Patents

Literature

121results about How to "Etch rate reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precursors for CVD silicon carbo-nitride films

ActiveUS20060258173A1Easy to movePromote formationGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingSilanesRoom temperature

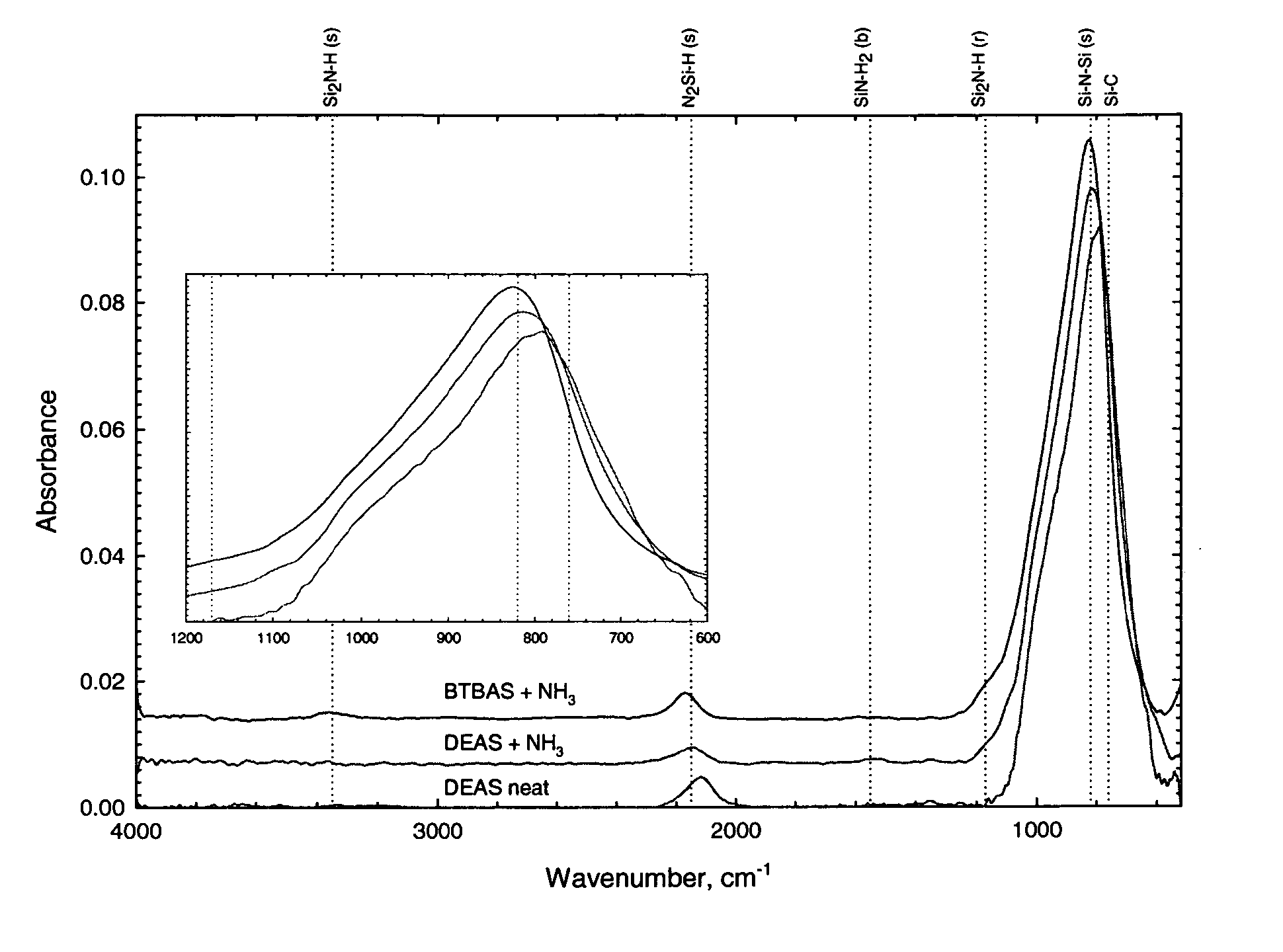

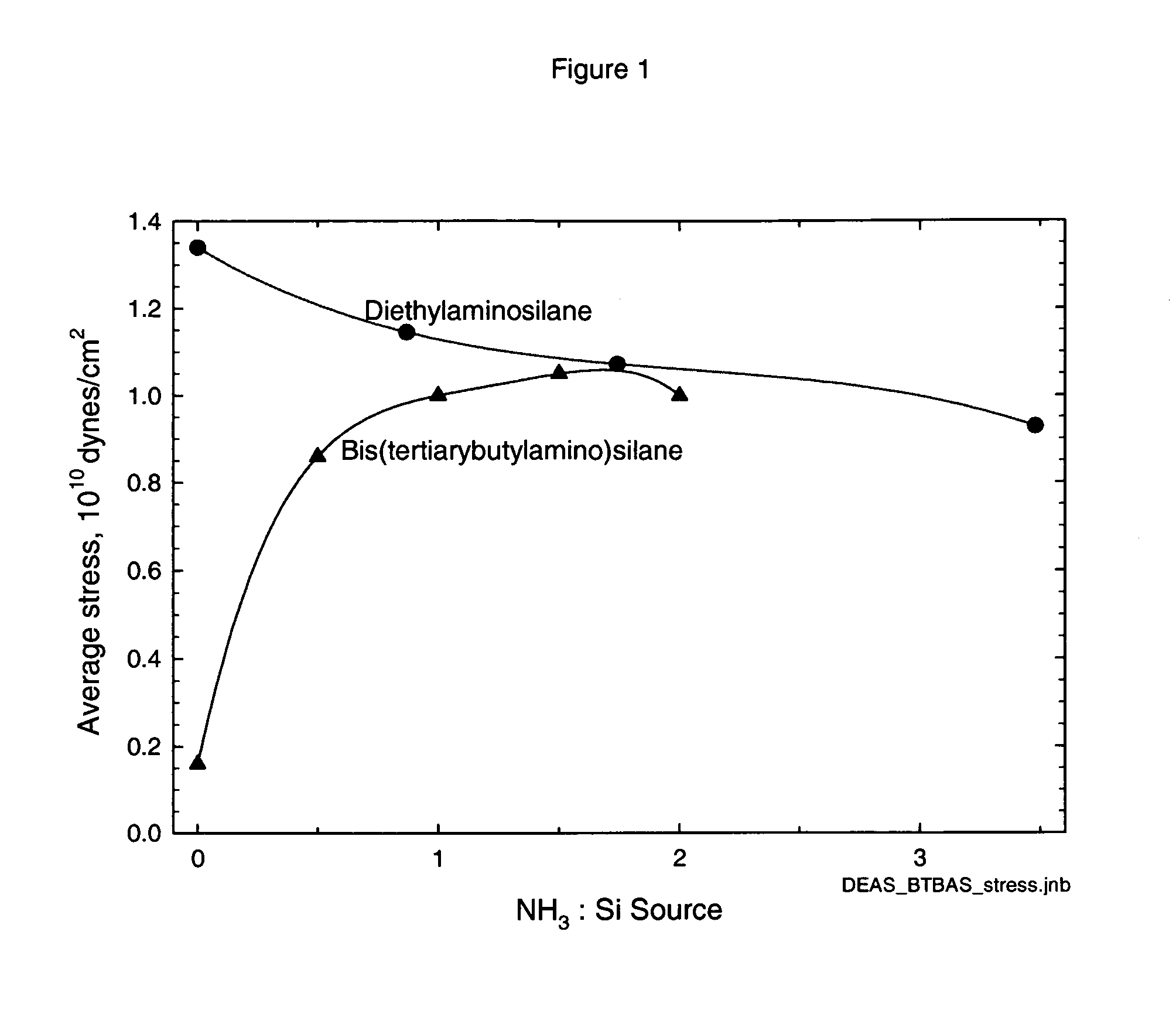

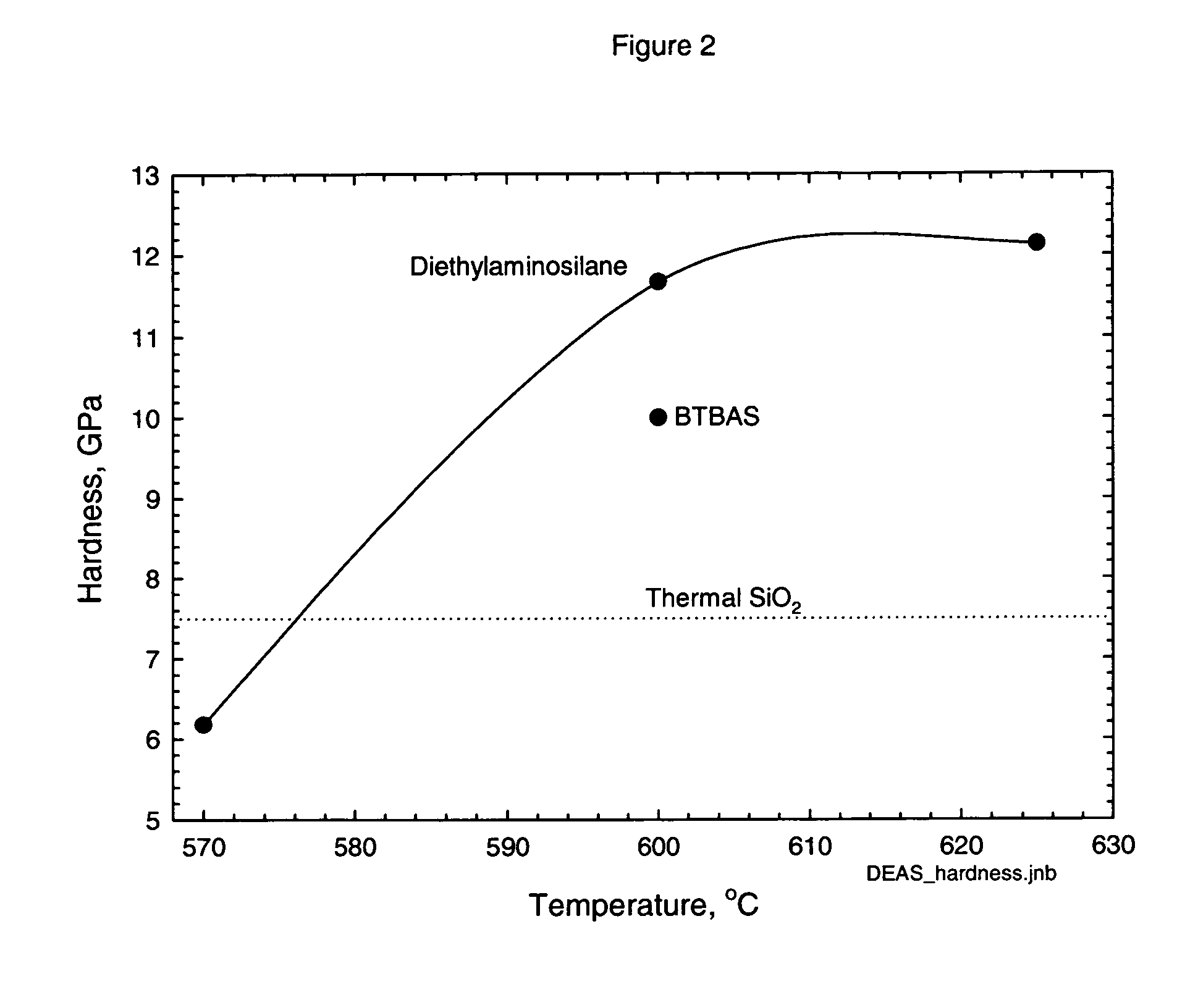

Classes of liquid aminosilanes have been found which allow for the production of silicon carbo-nitride films of the general formula SixCyNz. These aminosilanes, in contrast, to some of the precursors employed heretofore, are liquid at room temperature and pressure allowing for convenient handling. In addition, the invention relates to a process for producing such films. The classes of compounds are generally represented by the formulas: and mixtures thereof, wherein R and R1 in the formulas represent aliphatic groups typically having from 2 to about 10 carbon atoms, e.g., alkyl, cycloalkyl with R and R1 in formula A also being combinable into a cyclic group, and R2 representing a single bond, (CH2)n, a ring, or SiH2.

