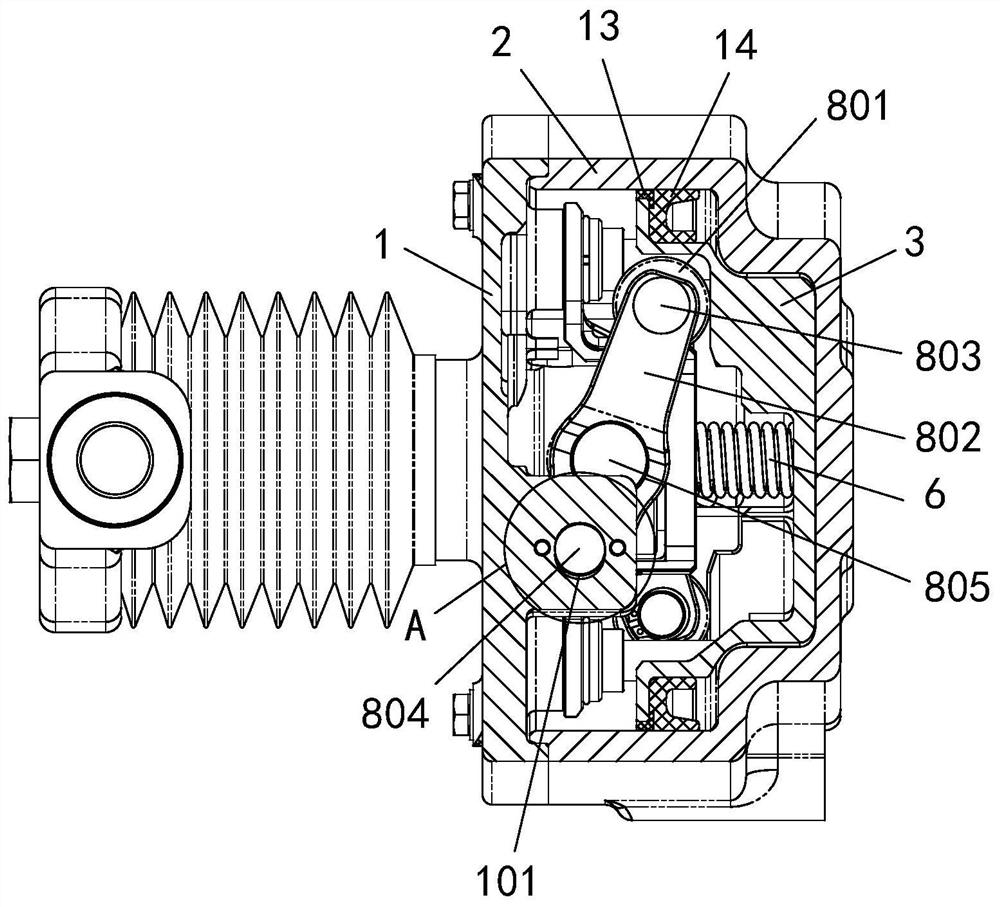

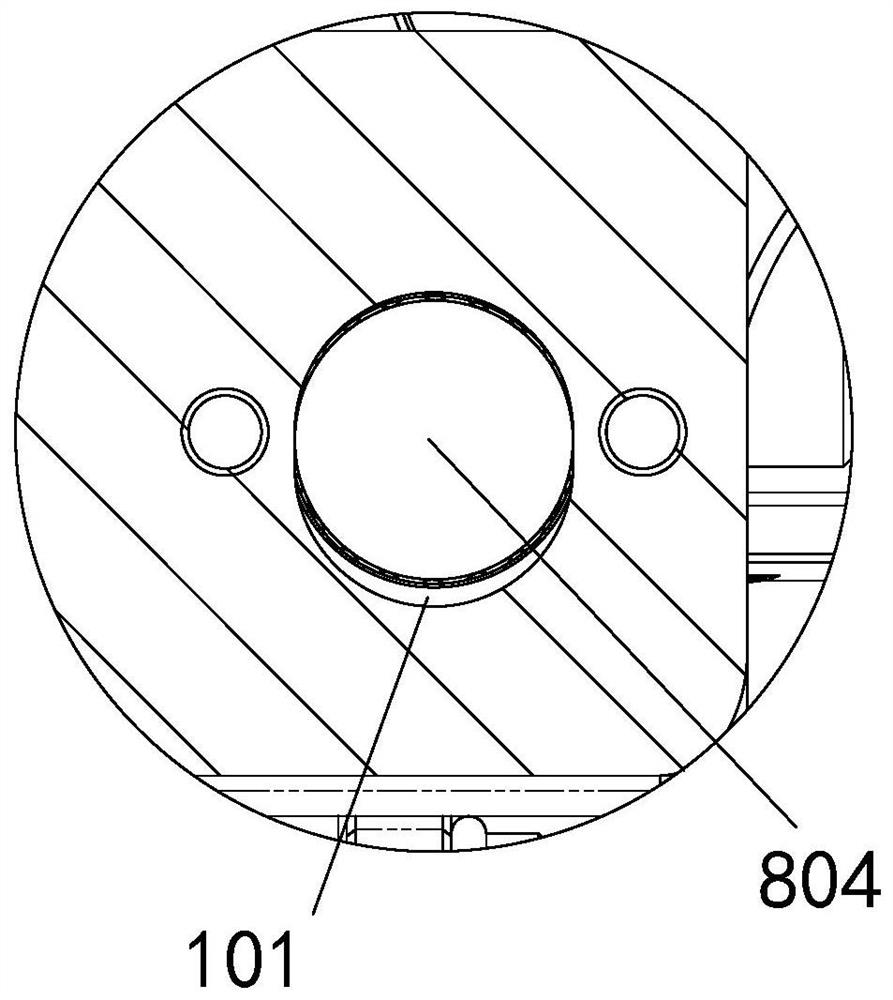

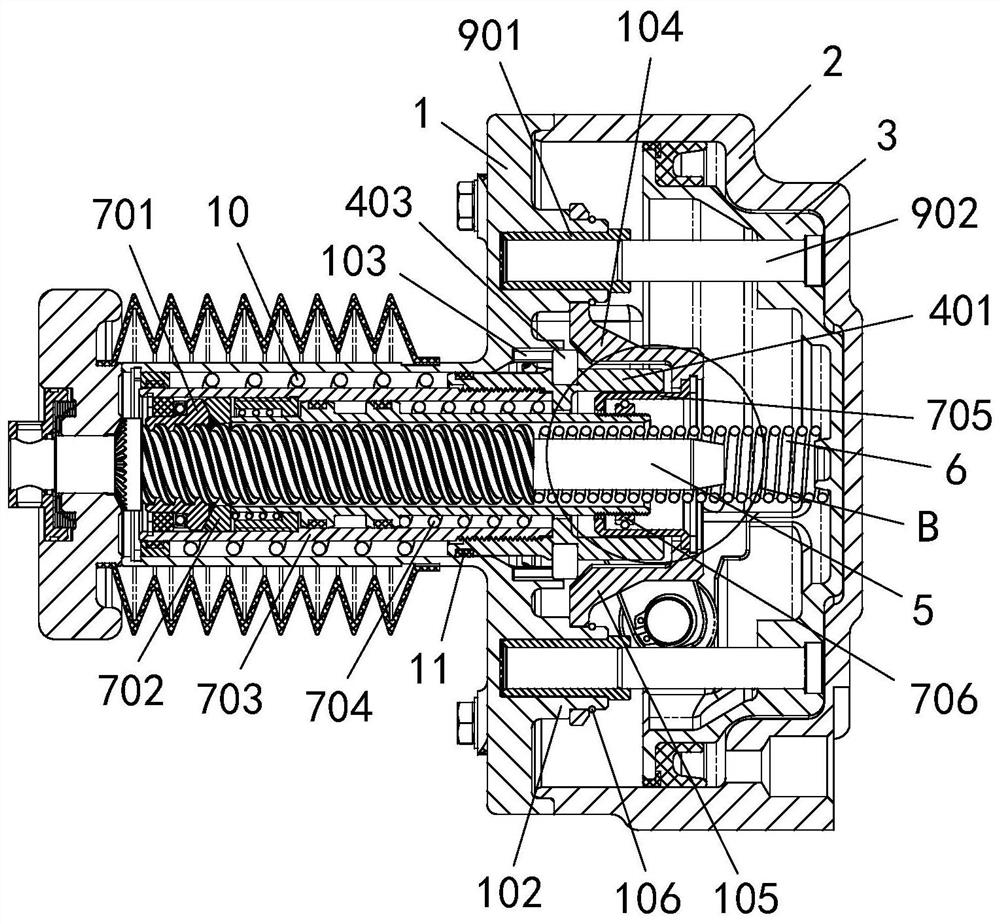

Pneumatic brake cylinder and brake clamp unit

ActiveCN112855809AReduce size and weightSimple structureBrake actuating mechanismsActuatorsPhysicsPiston

The invention relates to a pneumatic brake cylinder and a brake clamp unit. The pneumatic brake cylinder comprises a cylinder cover, a rear cover, a piston, a pushing part assembly, a lead screw, an adjusting spring, a gap adjusting mechanism and at least two amplifying mechanisms; the rear cover is connected with the cylinder cover and forms a sealing cavity with the cylinder cover; the piston is arranged in the sealing cavity; the pushing part assembly is arranged in the sealing cavity and is in sliding connection with the cylinder cover; the lead screw is arranged in the pushing part assembly in a sleeving manner; one end of the adjusting spring is pressed on the piston, and the other end of the adjusting spring is pressed on the lead screw; the gap adjusting mechanism is arranged between the pushing part assembly and the lead screw; the at least two amplifying mechanisms are circumferentially and symmetrically arranged, and each amplifying mechanism comprises a bearing and a lever, wherein the bearings are attached to the piston; and one ends of the levers are coupled with the bearings, the other ends of the levers are coupled with the cylinder cover, and the middles of the levers are coupled with the pushing part assembly. According to the pneumatic brake cylinder and the brake clamp unit, the internal space of the brake cylinder can be saved and the volume of the brake cylinder can be reduced on the premise of the same brake multiplying power.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

