3D (three dimensional) printing equipment for preparing thermoplastic elastomer product

A thermoplastic elasticity, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of product defects, limiting 3D printing applications, silk slipping and entanglement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

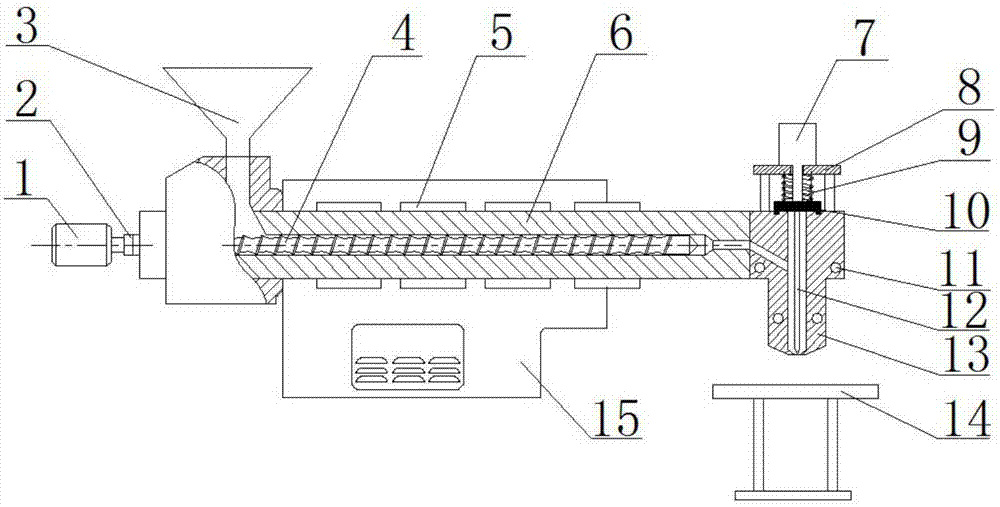

[0012] The present invention is a 3D printing device for preparing thermoplastic elastomer products, such as figure 1 As shown, it is mainly composed of a material melting conveying unit, a material extruding unit, a three-dimensional coordinate platform 12 and a frame 15; wherein the material melting conveying unit is mainly composed of a stepping motor 1, a coupling 2, a hopper 3, a screw 4, a heating Cooling device 5, machine barrel 6, etc., stepping motor 1 is connected with screw 4 through coupling 2, so as to control the speed of the screw, screw 4 is fixed in the machine barrel 6, the material enters the machine barrel 6 through the hopper 3, and is heated The cooling device 5 is fixed on the machine barrel 6, and the temperature in the machine barrel 6 is controlled by controlling the heating and cooling device 5 through the controller; wherein the material extruding unit is mainly composed of an electromagnet 7, a spring 9, an elevating platform 8, a heat insulator 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com