Owner:VERSUM MATERIALS US LLC

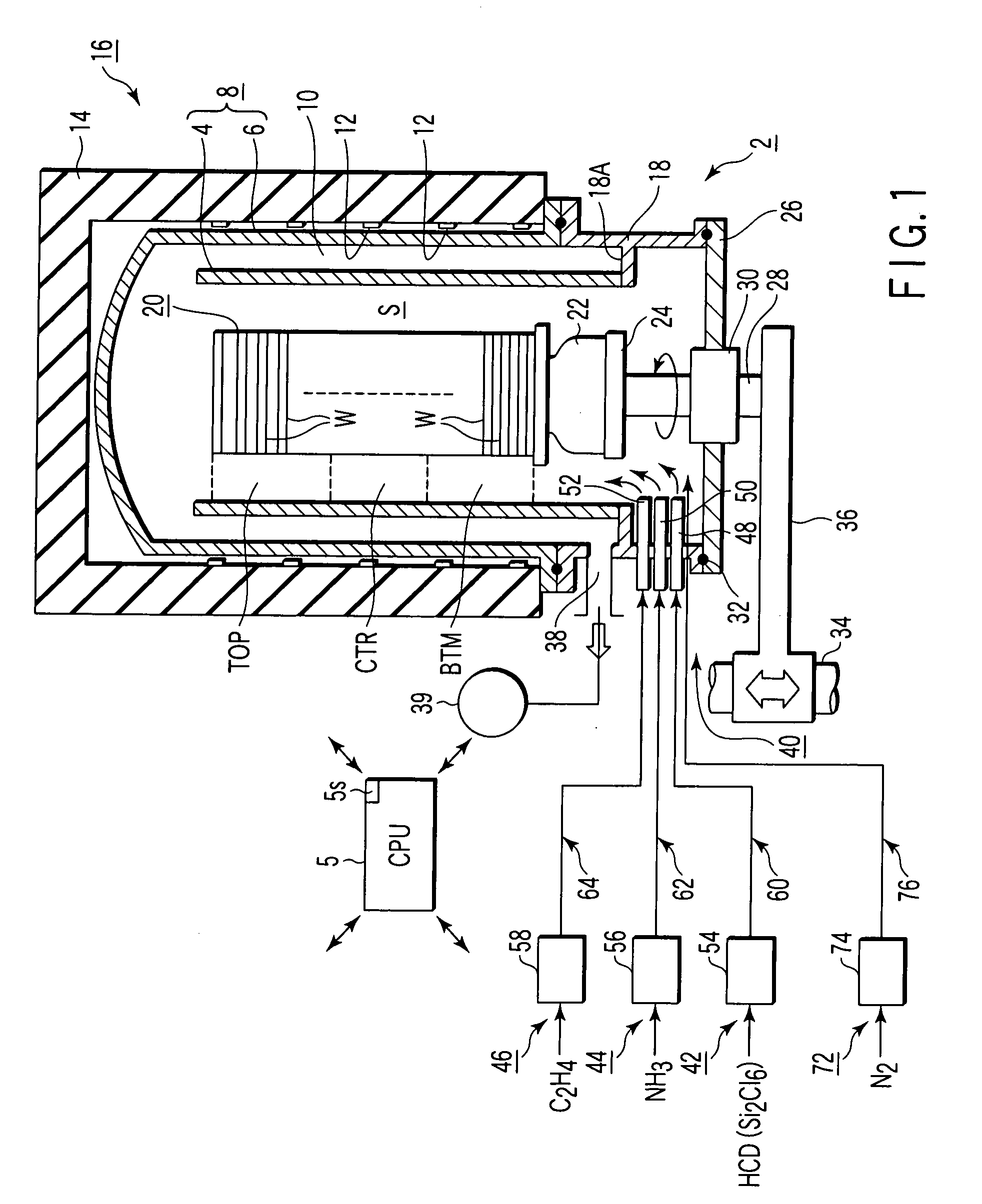

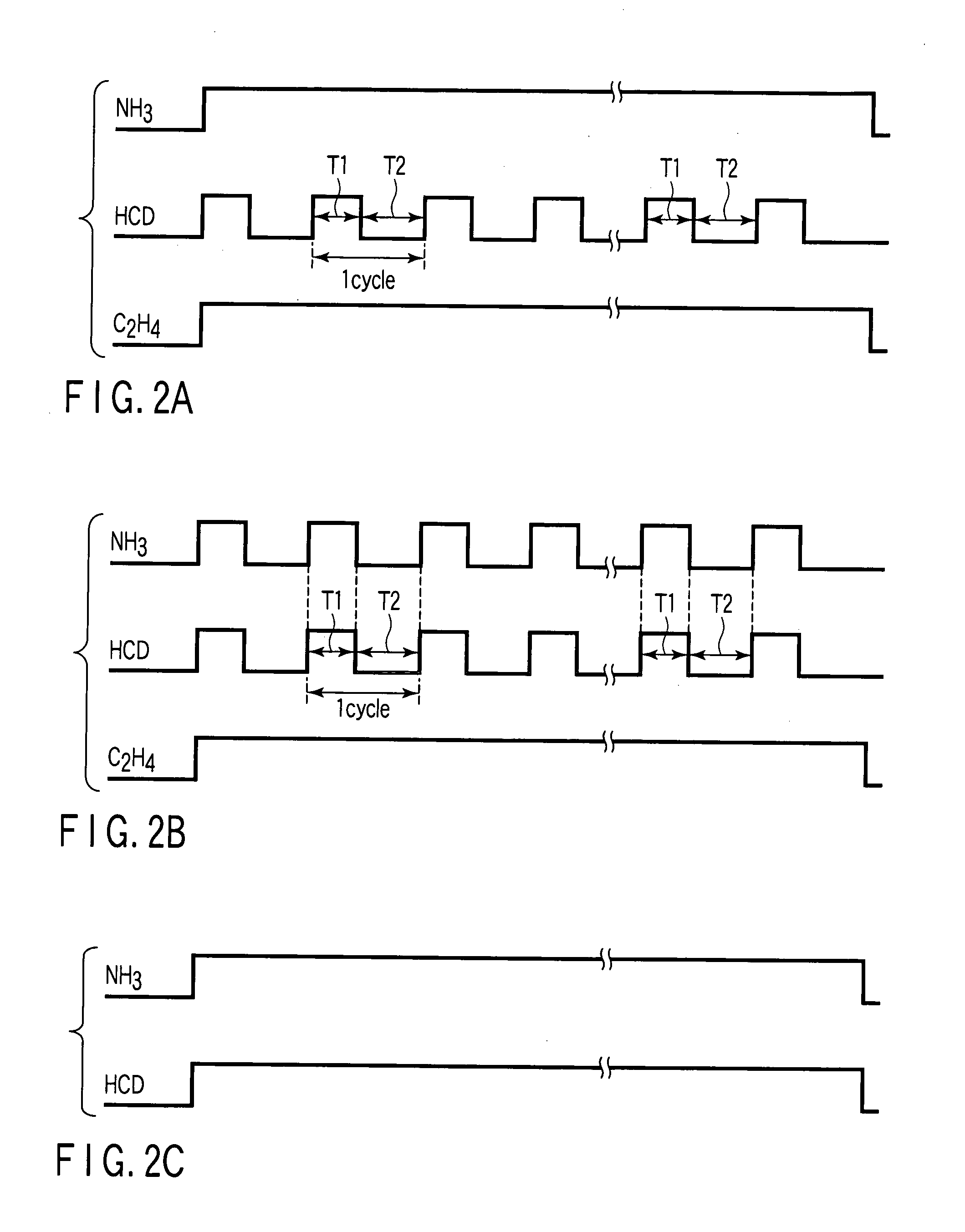

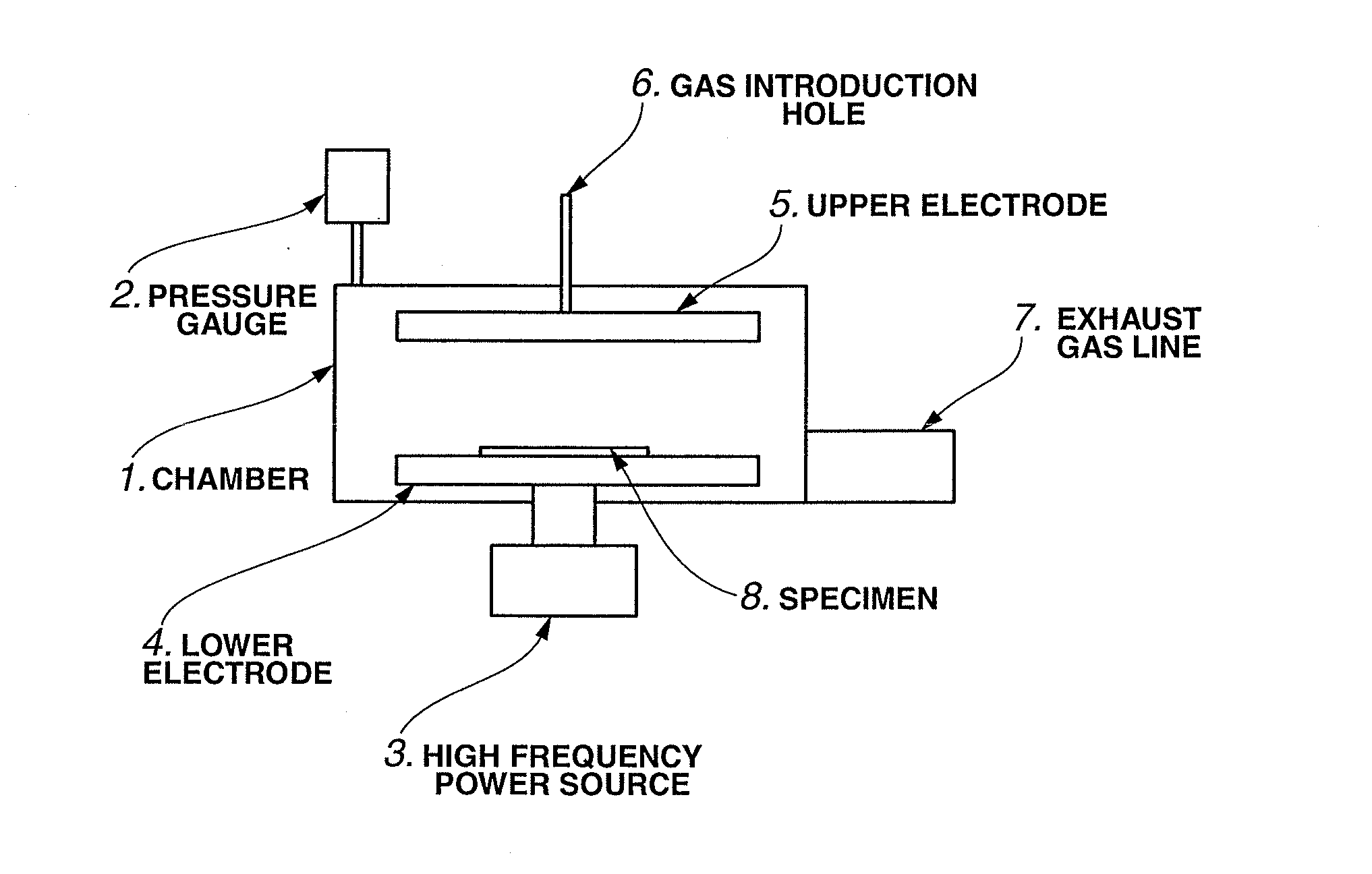

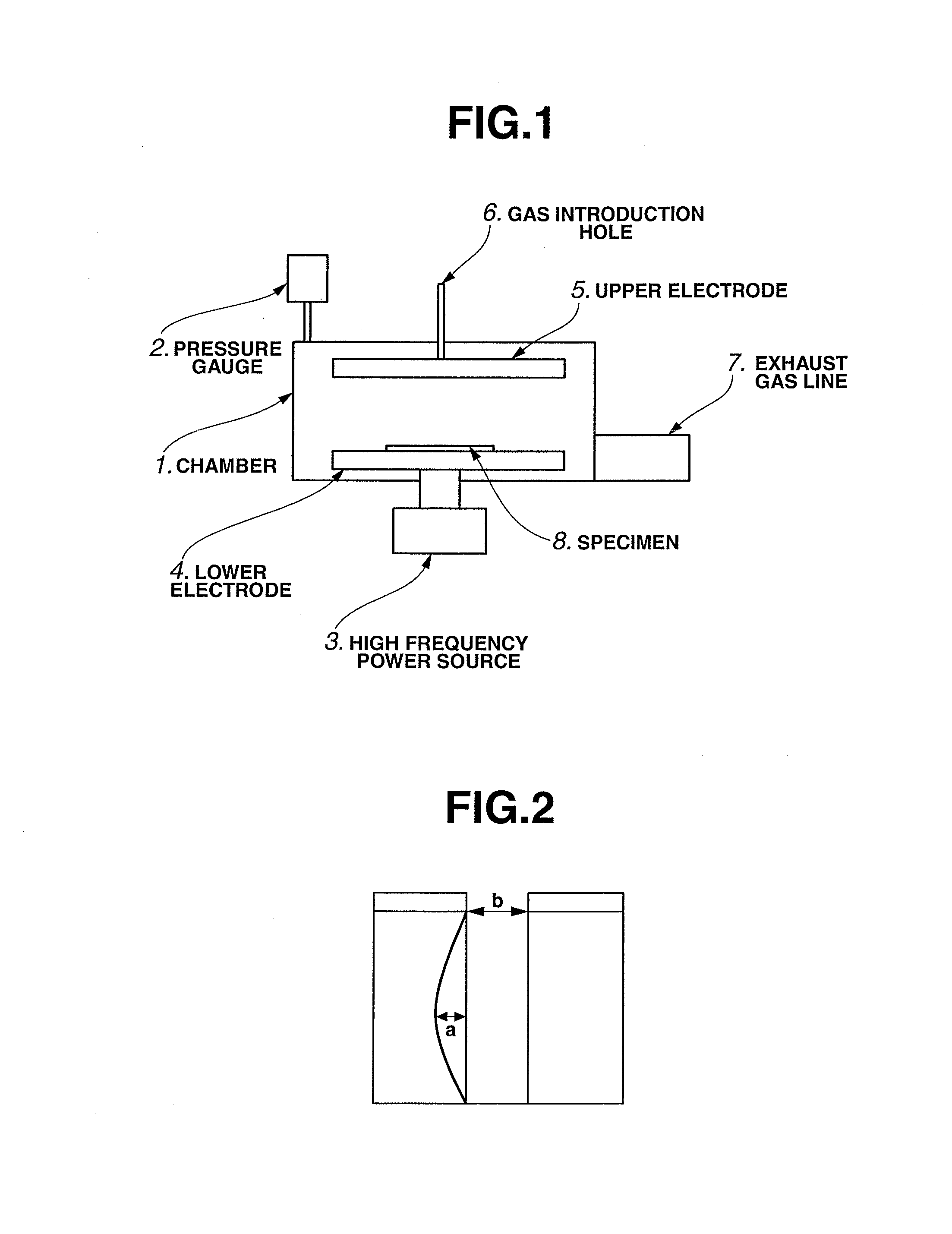

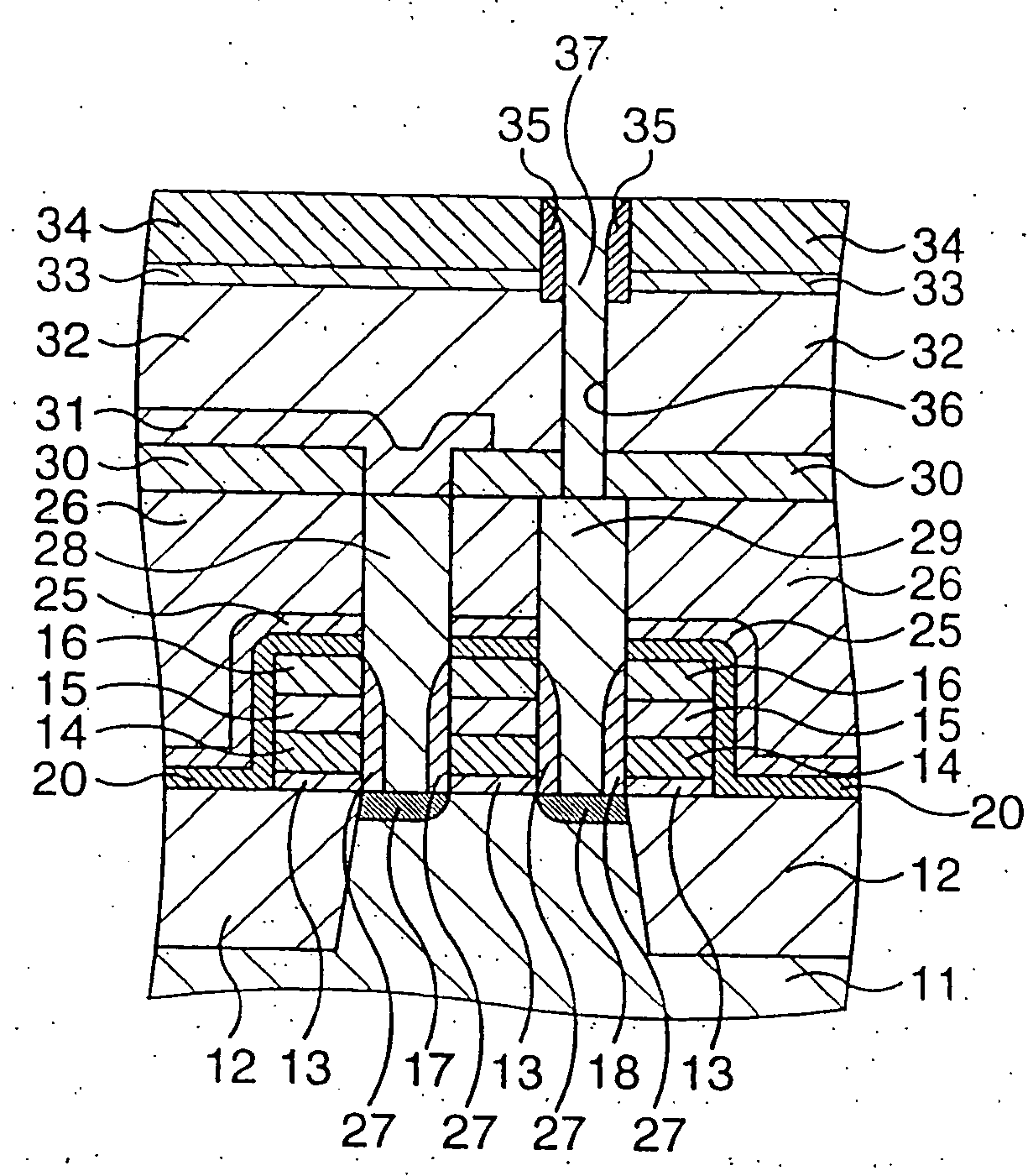

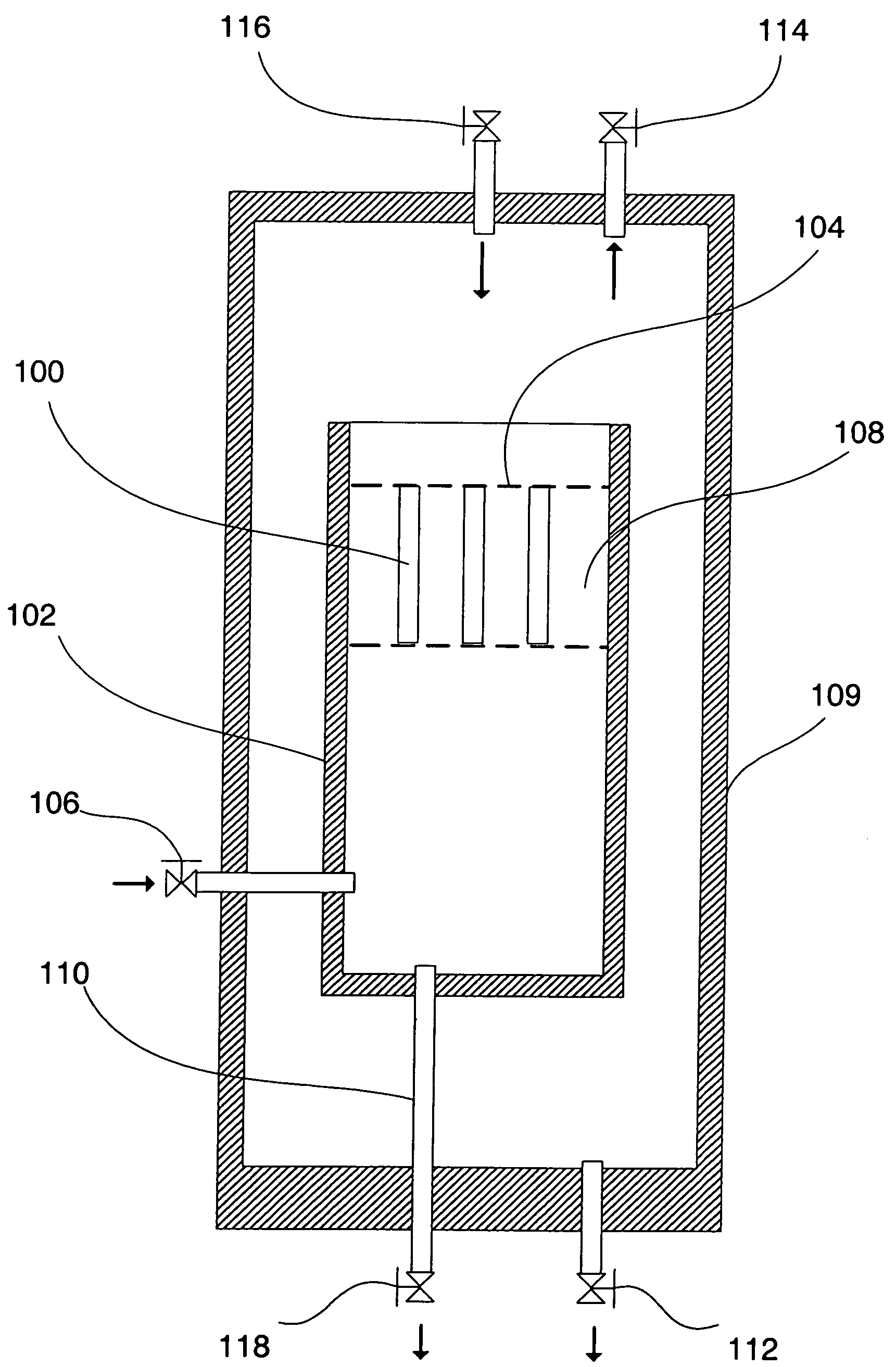

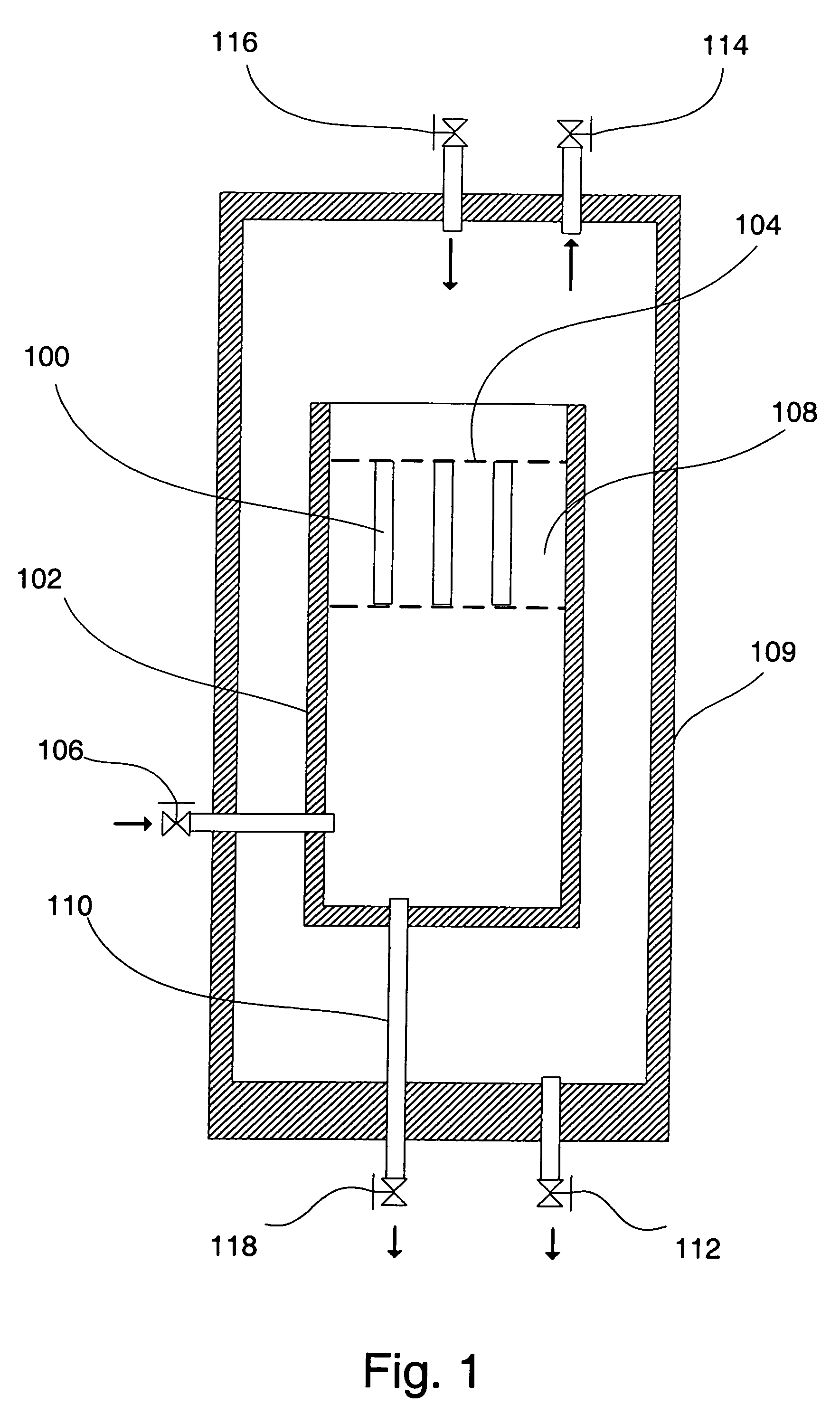

Cvd method for forming silicon nitride film

ActiveUS20060286817A1Low process temperatureImprove controllabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesAmmonia gas

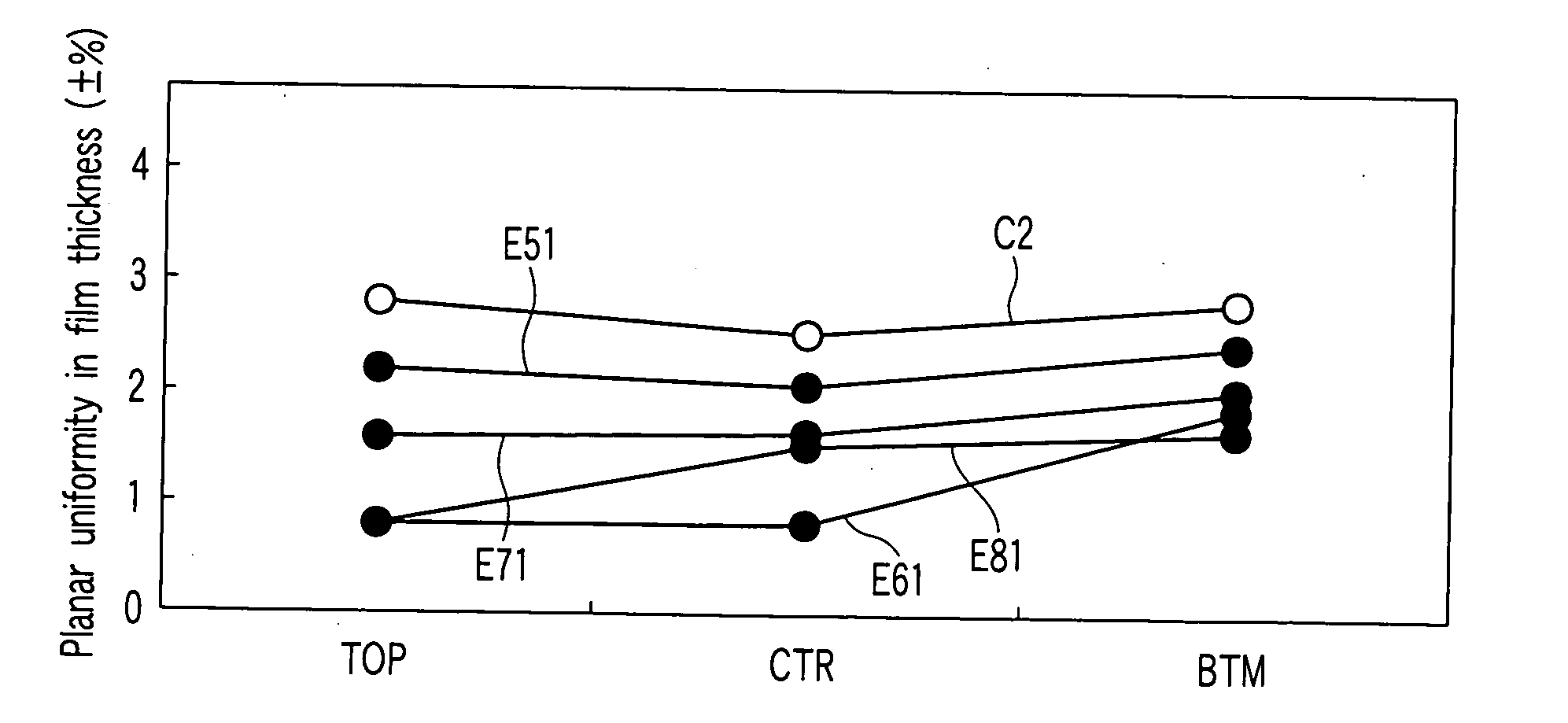

A CVD method for forming a silicon nitride film includes exhausting a process chamber (8) that accommodates a target substrate (W), and supplying a silane family gas (HCD) and ammonia gas (NH3) into the process chamber, thereby forming a silicon nitride film on the target substrate by CVD. Said forming a silicon nitride film on the target substrate alternately includes a first period of performing supply of the silane family gas (HCD) into the process chamber (8), and a second period of stopping supply of the silane family gas.

Owner:TOKYO ELECTRON LTD

