Lithium ion battery and manufacturing method thereof

A lithium ion battery and a manufacturing method technology are applied in the field of lithium ion batteries and their manufacturing, which can solve the problems of high equipment cost and manufacturing cost, increase the probability of micro-short circuit, hidden danger of battery safety, etc., so as to improve the safety performance of the battery and reduce the micro-short circuit. Probability, the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

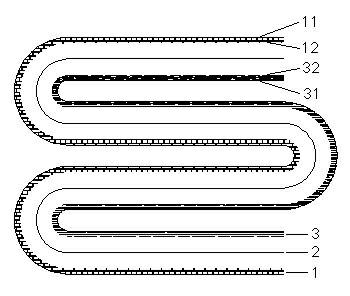

Embodiment 1

[0032] Such as figure 1 As shown, a lithium-ion battery includes a battery core, a casing, and an electrolyte. The battery core includes a first positive electrode sheet 1 , a first separator 2 and a first negative electrode sheet 3 . One side of the first positive electrode sheet 1 is coated with positive electrode material, and one side of the first negative electrode sheet is coated with negative electrode material. The first positive electrode sheet 1 , the first diaphragm 2 and the first negative electrode sheet 3 are sequentially stacked and folded repeatedly to form a continuous laminate. The first positive electrode sheet 1 , the first separator 2 and the first negative electrode sheet 3 can be repeatedly folded in a Z shape.

[0033] The manufacturing method of this embodiment is as follows: the positive electrode material 12 is coated on one side of the positive electrode foil 11 , and a metal strip is welded to make the first positive electrode sheet 1 . The nega...

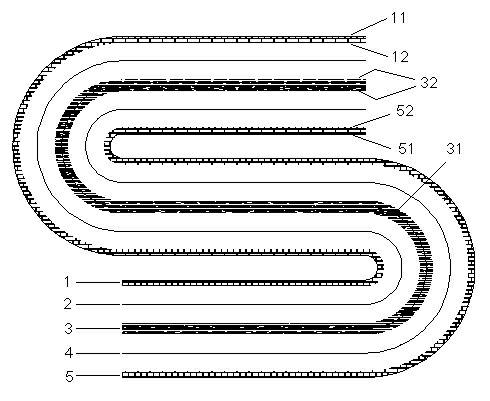

Embodiment 2

[0035] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the battery core further includes a second positive electrode sheet 5 and a second separator 4 . One side of the second positive electrode sheet 5 is coated with positive electrode material, and the other side of the first negative electrode sheet is also coated with negative electrode material. The second separator 4 , the second positive electrode sheet 5 , the first positive electrode sheet 1 , the first separator 2 and the first negative electrode sheet 3 are sequentially stacked and folded repeatedly to form a continuous laminate.

[0036] The manufacturing method of this embodiment is as follows: the positive electrode material 12 is coated on one side of the positive electrode foil 11 , and the tabs are left empty on the foil, and the first positive electrode sheet 1 with multiple tabs is formed by laser cutting. The positive electrode material 52 is coated on one side of...

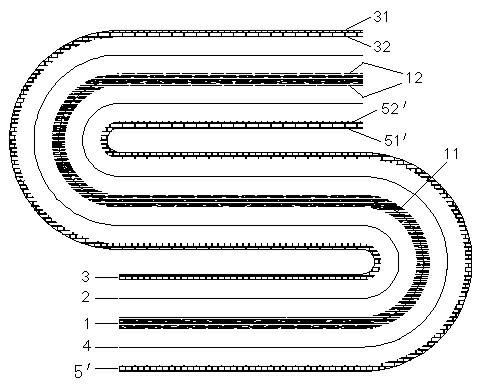

Embodiment 3

[0038] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the battery core further includes a second negative electrode sheet 5 ′ and a second separator 4 . One side of the second negative electrode sheet 5' is coated with negative electrode material, and the other side of the first positive electrode sheet 1 is also coated with positive electrode material. The second negative electrode sheet 5', the second separator 4, the first negative electrode sheet 3, the first separator 2 and the first positive electrode sheet 1 are sequentially stacked and folded repeatedly to form a continuous laminate.

[0039]The manufacturing method of this embodiment is as follows: the negative electrode material 32 is coated on one side of the negative electrode foil material 31 , the foil material is left with empty foils for tabs, and the first negative electrode sheet 3 with multiple tabs is formed by laser cutting. The negative electrode material 52' i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com