Molding method of complicated two-side cavity structure with multilayer ceramics

A technology of multi-layer ceramics and molding method, applied in the field of multi-layer ceramics, can solve the problems of difficult positioning, inability to guarantee, easy deformation, etc., to improve lamination efficiency and cleanliness, ensure bonding strength and air tightness, and save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

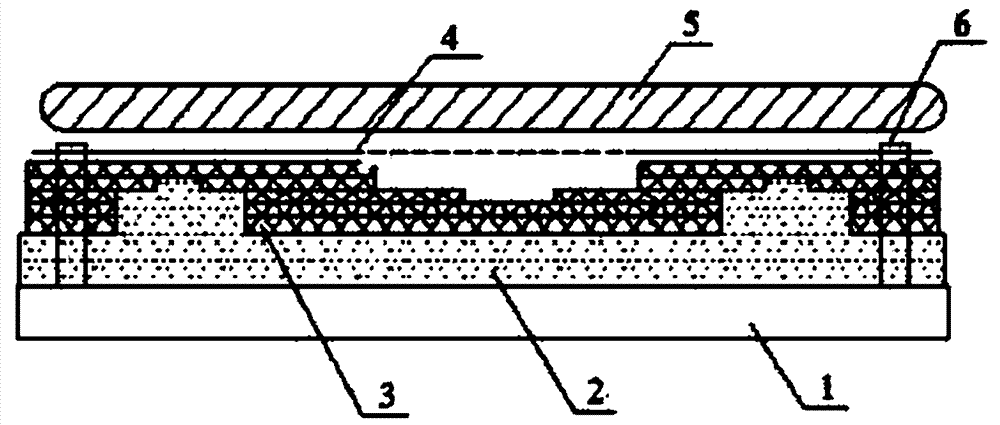

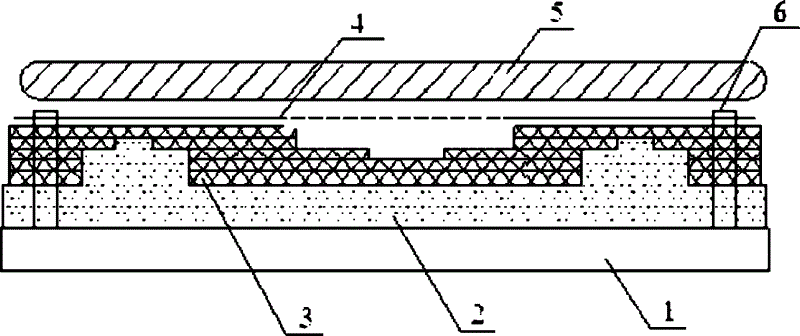

[0014] as attached figure 1 Shown, a kind of multilayer ceramic double-sided complex cavity structure molding method, it comprises the following steps:

[0015] First, prepare a silicone rubber plug punch that matches the bottom cavity of the multilayer ceramic, and set positioning holes around the silicone rubber plug punch, and the positioning hole passes through the positioning column 6 on the aluminum plate 1 so that the silicone rubber The plug punch is fixed on the aluminum plate 1; then a soft silicone pad 5 for filling is prepared, which is a soft rubber wrapped with a semi-fluid filler, which is made of liquid silicone A and B are mixed at a ratio of 2:1 to obtain a mixture, and then baked at 60-80°C for 1-2 hours to obtain a gel.

[0016] Then, through the process of punching, printing, and cavity opening, the tape-cast green ceramic sheet has positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com