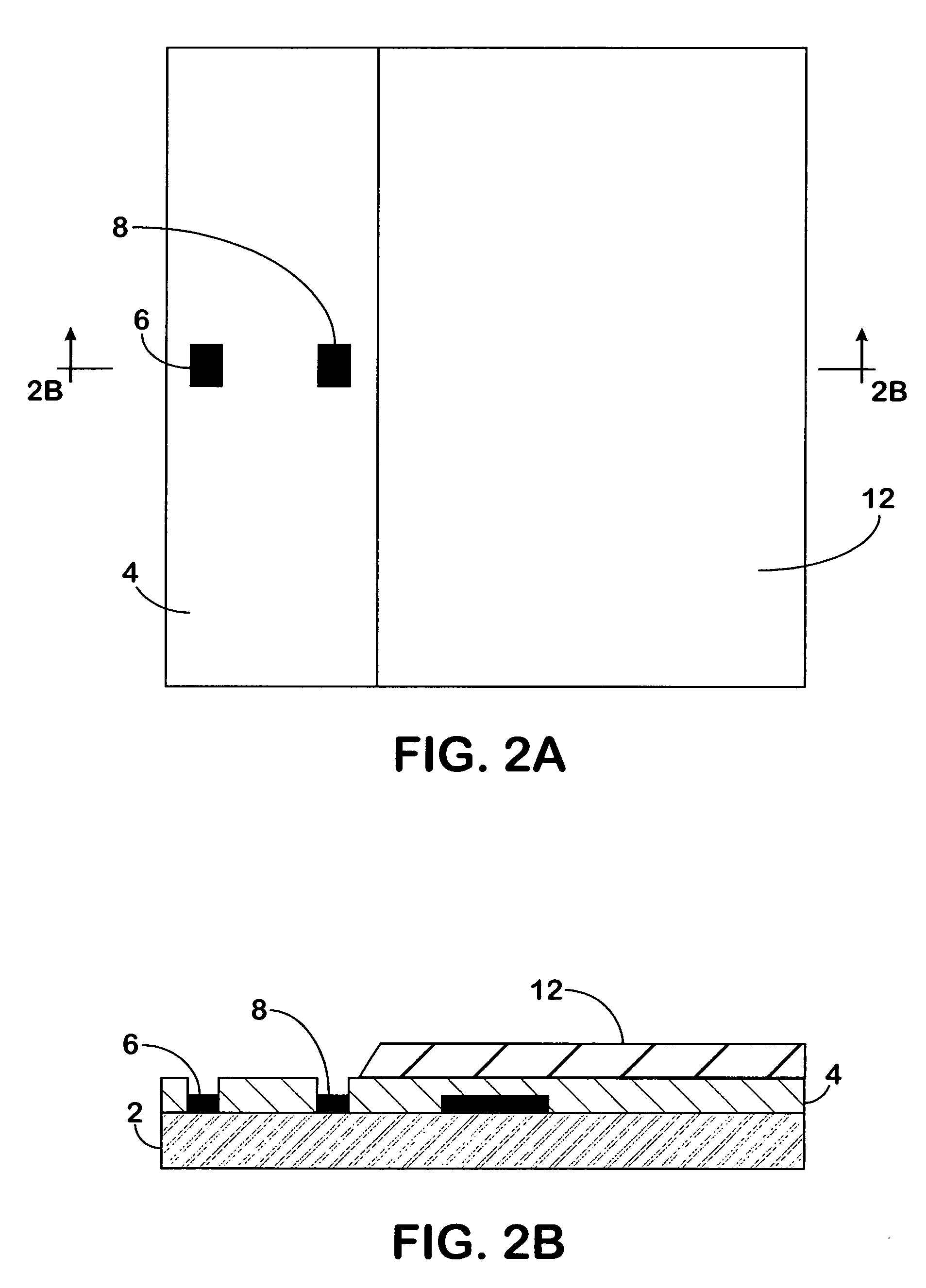

Manufacture of MEMS structures in sealed cavity using dry-release MEMS device encapsulation

InactiveUS7008812B1Eliminates undesirable liquid surface tensionIncrease etch rateAcceleration measurement using interia forcesSolid-state devicesMaterials sciencePlasma etching

The disclosed fabrication methodology addresses the problem of creating low-cost micro-electro-mechanical devices and systems, and, in particular, addresses the problem of delicate microstructures being damaged by the surface tension created as a wet etchant evaporates. This disclosure demonstrates a method for employing a dry plasma etch process to release encapsulated microelectromechanical components.

Owner:CYMATICS LAB CORP

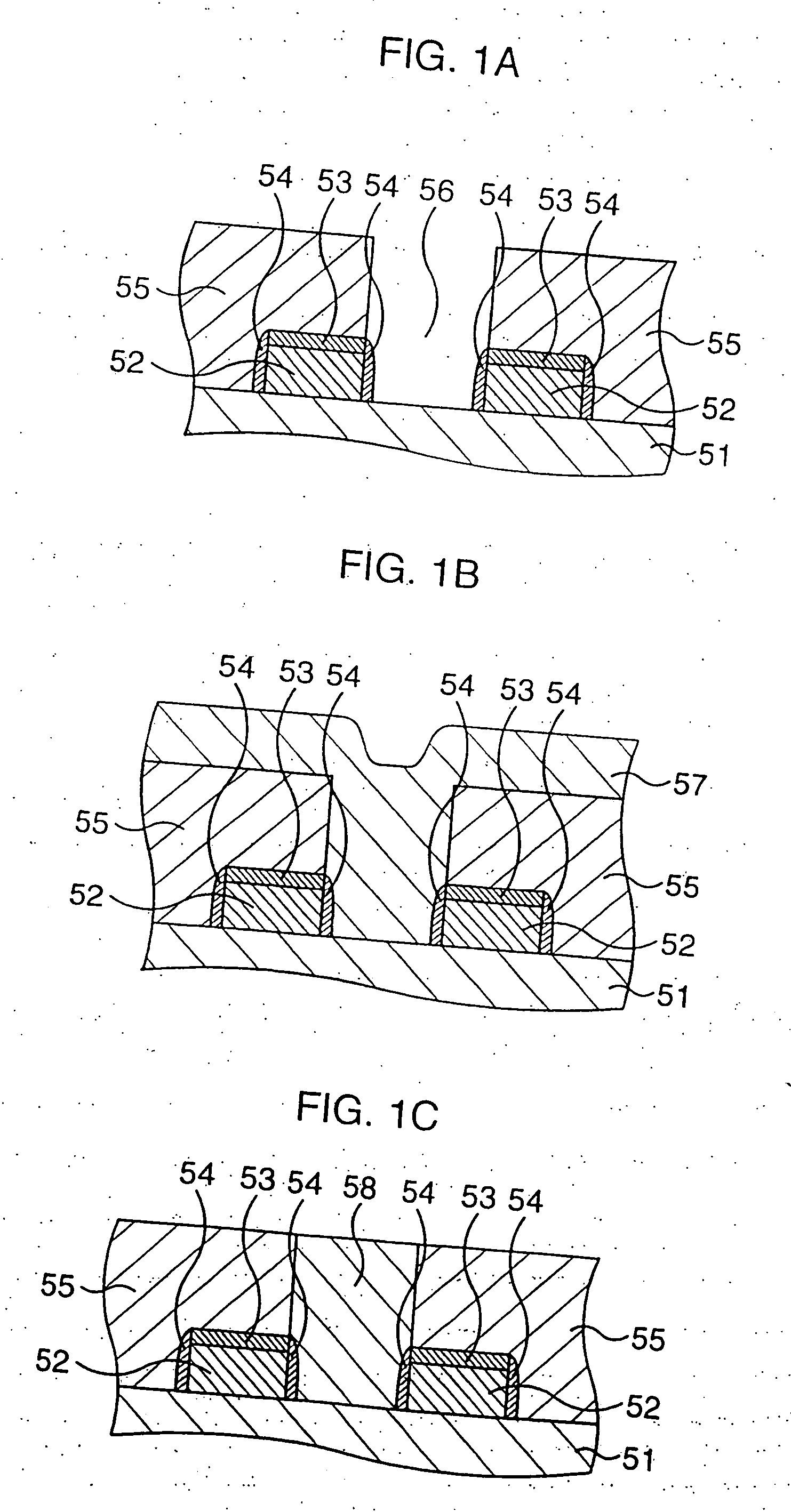

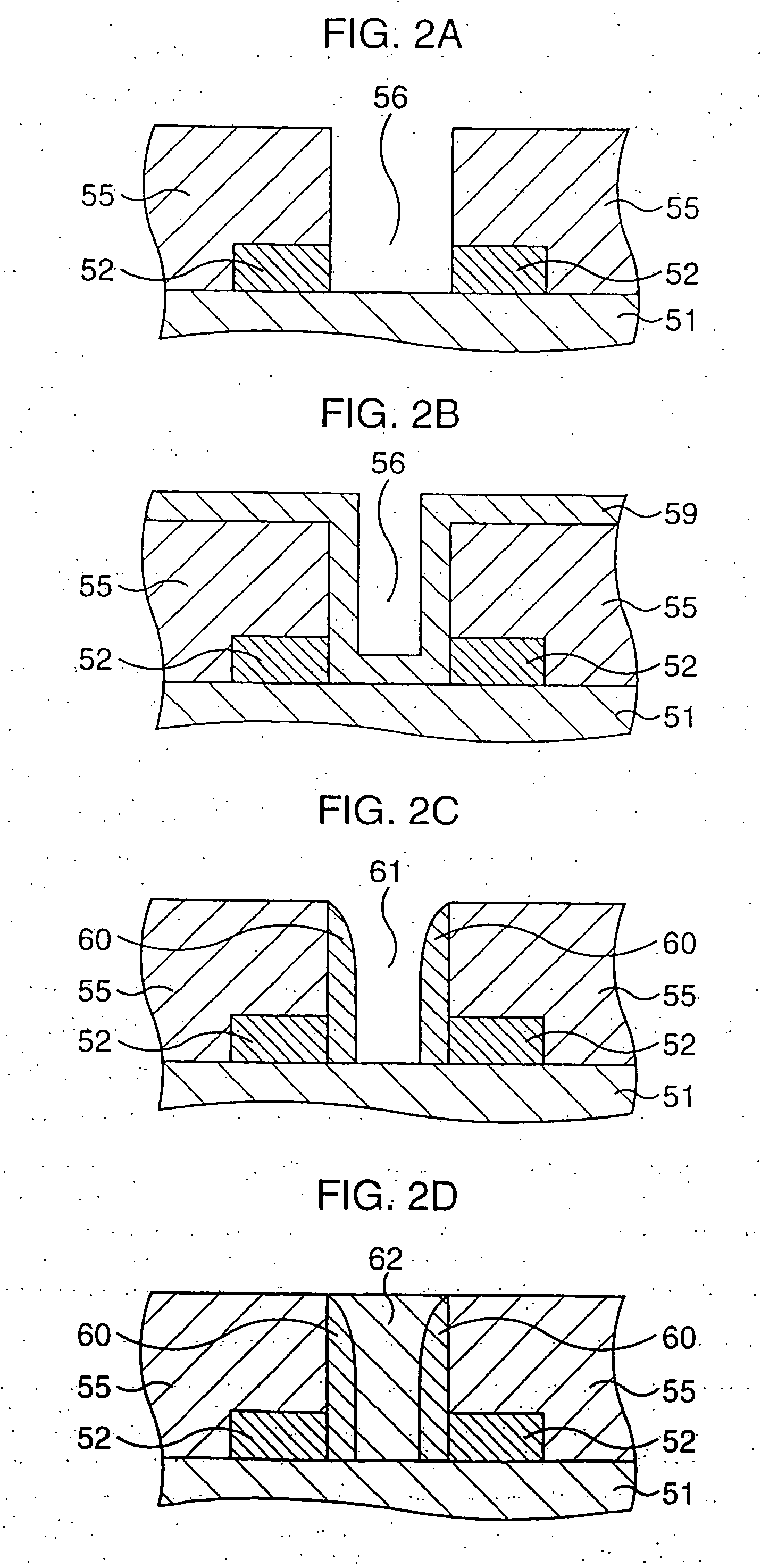

Shallow trench isolation process

ActiveUS6960781B2Improve performanceTrench sidewallTransistorSolid-state devicesEngineeringTransistor

A structure including a transistor and a trench structure, with the trench structure inducing only a portion of the strain in a channel region of the transistor.

