Multicolour screen printing machine

A technology for screen printing machines and racks, which is applied to screen printing machines, printing machines, rotary printing machines, etc., and can solve problems such as low repeat positioning accuracy, ratio limitation, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

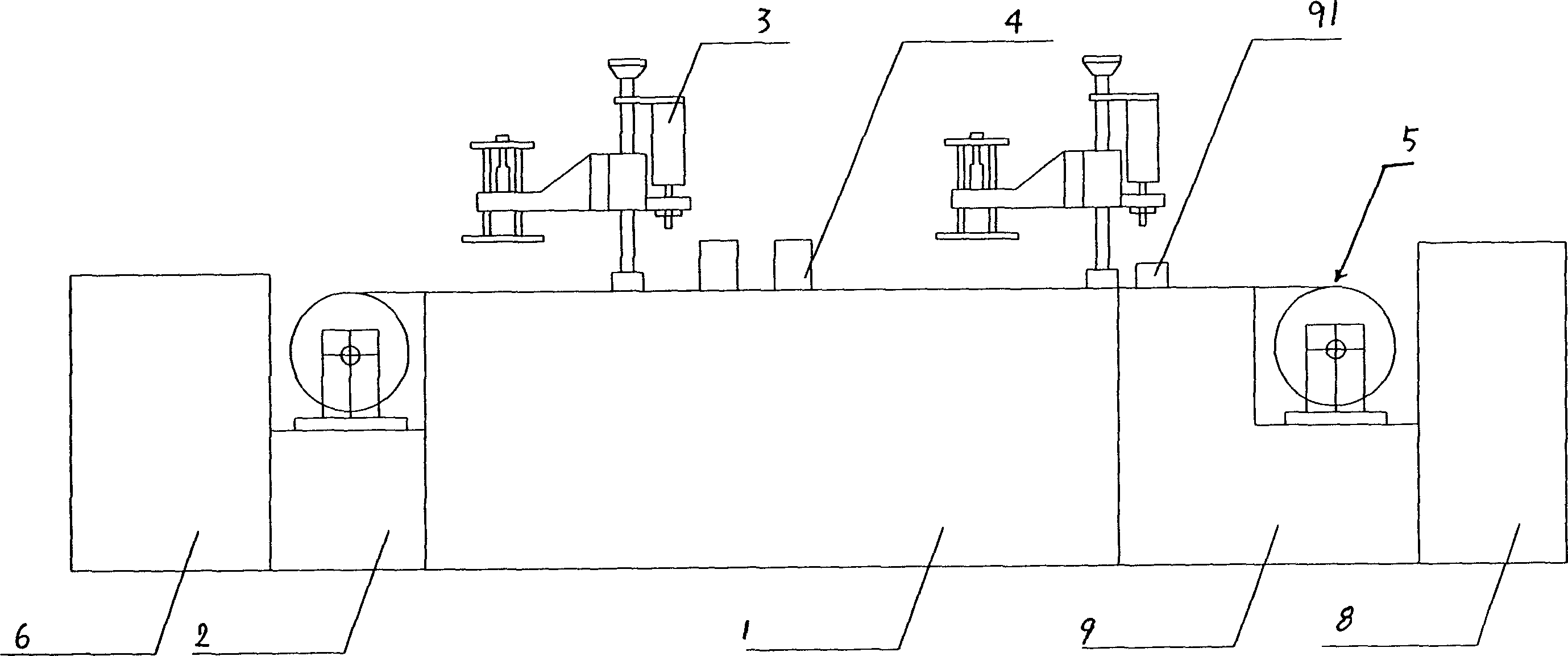

[0017] Such as figure 1 Shown is the overall overview of the multi-color automatic screen printing machine of the present invention; on the frame 1 of the multi-color automatic printing machine, a printing substrate 8, a positioning device 91, and two printing heads 3 are arranged, placed on two printing machines. Intermediate drying device 4, drive device 2, conveying device 5 and final drying device 6 between the heads. Of course, for the convenience of processing and transportation, the frame 1 can also be divided into multiple parts, and each part is installed with the above-mentioned devices in sequence, and then the various devices are connected in series. Or directly fixed to the place of use as needed.