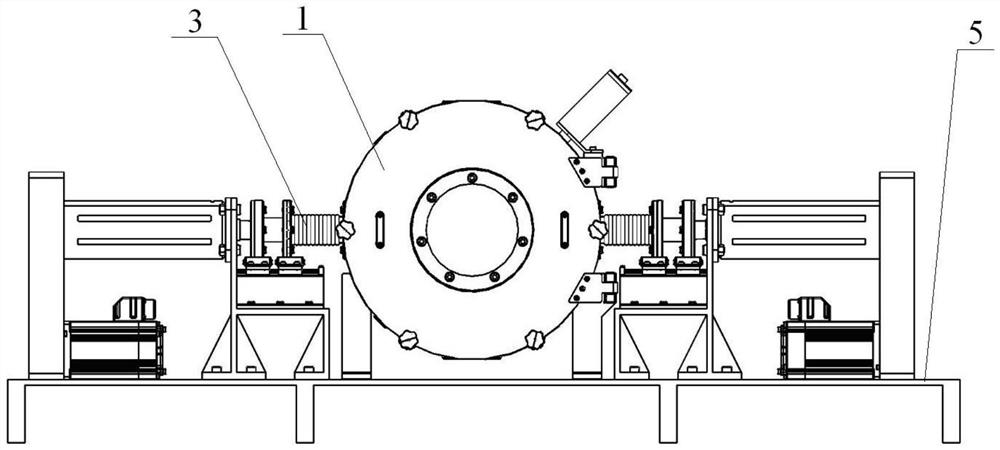

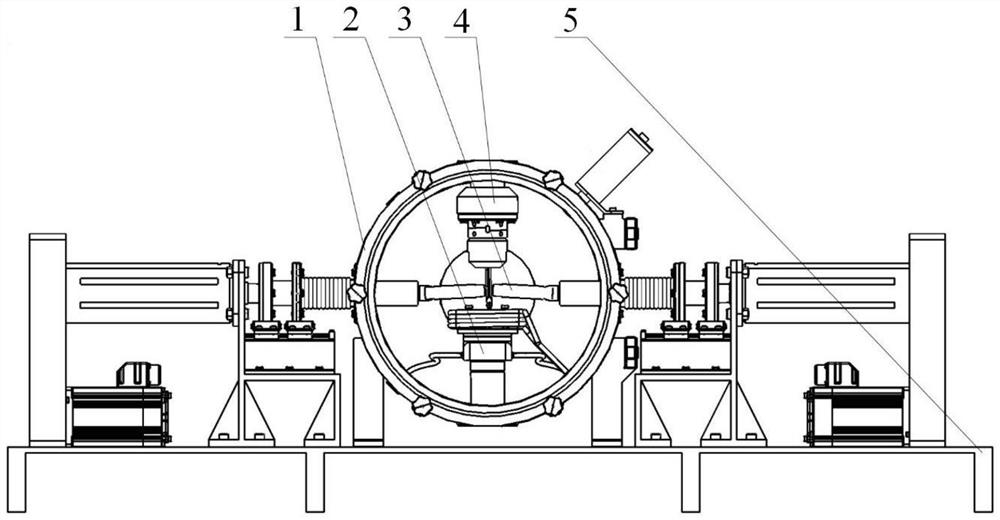

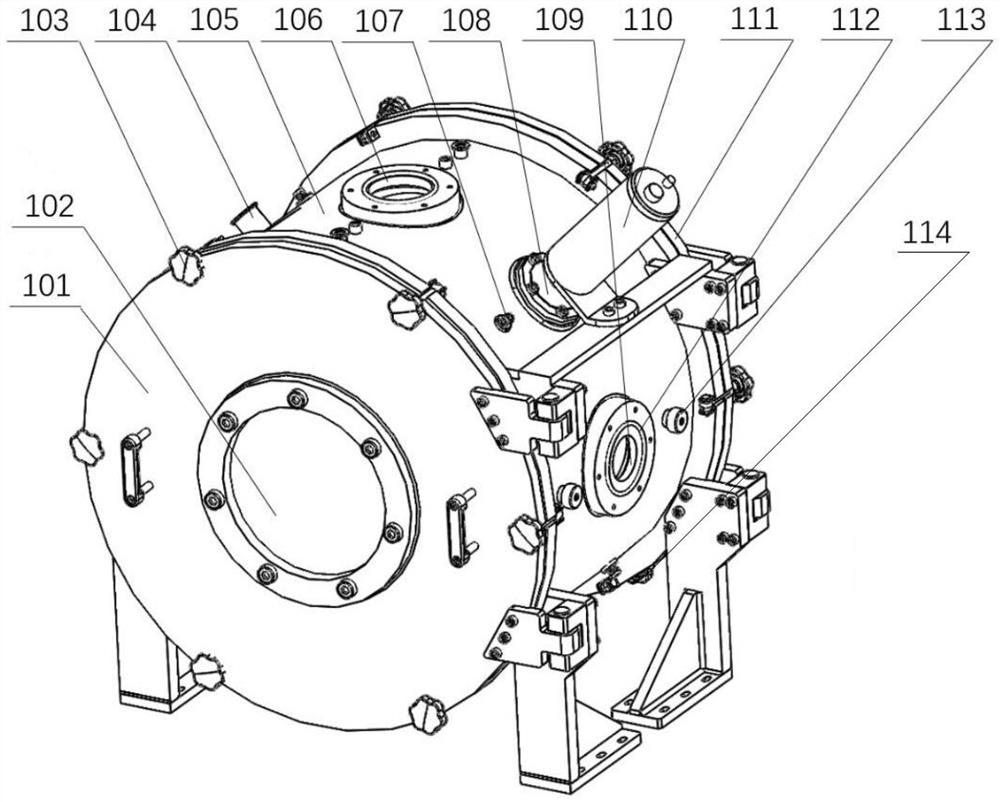

Swing type high-temperature friction and wear test device

PendingCN113984571ASimple structureEasy to connectUsing mechanical meansInvestigating abrasion/wear resistancePhysicsEngineering

