United material taking system and method for material yard

A material yard and reclaimer technology, which is applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of limited output lines and single reclaiming methods, and achieve reduction in process links, multiple output lines, and reclaiming The effect of flexible material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

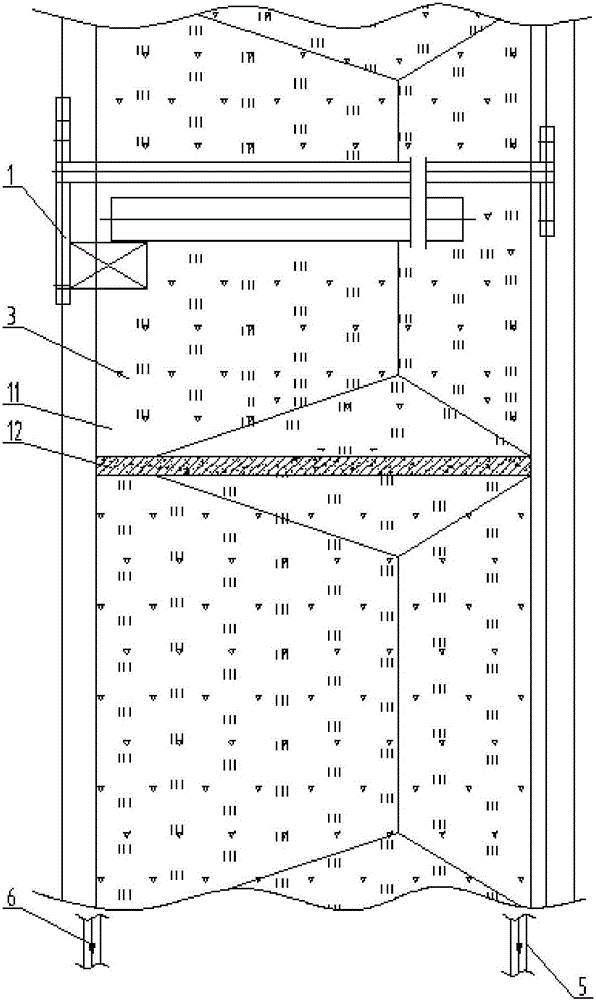

[0040] Wherein, the inner side and the outer side refer to the stockyard and the stockpile, and the inner side refers to the position near the retaining wall in the middle of the stockyard.

