Automatic production line of rebar ladder

A technology for automated production lines and steel ladders, applied in resistance welding equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of unstable welding quality, large use of steel ladders, poor quality stability, etc., and achieve stable product quality. , The effect of improving product yield and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

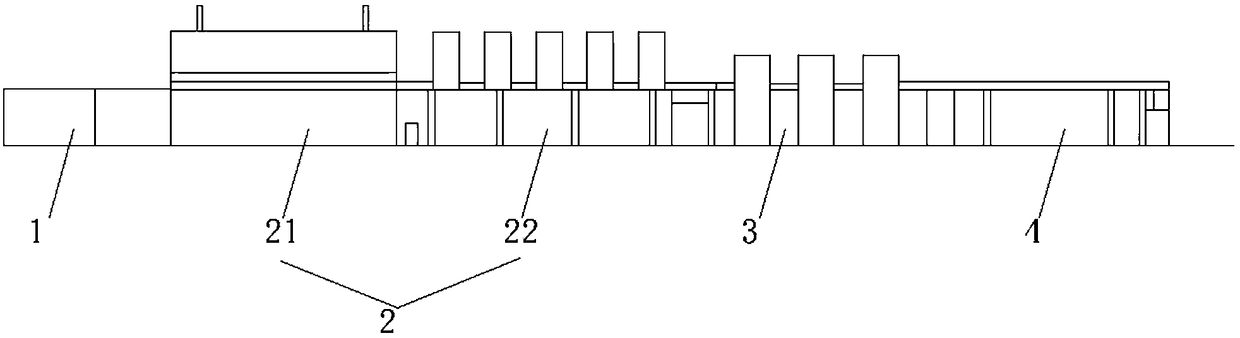

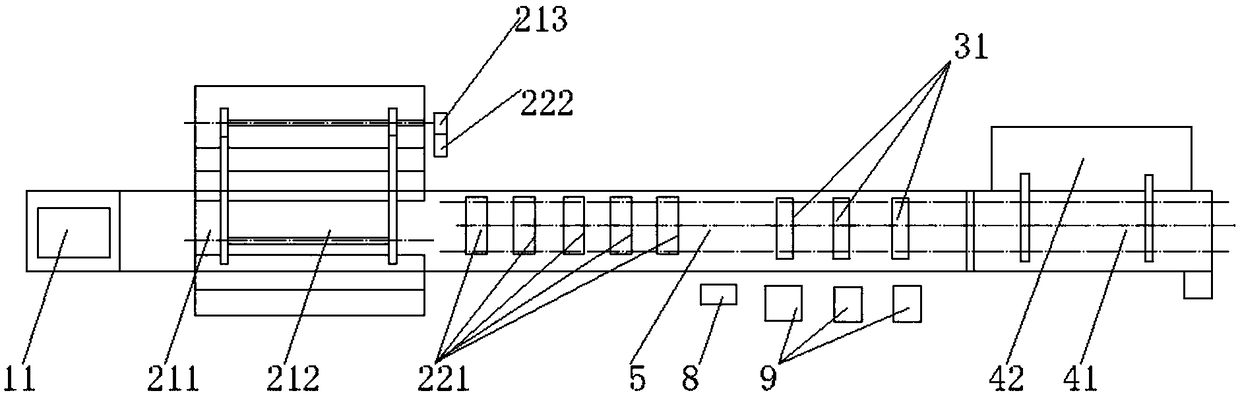

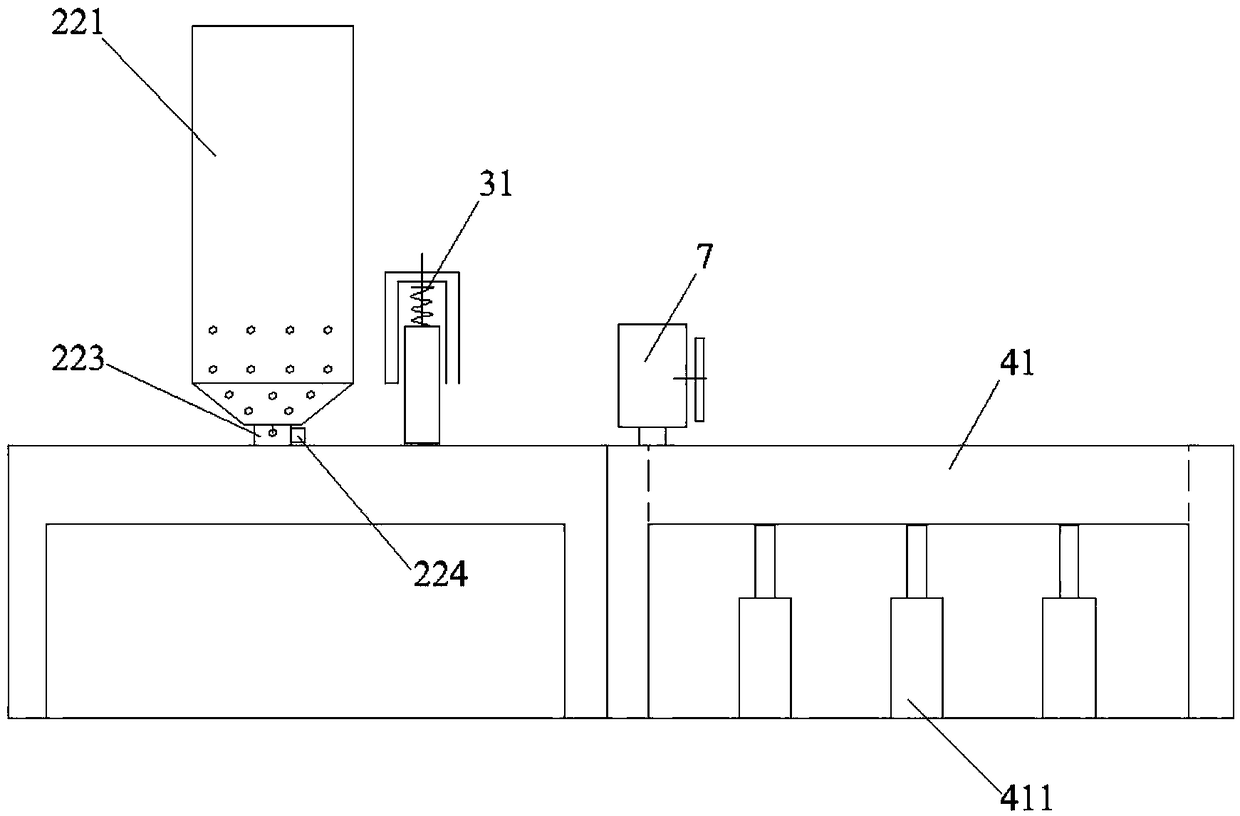

[0052] A common steel bar ladder includes two long bars parallel to each other and a plurality of short bars arranged between the two long bars and respectively connected to the two long bars. This embodiment provides a mine-used steel bar ladder automated production lines, such as figure 1 , figure 2 with image 3 As shown, it includes straightening area 1, reinforcement area 2, welding area 3 and finished product area 4 which are arranged in sequence according to the production process, and the material transportation between each area is carried out through the conveying line 5;

[0053] The straightening area includes a drawing and straightening machine 11, and the drawing and straightening machine 11 straightens the long tendons 61 and transports them to the tendon cloth area 2 through the conveying line 5. Preferably, the straightening The straightening area is equipped with double rows of drawing and straightening machines 11, which effectively improves the straighte...

Embodiment 2

