Construction steel structure glue-joint technique

A technology of structural glue and construction steel, which is applied in the direction of building construction, construction, measuring devices, etc., to achieve the effect of improving production efficiency, reducing production cost, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

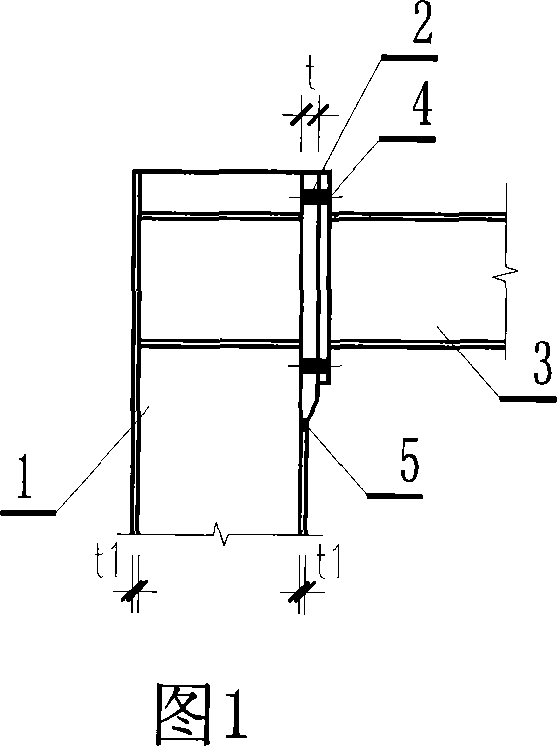

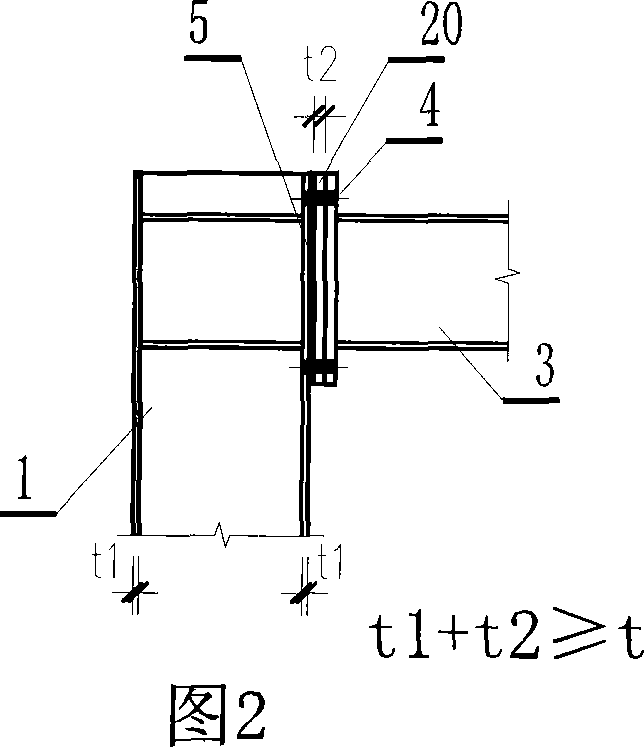

[0016] As shown in Figure 1 and Figure 2, in construction projects, the commonly used column 1 and beam 3 are all welded by three steel plates, and their cross-sectional shape is generally H-shaped. As shown in the prior art, as shown in Fig. 1, the connecting part of the column and the beam needs to be cut and processed into a thickened column flange plate 2, and the column 1 must also be cut into a hole corresponding to the size and shape of the flange plate. Then the thickened flange plate is welded to the column 1 here, and the weld needs to be ultrasonically inspected. The flange plate 2 welded to the column 1 and the end plate 4 welded to the beam 3 are connected with high-strength bolts to connect the column and the beam together. The feature of the present invention is that as shown in Figure 2, the thickened flange plate 20 (t 2 ) And the flange plate (connection part) surface of the steel column 1 should be straight, and then polish the fresh metal surface with a grindin...

example 2

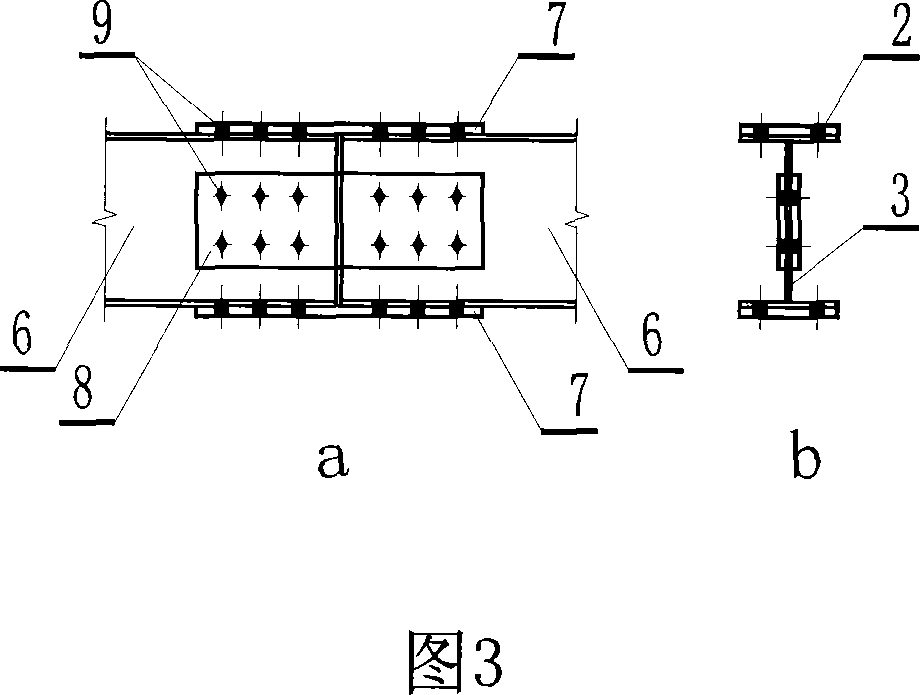

[0018] As shown in Figures 3 and 4, the two beams 6 are also H-shaped members formed by welding three steel plates. In the figure, a represents the schematic diagram of the axial connection of the two beams; in the figure b is the H-shaped schematic diagram of the cross-section of the beam. In the prior art, as shown in Fig. 3, the two steel beams 6 are connected together by flange splicing plates 7, web splicing plates 8, and high-strength bolts 9; the two steel beams 6 can also be connected together by riveting. For the connection of the two beams of the present invention, as shown in FIG. 4, the structural feature is that the flange plate splicing plate 7 and the web splicing plate 8 are directly glued to connect the two steel beams 6 together through the adhesive layer 10. . (The specific implementation method is the same as in Example 1)

example 3

[0020] For areas where the strength of the steel structure of the combined steel plate type is insufficient, reinforcement members are required. In the prior art, as shown in Figure 5, a reinforced steel plate 12 is welded to the insufficient strength of the original steel member 11, and the weld is represented by 13; in the present invention, as shown in Figure 6, the reinforced steel plate 12 is connected to the original steel member by a glue layer 14 11, both convenient and practical (the specific implementation method is the same as that in Example 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com