Three-dimensional stack structure of thin-film ceramic circuit

A three-dimensional stacking and thin-film technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve the problems of large restrictions, large product volume, and high cost, and achieve the goal of improving product adaptability, production efficiency, and integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

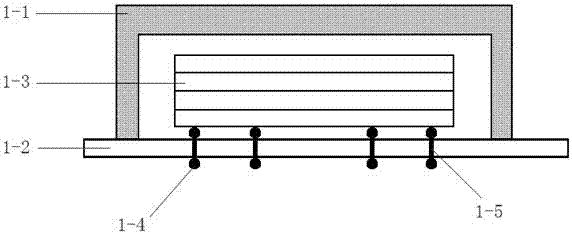

[0018] A three-dimensional stacked structure of thin-film ceramic circuits, between two adjacent layers of thin-film ceramic substrates, through ball planting welding or prefabricated pad 3-1 welding, so as to realize the stacking of more than three layers of thin-film ceramic circuit substrates; using solid metal through holes Realize conductive connection of any layer; include partial electromagnetic self-shielding structure of chips 2-4 and / or passive components; said partial electromagnetic self-shielding structure includes upper and lower metal layers and side solid metal through holes.

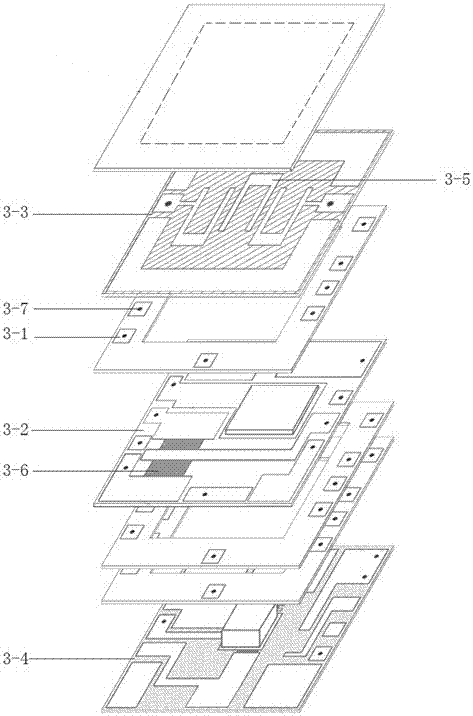

[0019] The two adjacent layers are soldered by ball bonding or prefabricated pads, and the image 3 In the specific embodiment shown, the stacking of substrates is realized by welding prefabricated pads between two adjacent layers. Similarly, ball planting (such as BGA ball planting) can also be used to achieve stacking of substrates. Those skilled in the art can Choose the settings acco...

specific Embodiment 2

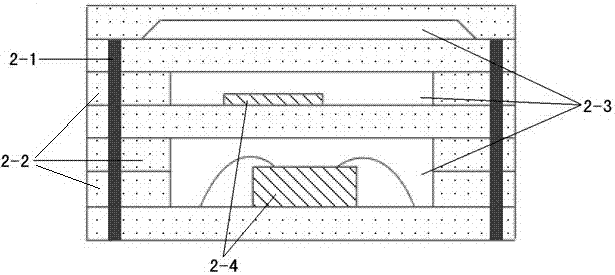

[0024] On the basis of the specific embodiment 1, including the support layer 2-2, a blind cavity structure 2-3 is formed between the support layer and the upper and lower layers of the support layer, so as to realize the chip and / or passive components (such as filters) 3-5, resistors 3-6 and capacitors, etc.) are embedded. In this specific embodiment, the control unit layer 3-2 and the power unit layer 3-4 are integrated into chips by gold wire bonding and flip-chip welding.

specific Embodiment 3

[0025] On the basis of specific embodiment 1 or 2, according to the circuit characteristics of each layer of thin film ceramic circuit, the base material of each layer of thin film ceramic circuit substrate is set. According to the circuit characteristics of each layer of thin film ceramic circuit, the base material of each layer of thin film ceramic circuit substrate can be set, such as the radio frequency filter unit layer 3-3 adopts ferrite base material (in this specific embodiment, the dielectric constant is greater than or equal to 20, less than or equal to 40 high-dielectric ferrite), the control unit layer 3-2 is made of alumina substrate, and the power unit layer 3-4 is made of aluminum nitride substrate; in this way, each layer of thin film ceramic circuit substrate can use different The base material realizes the optimized combination of the structural properties of each layer. The substrates selected for the multiple unit layers in this specific embodiment are just...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com