Owner:TAIWAN SEMICON MFG CO LTD

High pressure high non-reactive diluent gas content high plasma ion density plasma oxide etch process

InactiveUS6238588B1Increase pressureHigh strengthElectric discharge tubesDecorative surface effectsHigh plasmaOxygen

The invention is embodied in a method of processing a semiconductor workpiece in a plasma reactor chamber, including supplying a polymer and etchant precursor gas containing at least carbon and fluorine into the chamber at a first flow rate sufficient of itself to maintain a gas pressure in the chamber in a low pressure range below about 20 mT, supplying a relatively non-reactive gas into the chamber at second flow rate sufficient about one half or more of the total gas flow rate into the chamber, in combination with the first flow rate of the precursor gas, to maintain the gas pressure in the chamber in a high pressure range above 20 mT, and applying plasma source power into the chamber to form a high ion density plasma having an ion density in excess of 1010 ions per cubic centimeter. In one application of the invention, the workpiece includes an oxygen-containing overlayer to be etched by the process and a non-oxygen-containing underlayer to be protected from etching, the precursor gas dissociating in the plasma into fluorine-containing etchant species which etch the oxygen-containing layer and carbon-containing polymer species which accumulate on the non-oxygen-containing underlayer. Alternatively, the high pressure range may be defined as a pressure at which the skin depth of the inductive field exceeds {fraction (1 / 10)} of the gap between the inductive antenna and the workpiece.

Owner:APPLIED MATERIALS INC

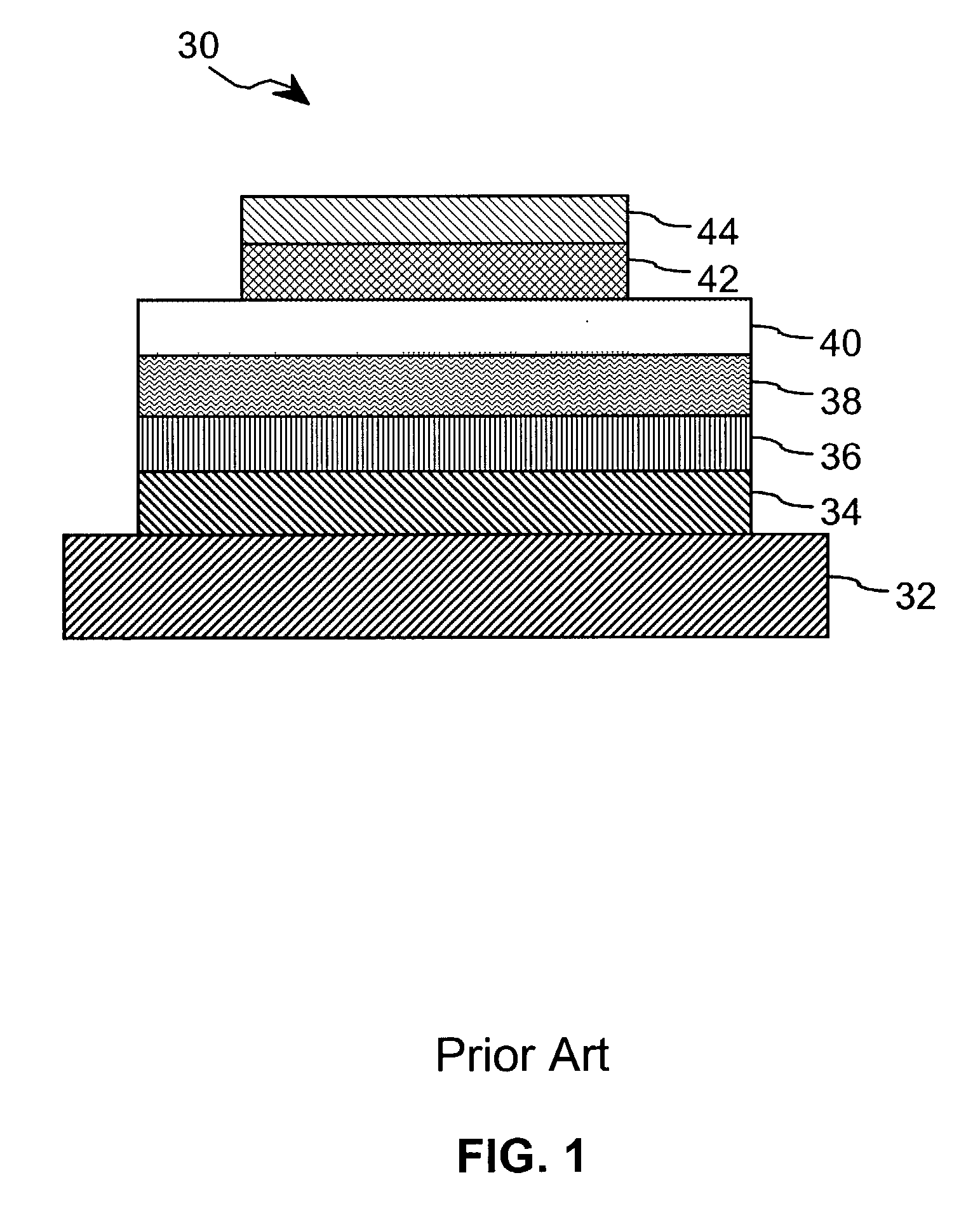

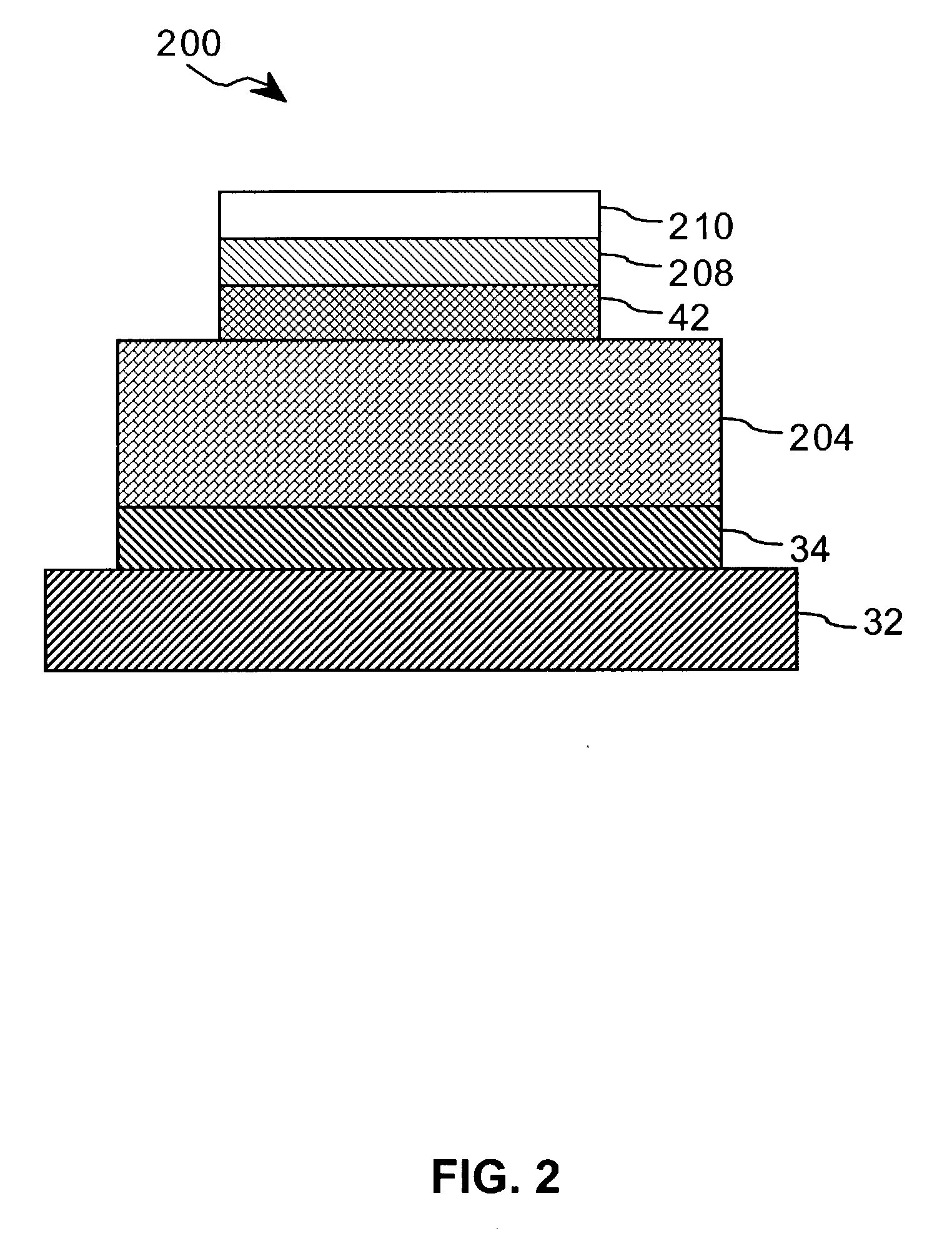

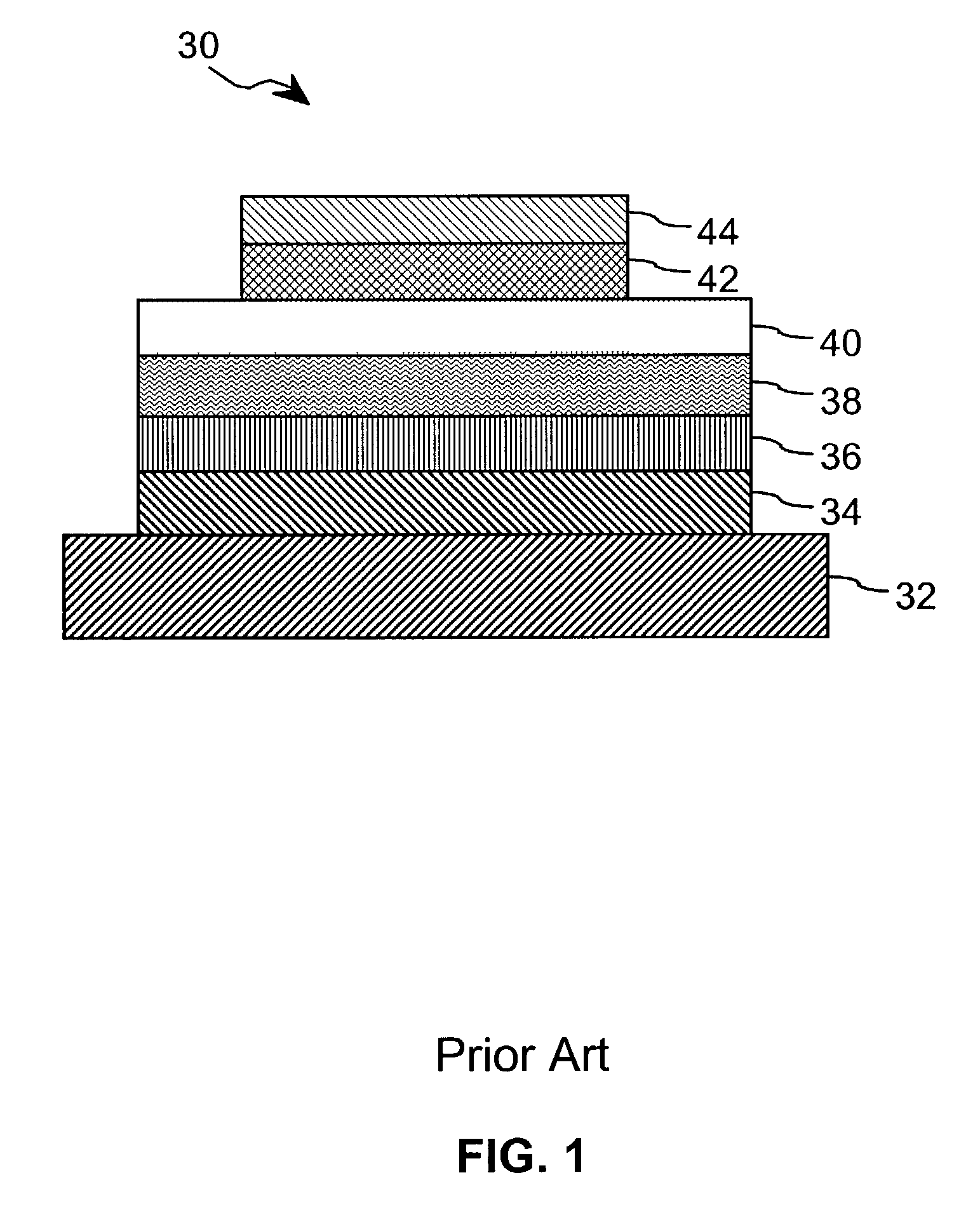

Low temperature process for passivation applications

InactiveUS20040113542A1Improve encapsulation propertyLow etch rateDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceAnode

An organic electroluminescent device comprising an anode layer on a substrate, an organic layer on the anode layer, and a cathode layer on the organic layer. In one embodiment, the cathode layer is subjected to H2 plasma prior to deposition of a protective layer over the cathode. In another embodiment, the organic electroluminescent device is encapsulated with an inner encapsulation layer on the cathode layer, and an outer encapsulation layer on the inner encapsulation layer. The inner layer is optimized for adhesion to the cathode layer.

