Chelating agent and preparation method and application thereof

A chelating agent and reaction technology, applied in the field of chelating agent and its preparation, can solve the problems of complex construction process, poor inhibition performance, poor temperature resistance, etc., and achieve the effects of wide source of raw materials, stable performance and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

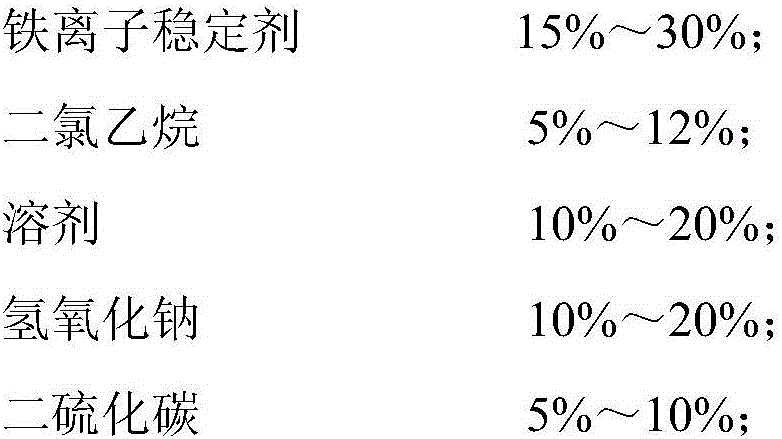

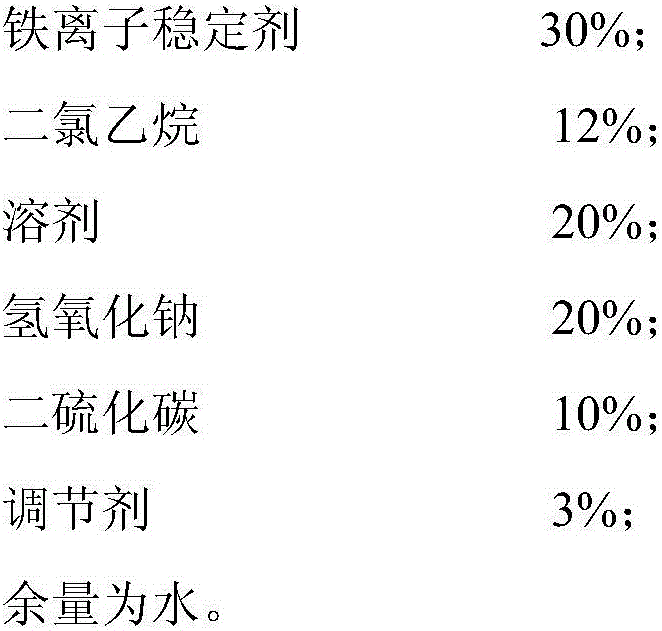

[0037] This embodiment 1 provides a chelating agent, which is composed of the following raw material components in mass percentage, 15% to 30% iron ion stabilizer, 5% to 12% dichloroethane, 10% to 20% ethanol, 10% ~20% sodium hydroxide, 5%~10% carbon disulfide, 1.5%~4.5% regulator, and the balance is water.

[0038] The iron ion stabilizer can chelate Ca 2+ 、AL 3+ , Fe 3+ and other metal ions to avoid the formation of secondary or tertiary precipitates. The solvent can make the iron ion stabilizer and ethylene dichloride react as a homogeneous reaction, and is commercially available chemically pure or industrially pure. 50%-100% of the mass fraction of the water phase of the dichloroethane reacts with the iron ion stabilizer to improve its chelating ability. The sodium hydroxide is commercially available chemically pure or industrially pure, which improves the reaction rate. The carbon disulfide is an analysis solvent and a reactant, and is an industrial product. The reg...

Embodiment 2

[0041] On the basis of Example 1, the iron ion stabilizer is a solution prepared from ethylenediaminetetraacetic acid and nitrilotriacetic acid, and the mass ratio is (1-1.5):(2-2.5). Preferably, the mass ratio of ethylenediaminetetraacetic acid to nitrilotriacetic acid is 1:2.

Embodiment 3

[0043] On the basis of Example 1, the regulator is a solution made of citric acid with a mass percentage concentration of 36% and acetic acid with a mass percentage concentration of 64%, and the mass ratio is (2~3):(1~1.5) . Preferably, the mass ratio of citric acid to acetic acid is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com