Hose cleaning robot

A technology for cleaning robots and hoses, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as difficult control, large number of drives, limited motion modes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

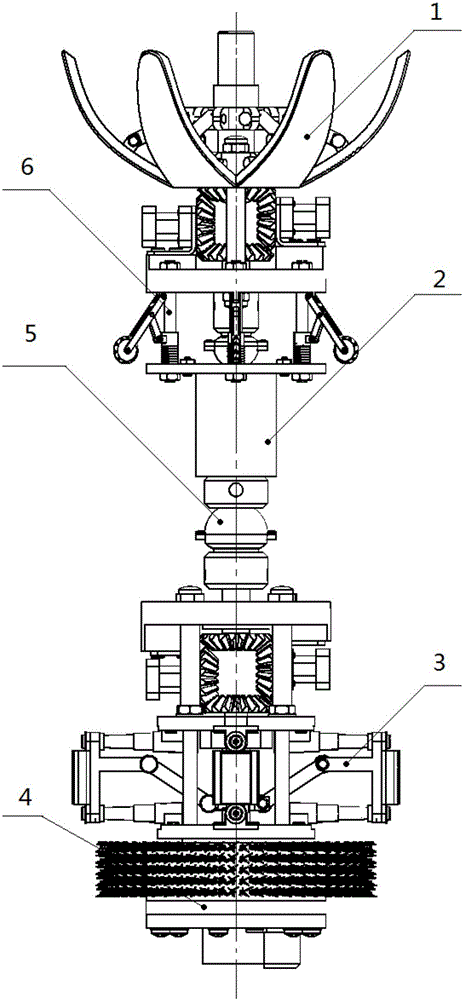

[0063] The invention realizes the functions of crawling and cleaning in the hose in any state, and mainly includes three parts: the upper fixing mechanism (1), the middle advancing mechanism (2) and the lower fixing mechanism (3), in addition to guide wheels Mechanism (6), universal joint mechanism (5), cleaning brush mechanism (4) functional parts.

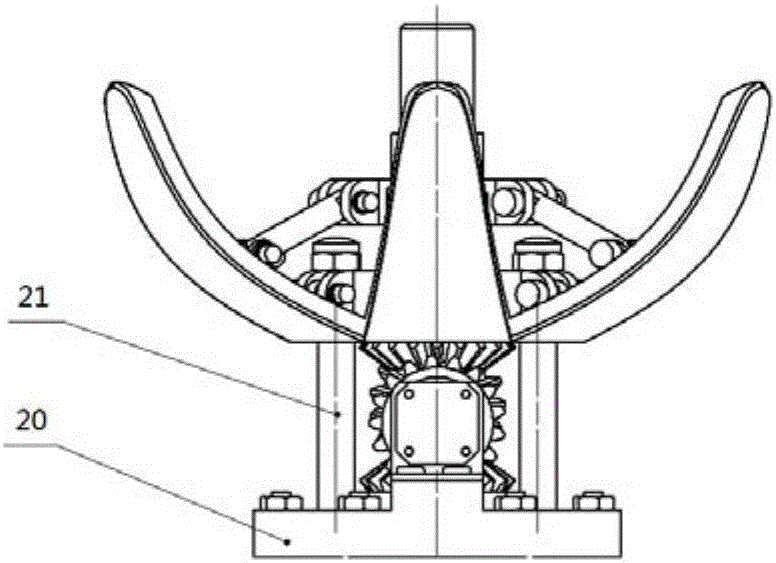

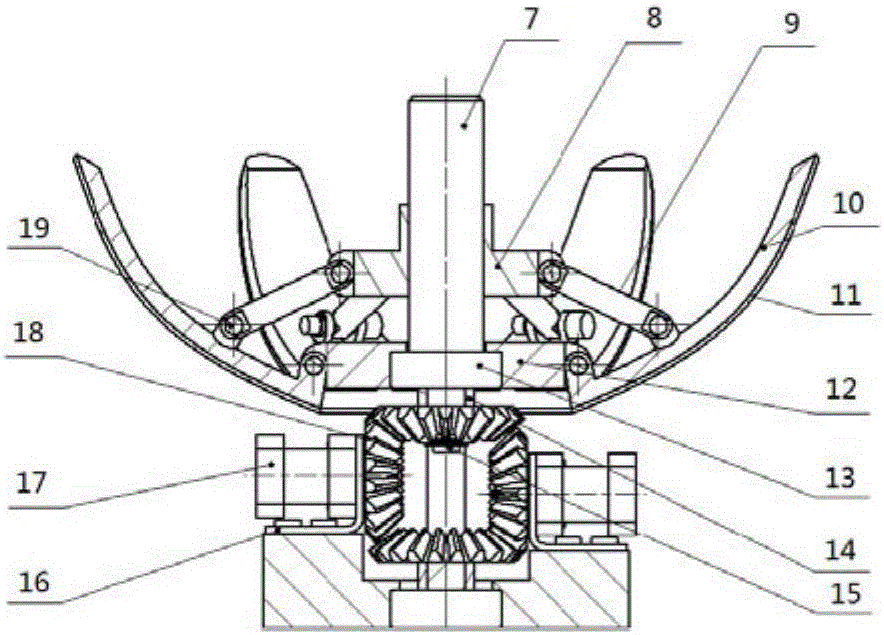

[0064] As shown in Figure 2, the upper fixing mechanism (1) includes an upper screw (7), an upper slider (8), an upper connecting rod (9), an upper support plate (10), an upper rubber pad (11), an upper bearing Seat (12), upper bearing (13), upper bearing cover (14), upper screw (15), upper motor seat (16), upper motor (17), upper bevel gear (18), upper fixed plate (20 ), the upper support column (21). The upper fixed plate (20) is connected with the upper bearing seat (12) through the upper support column (21), the upper motor (17) is fixed on the upper fixed plate (20) through the upper motor base (16), and the upper motor (17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com