Owner:APPLIED MATERIALS INC

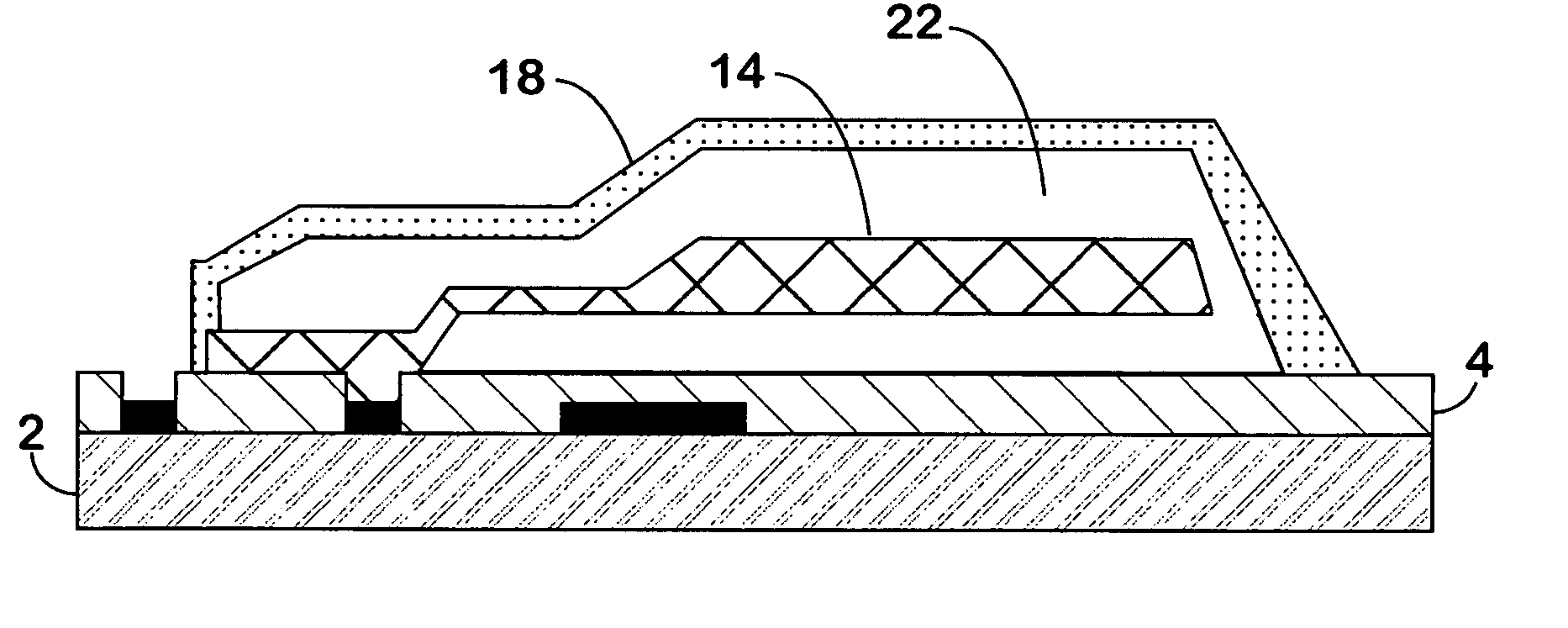

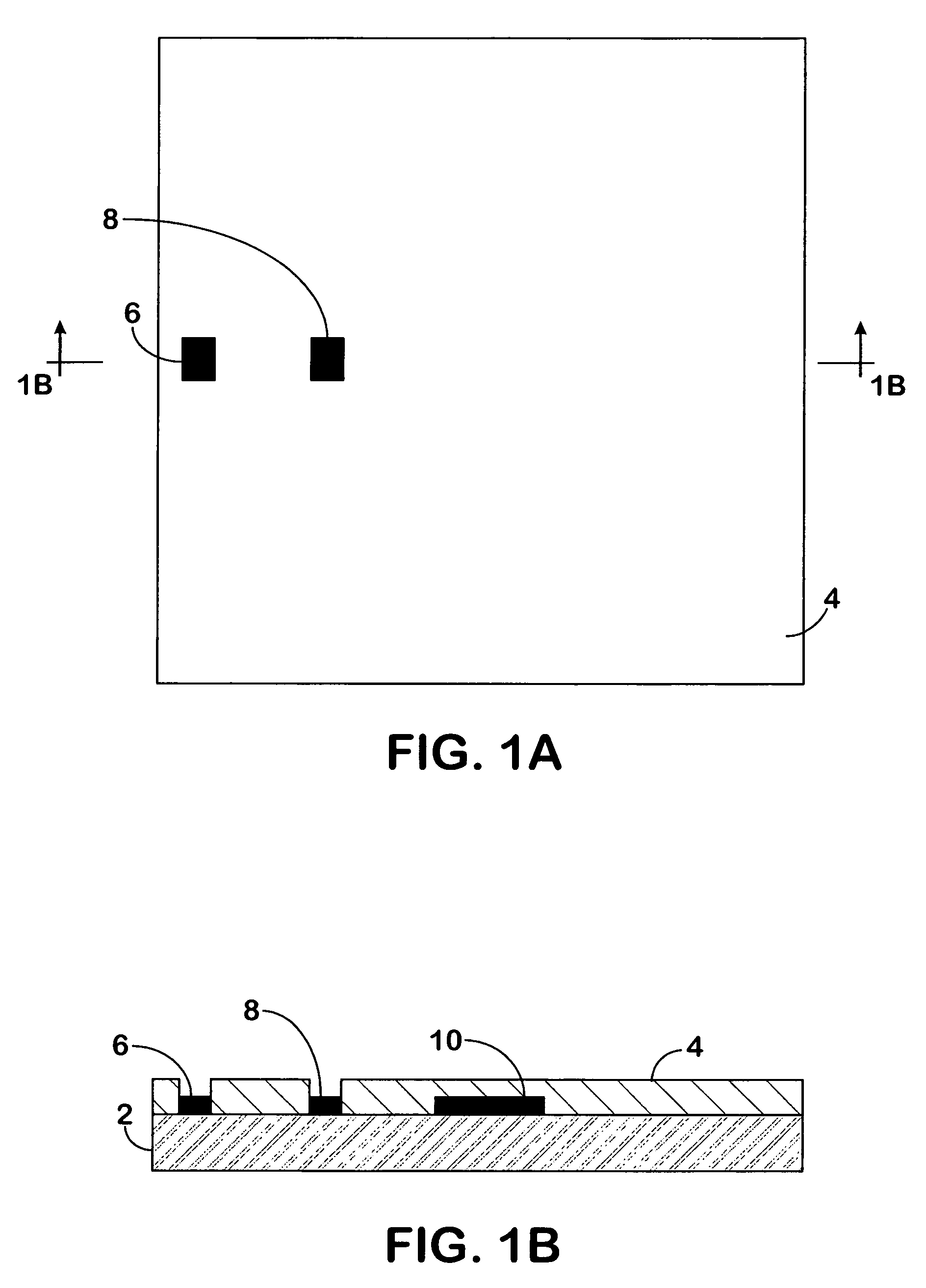

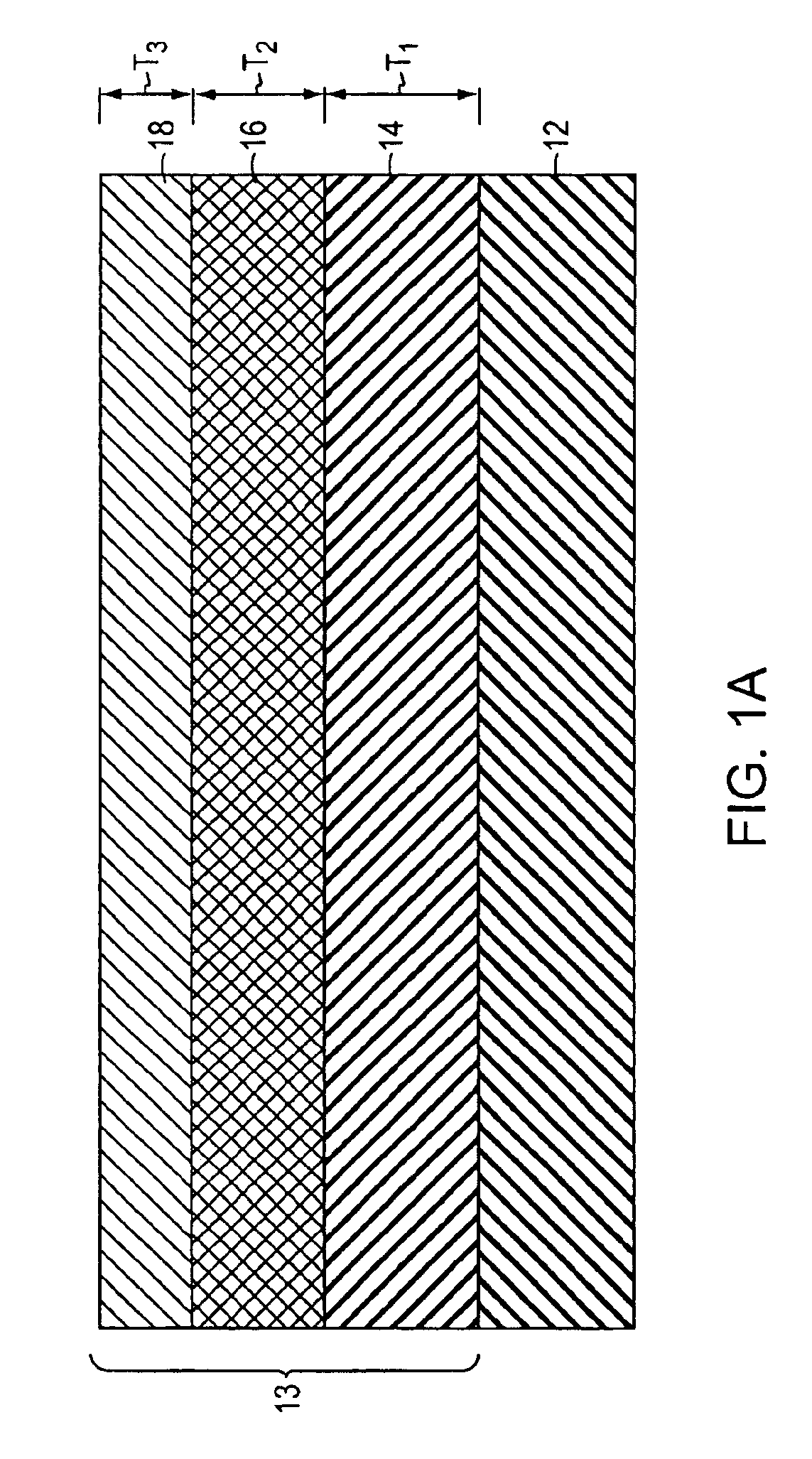

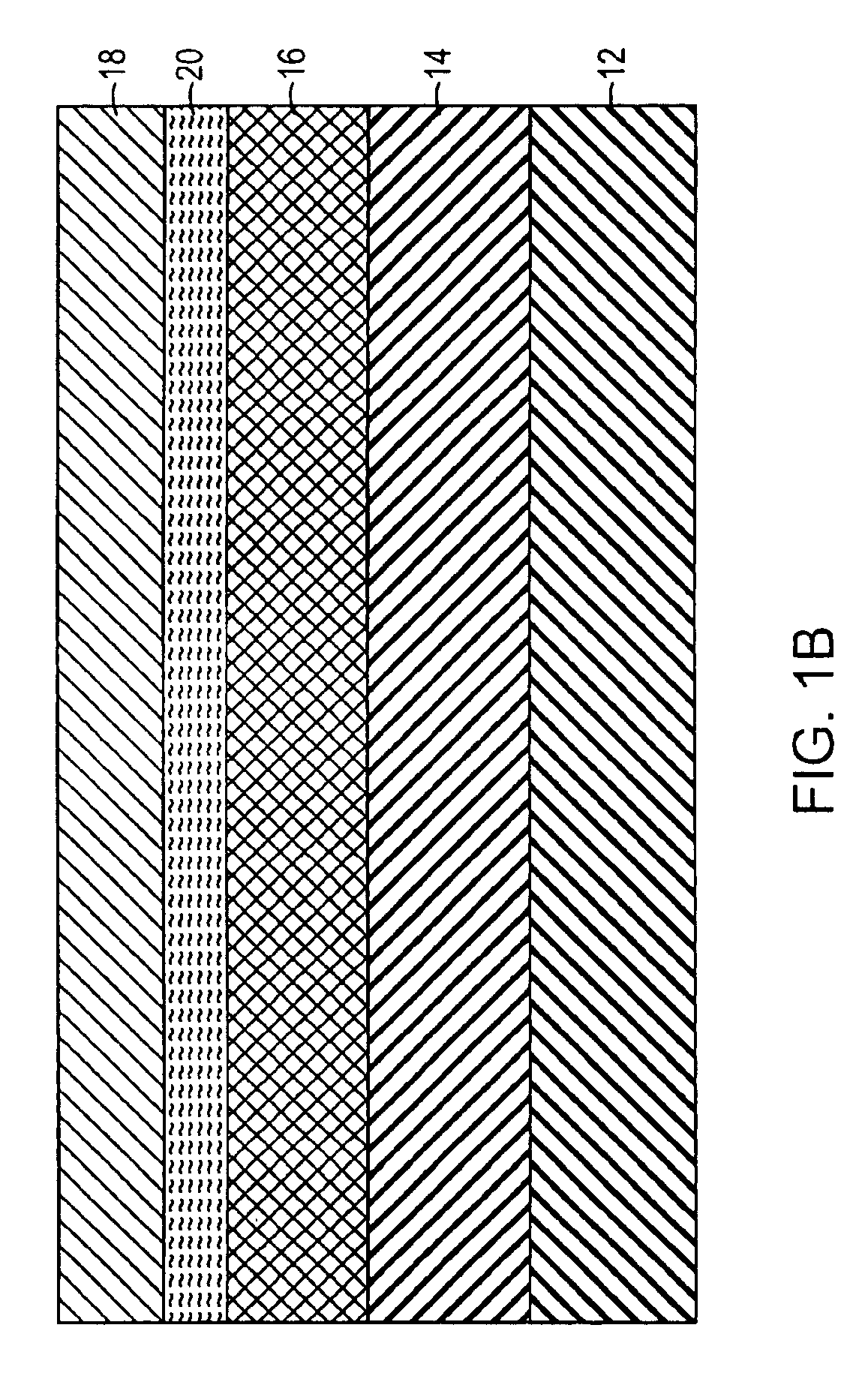

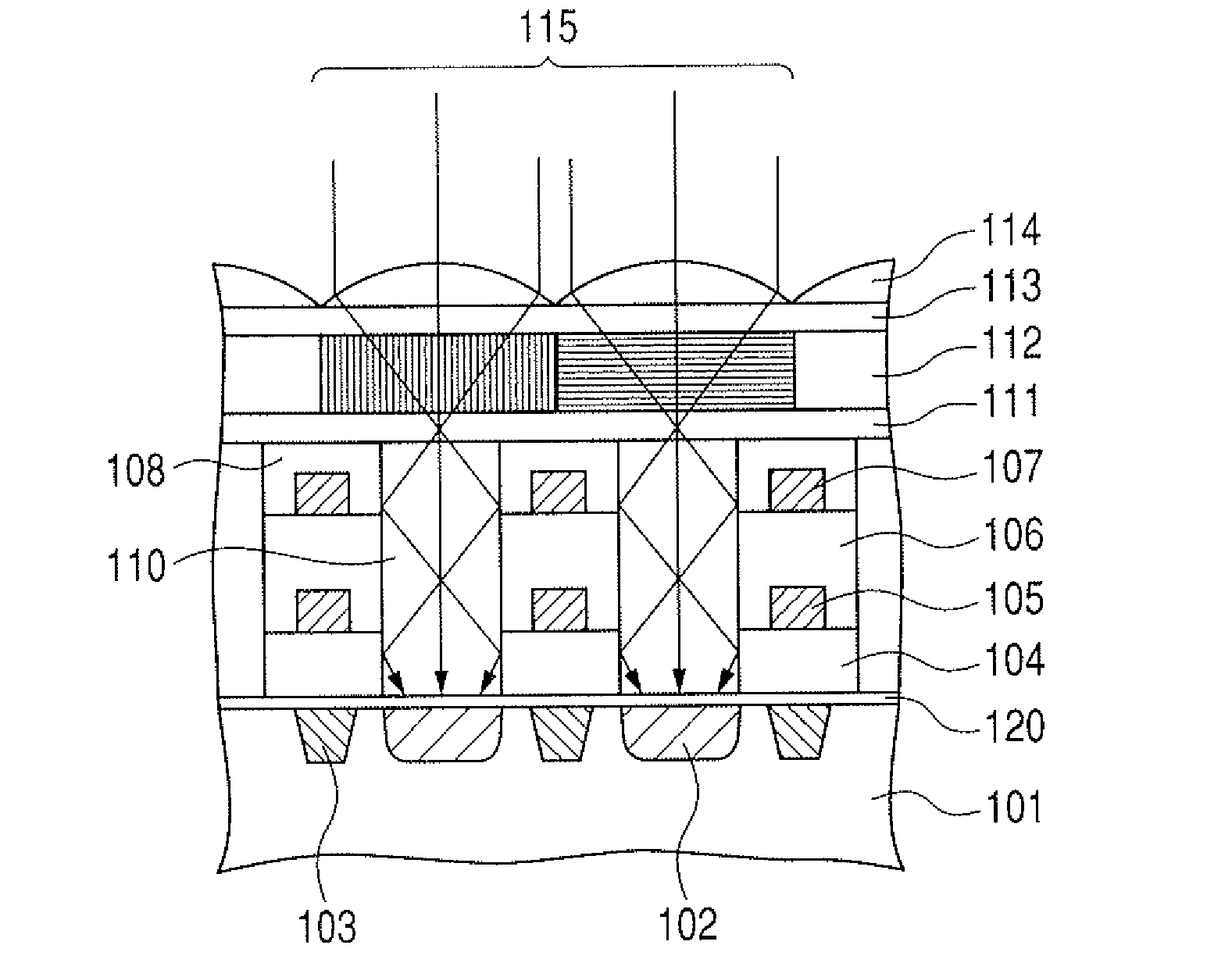

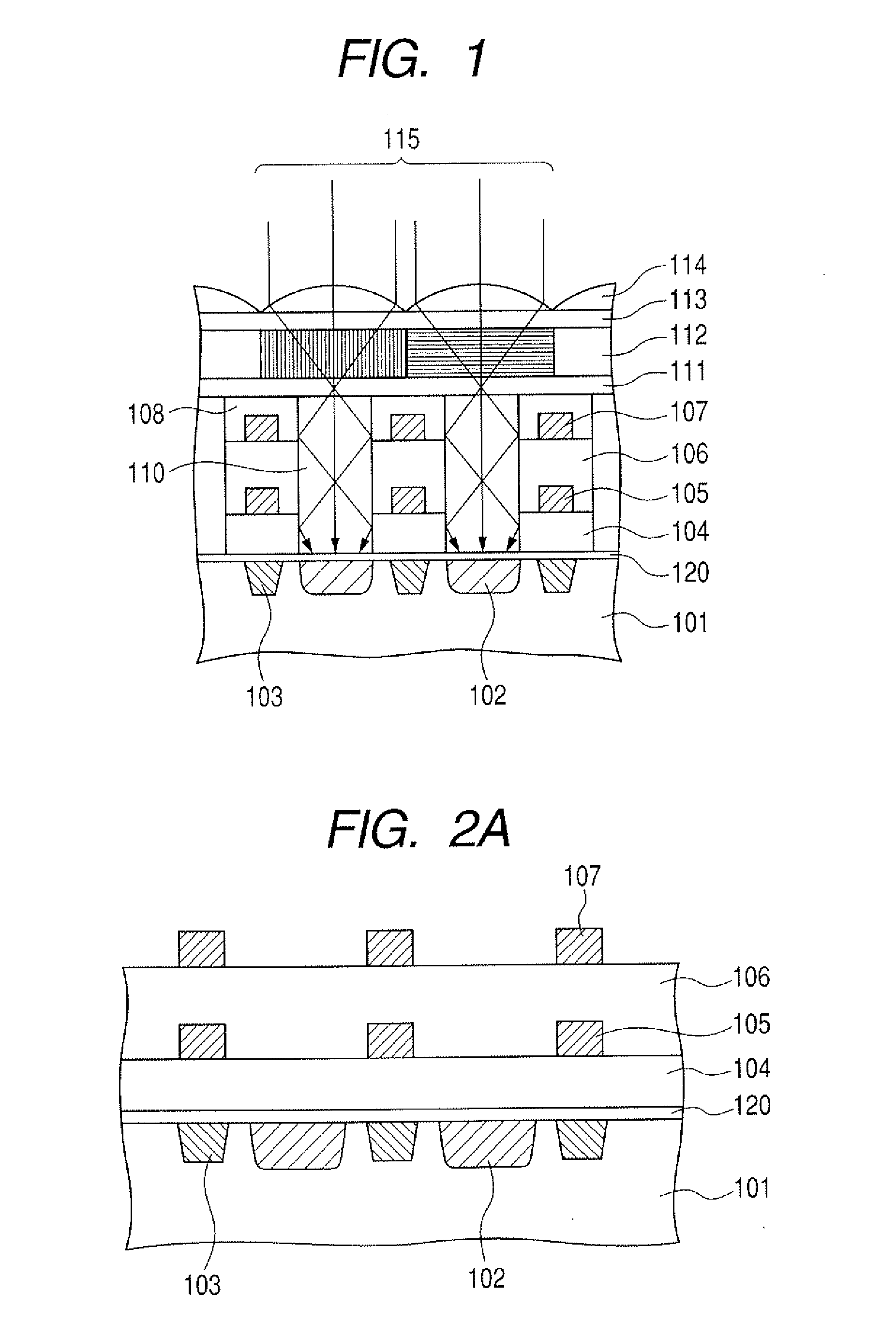

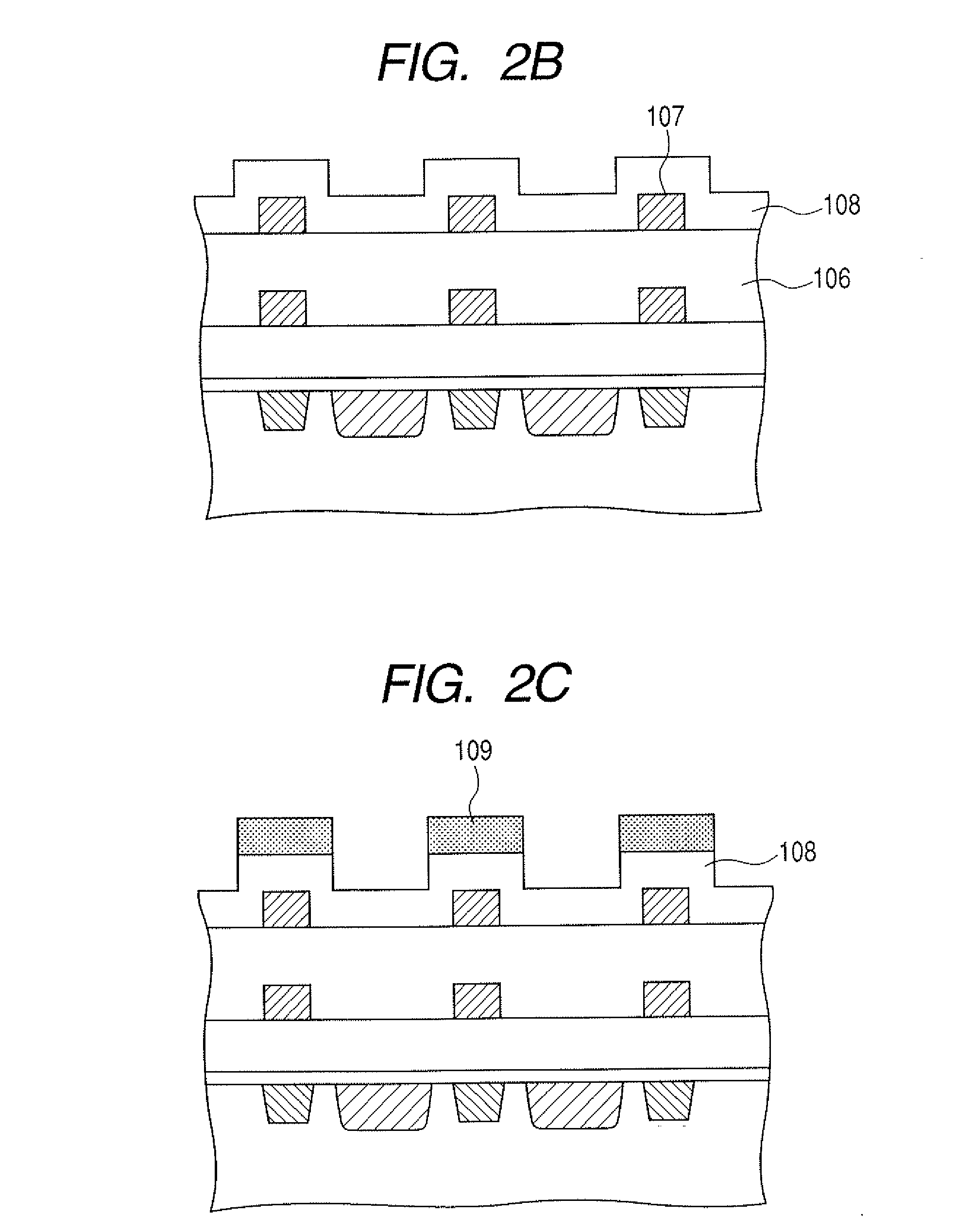

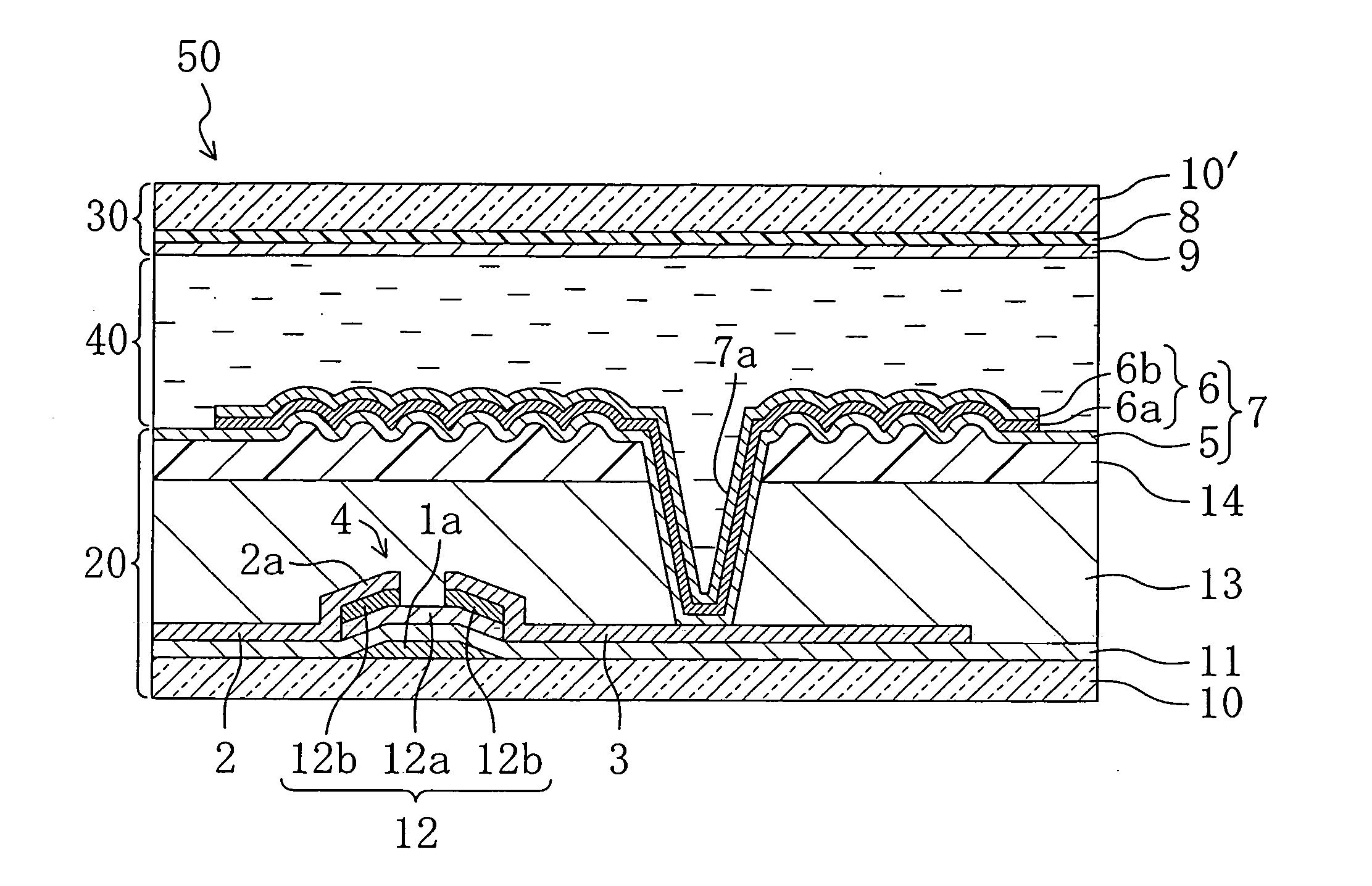

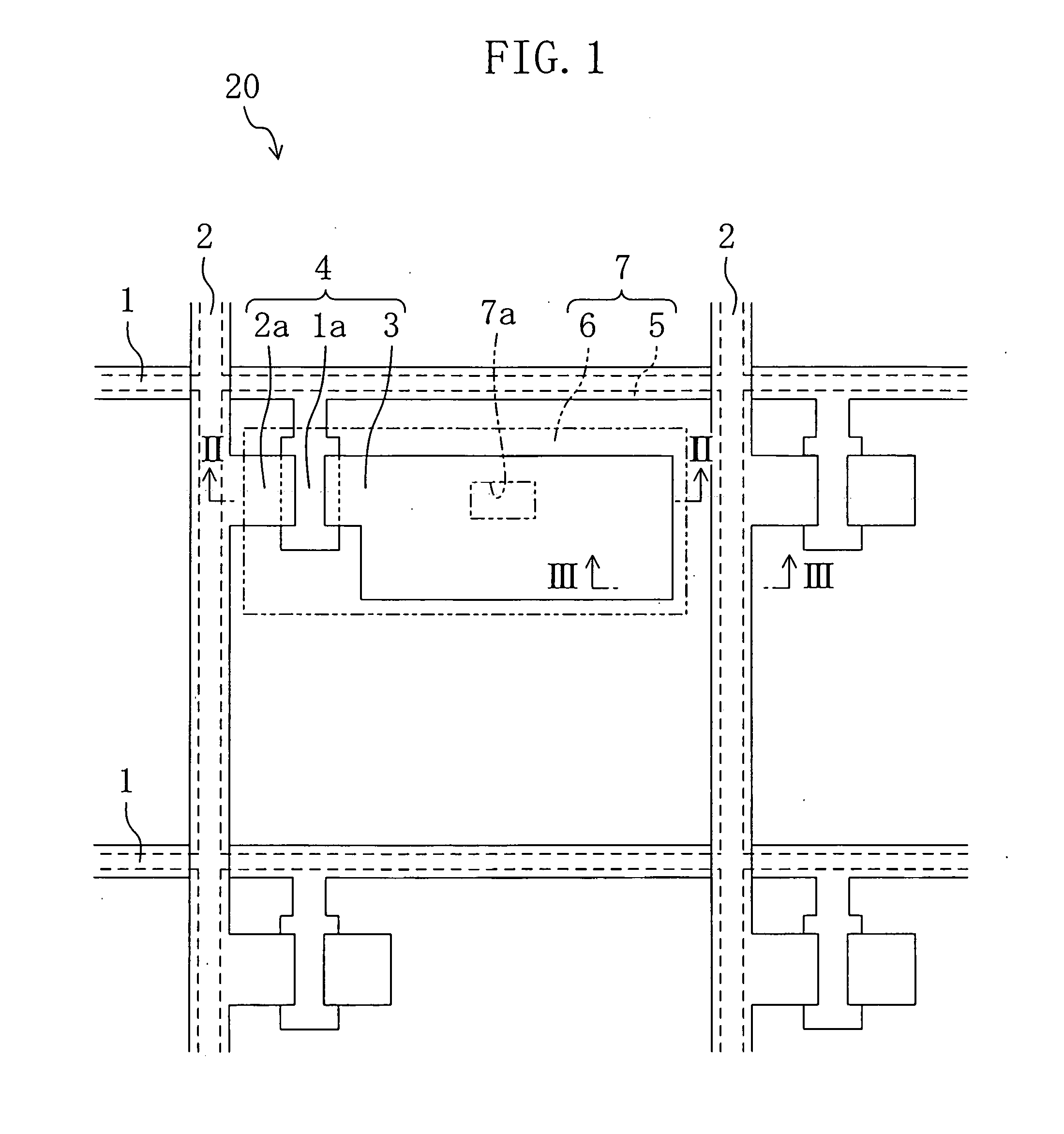

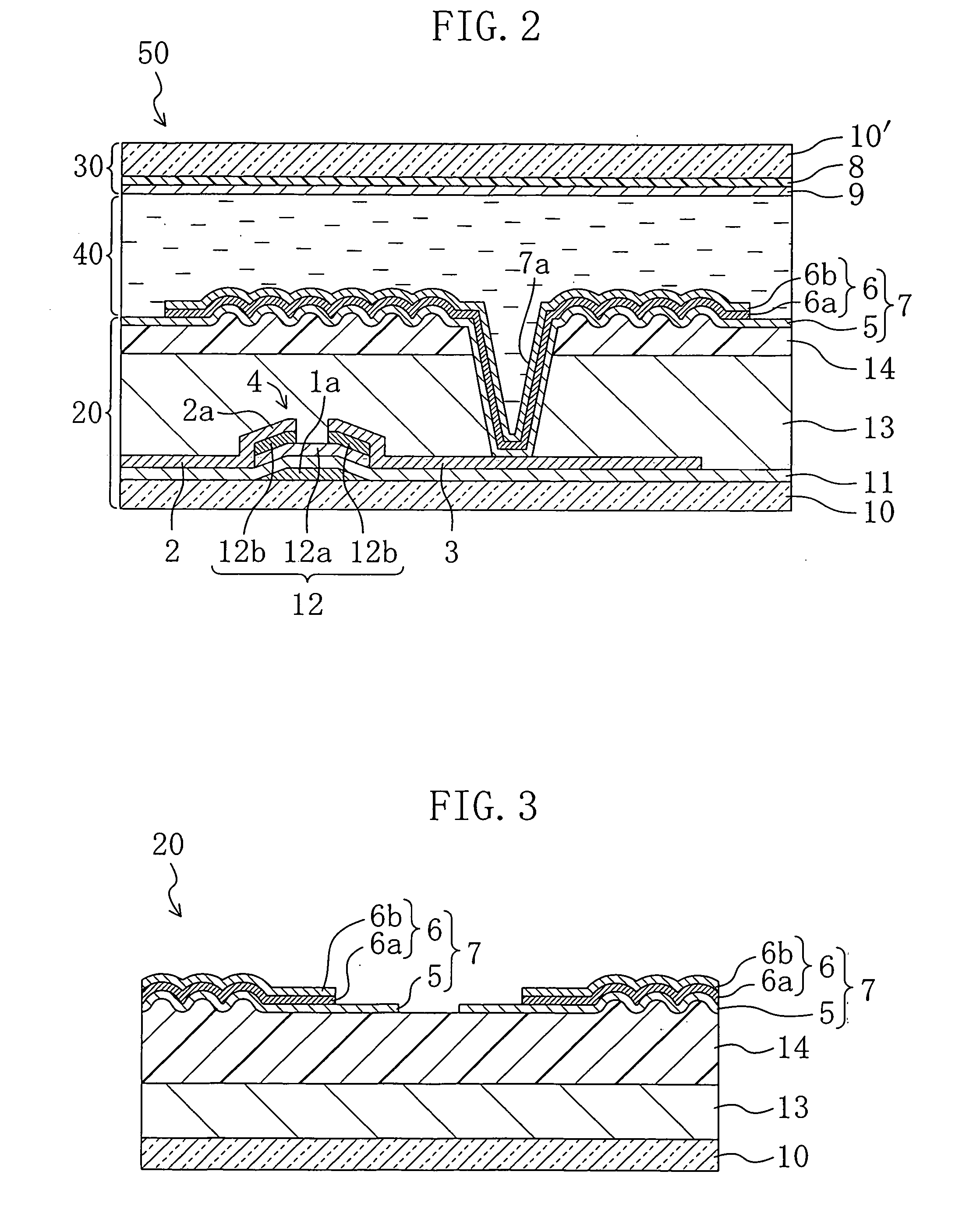

Photoelectric Conversion Device and Method for Producing Photoelectric Conversion Device

InactiveUS20060138577A1Condensing efficiency can be improvedReduce harmSolid-state devicesRadiation controlled devicesRefractive indexPhotoelectric conversion

A photoelectric conversion device according to the present invention has a plurality of photoreceiving portions provided in a substrate, an interlayer film overlying the photoreceiving portion, a large refraction index region which is provided so as to correspond to the photoreceiving portion and has a higher refractive index than the interlayer film, and a layer which is provided in between the photoreceiving portion and the large refraction index region, and has a lower etching rate than the interlayer film, wherein the layer of the lower etching rate is formed so as to cover at least the whole surface of the photoreceiving portion. In addition, the layer of the lower etching rate has a refractive index in between the refractive indices of the large refraction index region and the substrate. Such a configuration can provide the photoelectric conversion device which inhibits the lowering of the sensitivity and the variation of the sensitivity among picture elements.

Owner:CANON KK

Compositions substrate for removing etching residue and use thereof

ActiveUS20040063042A1Minimal silicon oxideEtch rate reductionInorganic/elemental detergent compounding agentsNon-surface-active detergent compositionsPhotoresistOrganic solvent

Compositions containing certain organic solvents and a fluorine source are capable of removing photoresist and etching residue.

