Photovoltaic photo-thermal dual-curing POE packaging adhesive film and preparation method thereof

An encapsulating film and dual-curing technology, used in photovoltaic power generation, adhesives, film/sheet-like adhesives, etc. The effect of improved lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

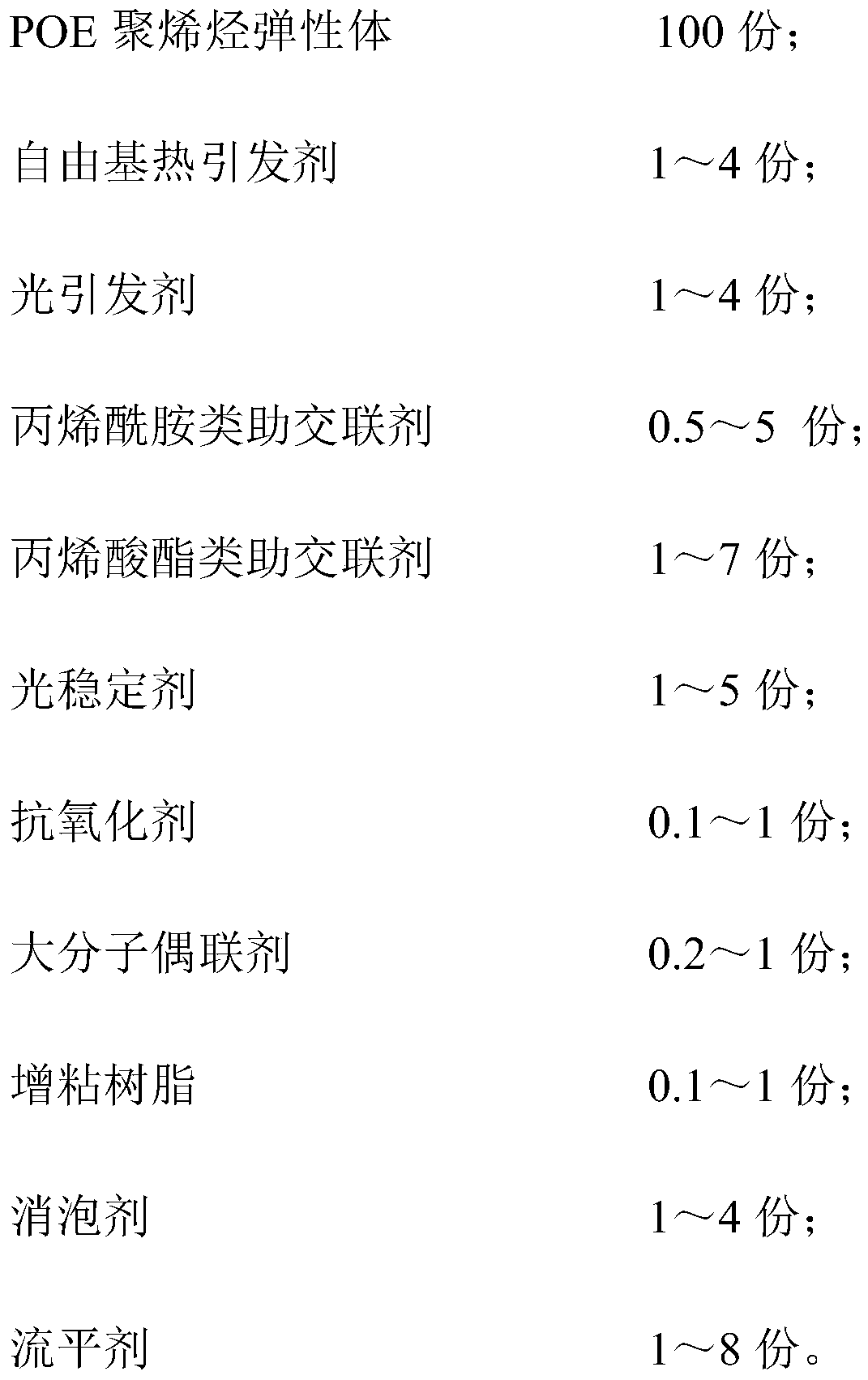

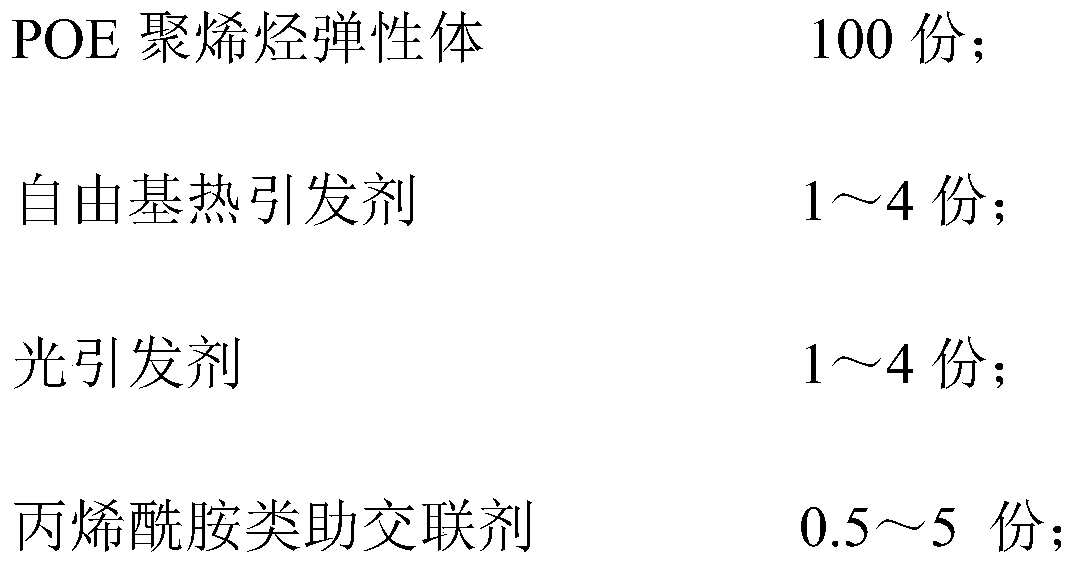

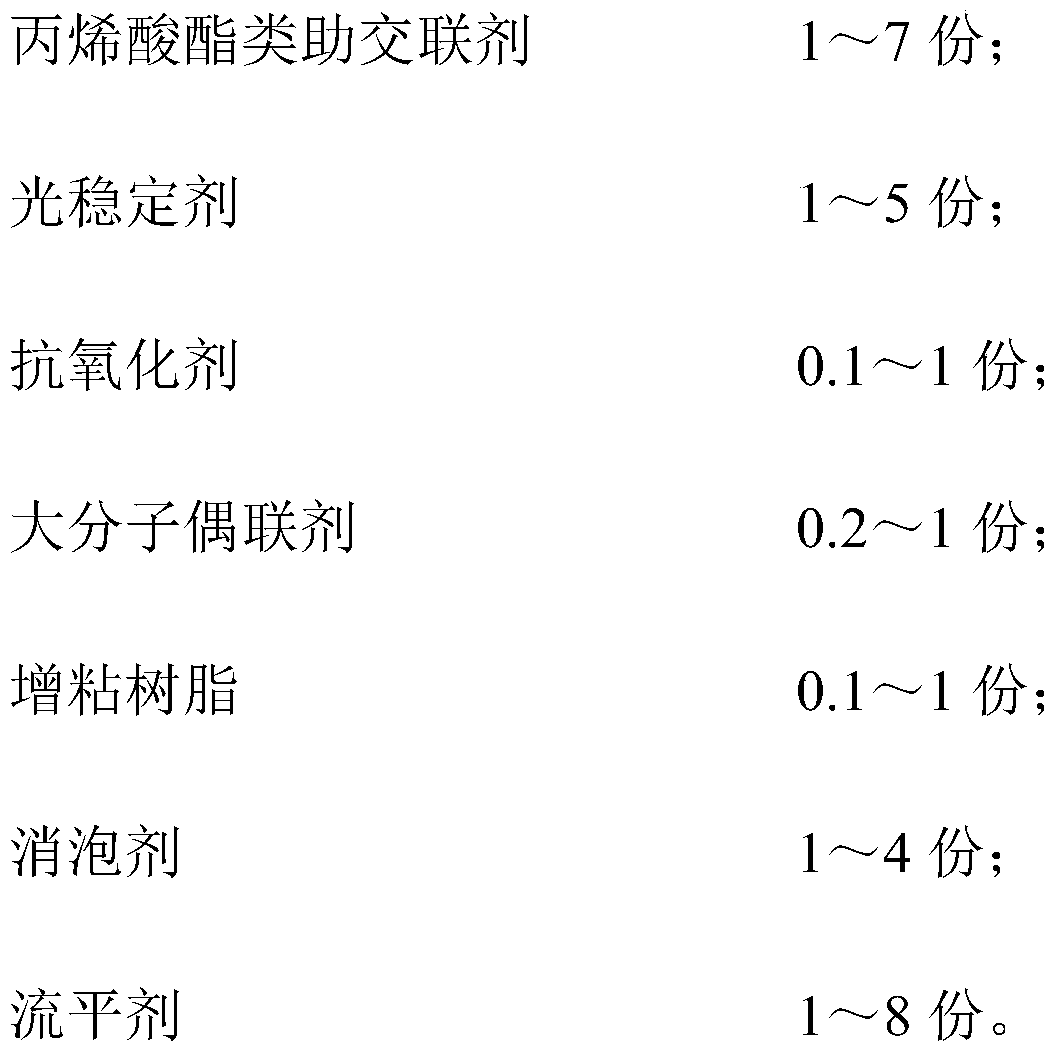

Method used

Image

Examples

Embodiment 1

[0058] Take 27 parts of 10-15g / 10min POE, 55 parts of 30-40g / 10min POE, stir and mix evenly, then take 18 parts of 3-5g / 10min POE particles, under the condition of temperature 60°C and stirring speed 20rpm, heating and mixing for 50min to form the first mixture;

[0059]Take 5 parts of acrylamide auxiliary crosslinking agent, 7 parts of acrylate auxiliary crosslinking agent, 1 part of macromolecular coupling agent and 1 part of tackifying resin, and add them into the first mixture at a speed of 60 g / min. Under the conditions of a temperature of 60° C. and a stirring speed of 20 rpm, heat and mix for 40 minutes to form a second mixture;

