Natural gas hydrate sediment triaxial test device

A hydrate sediment, triaxial test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, to achieve the effects of improving accuracy, reducing volume, avoiding cavity deformation and hydraulic water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

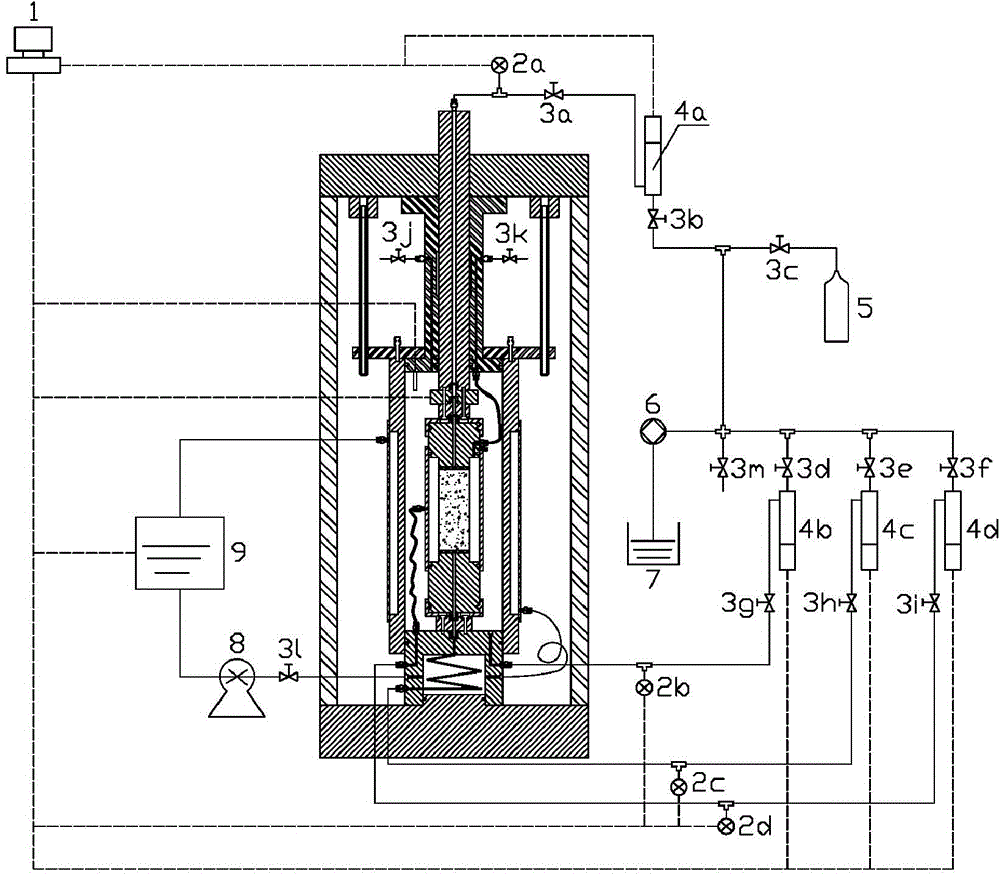

[0026] figure 1 Shown is a system diagram of a gas hydrate sediment triaxial test device. The following describes the gas hydrate sediment triaxial test process according to each system function:

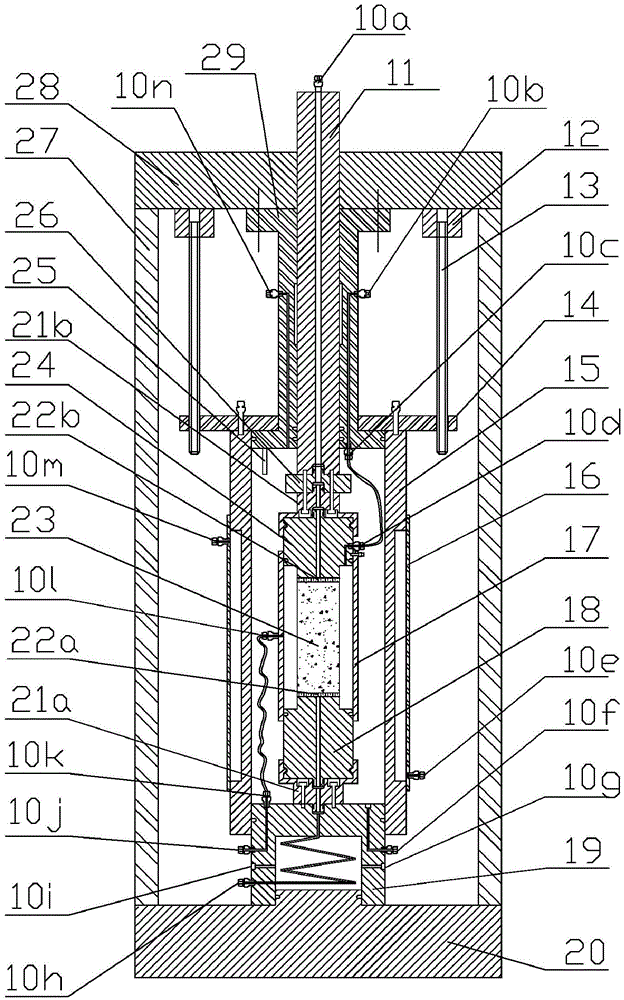

[0027] 1) The working process of the temperature control system: the constant temperature tank 9 injects a certain temperature cooling liquid into the cavity of the base 19 and the ring cavity formed by the pressure chamber cylinder 15 and the heat preservation cover cylinder 16 through the circulation pump 8 and the needle valve 31. The cooling liquid in the cavity of the base 19 pre-cools the pore gas and pore water entering the natural gas hydrate deposit sample 23 to prevent the decomposition of natural gas hydrate, and at the same time controls the temperature of the liquid in the pressure chamber through the upper surface of the base 19; The cooling liquid in the annular cavity formed by the pressure chamber cylinder 15 and the insulation cover cylinder 16 is used to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com