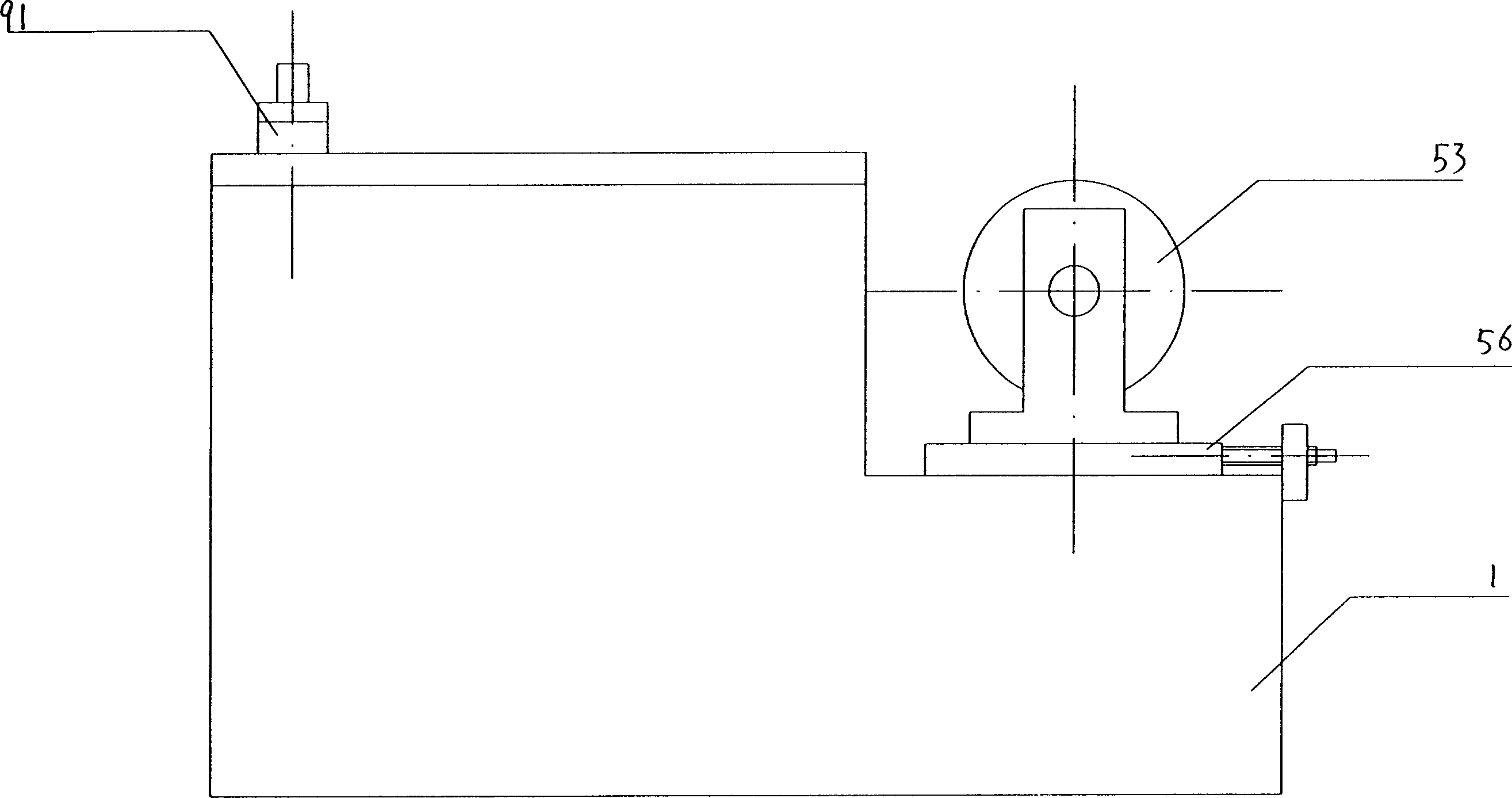

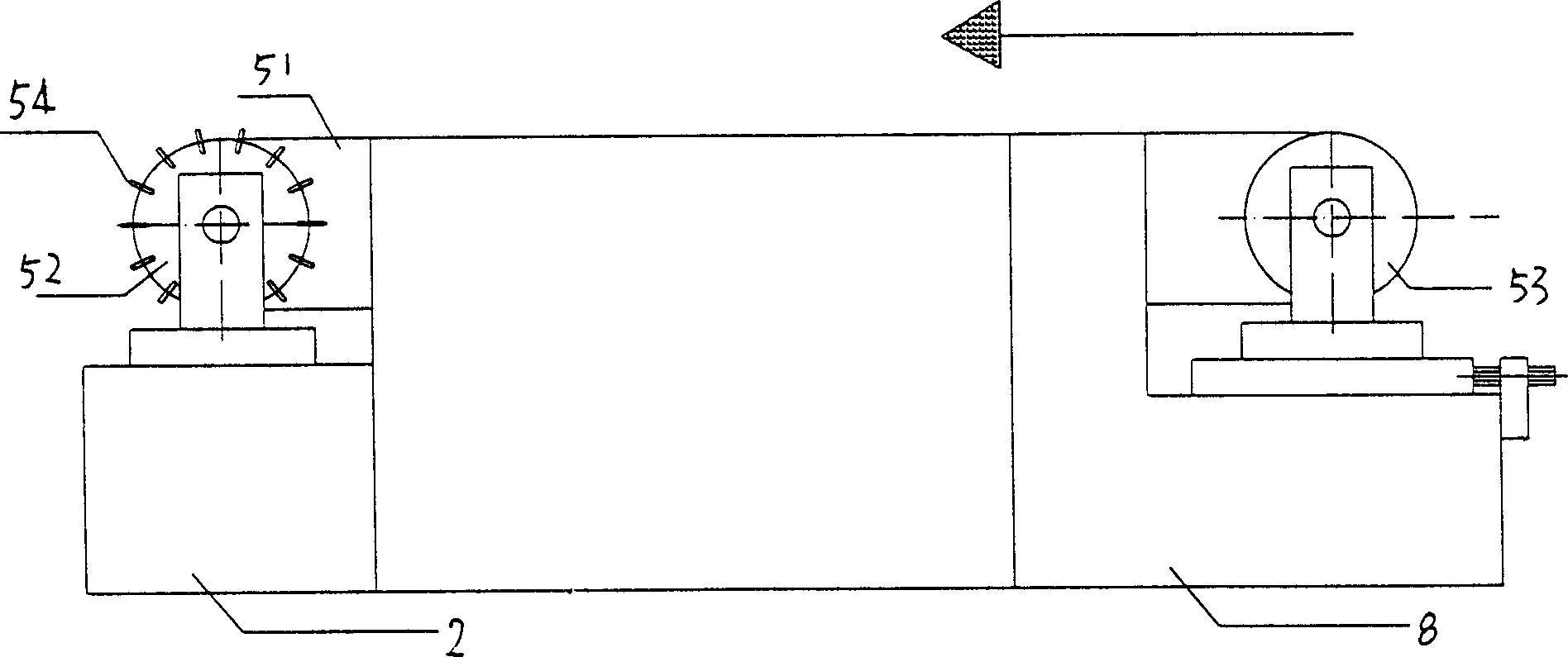

[0018] Such as Figure 6 Shown is the cross-sectional view of the printing frame of the multi-color screen printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com