Pneumatic brake cylinder and brake clamp unit

A pneumatic braking and cylinder head technology, applied in the field of rail transit, can solve the problems of increased volume of the brake caliper unit, limited space for braking air pressure, and no braking force amplifying mechanism. The effect of small force, volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

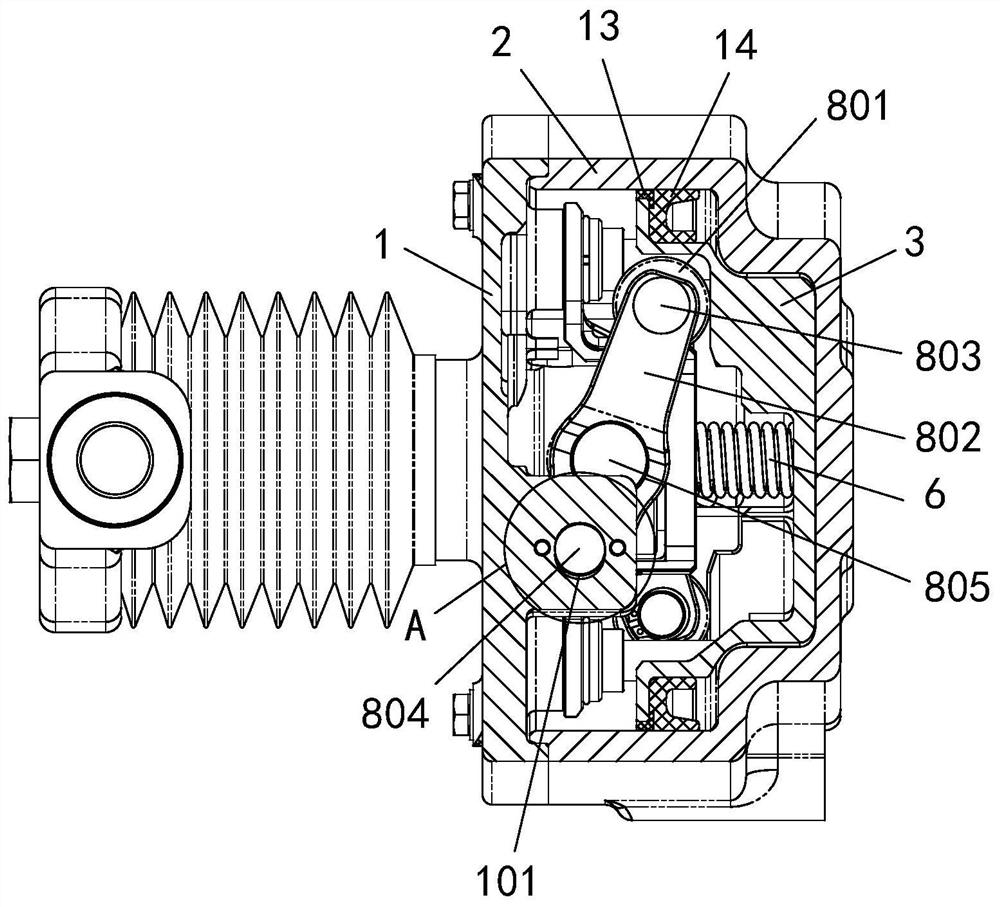

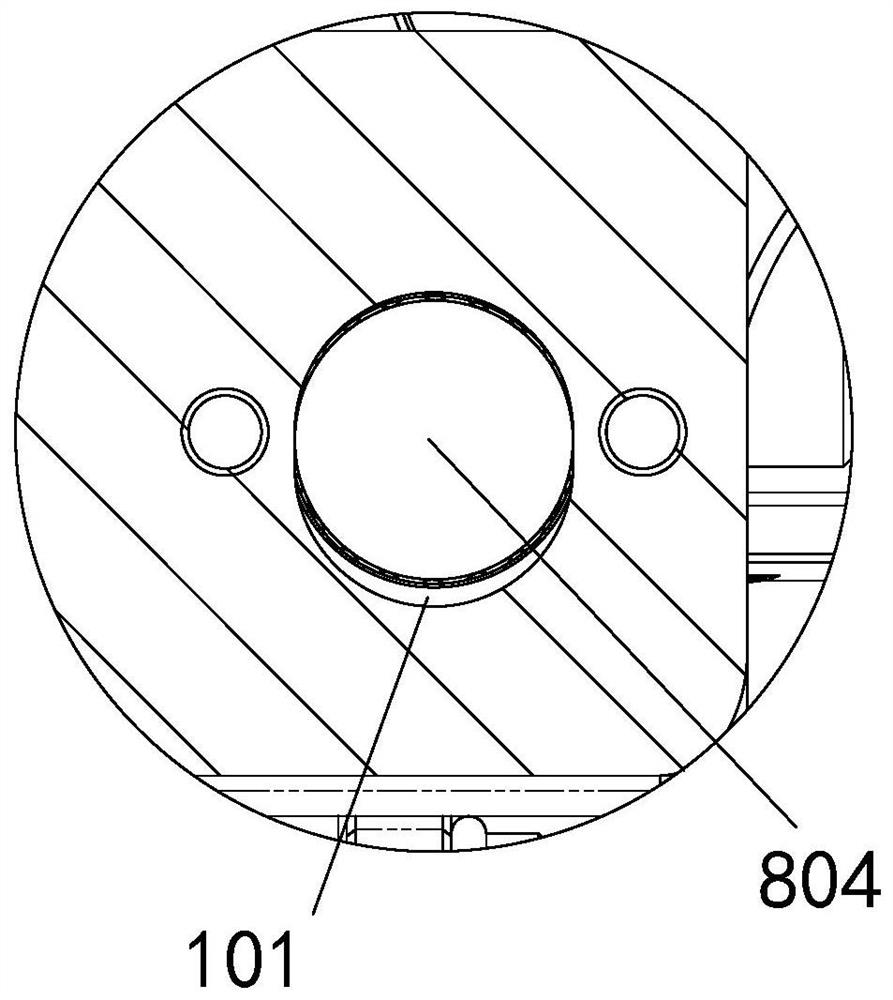

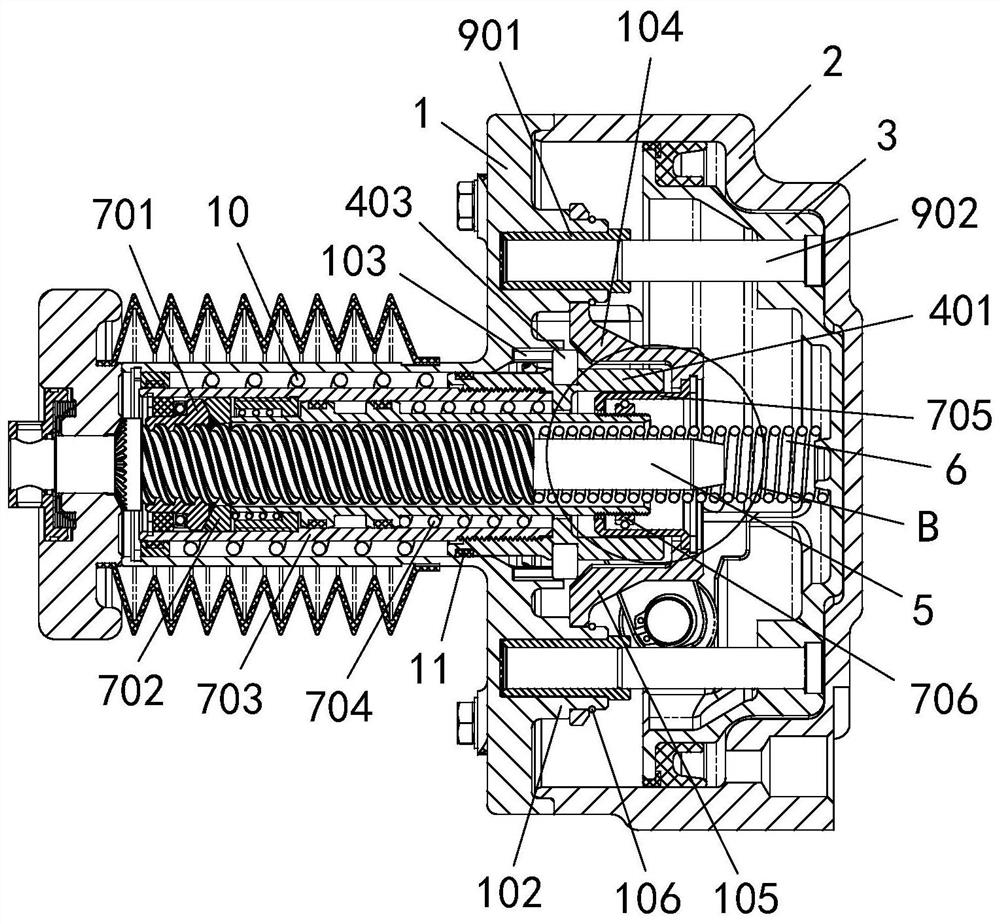

[0067] Embodiment 1: see figure 1 , image 3 , Figure 6 , a pneumatic brake cylinder, comprising:

[0068] cylinder head 1;

[0069] The rear cover 2 is connected with the cylinder head 1 and forms a sealed cavity with the cylinder head 1;

[0070] The piston 3 is located in the sealed chamber;

[0071] The pushing part assembly is arranged in the sealed cavity and is slidably connected with the cylinder head 1;

[0072] Lead screw 5 is sleeved in the push part assembly;

[0073] Adjust the spring 6, one end is pressed on the piston, and the other end is pressed on the lead screw;

[0074] The gap adjustment mechanism is located between the pusher component and the lead screw 5;

[0075] Two amplifying mechanisms are arranged symmetrically around the circumference, and the amplifying mechanisms include:

[0076] Bearing 801 abuts against piston 3;

[0077] One end of the lever 802 is pivotally connected to the bearing 801, the other end is pivotally connected to the ...

Embodiment 2

[0112] Example 2: see Figure 10 , the present embodiment provides a brake caliper unit, including a caliper arm assembly 15 and a pneumatic brake cylinder 16, the pneumatic brake cylinder 16 is hinged to the caliper arm of the caliper arm assembly 15 through a connecting bolt 17, the The pneumatic brake cylinder 16 adopts the pneumatic brake cylinder described in Embodiment 1. Wherein, the clamp arm acts as a force transmission lever, and the braking output force of the pneumatic brake cylinder 16 is transmitted to the brake pad holder 18 through the clamp arm.

[0113] The brake caliper unit described in this embodiment adopts the pneumatic brake cylinder described in the embodiment, which not only has a high braking ratio, but also reduces the volume of the brake caliper unit, and the installation space is small.

[0114] In this embodiment, the brake caliper unit is installed on the bogie frame of the rail transit vehicle, and the brake disc is held tightly by the brake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com