The invention relates to a swing type high-temperature friction and wear test device, and belongs to a test device for friction and wear of a material at a high temperature. The device is characterized in that a vacuum cavity and driving modules are fixedly connected with the upper portion of a rack, the driving modules penetrate through the vacuum cavity from the two sides, the top end of a friction and wear module is installed in the vacuum cavity, a swing rod at the lower end is hinged to connecting rods of the driving modules symmetrically arranged on the two sides, and the bottom of a high-temperature loading module is fixed in the vacuum cavity through a bolt and is positioned below the friction and wear module. According to the invention, the device has the advantages that the structure is novel, the friction coefficient of a material in a high-temperature vacuum environment can be obtained, the linear motion of the push-pull rod of the driving module is ensured, the device is safer, the heating efficiency of a plate-shaped test piece is effectively improved, the uniformity of temperature distribution on the plate-shaped test piece is ensured, the accuracy of test data is improved, and the safety of test equipment and testers is protected.

Owner:JILIN UNIV

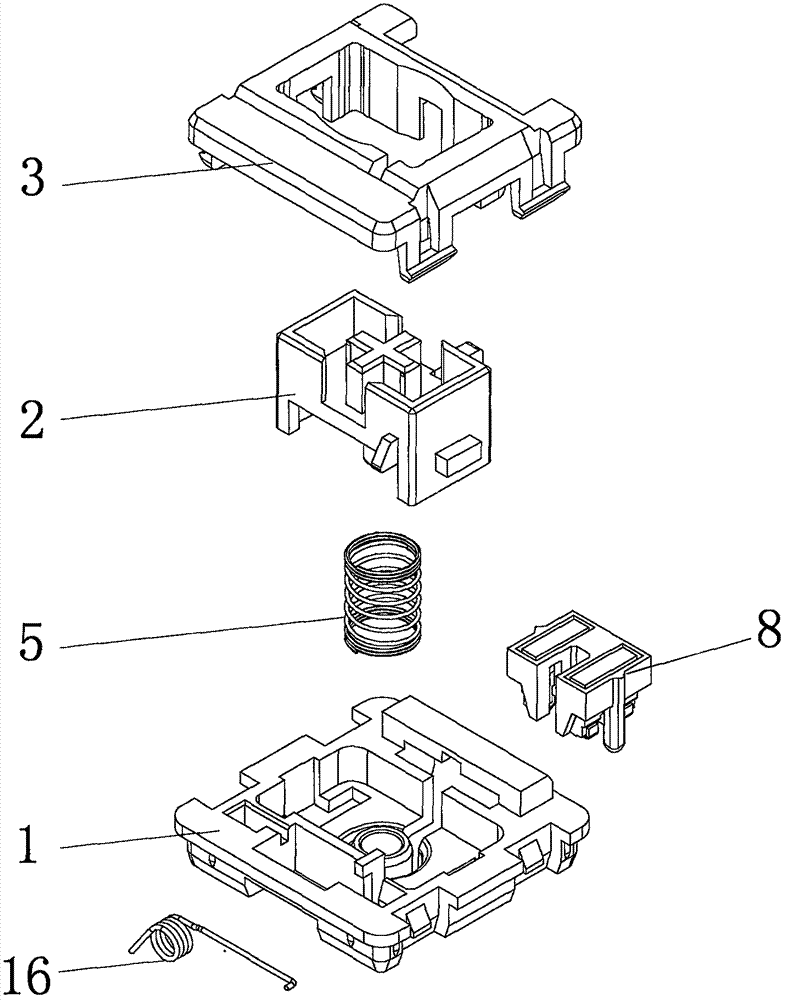

Square thin photoelectric mechanical keyboard switch

InactiveCN107464710AStable functionEasy to install and removeElectric switchesTactile feedbackEngineeringFriction force

