Flow channel regulation agent for fractured-vuggy oil reservoir and preparation method thereof

A fracture-cavity type, adjusting agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of limited recovery, high pipeline requirements, and damaged pipe strings, and achieves low friction resistance, Good fluidity and size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to another aspect of the present invention, the present invention also provides a preparation method of the above-mentioned fracture-cavity reservoir flow path regulator, comprising:

[0037] Slowly add the polymer into water according to the above ratio to obtain a carrier fluid;

[0038] Heating the high molecular polymer above the softening point, then adding calcium carbonate and bentonite to the high molecular polymer according to the above ratio, mixing evenly, adjusting the density, and granulating by conventional methods after cooling to obtain plugging regulating particles;

[0039] Mix the carrier fluid and plugging adjustment particles according to a predetermined ratio.

[0040] The fracture-cavity reservoir flow channel regulator of the present invention can be applied to failed water injection well groups, and can effectively realize the deep adjustment of the dominant water flow channels between well groups, expand the water injection sweep rang...

Embodiment 1

[0044] The composition of the carrier liquid in the flow channel regulator of the fractured-cavity reservoir of the present embodiment is: 2 parts of guar gum, 98 parts of water; the composition of the regulating plugging particles is: 97 parts of polyurethane, 3 parts of calcium carbonate, and 3 parts of bentonite; The composition of the flow channel regulator for fracture-cavity reservoirs is: 80 parts of carrier fluid and 20 parts of plugging regulating particles.

[0045] The preparation method is:

[0046] Add guar gum to water to obtain carrier fluid;

[0047] Heating the polyurethane to above the softening point, then adding calcium carbonate and bentonite to the polyurethane, mixing evenly, cooling and granulating to obtain plugging-adjusting granules;

[0048] The carrier fluid and the plugging regulating particles are mixed to prepare the fracture-cavity reservoir flow path regulating agent of this embodiment.

Embodiment 2-12

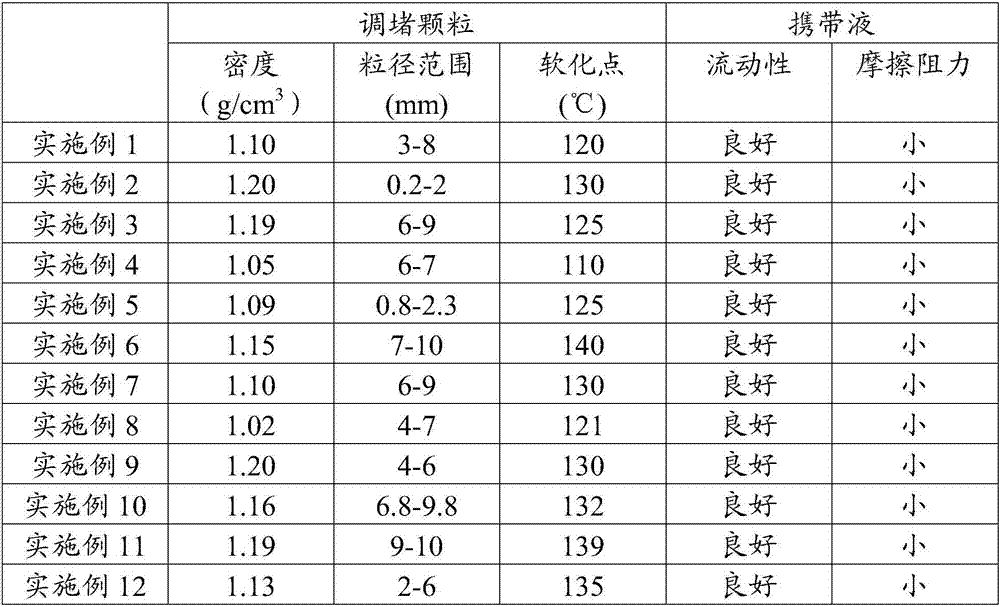

[0050] According to the method of embodiment 1, implement embodiment 2-12. The content of each component is shown in Table 1-Table 3.

[0051] Table 1 When the polymer is guar gum and the high molecular weight polymer is polyurethane

[0052]

Example 2

Example 3

Example 4

Guar Gum

0

1

3

water

100

99

97

95

98

100

5

2

0

5

2

0

carrier fluid

10

30

100

Plugging particles

90

70

0

[0053] Table 2 When the polymer is polyacrylamide polymer and rubber particles

[0054]

Example 5

Example 6

Example 7

Example 8

2

0

1

3

water

98

100

99

97

rubber particles

97

95

98

100

3

5

2.5

0

3

5.5

2

0

carrier fluid

80

10

32

100

Plugging pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com