Aluminum substrate used for packaging LED (Light Emitting Diode)

A technology of LED packaging and aluminum substrates, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of complex processing, low luminous efficiency, poor consistency, etc., and achieve the effects of good heat dissipation, improved luminous efficiency, and simplified processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

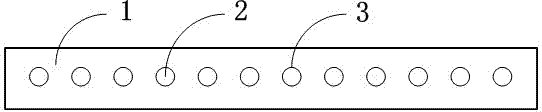

[0024] Such as figure 1 Shown is a top view of the aluminum substrate used for LED packaging in the embodiment of the present invention. According to the number of LED chips to be packaged, round holes are punched on the common aluminum plate 1 . The mirror aluminum plate 2 with the same length and width as the ordinary aluminum plate 1 is taken, and it is pressed at high temperature to become one body after pressing. The holes of the ordinary aluminum plate 1 and the mirror aluminum plate 2 form a circular groove 3 .

[0025] The ordinary aluminum plate 1 and the mirror aluminum plate 2 have the same shape and size.

[0026] The thermal conductivity of the mirror aluminum plate 2 is 1.3 times that of the ordinary aluminum plate 1, and has a good reflective effect, with a reflectivity of 85% and high tensile strength.

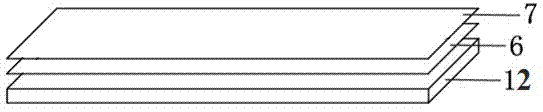

[0027] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com