The invention discloses a square thin photoelectric mechanical keyboard switch which comprises a base, a central spindle and an upper cover, wherein a first mounting seat is arranged in the middle of the upper surface of the base; a spring is arranged on the outer side of the upper end of the first mounting seat; guide rails are arranged at positions, which are positioned on two sides of the first mounting seat, of the base; a first groove is formed in the position, which is positioned on one side of the first mounting seat, of the base; a photoelectric switch module is arranged on the outer side, which is positioned at the lower end of one side of the first groove, of the base; a second groove is formed in one side, which is close to the base, of the photoelectric switch module; the central spindle is arranged just above the base; a second mounting seat is arranged in the middle of the lower end of the central spindle; the lower end of the second mounting seat is connected with the upper end of the spring; a fixing block is arranged on the outer side of the central spindle; an infrared information partition plate is arranged on one side of the outer part of the central spindle; the upper cover is arranged above the central spindle; and a square through hole is formed in the middle of the upper cover. The square thin photoelectric mechanical keyboard switch disclosed by the invention is simple in structure, low in friction force and long in service life.

Owner:DONGGUAN GAOTE ELECTRONICS

Laminate flooring edge groove forming device

InactiveCN107599084AAchieve fixationGuaranteed straightnessWood mortising machinesMetal working apparatusThree-phaseEngineering

The invention discloses a laminate flooring edge groove forming device. The laminate flooring edge groove forming device comprises a base, vertical pillars, a sliding table, air cylinder holding platforms, compressing mechanisms, a sliding seat, a servo motor, a three-phase asynchronous alternate-current motor and a working platform. The lower ends of the vertical pillars are connected with the base, and the top ends of the vertical pillars are connected with the working platform. First connecting sleeves are arranged at the lower end of the sliding table and connected with the middles of thevertical pillars in a locking mode. A rack is arranged on the lateral surface of the sliding table. Second connecting sleeves are arranged at the lower ends of the air cylinder holding platforms. Thecompressing mechanisms are fixedly connected with the air cylinder holding platforms. Rolling wheels are arranged in the middle of the sliding seat, and the sliding seat is connected with the slidingtable through the rolling wheels. The servo motor is connected with the sliding seat. A gear is arranged on an output shaft of the servo motor and engaged with the rack. The three-phase asynchronous alternate-current motor is connected with the sliding seat, and a groove forming tool disc is arranged on an output shaft of the three-phase asynchronous alternate-current motor. Laminate flooring is fixed, a cutting tool moves and forms splicing edge grooves, and the straightness of the splicing edge grooves is guaranteed, so that the uniformity of splicing quality is guaranteed.

