Automatic steel ring grabbing system

A steel ring, automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow manual winding speed, labor and man-hour consumption, low production efficiency, etc., to reduce production costs and improve production efficiency. , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

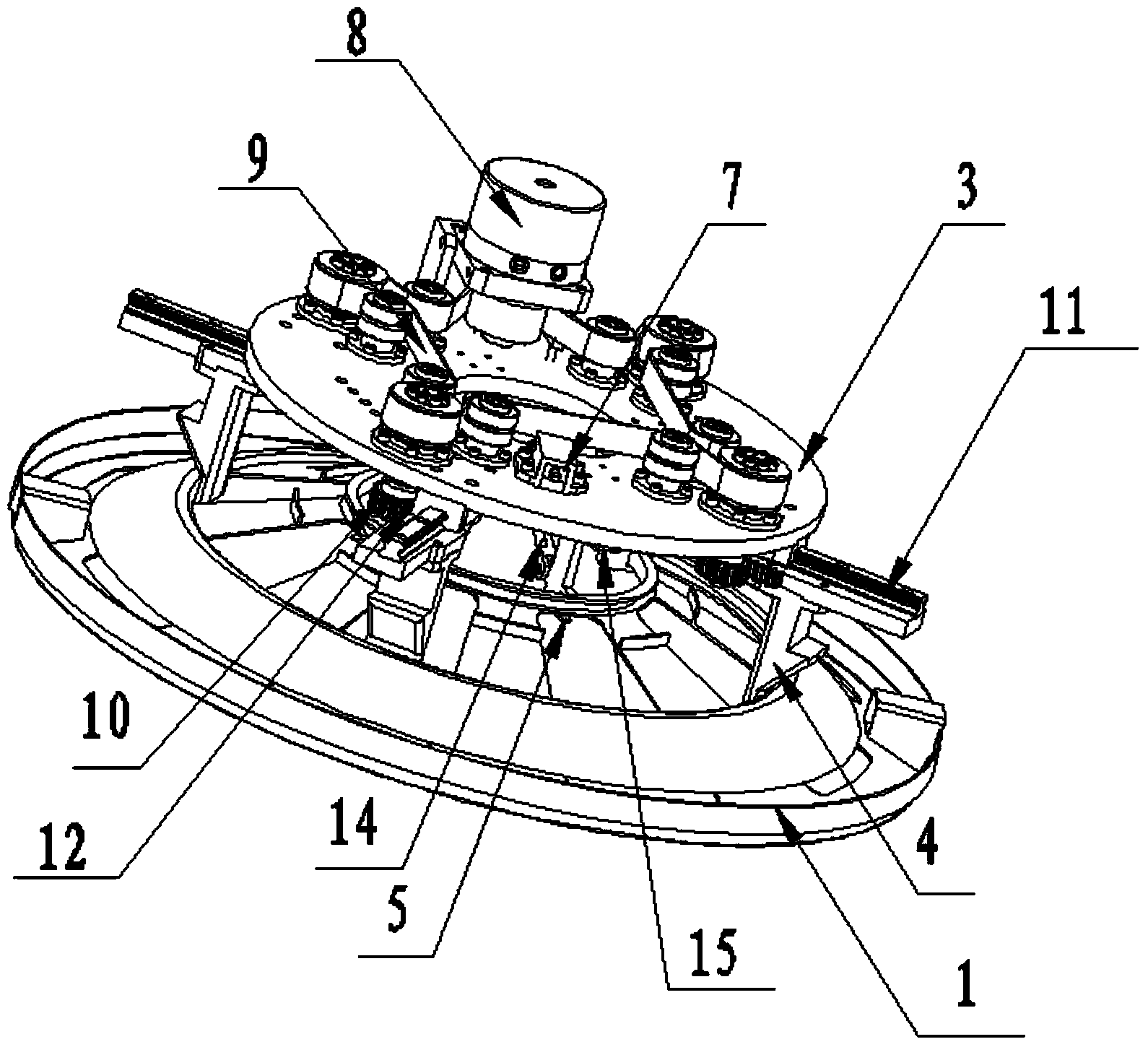

[0023] Embodiment: A steel ring automatic grabbing system, including a steel ring tray 1, a steel ring grabbing mechanism, a position sensing device 7, a conveying mechanism and a controller, wherein:

