Intelligent yarn storage device, control system and control method of carbon fiber multi-axial warp knitting machine

A multi-axial, warp knitting machine technology, applied in warp knitting, comprehensive factory control, comprehensive factory control and other directions, can solve problems such as the unusable creel system, achieve macro synchronization, reduce motion errors, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

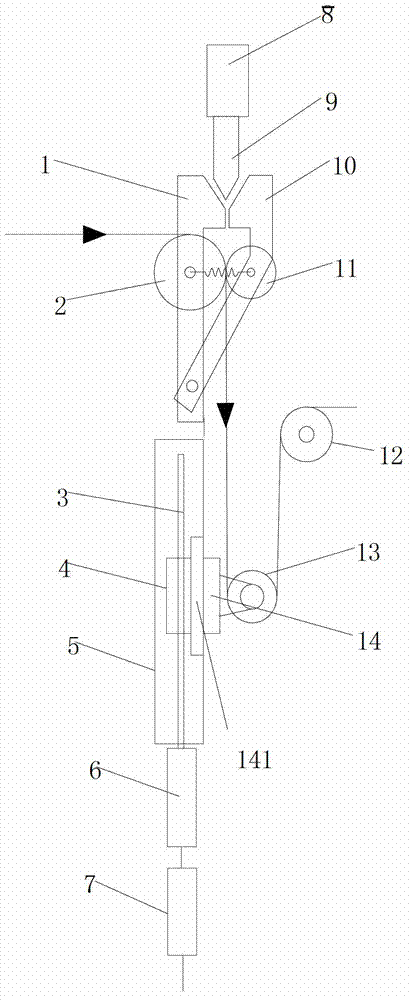

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings.

[0023] Such as figure 1 The shown carbon fiber multiaxial warp knitting machine intelligent yarn storage device is characterized in that it includes a pulling device for feeding carbon fiber materials, the pulling device is connected with a yarn storage device, and the yarn storage device includes a sealing Housing 5, one side of the housing 5 is a high-durability stainless steel plate, the inside of the housing 5 is provided with a moving mechanism that moves up and down, and the high-durability stainless steel plate of the housing 5 is provided with a sliding block 14, the described The sliding block 14 is magnetically connected with the moving mechanism, and the sliding block 14 is provided with a yarn storage wheel 13 .

[0024] The yarn storage device drives the sliding block to move up and down through the moving mechanism, and the sliding block drives the yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com