Y-shaped double-side-roller push and pull chain

A technology of pushing zippers and rollers, applied in the directions of belts/chains/gears, chain elements, transmission chains, etc., can solve the problems of easy damage to the screw nut, service life, application obstacles in compact space, and inability to meet cost performance, and achieve assembly adjustment. Convenience, compact structure, convenient assembly and disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

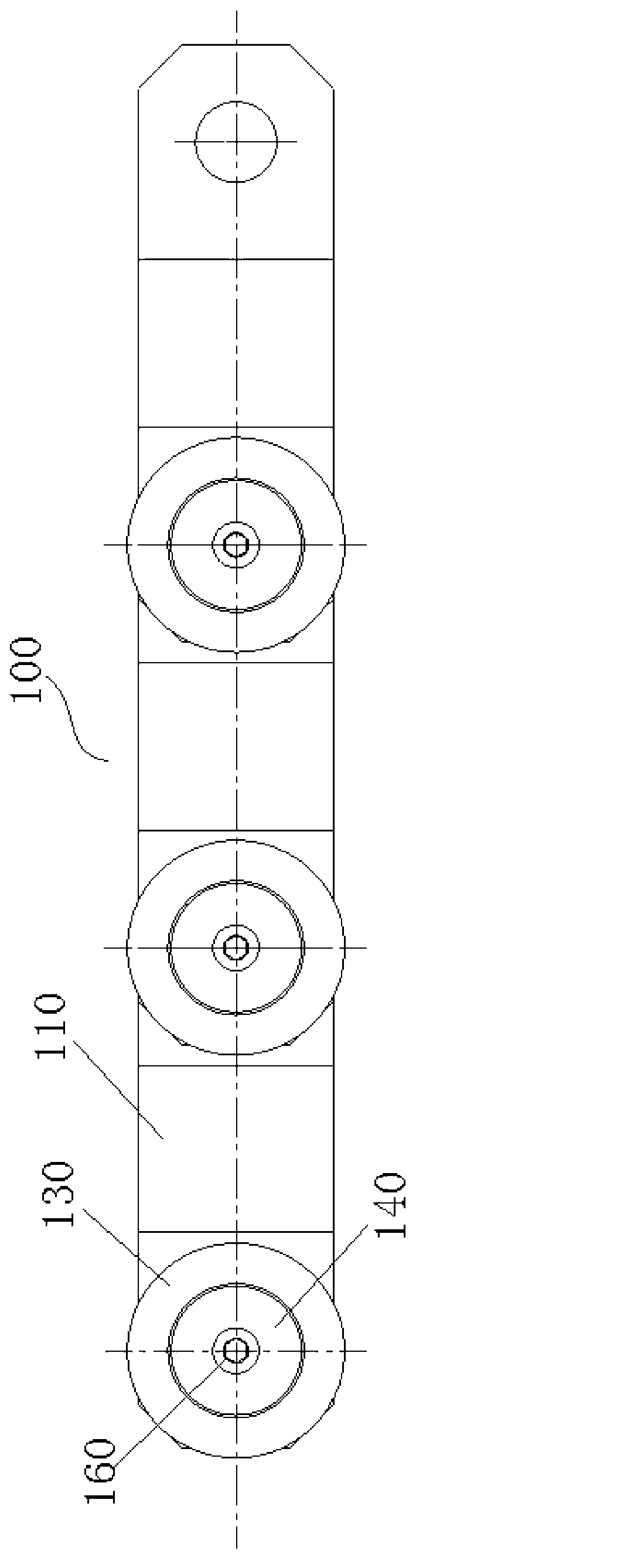

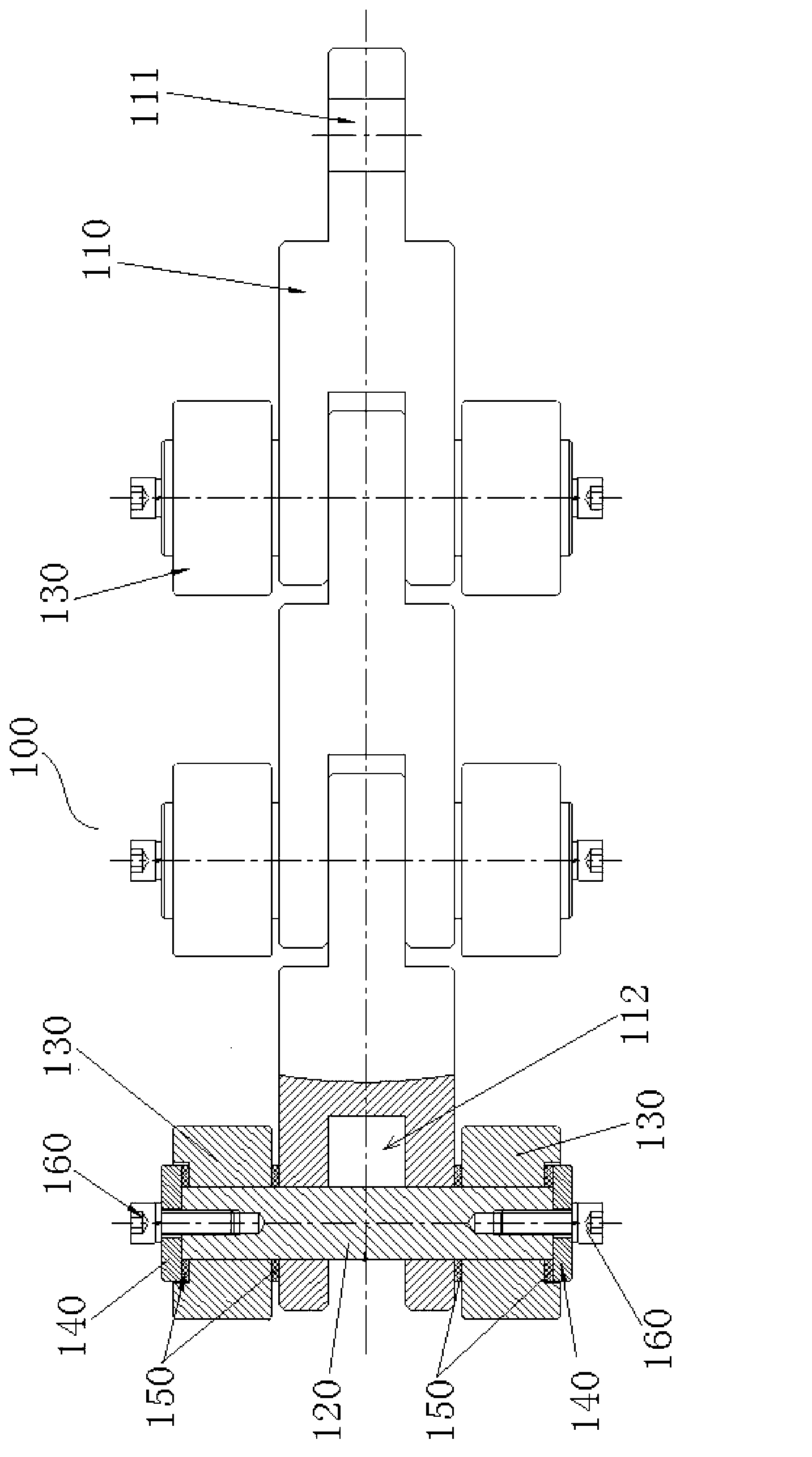

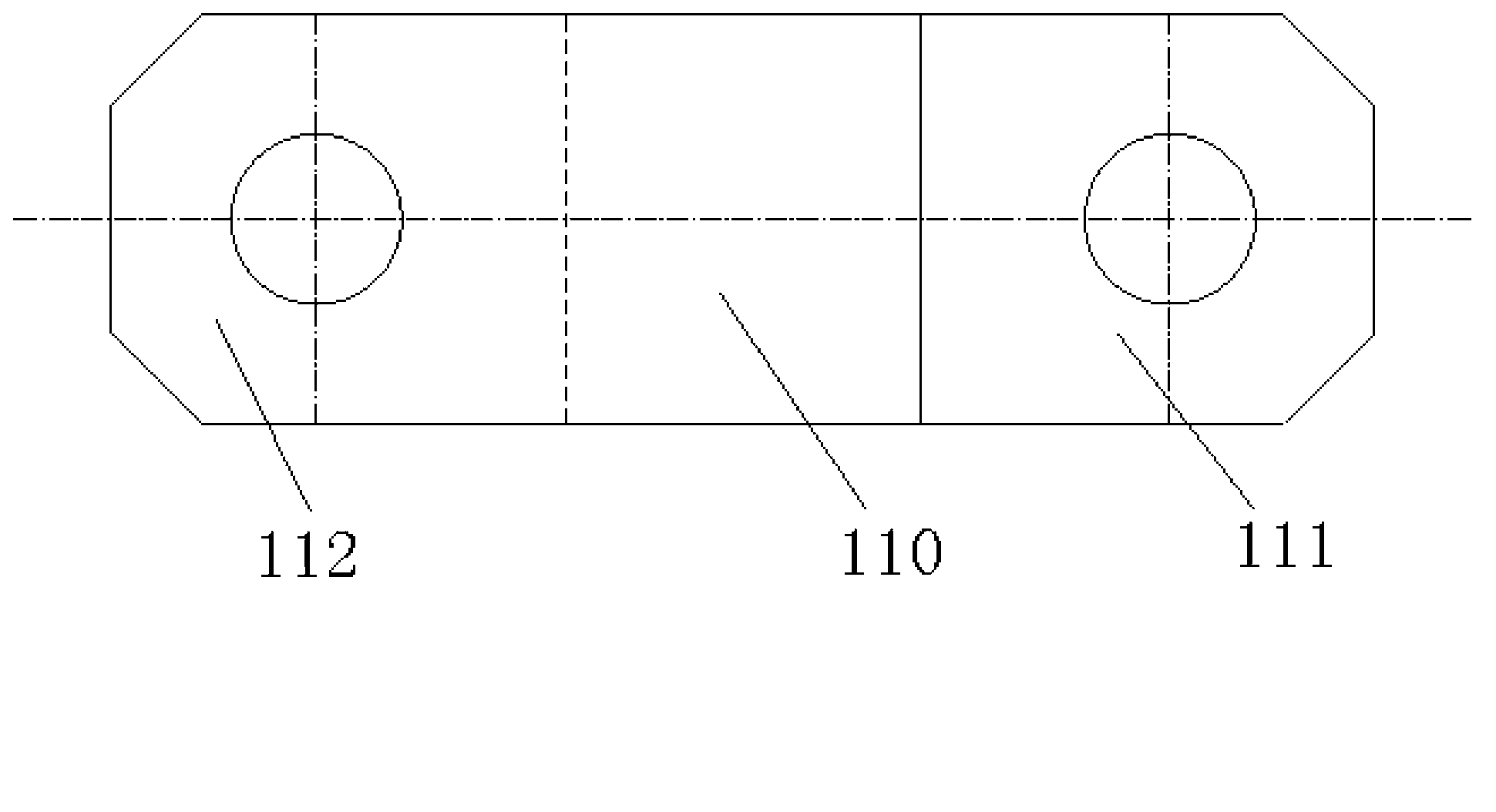

[0032] figure 1 The front view of the Y-shaped double-sided roller push zipper strip of Example 1, figure 2 It is a top view of the Y-shaped double-sided roller push fastener chain of Example 1. Such as figure 1 with figure 2 As shown, the Y-shaped double-sided roller push