Automatic stacking system for television backboards

A palletizing system and backplane technology, which is applied in the field of TV backplane automatic palletizing system, can solve the problems of increasing the operating burden of workers, being unable to adapt to automated workplaces, and reducing the work efficiency of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

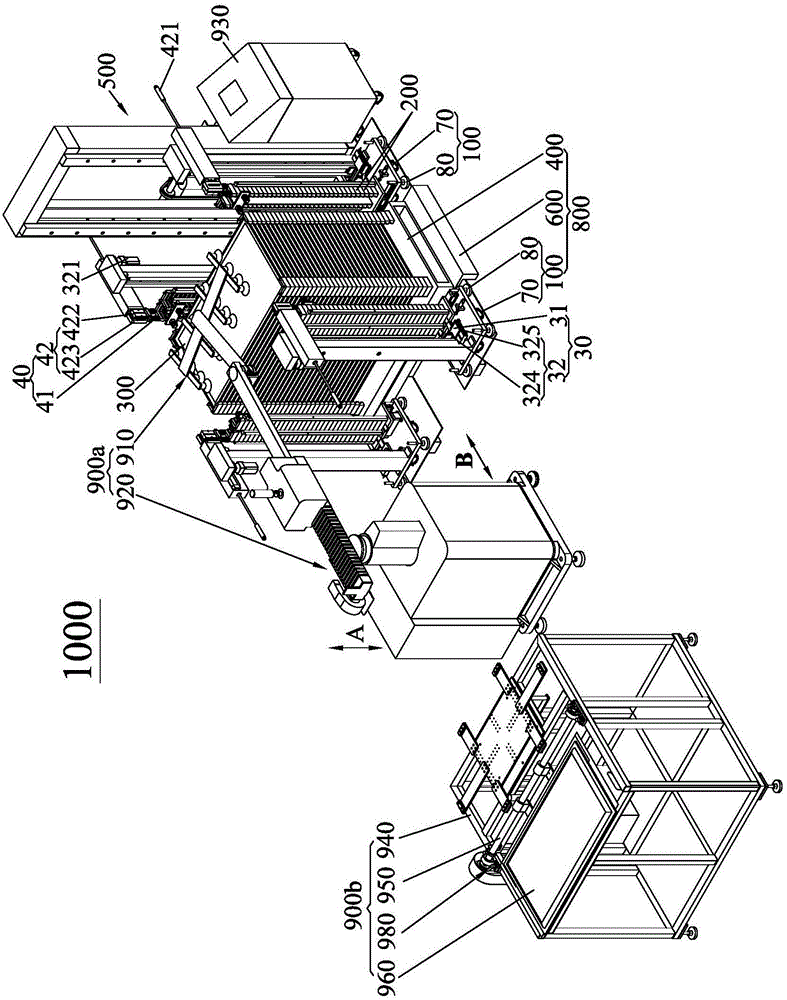

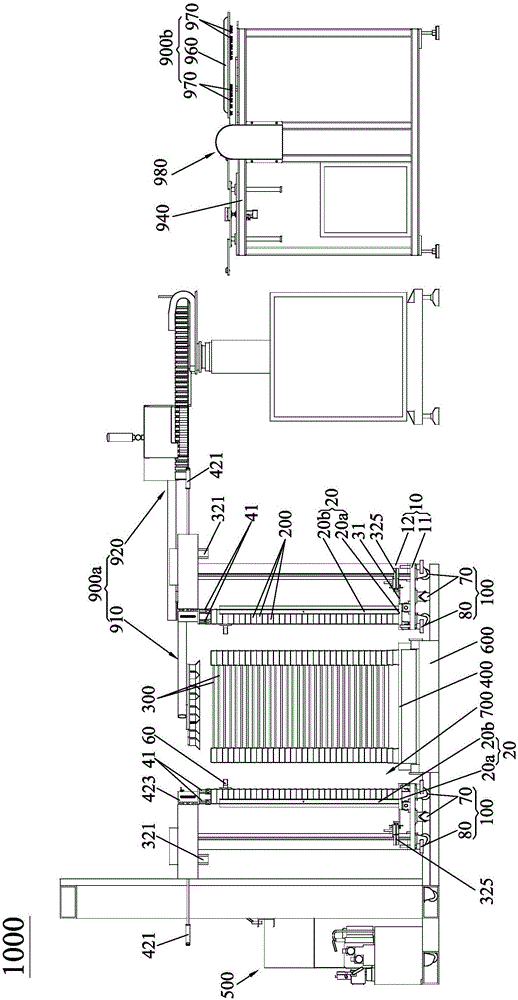

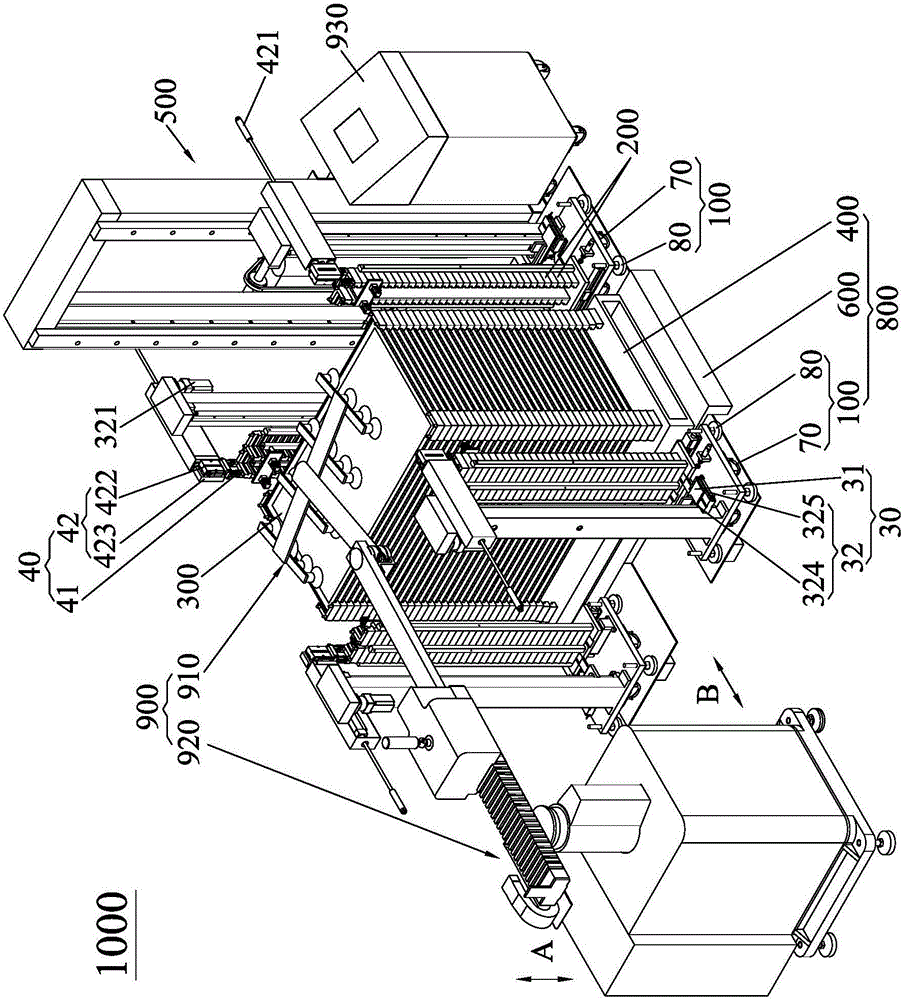

[0030] see figure 1 and figure 2 , the TV backplane automatic palletizing system 1000 of the present invention is adapted to automatically palletize the TV backplane 300 delivered from the production line, so as to realize the purpose of automatic palletizing of the TV backplane 300. Wherein, the automatic TV backboard palletizing system 1000 of the present invention includes a manipulator 900 a , a turning device 900 b and a TV backboard palletizing device 800 . The overturning device 900b turns over the TV backplane 300 conveyed by the production line from the first position to the second position, so as to match the grabbing requirements of the manipulator 900a; specifically, in this embodiment, the TV backplane 300 at the first position and When the TV bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com