[0060] The second mixture is uniformly mixed and extruded by a twin-screw granulator, and the extrusion temperature is controlled at 100 ° C. The extruded product is cooled, drawn and pelletized to make a graft masterbatch;

[0061] Take 4 parts of free radical thermal initiator, 4 parts of photoinitiator, 5 parts of light stabilizer, 1 part ...

Embodiment 2

[0063] Take 33 parts of 10-15g / 10min POE, 45 parts of 30-40g / 10min POE, stir and mix evenly, then take 22 parts of 3-5g / 10min POE particles, under the condition of temperature 60°C and stirring speed 20rpm, heating and mixing for 60min to form the first mixture;

[0064] Take 2.5 parts of acrylamide auxiliary cross-linking agent, 7 parts of acrylate auxiliary cross-linking agent, 0.5 part of macromolecular coupling agent and 0.5 part of tackifying resin, and add them into the first mixture at a speed of 60 g / min. Under the conditions of a temperature of 50° C. and a stirring speed of 20 rpm, heat and mix for 40 minutes to form a second mixture;

[0065] The second mixture is uniformly mixed and extruded by a twin-screw granulator, and the extrusion temperature is controlled at 150 ° C. The extruded product is cooled, drawn and pelletized to make a graft masterbatch;

[0066] Take 2 parts of free radical thermal initiator, 2 parts of photoinitiator, 2.5 parts of light stabiliz...

Embodiment 3

[0068] Take 42 parts of 10-15g / 10min POE, 30 parts of 30-40g / 10min POE, stir and mix evenly, then take 28 parts of 3-5g / 10min POE particles, under the condition of temperature 60°C and stirring speed 30rpm, heating and mixing for 50min to form the first mixture;

[0069] Take 0.5 part of acrylamide auxiliary cross-linking agent, 1 part of acrylate auxiliary cross-linking agent, 0.2 part of macromolecular coupling agent and 0.1 part of tackifying resin and mix them into the first mixture at a speed of 60 g / min. Under the conditions of a temperature of 50° C. and a stirring speed of 20 rpm, heat and mix for 40 minutes to form a second mixture;

[0070] The second mixture is uniformly mixed and extruded by a twin-screw granulator, and the extrusion temperature is controlled at 200 ° C. The extruded product is cooled, drawn and pelletized to make a graft masterbatch;

[0071] Take 1 part of free radical thermal initiator, 1 part of photoinitiator, 2 parts of light stabilizer, 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com