Owner:VERSUM MATERIALS US LLC

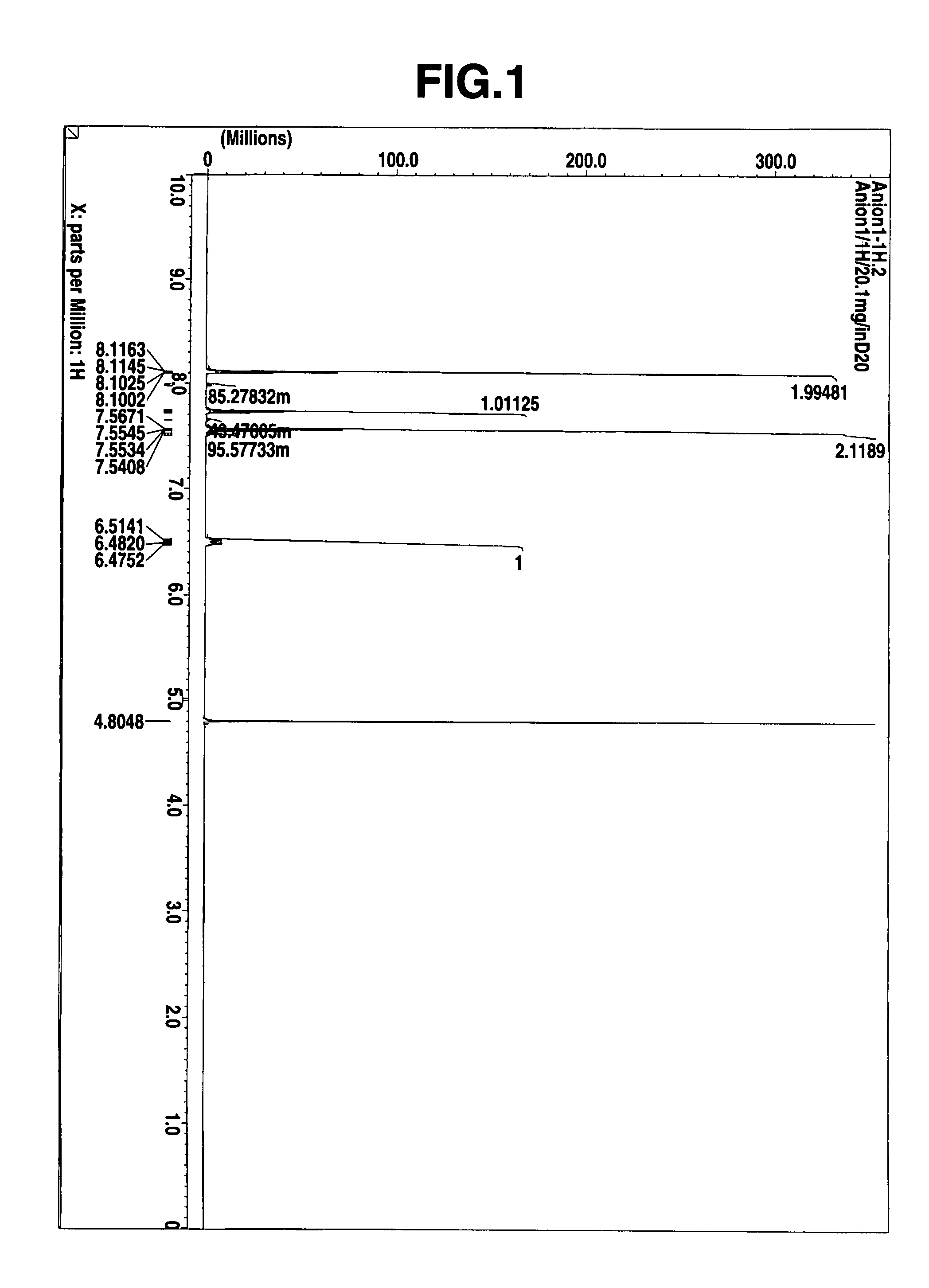

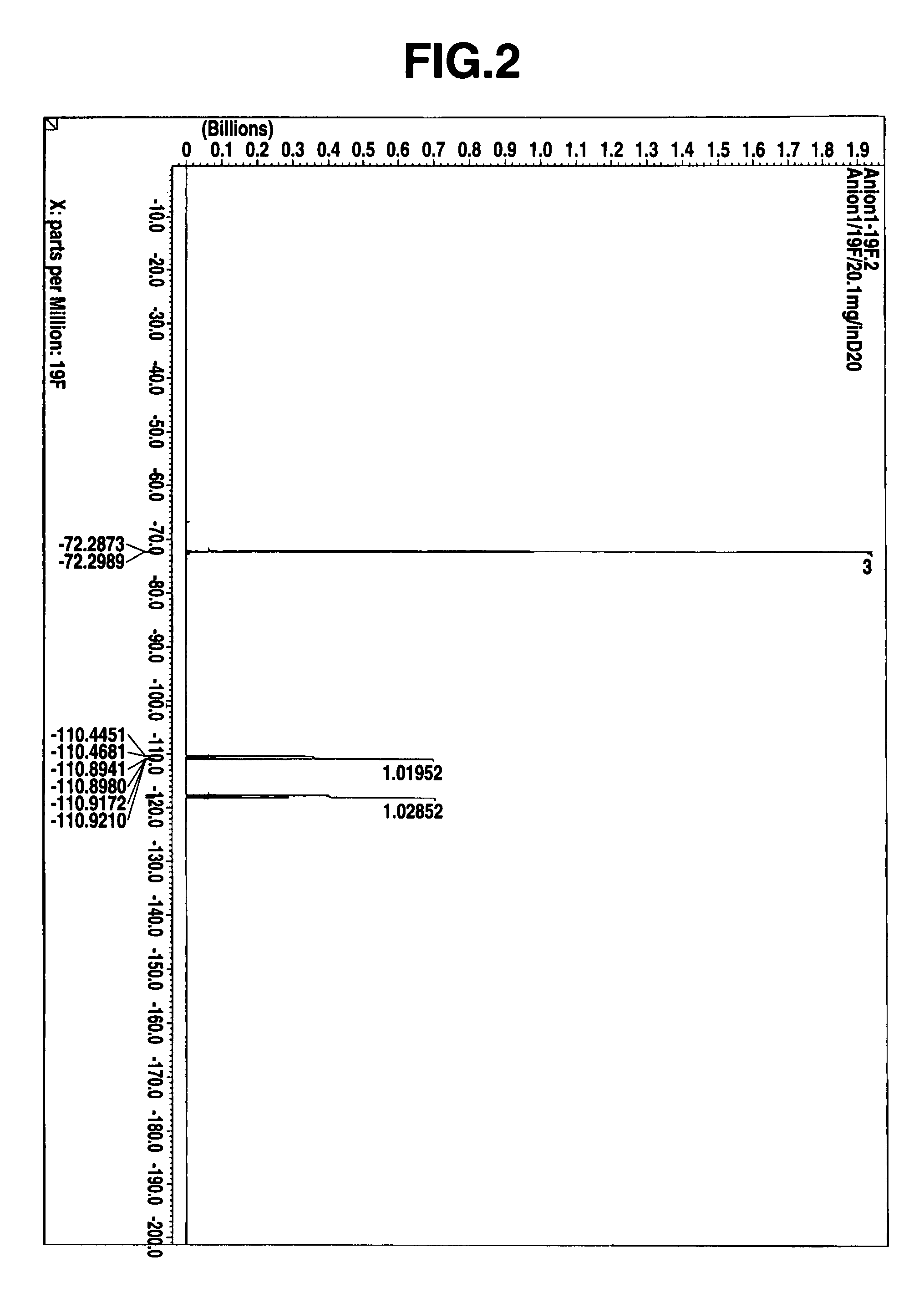

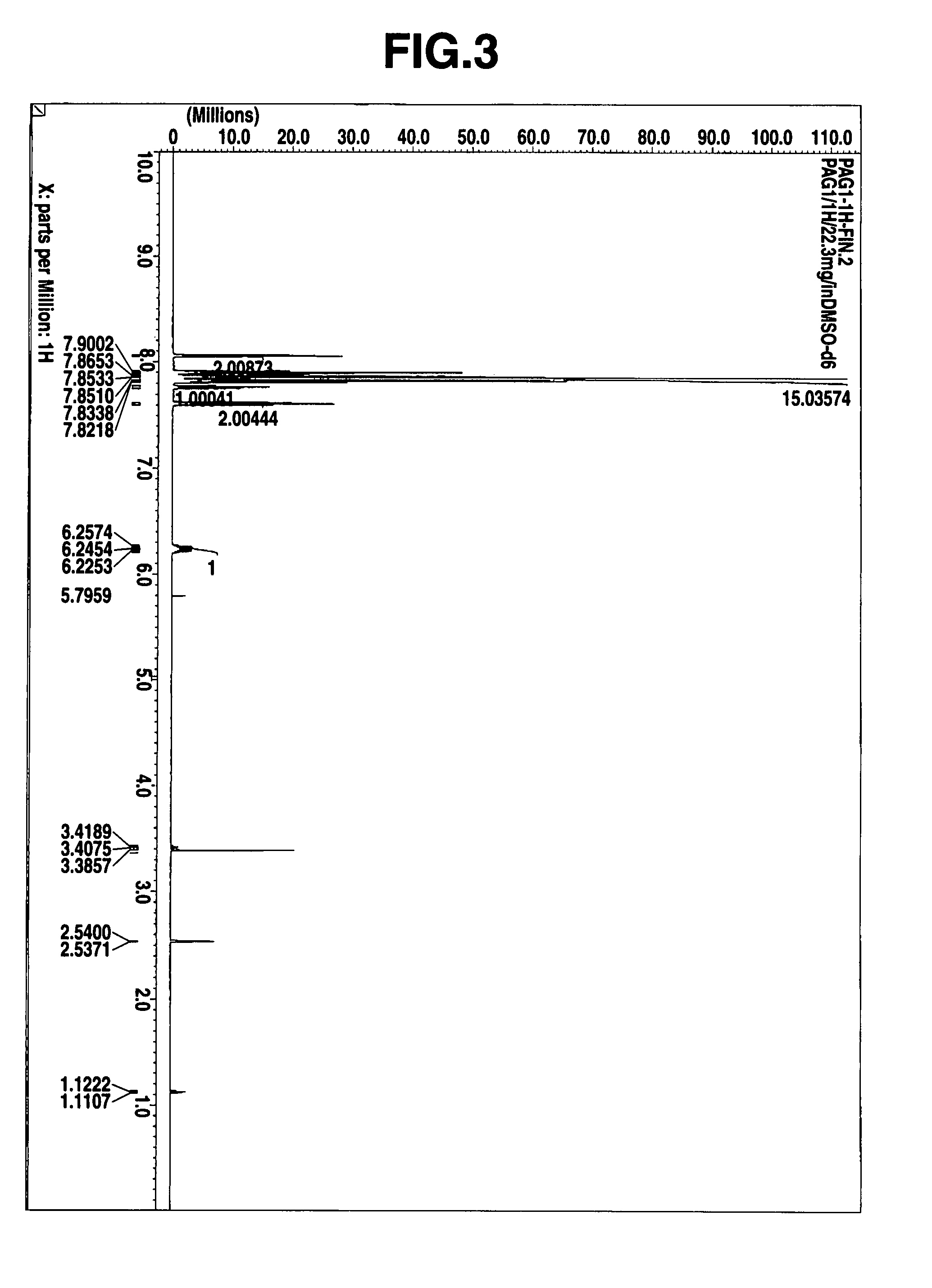

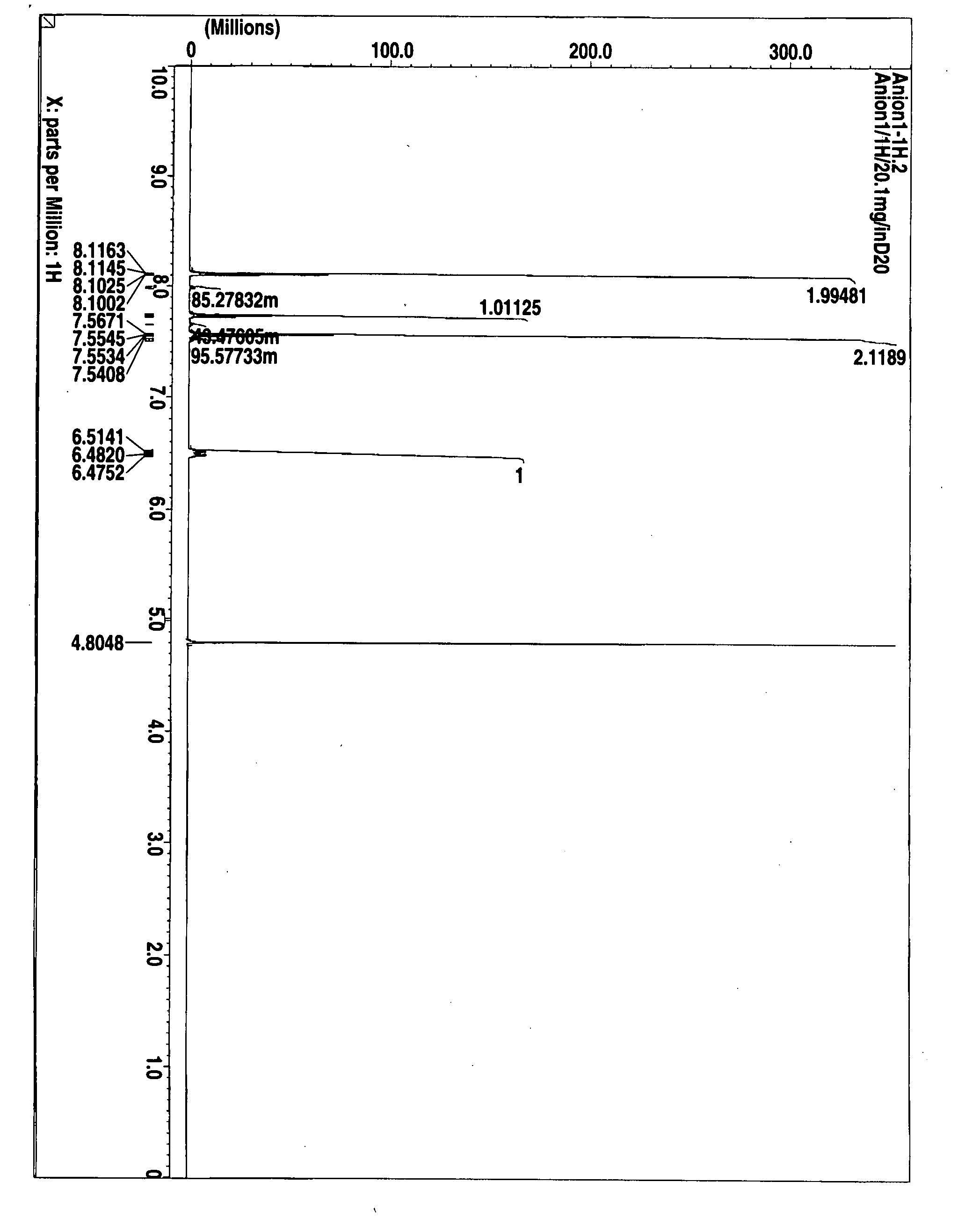

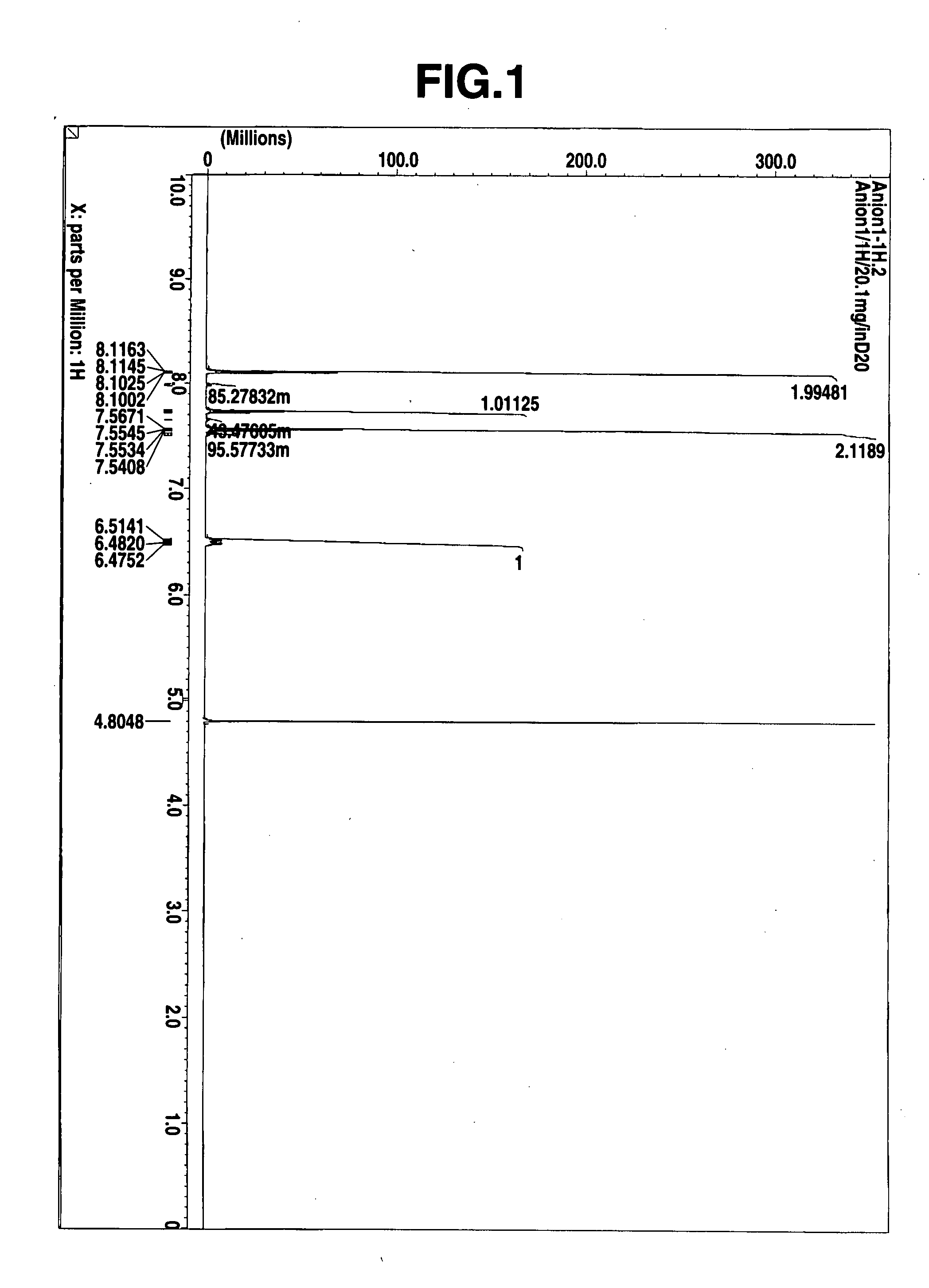

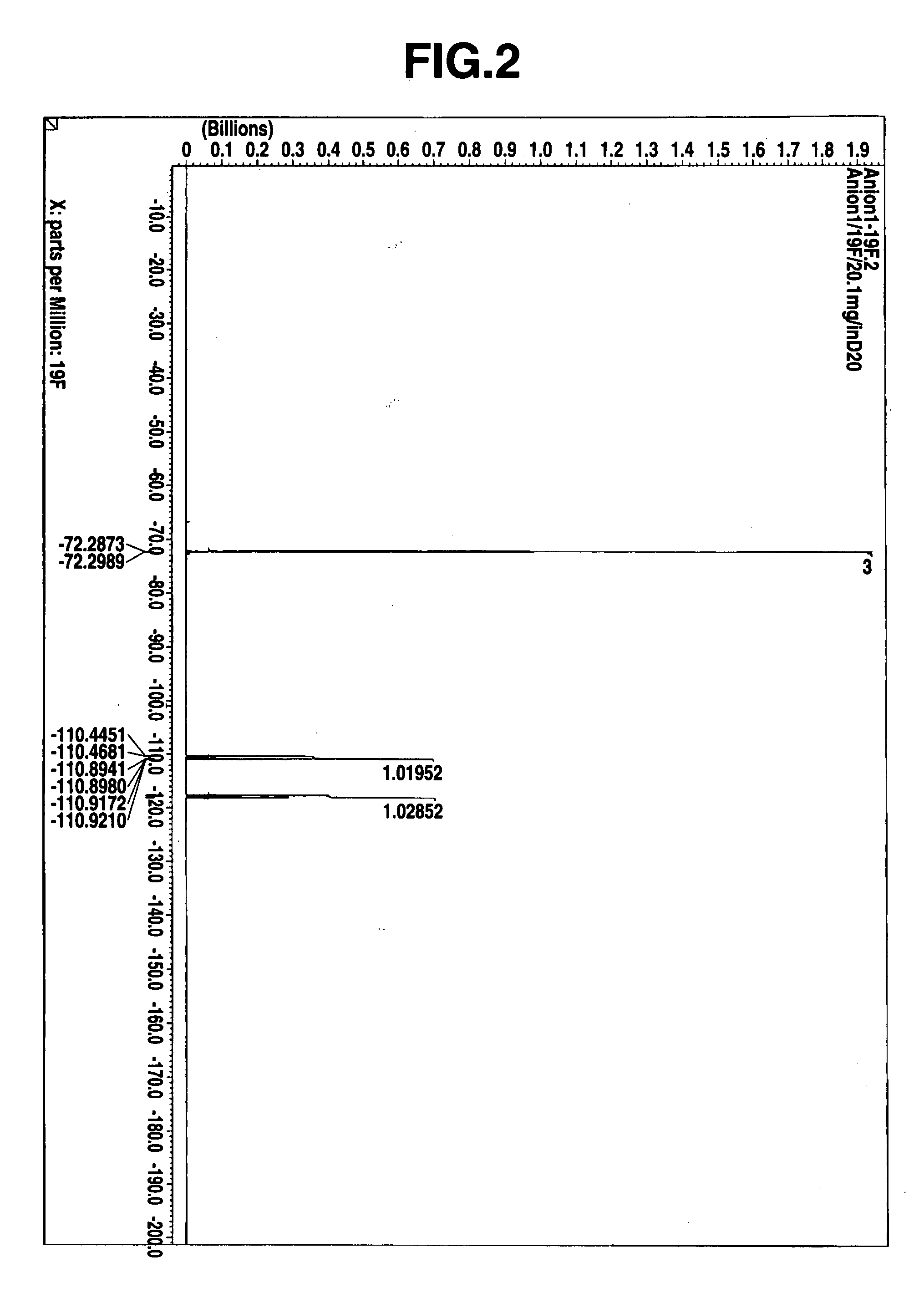

Thermal acid generator, resist undercoat material and patterning process

ActiveUS7514202B2Increase etch rateEtch rate reductionOrganic chemistryPhotosensitive materialsArylResist

A thermal acid generator of generating an acid on heating above 100° C. has formula: CF3CH(OCOR)CF2SO3−(R1)4N+ wherein R is alkyl or aryl, R1 is hydrogen, alkyl, alkenyl, oxoalkyl, aryl, aralkyl or aryloxoalkyl, or R1 may bond together to form a ring with N. The sulfonic acid generated possesses an ester site within molecule so that less bulky acyl groups to bulky groups may be incorporated therein. The thermal acid generator provides a sufficient acid strength, is less volatile due to a high molecular weight, and ensures film formation. Upon disposal of used resist liquid, it may be converted into low accumulative compounds.

Owner:SHIN ETSU CHEM IND CO LTD

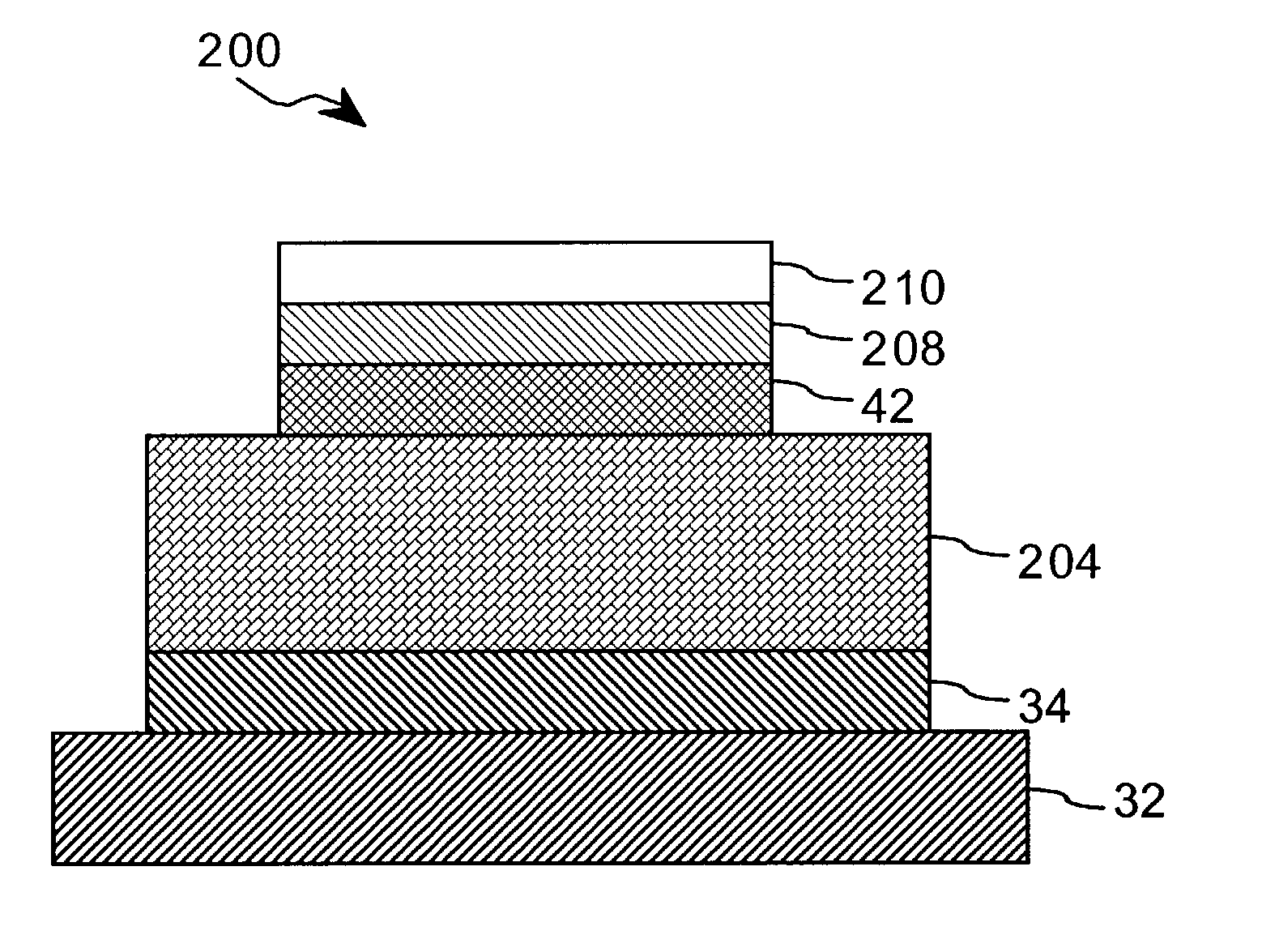

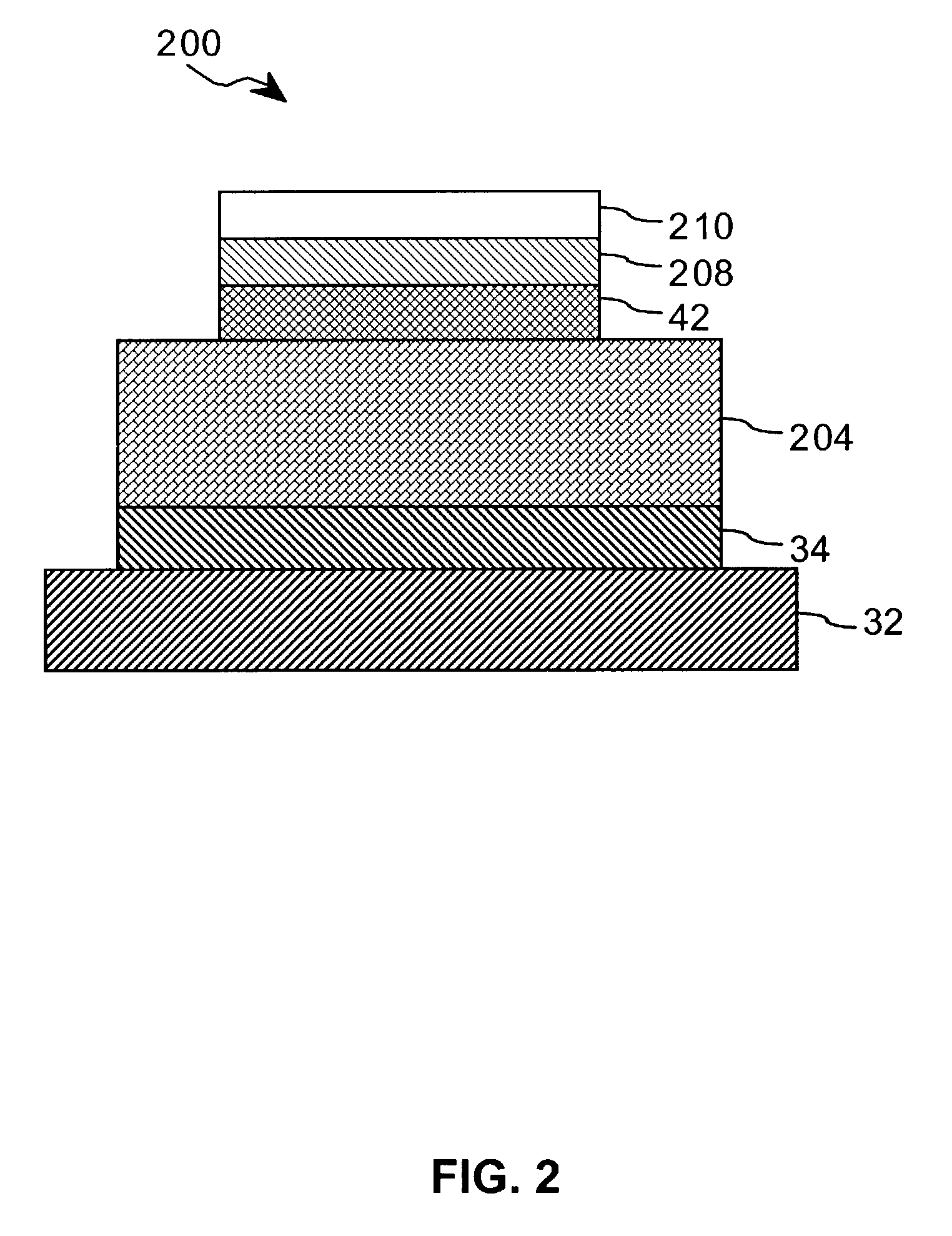

Low temperature process for passivation applications

InactiveUS7086918B2Improve propertiesImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerOrganic electroluminescence

An organic electroluminescent device comprising an anode layer on a substrate, an organic layer on the anode layer, and a cathode layer on the organic layer. In one embodiment, the cathode layer is subjected to H2 plasma prior to deposition of a protective layer over the cathode. In another embodiment, the organic electroluminescent device is encapsulated with an inner encapsulation layer on the cathode layer, and an outer encapsulation layer on the inner encapsulation layer. The inner layer is optimized for adhesion to the cathode layer.

