Die-cutting lamination system and method

A lamination and cutting technology, applied in electrochemical generators, electrical components, climate sustainability, etc., can solve the problem that the speed of lamination cannot be substantially improved, reduce the speed of manipulator feeding, maintenance costs, energy consumption, etc. Problems such as large consumption, to achieve the effect of reducing the risk of diaphragm folds and outer drain electrodes, small space occupancy, and breaking through the limitations of mechanical structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

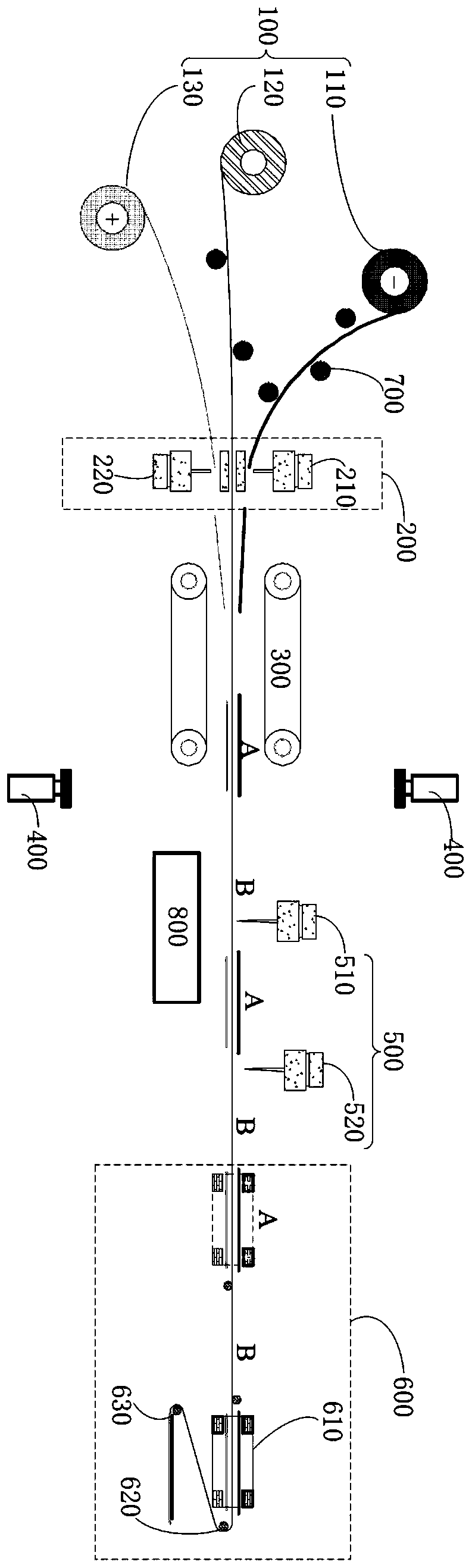

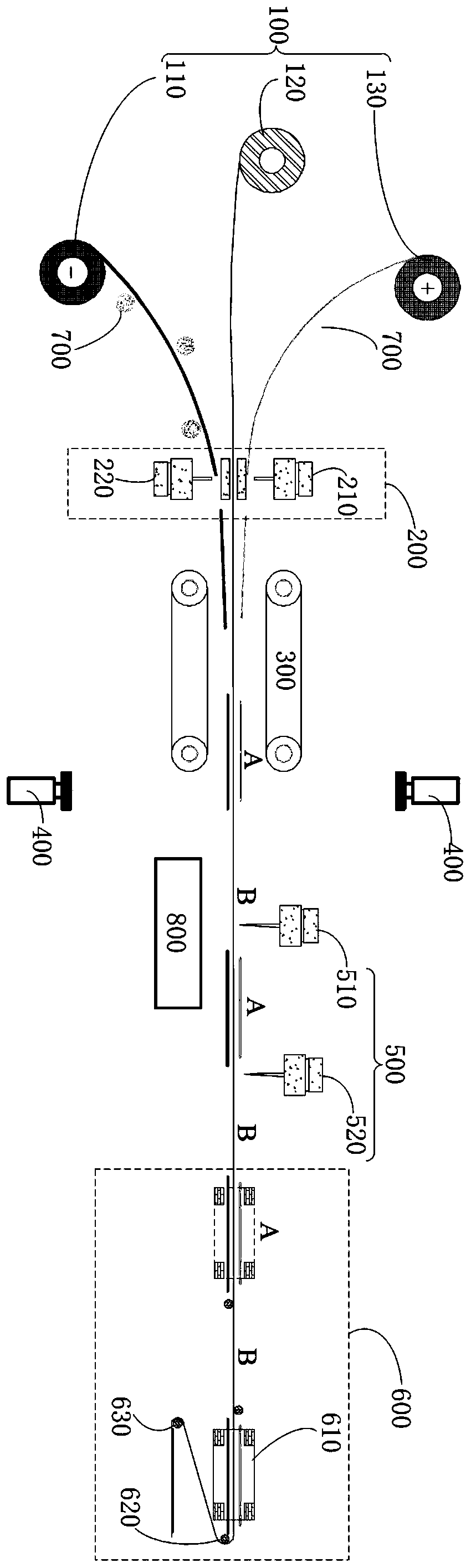

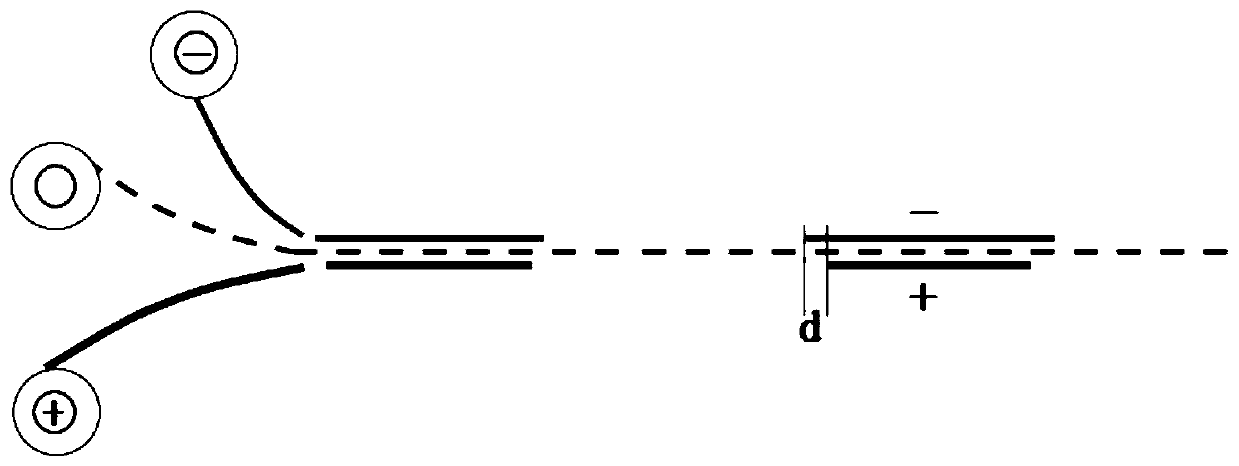

[0038]According to a first aspect of the invention, the invention proposes a die-cut lamination system. According to an embodiment of the present invention, such as figure 1 or figure 2 As shown, the system includes: an unwinding mechanism 100 , a pole roll cutting mechanism 200 , a preheating rolling device 300 , a detection device 400 , a diaphragm cutting mechanism 500 and a stacking device 600 .

[0039] The following will refer to the attached Figure 1-7 The above-mentioned die-cut lamination system will be described in detail in conjunction with the embodiments.

[0040] Unwinding mechanism 100 and pole roll cutting mechanism 200

[0041] According to an embodiment of the present invention, the unwinding mechanism 100 includes a negative electrode unwinding mechanism 110, a diaphragm unwinding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com