Rewinding shaft tension converting device for cutting and rewinding materials

A technology of slitting, rewinding, and converting device, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., to achieve the effect of good effect, easy to popularize and use, and novel and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

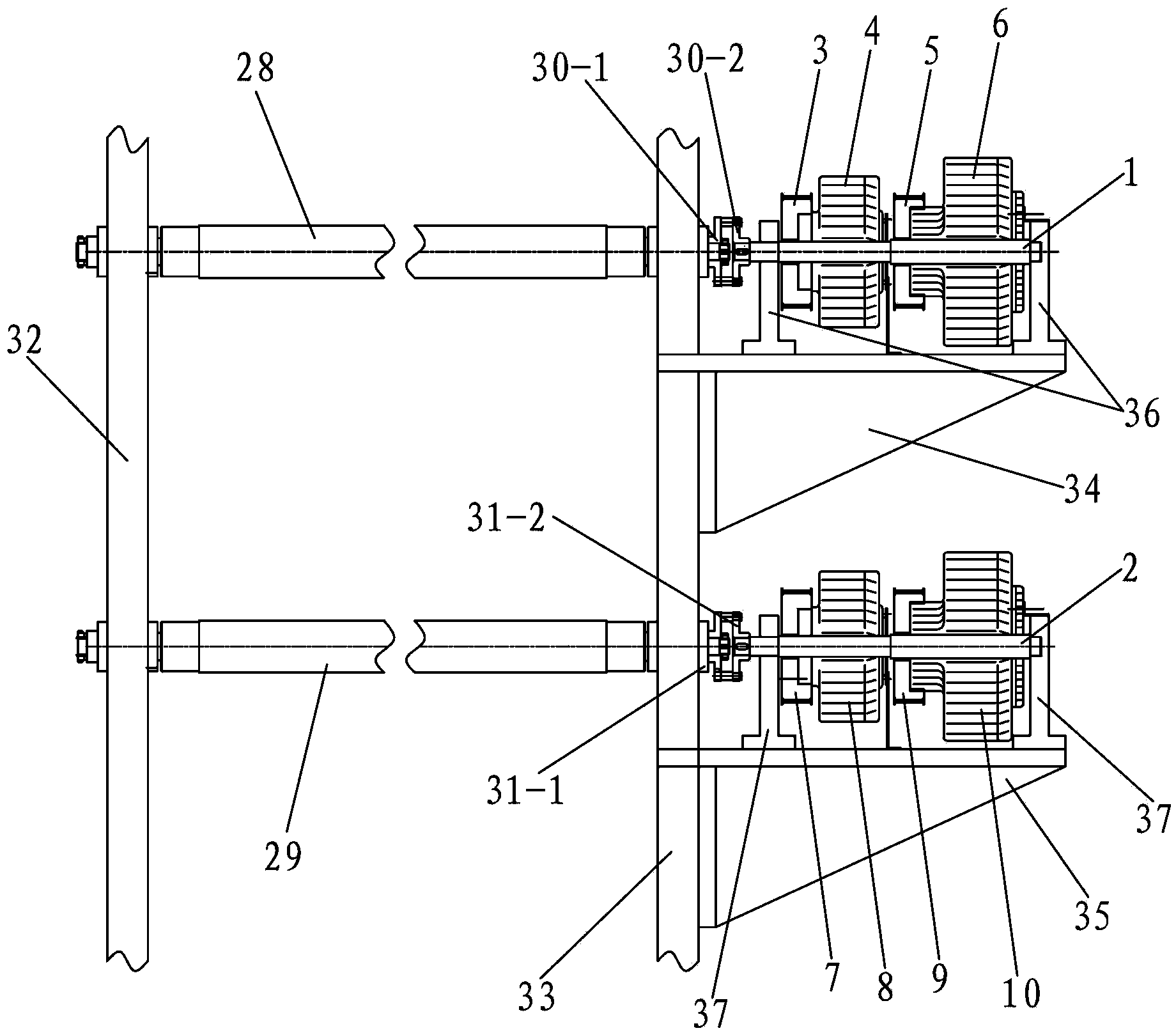

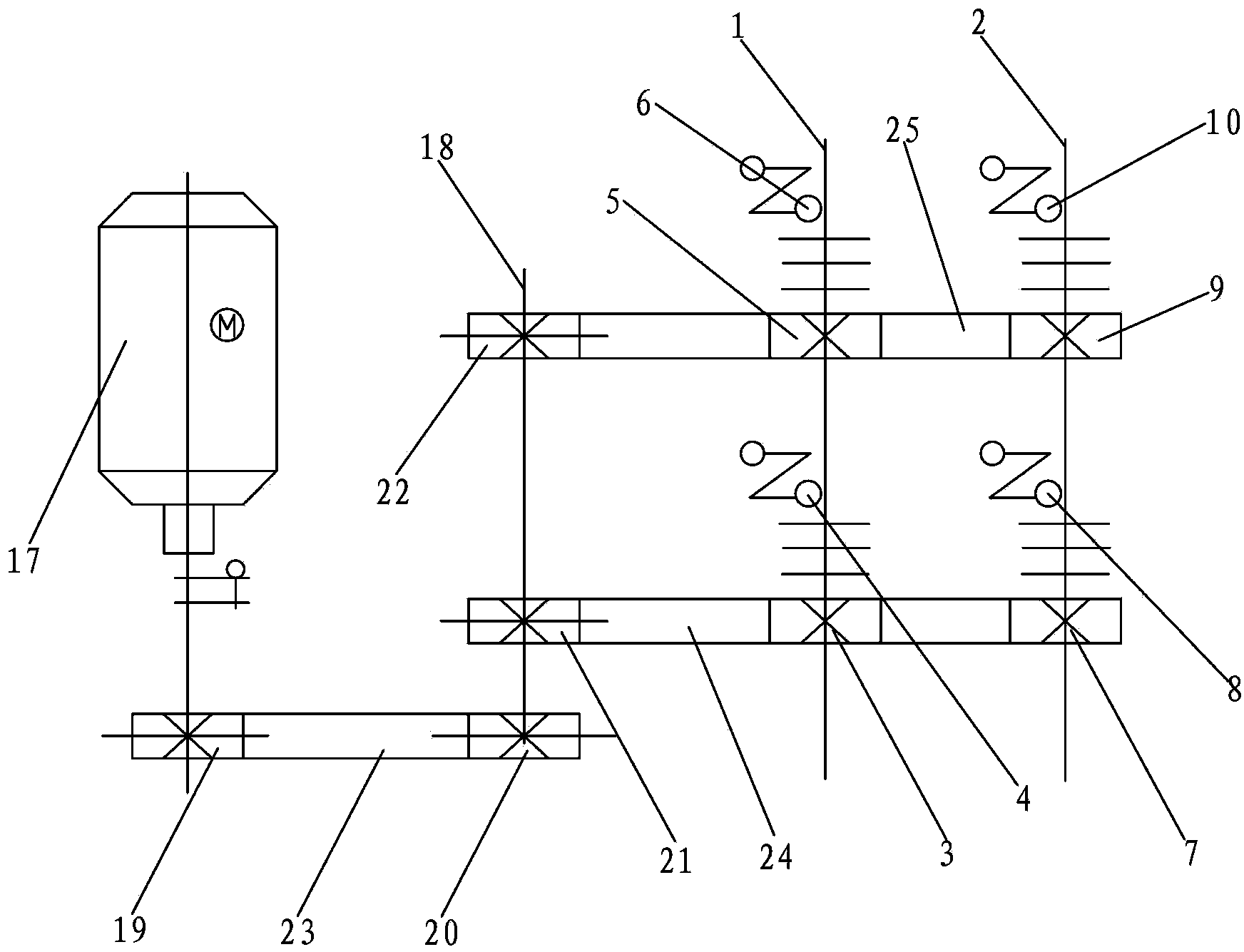

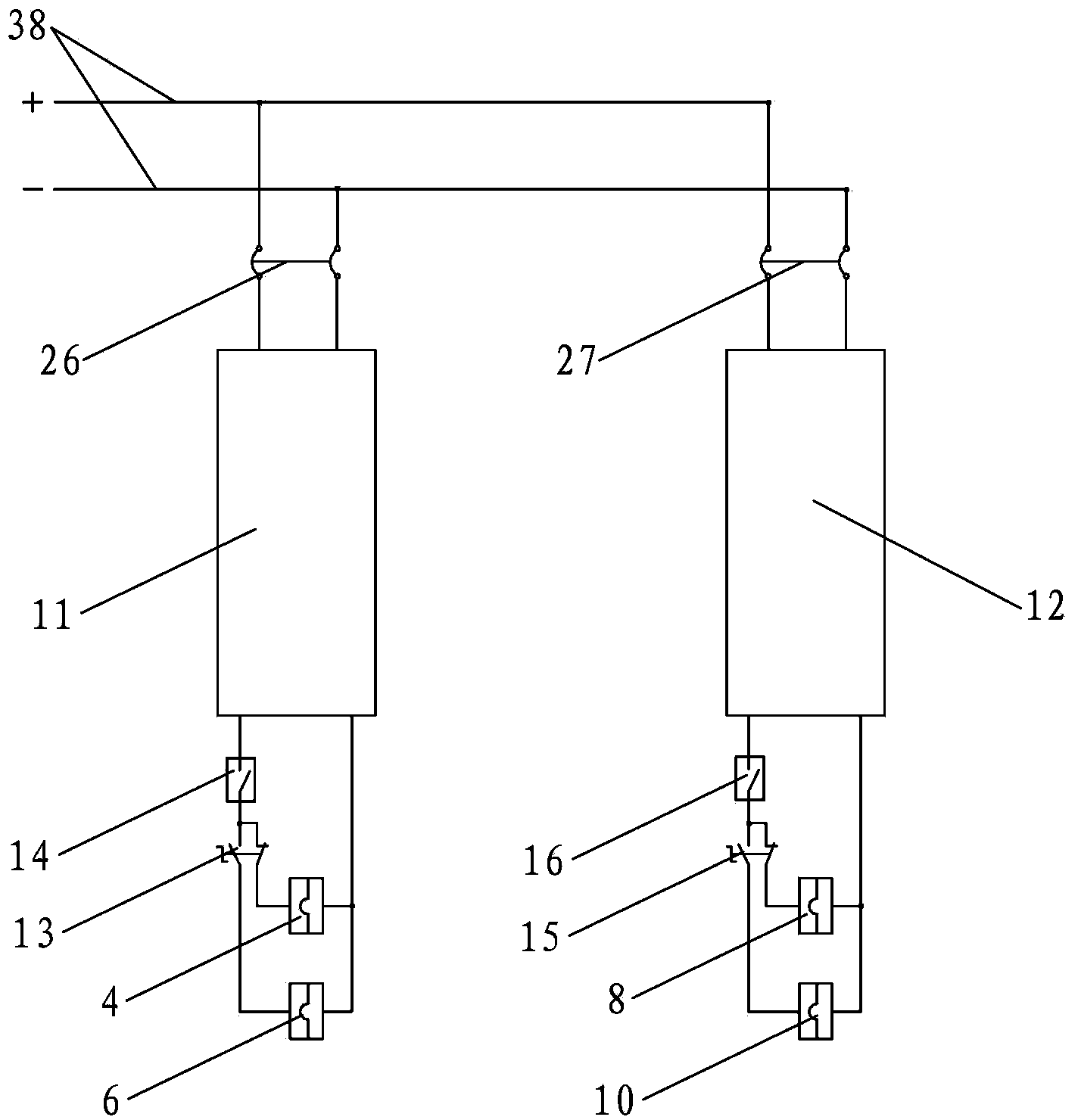

[0041] Such as figure 1 As shown, the present invention comprises the first driving shaft 1 connected with the first winding shaft 28 through the first shift fork assembly and the second driving shaft 2 connected with the second winding shaft 29 through the second shift fork assembly. The first toothed pulley 3, the first magnetic powder clutch 4 connected with the first toothed pulley 3, the second toothed pulley 5 and the first toothed pulley 5 connected with the second toothed pulley 5 are installed on the first transmission shaft 18. The second magnetic powder clutch 6, the rated torque of the first magnetic powder clutch 4 and the second magnetic powder clutch 6 is one large and one small, and the third toothed pulley 7 and the third toothed pulley 7 are installed on the second drive shaft 2. The third magnetic powder clutch 8 connected with the toothed pulley 7, the fourth toothed pulley 9 and the fourth magnetic powder clutch 10 connected with the fourth toothed pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com