Flexible wing structure based on shape memory alloy and manufacturing method thereof

A technology of memory alloy and memory alloy wire, which is applied in the field of aircraft parts, can solve the problems of low fatigue life of wing part structure, difficult control of wing structure, control structure defects, etc., and achieve light weight, low cost and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

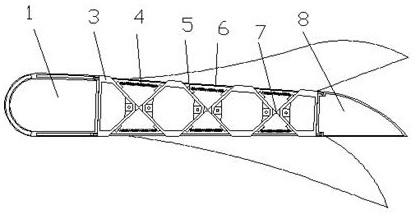

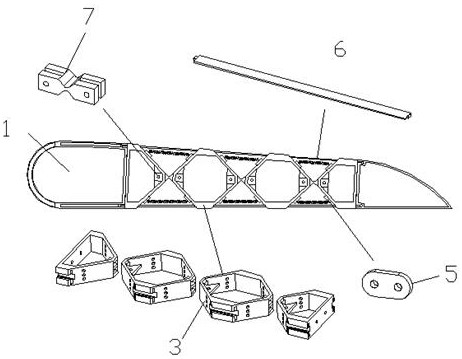

[0037] As shown in the accompanying drawings, a flexible wing structure based on a shape memory alloy of the present invention includes a shaping frame 1 and several independent bending mechanisms 2; the entire flexible wing structure is comb-shaped, the shaping frame 1 is U-shaped, and the bending mechanism 2 Comb-shaped evenly distributed on the U-shaped inner side of the shaping frame 1.

[0038] The bending mechanisms 2 are arranged side by side along the wing arm direction, and one side of each bending mechanism 2 is fixedly connected with the shaping frame 1 respectively.

[0039] The bending mechanism 2 includes components such as a memory alloy piece 4, a flexible hinge 7, an elastic skin 6, a swing tail 8, and 2-5 rigid connectors 3, and the rigid connectors 3 on the left and right are triangular; The rigid connector 3 in the middle is quadrangular; the tapered corners of each rigid connector 3 are the connecting parts; the edge of the leftmost rigid connector 3 is fi...

Embodiment 2

[0043] On the basis of the structure of Example 1, the memory alloy piece 4 is a memory alloy spring

[0044] The manufacture method of this memory alloy spring comprises the steps:

[0045] S1: Pre-treatment: select NiTi wire with a diameter of 0.7mm (Af=70°C) as the base material, wind it on a stud with a diameter of 8mm, and fix both ends with iron wires whose melting point is higher than the heat treatment temperature of NiTi wire;

[0046] S2: Heat treatment process: Put the fixed studs and NiTi wire into the crucible, then put them into the heat treatment furnace together and lock the furnace door, and cool with the furnace after heat treatment.

[0047] NiTi wire is a solid alloy wire with a mass fraction of Ni of 55.72%. In the heat treatment process, the heat treatment temperature in the heat treatment furnace is 500°C for 1 hour.

Embodiment 3

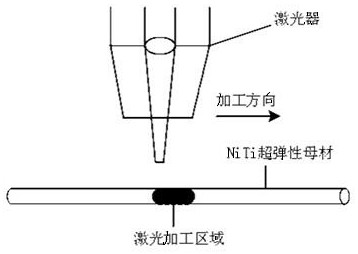

[0049] On the basis of the structure of Example 1, the memory alloy part 4 is a shape memory alloy wire with multiple shape memory effects. Laser treatment, the difference of laser treatment is embodied in laser treatment power, laser wavelength, laser frequency, time, etc., so that it has different shape memory effects at different treatment points; the shape memory alloy wire with multiple shape memory effects is A structure that is laser processed and has the property of undergoing electrical deformability, an example of a spot laser processing method is the following steps:

[0050] S1: Choose a NiTi alloy wire with a shape memory function of 2mm in diameter, wash it with acetone, alcohol and deionized water in sequence, and then dry it for later use; fix the NiTi alloy wire, and pass inert protective gas at the part to be treated by laser; The inert protective gas generally adopts argon;

[0051] S2: Before the laser treatment, the shielding gas is passed for 30s, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com