Laminating machine capable of driving film discharging by rotary loading

A technology of rotary feeding and stacking machine, which is applied in the field of battery cell manufacturing and battery manufacturing equipment, can solve the problems of low production efficiency of equipment, high manufacturing cost of stacking machine, large inertia of moving parts, etc., and achieve low manufacturing cost , maintenance and repair is simple, the effect of small motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

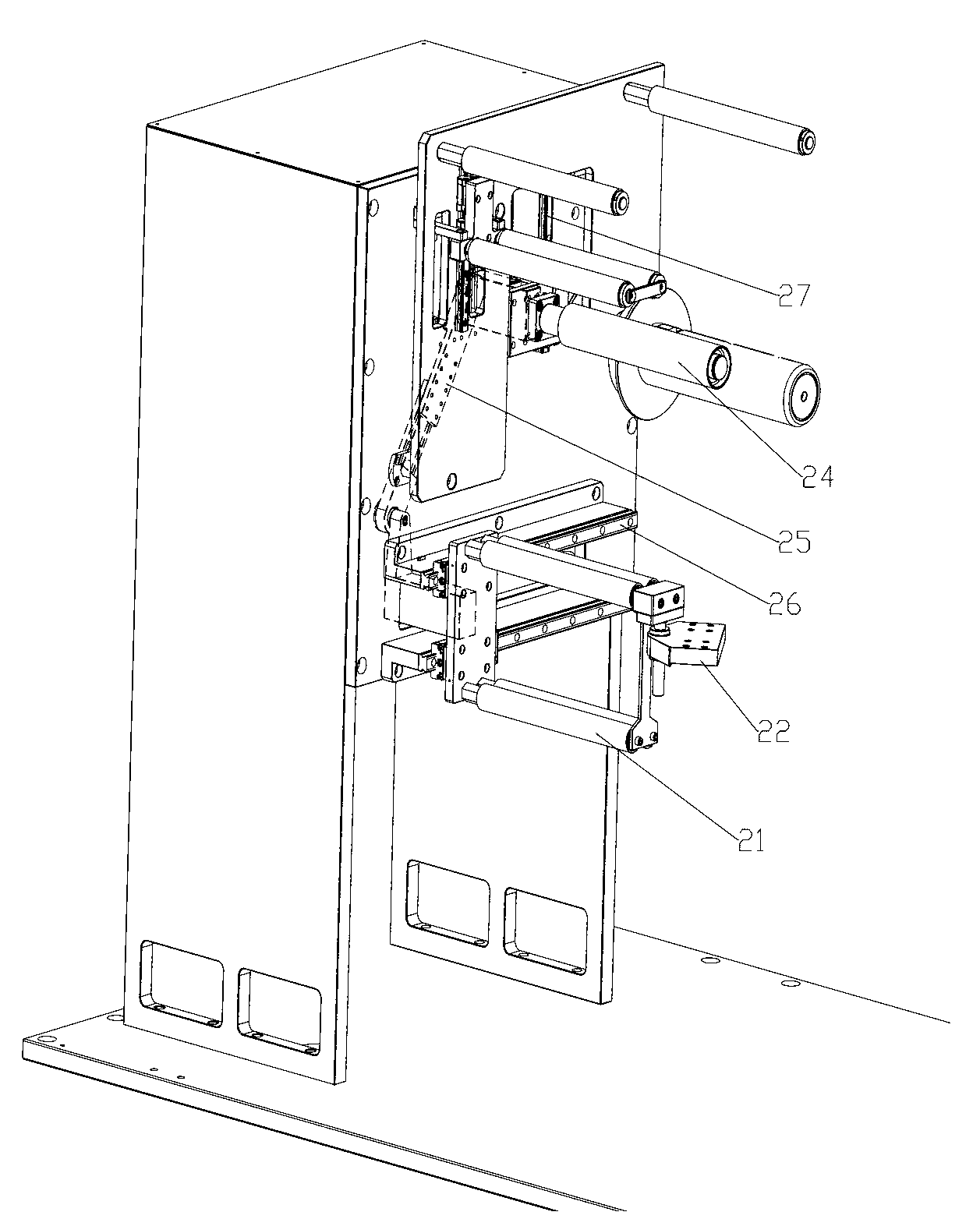

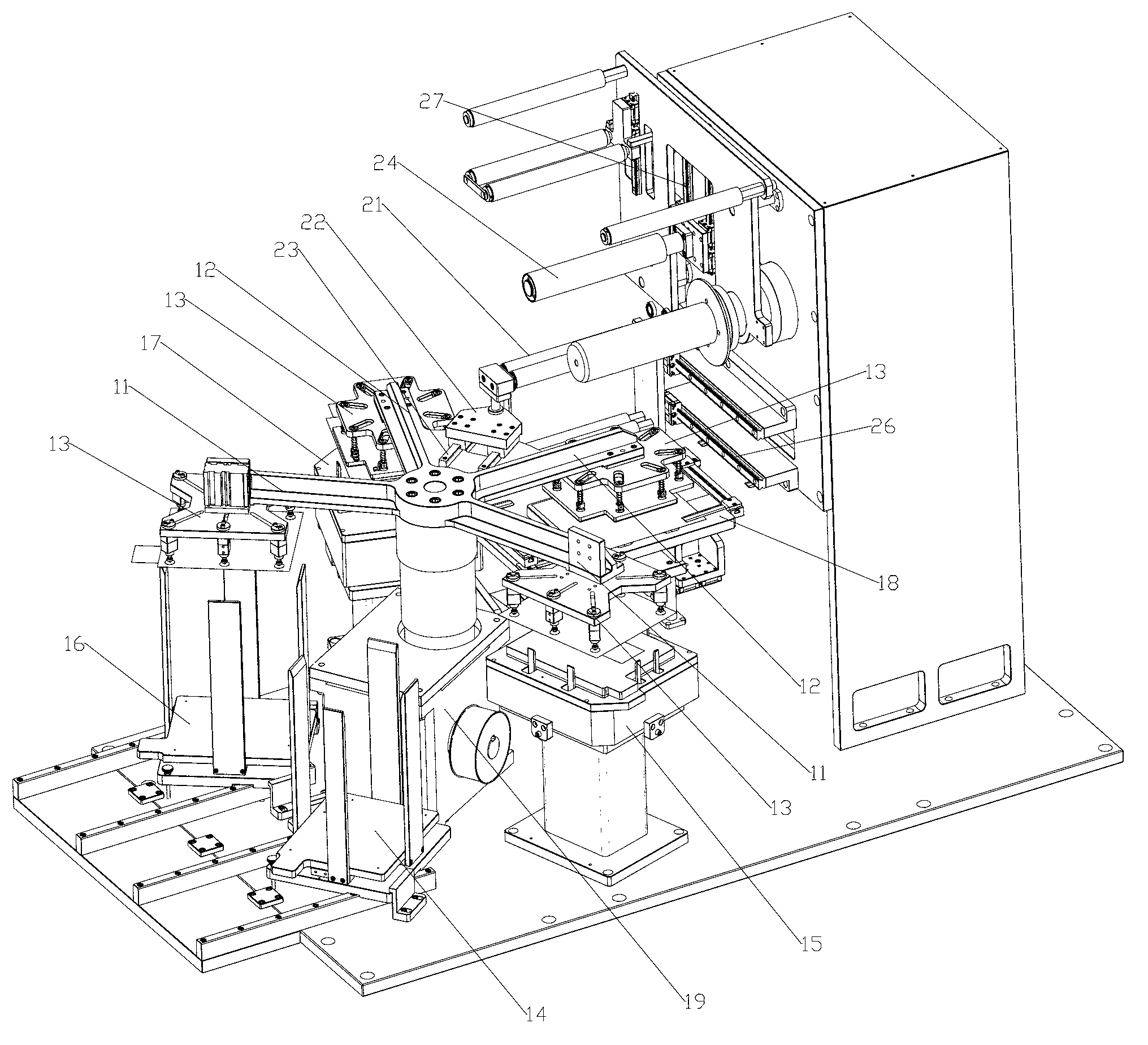

[0025] figure 1 It is a structural schematic diagram of an embodiment of a lamination machine in which rotating feeding drives film discharging according to the present invention, figure 2 It is a schematic diagram of the discharging mechanism of the stacking machine embodiment.

[0026] As shown in the figure, the lamination machine of the present invention, which drives film discharge by rotating feeding, includes a rotating feeding mechanism for transferring battery pole pieces. A cam splitter is used to drive the large turntable to rotate reciprocally. There are four feeding arms on the big turntable, among which the front feeding arm 11 with the two largest included angles is the rear feeding arm 12 with the smallest included angle. The big turntable is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com