Composite wood board automatic processing device and composite wood board processing process

A technology for automatic processing and composite wood boards, which is applied to wood processing equipment, adhesive application devices, plywood presses, etc., and can solve problems such as low productivity and uneven quality of wood boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

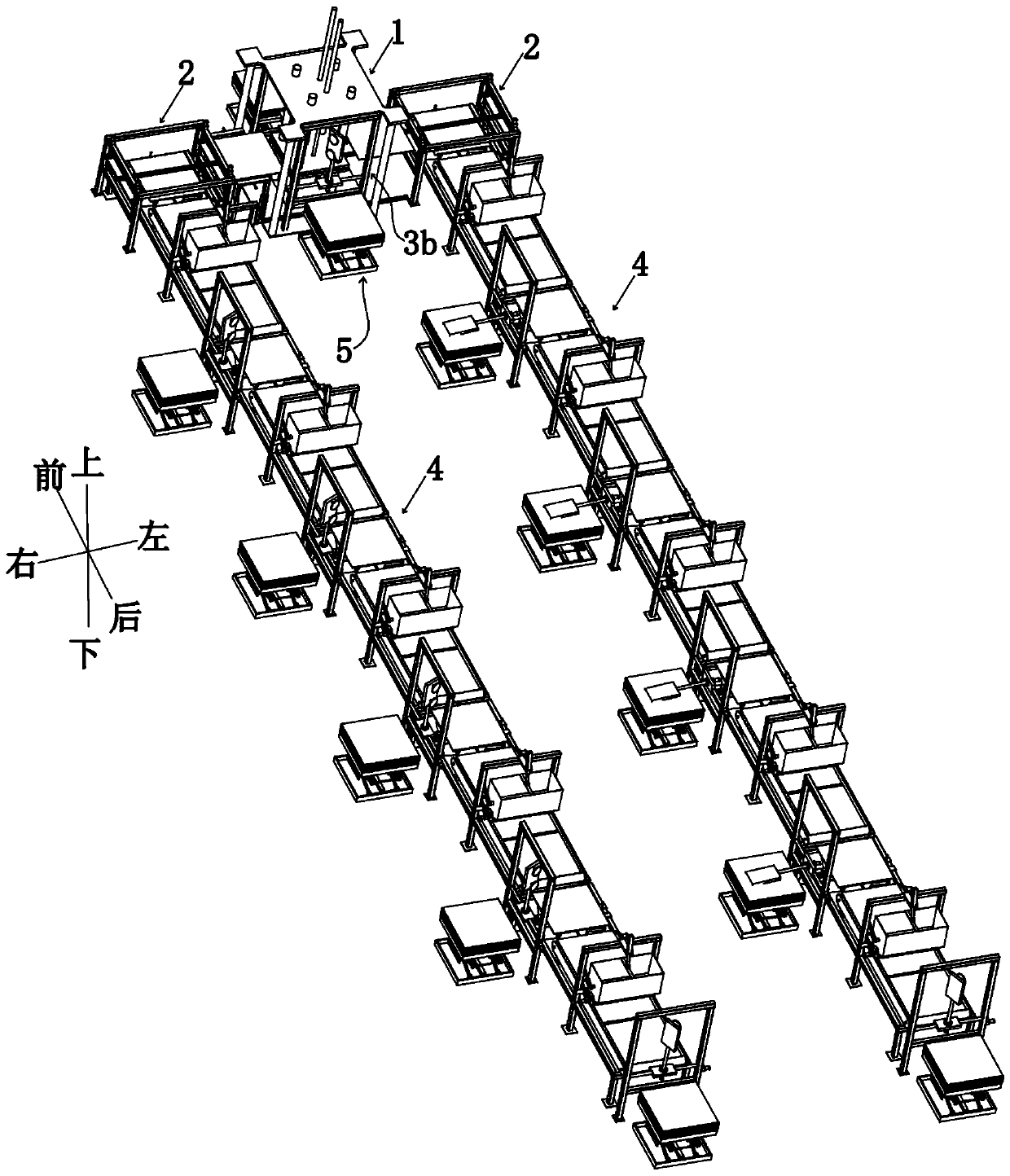

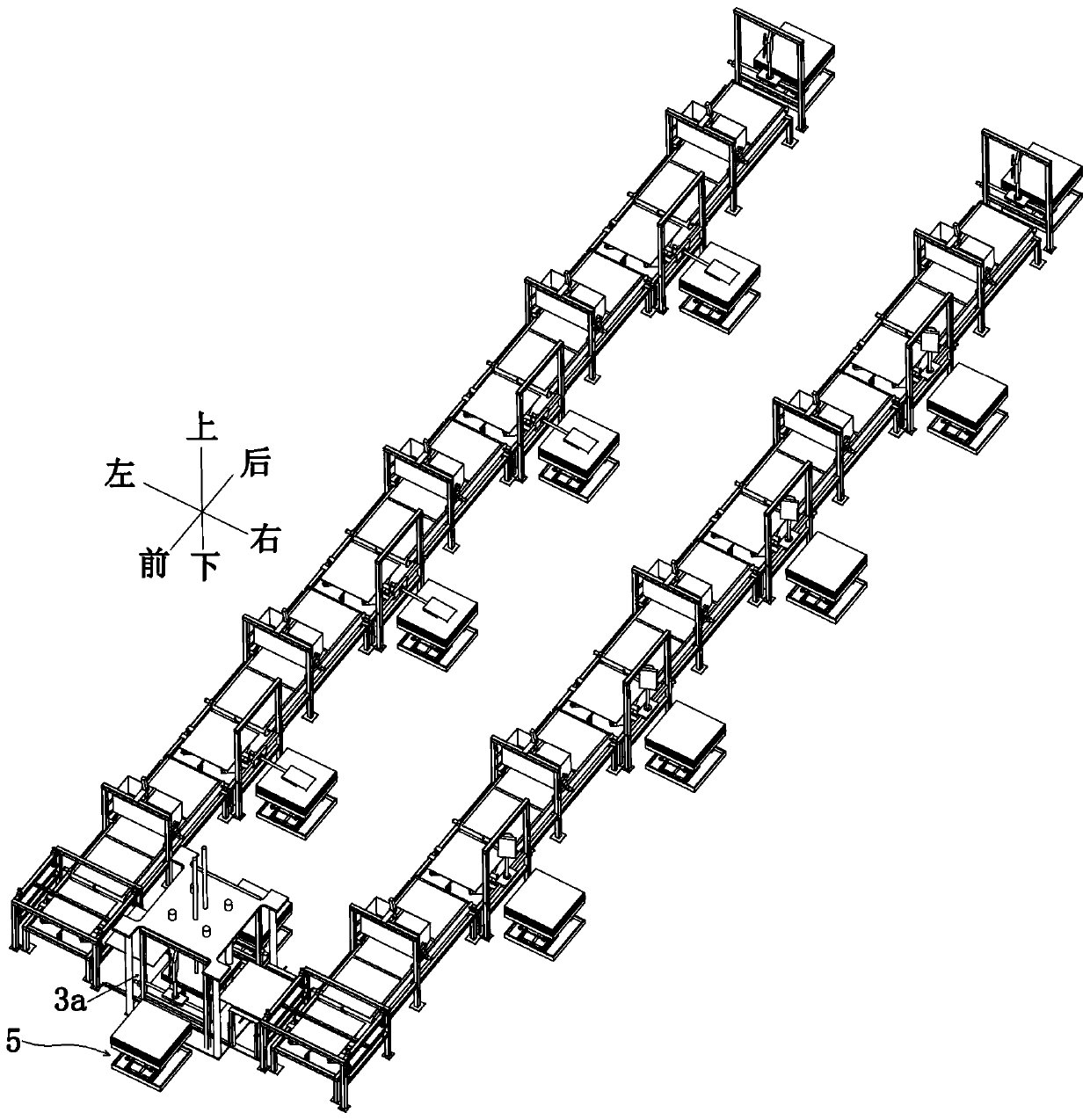

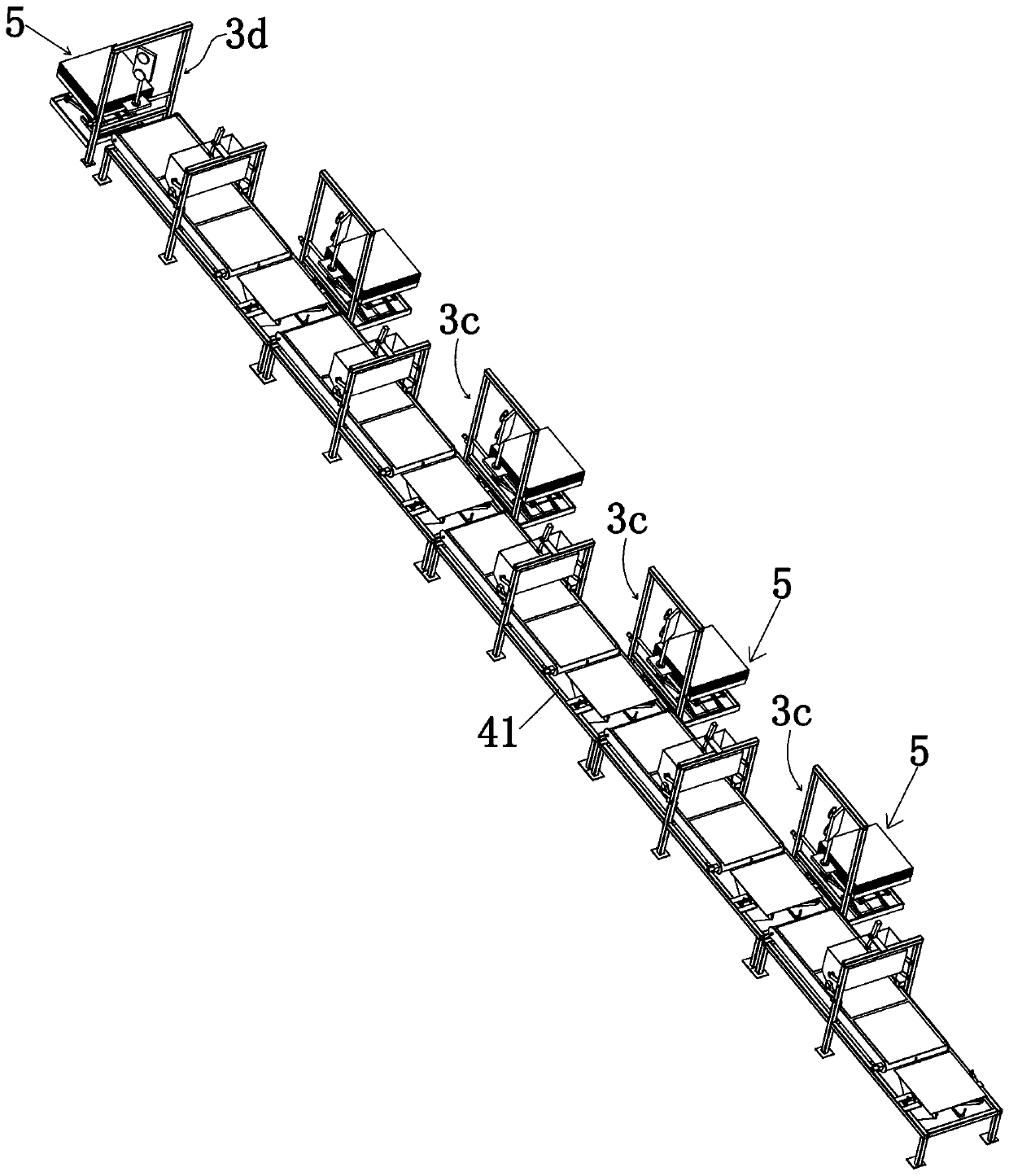

[0045] see Figure 1-26 As shown, an automatic processing device for composite wood boards includes a press assembly 1, a glue template handling assembly 2 arranged on the left and right sides of the press assembly 1, a first upper board assembly 3a arranged on the front side of the press assembly 1, The lower plate assembly 3b arranged on the rear side of the press assembly 1; also includes two stacked plate assemblies 4 respectively arranged at the two gluing template handling assemblies 2, and the stacked plate assemblies 4 are used to combine a plurality of thin plates 001 Apply glue on the upper surface and stack them together to form the laminated boards to be pressed, and send the laminated boards to be pressed to the gluing template handling assembly 2, and the gluing template handling assembly 2 is used to transport the laminated boards to be pressed to the press assembly 1, the first upper board assembly 3a is used to place the thin plate above the laminated board to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com