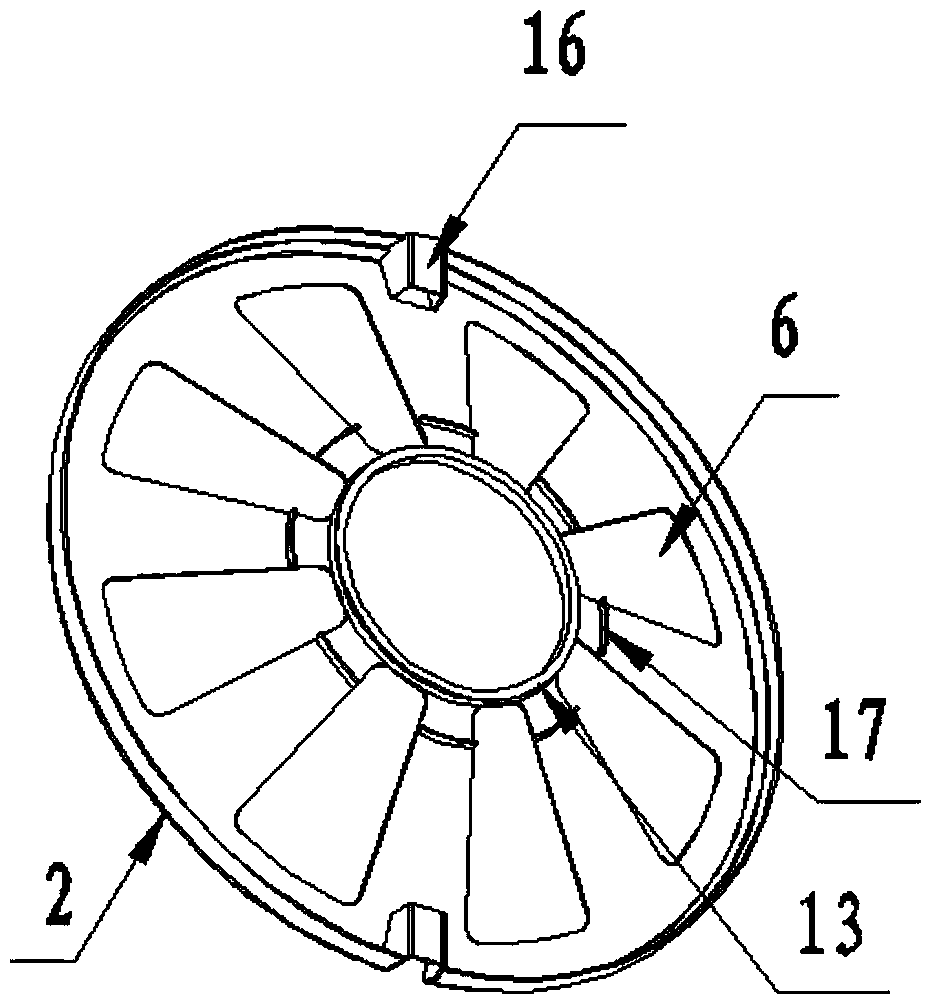

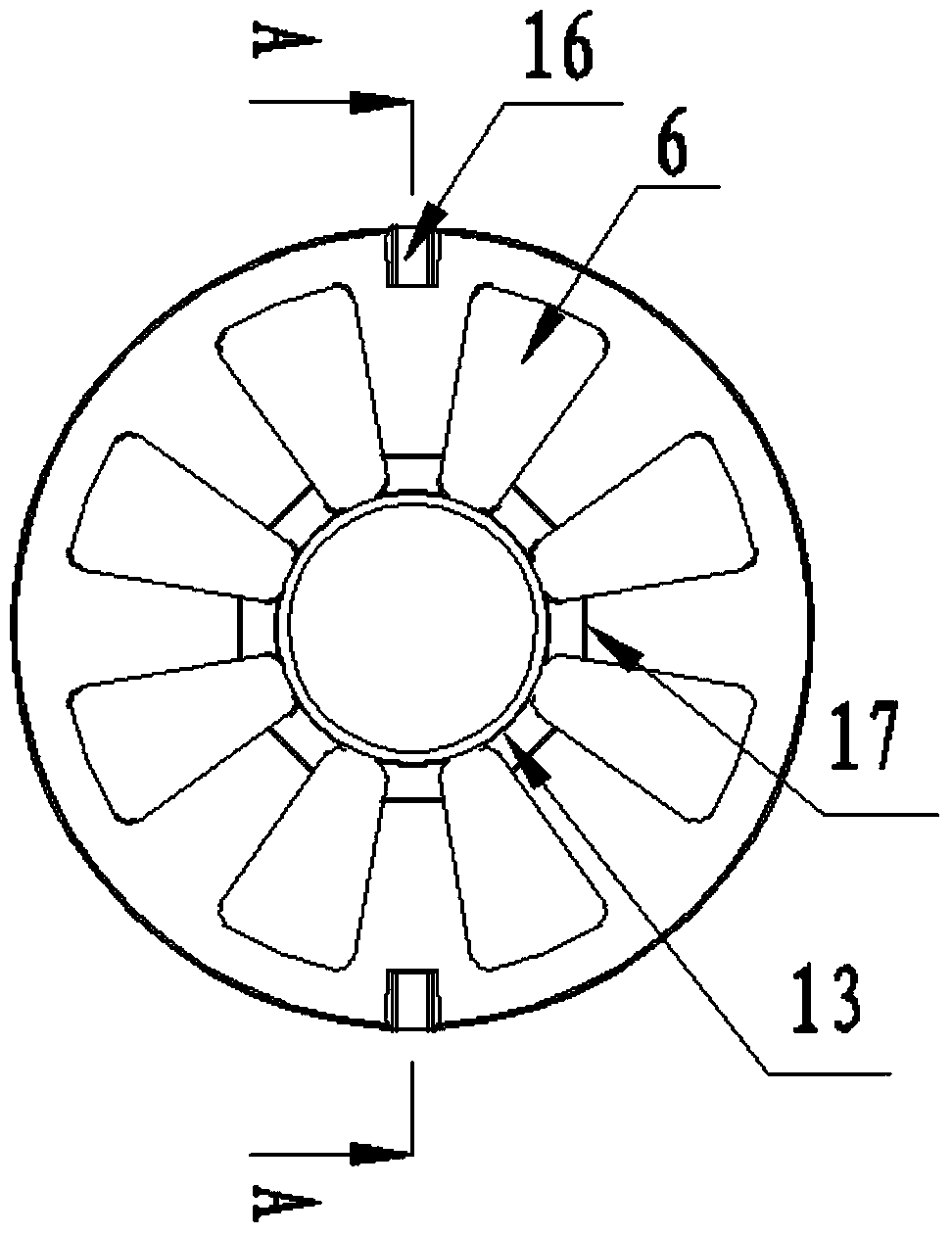

[0024] One side of the steel ring tray 1 forms a space for the steel ring to be positioned and placed. The edge of one side of the steel ring tray 1 also forms a circle of outer seam 2, and the other edge of the steel ring tray 1 forms an inner ring corresponding to the position of the outer seam 2. Shrinking step structure, the outer stop 2 on one side of the steel ring tray 1 can just be sleeved on the outer side of the inner shrinking step structure of the adjacent steel ring tray 1 to form a superimposed state;

[0025] The steel ring grasping mechanism includes a positioning plate 3, a steel ring gripper 4, a pallet gripper 5, a first drive mechanism and a second drive mechanism, and the steel ring gripper 4 and the pallet gripper 5 are respectively positioned on the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com