[0077] The steel bar ladder automatic production line of the present embodiment is basically the same as the first embodiment, the difference is that, as Figure 5 As shown, the welding electrodes 313 are two welding copper rods arranged in parallel, the welding ends of the welding copper rods are provided with cut corners 317, and the slopes of the cut corners 317 can be pressed against the corresponding long ribs 61 When welding, the welding robot arm 312 drives the welding copper bar to move in the direction where the long rib 61 is located, the slope of the cut corner 317 is in contact with the outer surface of the long rib 61, and the The cut corner 317 can exert inward pressure on the long rib 61 along with the movement of the welding copper rod. That is, the welding copper rod moves toward the direction where the long rib 61 is located, and the welding copper rod cooperates with the welding pressure-bearing copper block 315 to heat the welding point between the long rib...

Embodiment 3

[0080] The steel bar ladder automatic production line of this embodiment is basically the same as that of Embodiment 1, the difference is that a welding inspection area (not shown) is provided between the welding area 3 and the finished product area 4, and the welding inspection area includes a welding inspection area. device and a repair welding device, the welding detection device includes a weld detector, the weld detector is connected to the repair welding device and can transmit signals to the repair welding device, and the weld seam welding device The structure is the same as that of the welding device 31 in the welding area 3 , the repair welding device receives the signal transmitted by the weld detector and performs repair welding on the welding defect. The increase of the welding detection area effectively reduces the scrap rate of products, improves the quality of products, makes the production stability of the production line good, and the overall production efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com