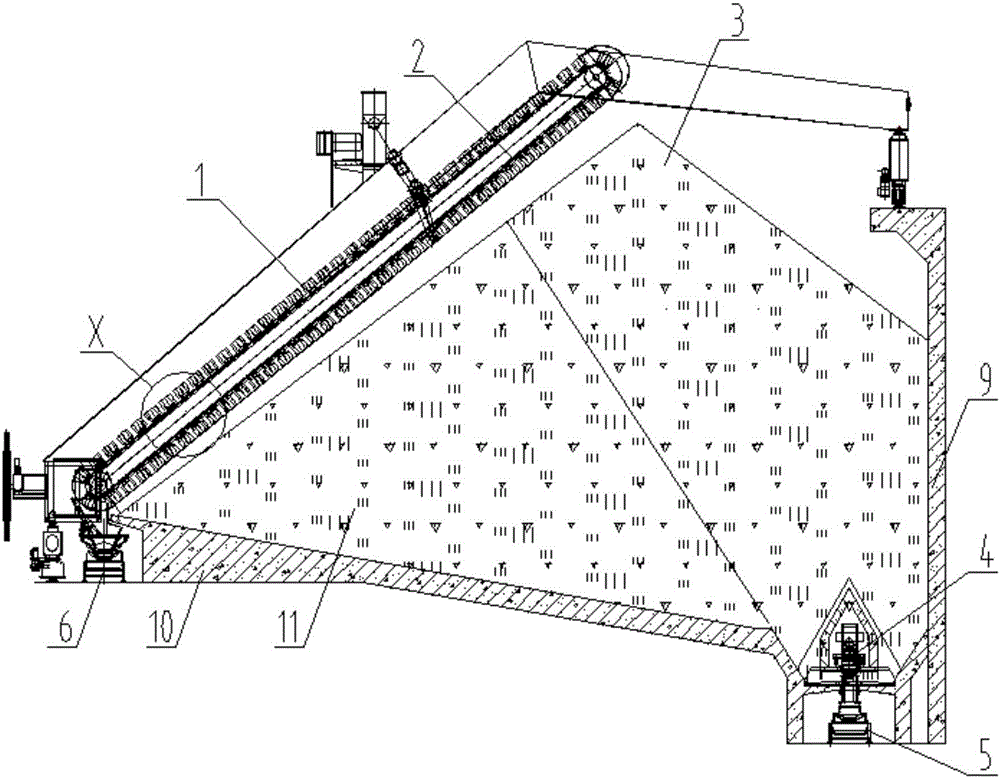

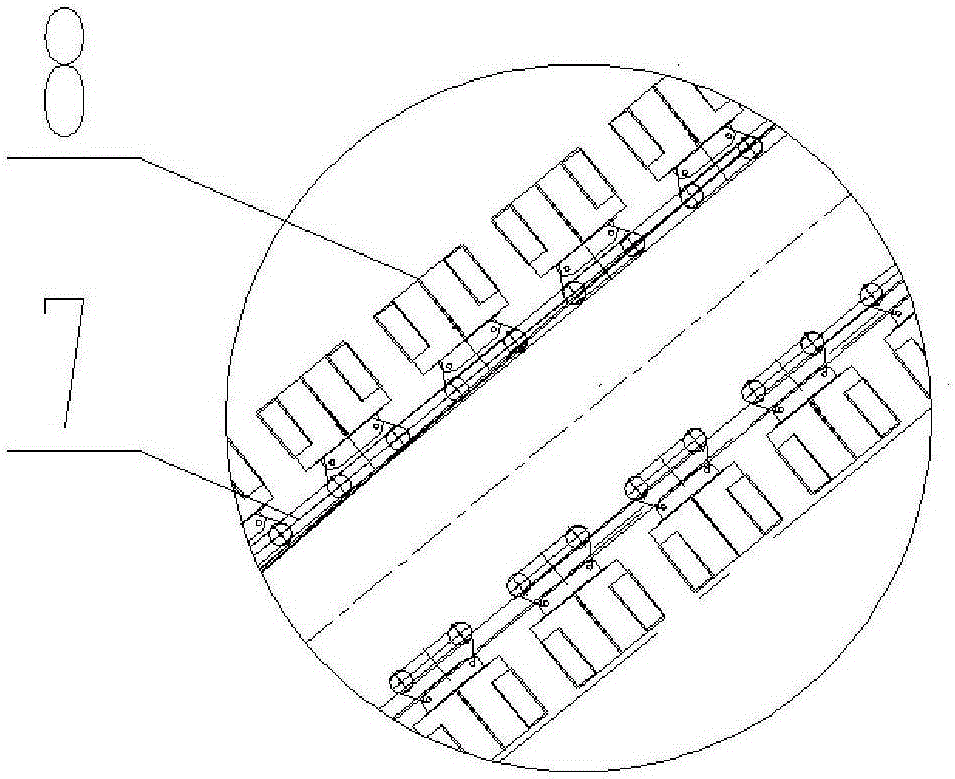

[0041] Such as Figure 1 to Figure 3 As shown, a material yard combined reclaiming system includes an outer output conveyor 6 and a scraper reclaimer 1. The scraper reclaimer 1 is provided with a scraper mechanism 2, wherein the outer output conveyor 6 is located outside the material pile 3, and It includes an inner feeder 4 and an inner output conveyor 5 arranged below the stock pile, and the inner output conveyor 5 is located below the inner feeder 4 ; preferably, the inner feeder 4 is arranged below the inner side of the stock pile 3 . Among them, the scraper mechanism 2 includes a chain 7 and a scraper 8 installed on the chain 7, and the chain 7 moves forward or reversely under the action of the driving device to drive the scraper 8 to push the material 3 to the corresponding discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com