zipper strip 100 proposed in this embodiment includes several image 3 with Figure 4 In the Y-shaped structure of the chain link 110 shown, one end of the chain link 110 is a convex end 111 and the other end is a concave end 112. The adjacent chain links 110 are connected in series by the convex end 111 and the concave end 112 to form a whole. Such as figure 2 As shown, the male end 111 is inserted into the female end 112, and a center pin 120 is inserted through each of the male and female ends 111 and 112 that engage with each other for connection and fixation. The center pin 120 protrudes from two of the chain links 110. Each end is provided with a roller 130 for guiding and motion support.

[0033] Such...

Embodiment 2

[0038] Figure 7 It is a top view of the Y-shaped double-sided roller push fastener chain of the second embodiment. Such as Figure 7 As shown, the second embodiment is similar to the first embodiment above in structure, except that the roller 130 is a combined bearing structure, and the combined bearing structure includes a needle roller bearing 131 and a bearing roller 132, and the needle roller bearing 131 is sleeved on The center pin 120 protrudes from the end of the chain link 110, and the bearing roller 132 is sleeved on the needle bearing 131, which can realize operation with lower friction resistance, smoother work, and higher running speed. Exemplary, such as Figure 7 As shown, a baffle 140 for fixing the combined bearing structure is provided on each end surface of the center pin 120. The baffle 140 is fixed on the end surface of the center pin 120 by a screw 160. The screws 160 sequentially press the baffle and the outer side. End bearing, combined bearing struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com