Constant tension diaphragm discharging device

A technology of unwinding device and constant tension, which is applied in the direction of thin material handling, transportation and packaging, and winding strips, etc. It can solve the problems of difficulty in ensuring accuracy, inability to increase lamination speed, and low production efficiency, so as to improve quality and Accuracy, diaphragm tension stability, and the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

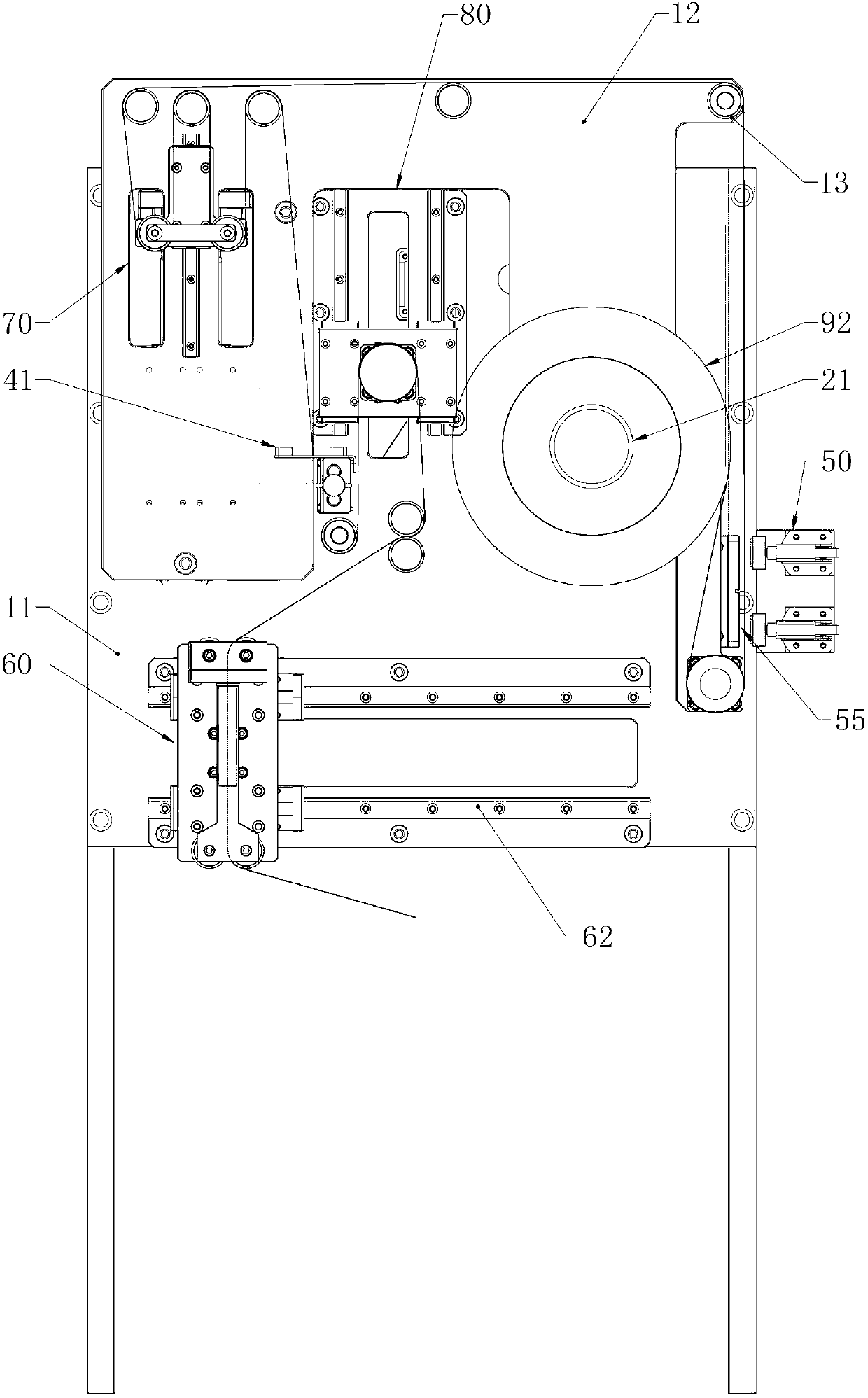

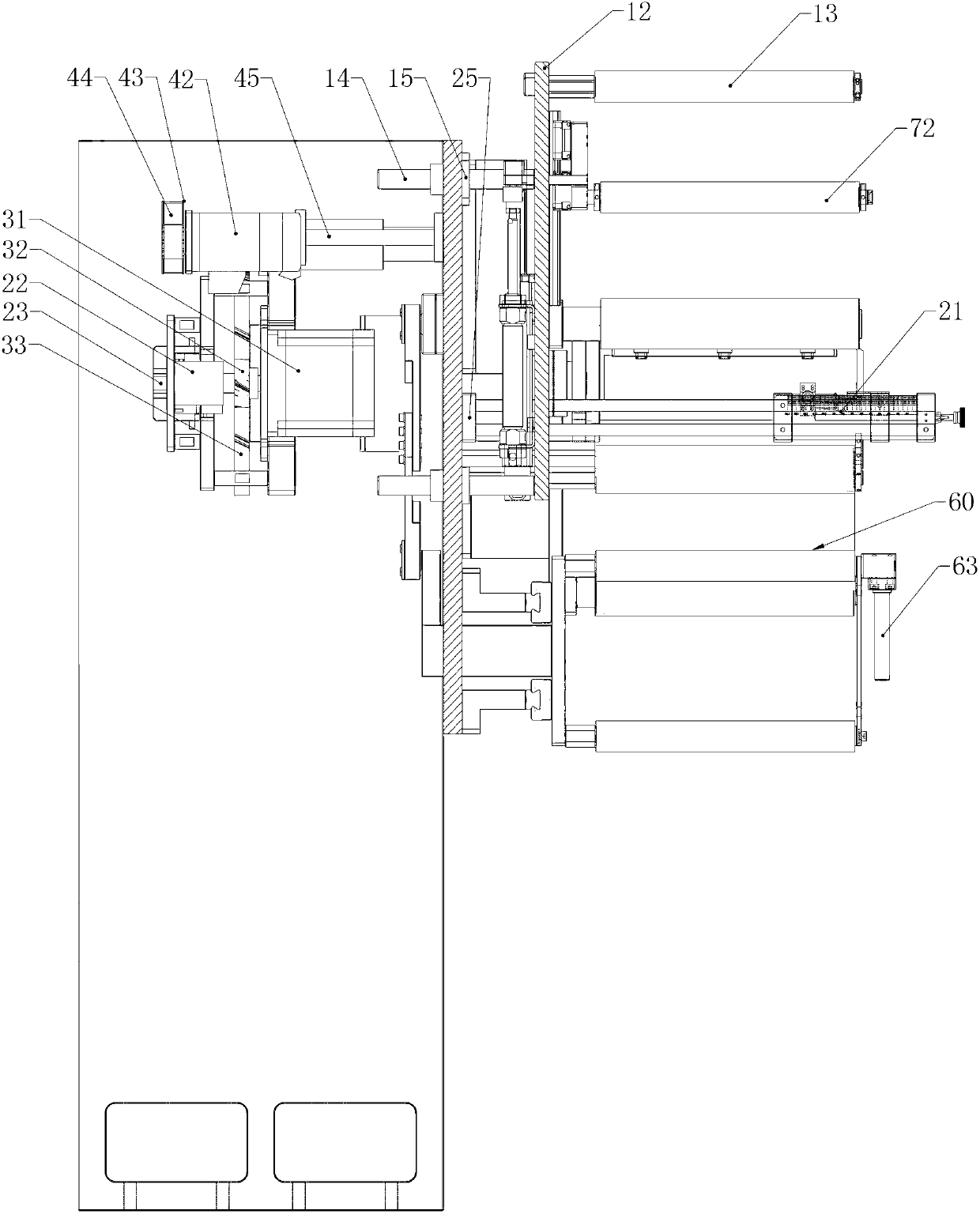

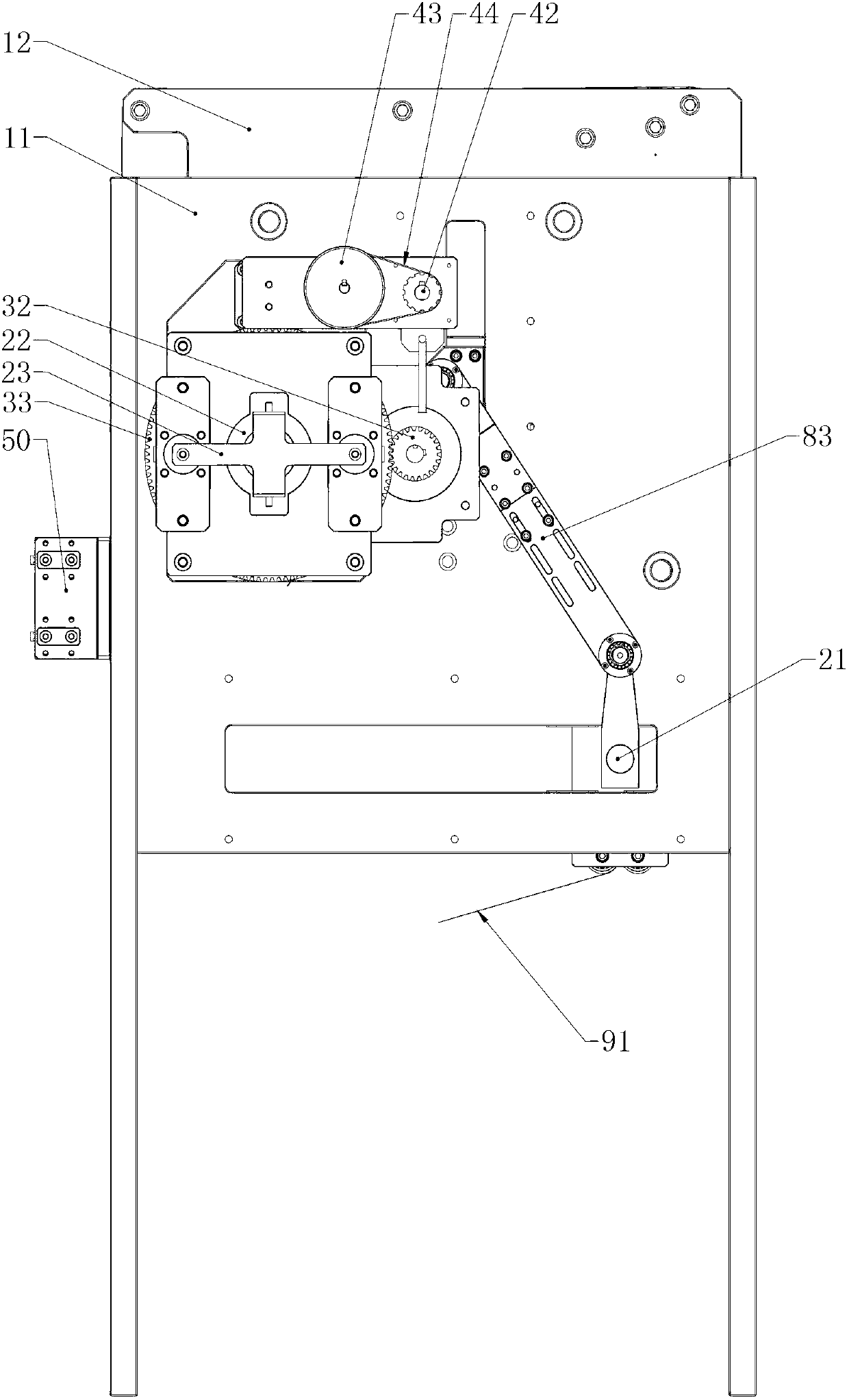

[0031] figure 1 It is the front view of the embodiment of the diaphragm discharging device with the expansion cylinder of the present invention, figure 2 is the left side view of the embodiment, image 3 is the rear view of this embodiment.

[0032] The embodiment of the constant tension diaphragm unwinding device of the present invention includes an unwinding mechanism 20 for installing the diaphragm material roll 92, a transmission mechanism 30 for driving the unwinding mechanism 20 to rotate, a deviation correction mechanism 40 for controlling the running accuracy of the diaphragm 91, and a device for connecting the diaphragms. Belt connection mechanism 50; and reciprocating diaphragm stacking mechanism 60 for diaphragm folding and discharging, providing te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com