Laminating device used for identifying labels and operation method of laminating device

A technology of laminating device and signs, applied in the field of sign sign processing, can solve the problems of high labor intensity for operators, easy damage to the surface of sign signs, and low quality of film, so as to improve film efficiency, avoid damage, and improve film cover. Effect of Membrane Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

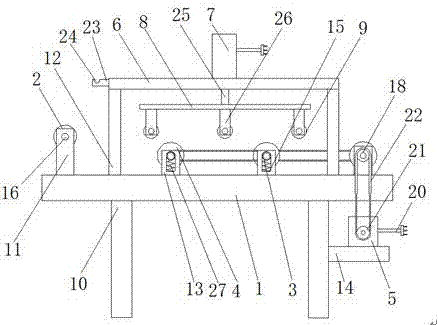

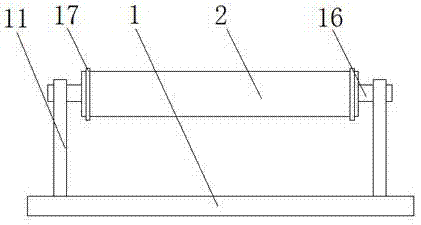

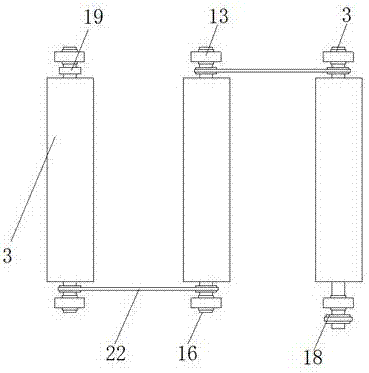

[0028] as attached Figure 1-4 As shown, a film laminating device for marking signs includes an operation table 1, a guide roller 2, a shaft sleeve 3, a drive roller 4, a motor 5, a top plate 6, a cylinder 7, an adjustment plate 8 and a pressure roller 9, and its characteristics In that: the console 1 is set on the support 10, and the console 1 is provided with a fixed plate 11, a column 12, a vertical plate 13, the support 10 is provided with a bearing plate 14, the vertical plate 13 is provided with a limit groove 15, the guide roller 2 is arranged between the fixed plate 11 and the fixed plate 11 through the connecting shaft 16, the shaft sleeve 3 is arranged in the limit groove 15, and the transmission roller 4 Both ends are provided with connecting shaft 16, the connecting shaft 16 is arranged in the axle sleeve 3, and the driving wheel 18 and the driven wheel 19 are arranged on the connecting shaft 16 of the drive roller 4, and the described motor 5 is arranged on the be...

Embodiment 2

[0043] as attached Figure 5 As shown, a film laminating device for marking signs includes an operation table 1, a guide roller 2, a shaft sleeve 3, a drive roller 4, a motor 5, a top plate 6, a cylinder 7, an adjustment plate 8 and a pressure roller 9, and its characteristics In that: the console 1 is set on the support 10, and the console 1 is provided with a fixed plate 11, a column 12, a vertical plate 13, the support 10 is provided with a bearing plate 14, the vertical plate 13 is provided with a limit groove 15, the guide roller 2 is arranged between the fixed plate 11 and the fixed plate 11 through the connecting shaft 16, the shaft sleeve 3 is arranged in the limit groove 15, and the transmission roller 4 Both ends are provided with connecting shaft 16, the connecting shaft 16 is arranged in the axle sleeve 3, and the driving wheel 18 and the driven wheel 19 are arranged on the connecting shaft 16 of the drive roller 4, and the described motor 5 is arranged on the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com