Swing type high-temperature friction and wear test device

A friction and wear test, a technology of friction and wear, applied in the direction of measuring devices, using mechanical devices, testing wear resistance, etc., can solve the problems of high temperature loading temperature and low loading rate, and achieve easy connection, accuracy assurance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

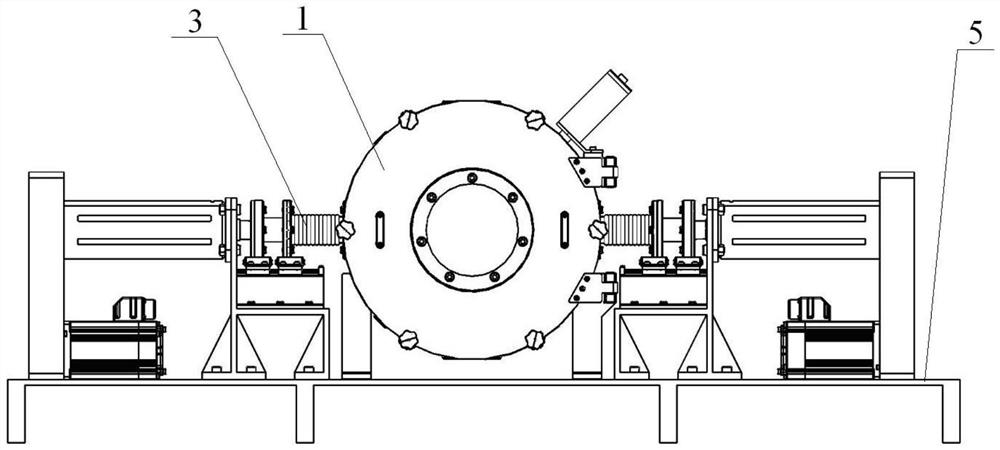

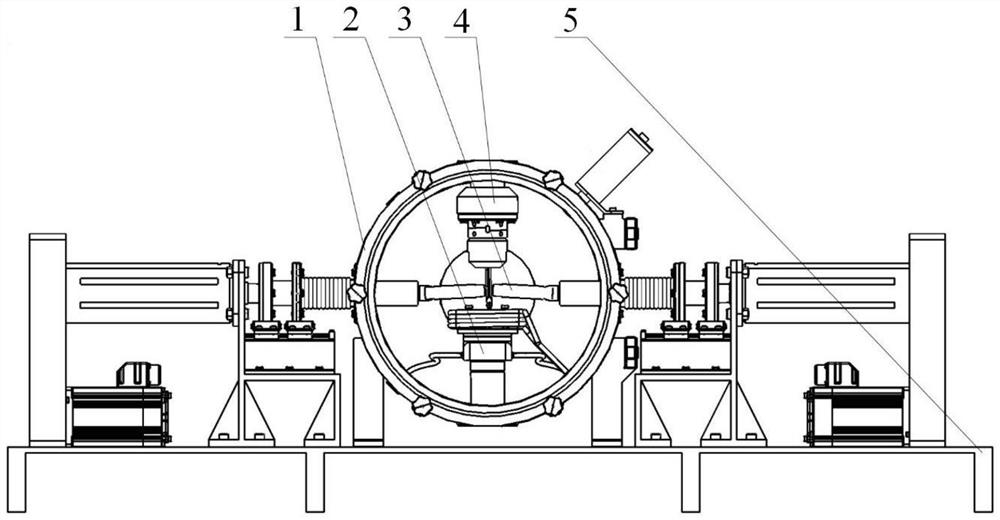

[0027] see figure 1 , 2 , including a vacuum chamber 1, a high temperature loading module 2, a driving module 3, a friction and wear module 4 and a frame 5, wherein the vacuum chamber 1 and the driving module 3 are respectively fixedly connected to the top of the frame 5, and the driving module 3 is connected from both sides Through the vacuum chamber 1, the top of the friction and wear module 4 is installed inside the vacuum chamber 1, the swing rod 407 at the lower end is hinged with the connecting rod 310 of the drive module 3 arranged symmetrically on both sides, and the bottom of the high-temperature loading module 2 is fixed on the vacuum chamber by bolts. The interior of the cavity 1 is located below the friction and wear module 4 .

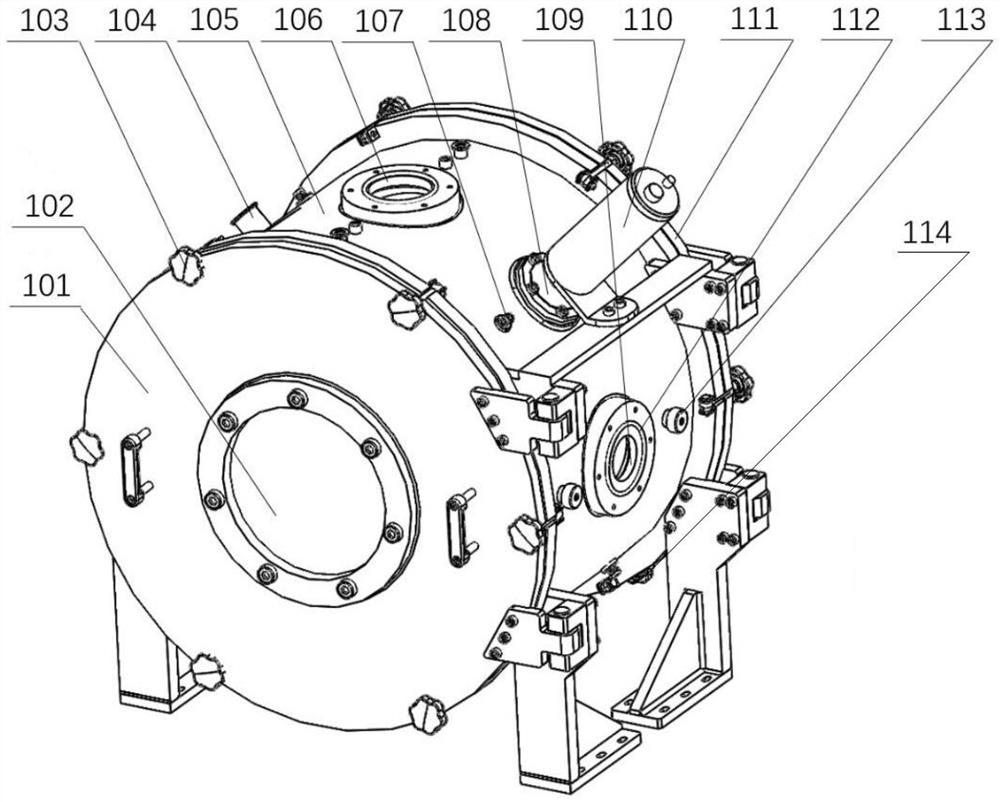

[0028] see image 3The vacuum cavity 1 of the present invention includes a cavity front door 101, a front and rear cavity observation window 102, a tightening handle 103, a vacuum interface 104, a cavity body 105, a friction and wear mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com