Owner:芜湖易迅生产力促进中心有限责任公司

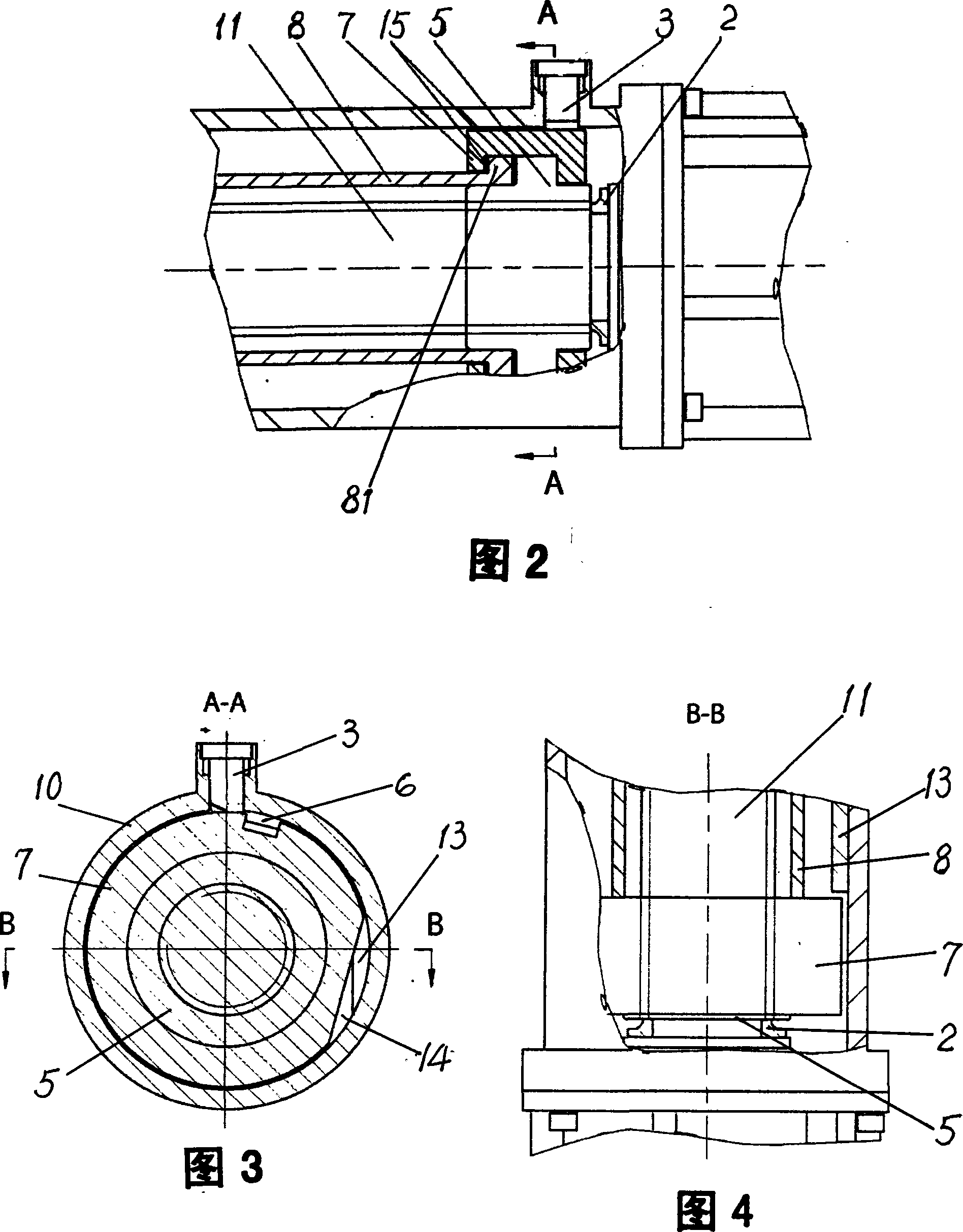

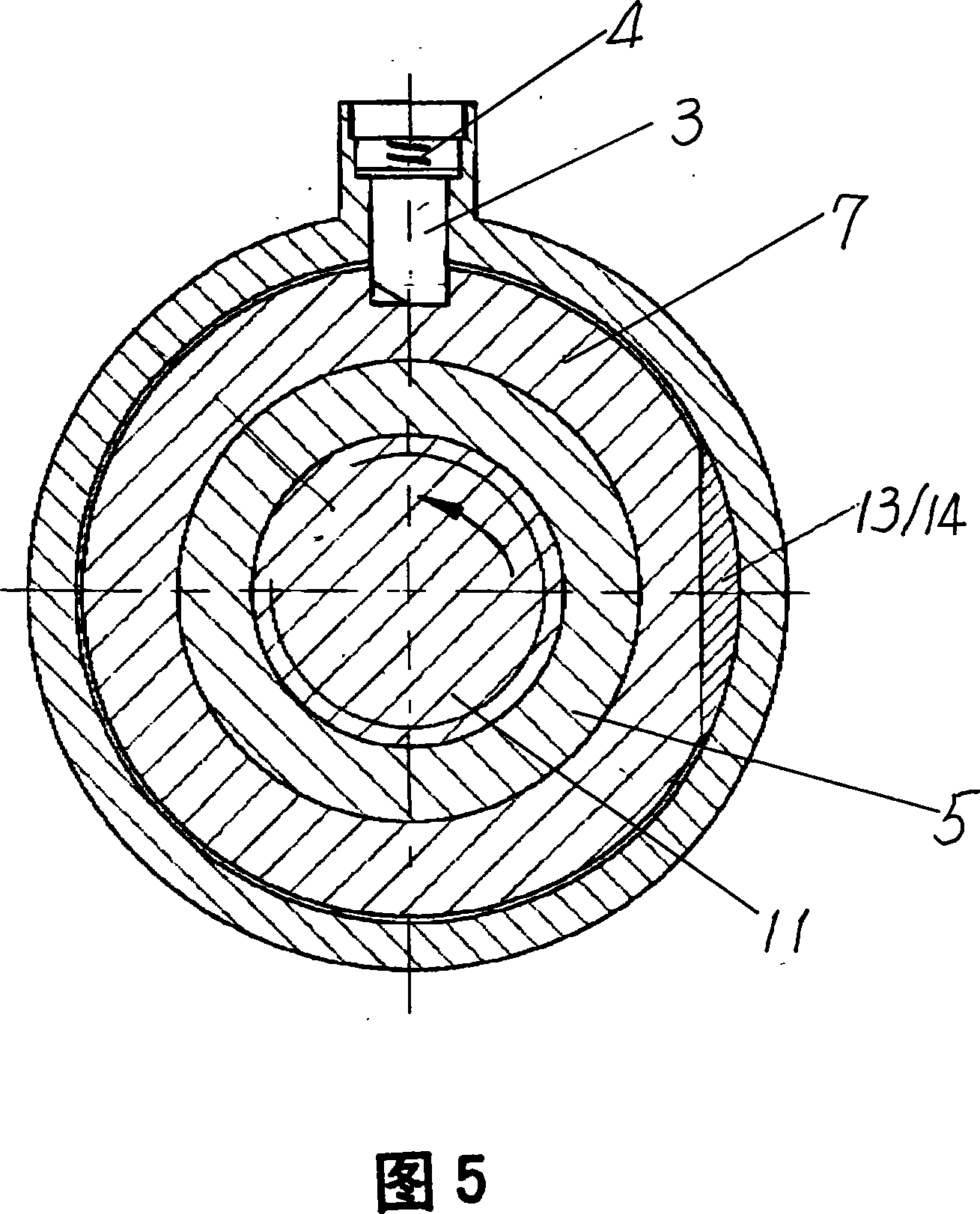

Overflow valve

The invention discloses an overflow valve, wherein the tail end of a valve bush is provided with a first arrangement cavity; the inner wall of the first arrangement cavity is provided with an internal thread; a flow hole is communicated with the first arrangement cavity; the front part of a valve body is matched with the first arrangement cavity; an external thread is arranged on the circumference of the front part of the valve body; the valve body is also provided with a flow hole along the axis; the front part of the valve body is provided with a second arrangement cavity; the front end of a stainless steel valve seat is pressed in the first arrangement cavity of the valve bush to close the flow hole; the external diameter of the rear part of a stainless steel valve seat is equal to the internal diameter of the second arrangement cavity; a stainless steel spring is arranged between the rear part of the stainless steel valve seat and the bottom of the second arrangement cavity; the circumferential wall of the front part of the stainless steel valve seat is provided with a vertical first circular hole; and the rear end face of the stainless steel valve seat is provided with a second circular hole, which is communicated with the first circular hole, along the axis. The overflow valve has the advantages that the stainless steel valve seat does not deflect during movement, rectilinear motion can be guaranteed and the flow hole of the valve bush can be completely closed by the stainless steel valve seat after pressure in a system falls back.

Owner:PINGHU RUIYANG PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com