Blast furnace cooling-wall cooling water pipe repairing method and structure thereof and pressure leakage detection device

A technology of cooling water pipe and repair method, applied in the direction of cooling device, inspection device, etc., can solve the problems of high repair cost, affecting the service life of blast furnace cooling stave, uneven local cooling effect and peripheral cooling effect, etc., to save maintenance time, The effect of saving spare parts and maintenance costs, improving indicators and operating rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

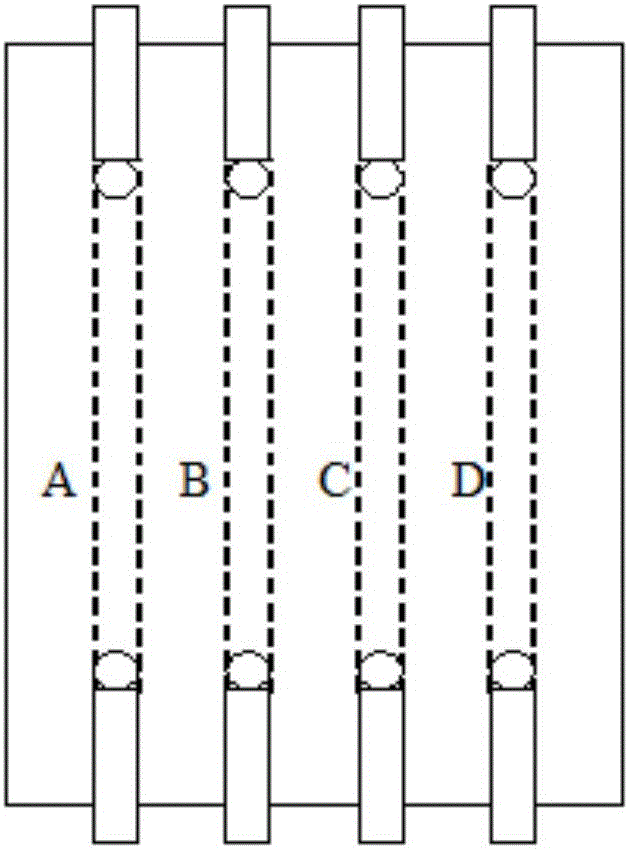

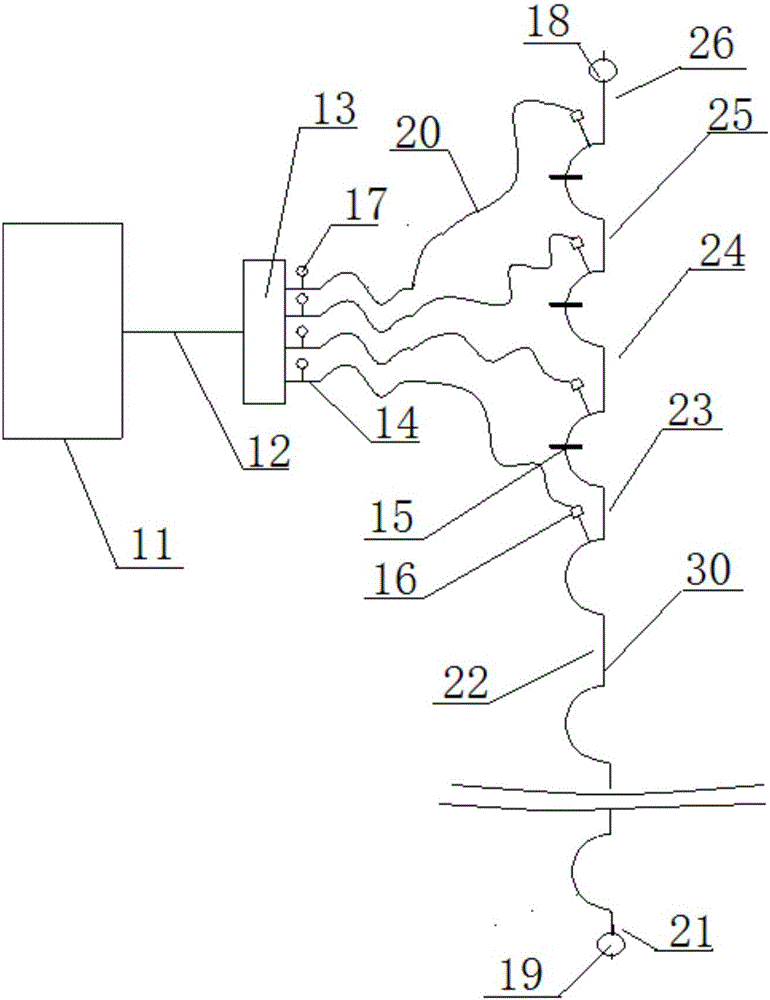

[0060] A steel plant with a 4000m 3 Since the blast furnace was ignited and put into operation in February and May of 2005, the production has been running stably and efficiently. However, since this year, it has been found that the stave has been damaged to varying degrees. Through investigation, there are currently three through cooling in the middle of the A blast furnace shaft 8B, 20D, and 57A. The water pipe leaks, that is, there is water leakage in at least three staves. The stave water pipe structure above the 12th floor of A blast furnace is as follows: figure 1 As shown, each stave has 4 water pipes, which are marked as A, B, C, and D respectively. 8B represents No. B pipe of the eighth stave, and the rest are analogized.

[0061] In view of past experience, once the blast furnace body cooling equipment is damaged, the damage speed of the blast furnace body cooling equipment will become faster and faster; the blast furnace has entered the stage of furnace protection...

Embodiment 2

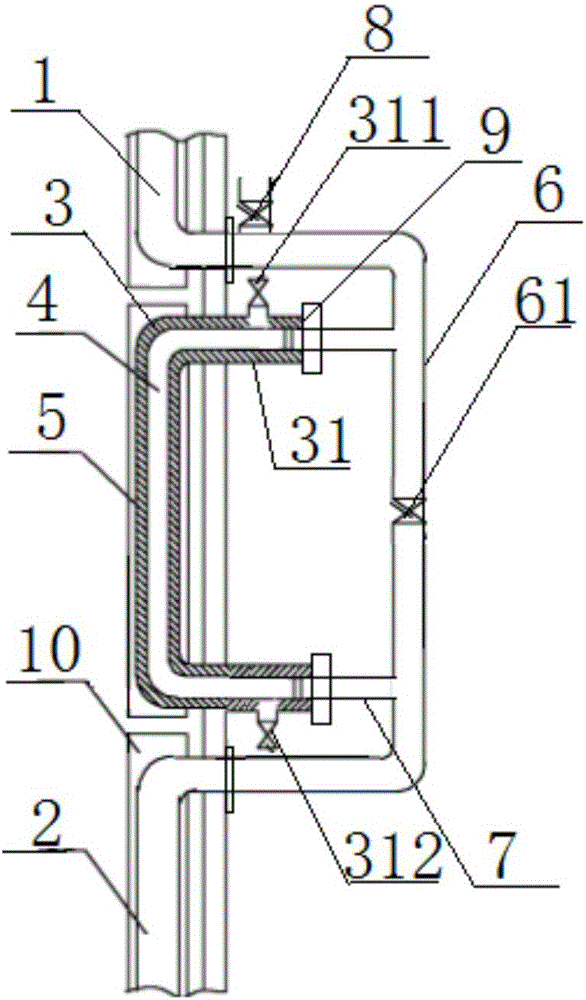

[0081] A method for repairing cooling water pipes of blast furnace staves in this embodiment, the specific steps are basically the same as in Embodiment 1, the improvement is that it also includes step 7, grouting: through the beating port opened at the extended end 31 of the damaged cooling water pipe 3 312 Fill the gap between the metal hose 4 and the damaged cooling water pipe 3 with high thermal conductivity grouting material, which has the dual functions of fixing the metal hose and conducting heat, and avoiding the frictional displacement of the metal hose due to the action of water flow. And reduce the service life of the metal hose, and open the air hole 311 at the protruding end 31 of the other end, and seal the annular ports at both ends, so that the beating work is smoother and more uniform, and avoid unnecessary air bubbles inside the slurry during beating Uniform distribution of slurry.

Embodiment 3

[0083] The method for repairing the cooling water pipe of a blast furnace stave in this embodiment, the specific steps are basically the same as in the embodiment 2, and the improvement is that in step 6, the two ends of the metal hose 4 are connected to the external cooling pipe 6 through the seamless connection pipe 7 The water inlet pipe and the water outlet pipe are formed to make the cooling water flow synchronously and improve the synchronization of the cooling effect. A water valve 61 can also be set on the external cooling pipe 6 between the water inlet pipe and the water outlet pipe. When synchronization is required, the water valve is closed, and when synchronization is not required, the water valve is opened. The operation is simple and the flexibility is strong.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com