Owner:APPLIED MATERIALS INC

Abrasive liquid for metal and method for polishing

InactiveUS6896825B1Etch rate reductionImprove reliabilitySemiconductor/solid-state device manufacturingSurface treatment compositionsChemical LinkageTectorial membrane

An abrasive liquid for a metal comprising (1) an oxidizing agent for a metal, (2) a dissolving agent for an oxidized metal, (3) a first protecting film-forming agent such as an amino acid or an azole which adsorbs physically on the surface of the metal and / or forms a chemical bond, to thereby form a protecting film, (4) a second protecting film-forming agent such as polyacrylic acid, polyamido acid or a salt thereof which assists the first protecting film-forming agent in forming a protecting film and (5) water; and a method for polishing.

Owner:RESONAC CORPORATION +1

Thermal acid generator, resist undercoat material and patterning process

ActiveUS20070264596A1Increase etch rateEtch rate reductionOrganic chemistryPhotosensitive materialsResistAryl

A thermal acid generator of generating an acid on heating above 100° C. has formula: CF3CH(OCOR)CF2SO3−(R1)4N+ wherein R is alkyl or aryl, R1 is hydrogen, alkyl, alkenyl, oxoalkyl, aryl, aralkyl or aryloxoalkyl, or R1 may bond together to form a ring with N. The sulfonic acid generated possesses an ester site within molecule so that less bulky acyl groups to bulky groups may be incorporated therein. The thermal acid generator provides a sufficient acid strength, is less volatile due to a high molecular weight, and ensures film formation. Upon disposal of used resist liquid, it may be converted into low accumulative compounds.

Owner:SHIN ETSU CHEM IND CO LTD

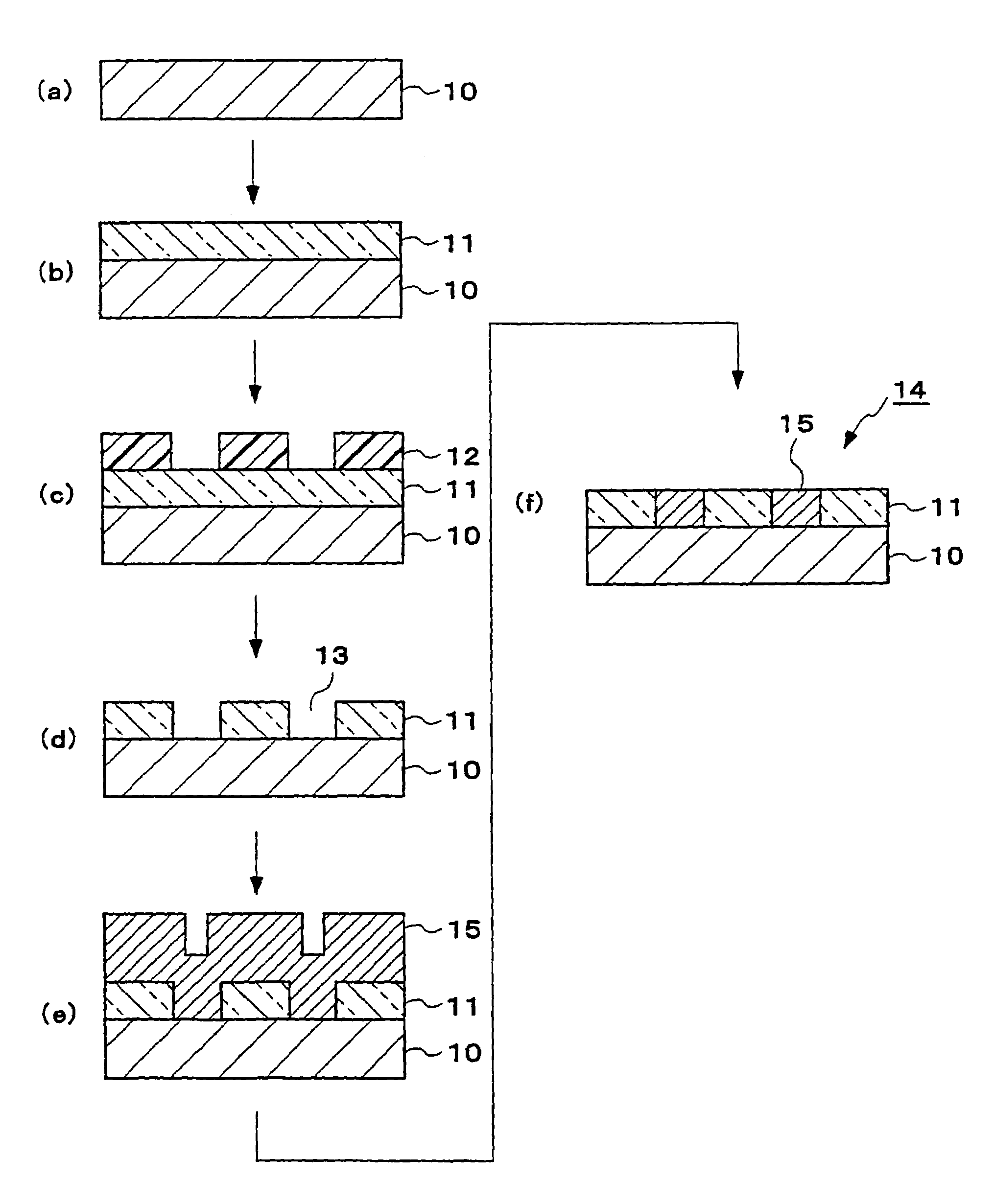

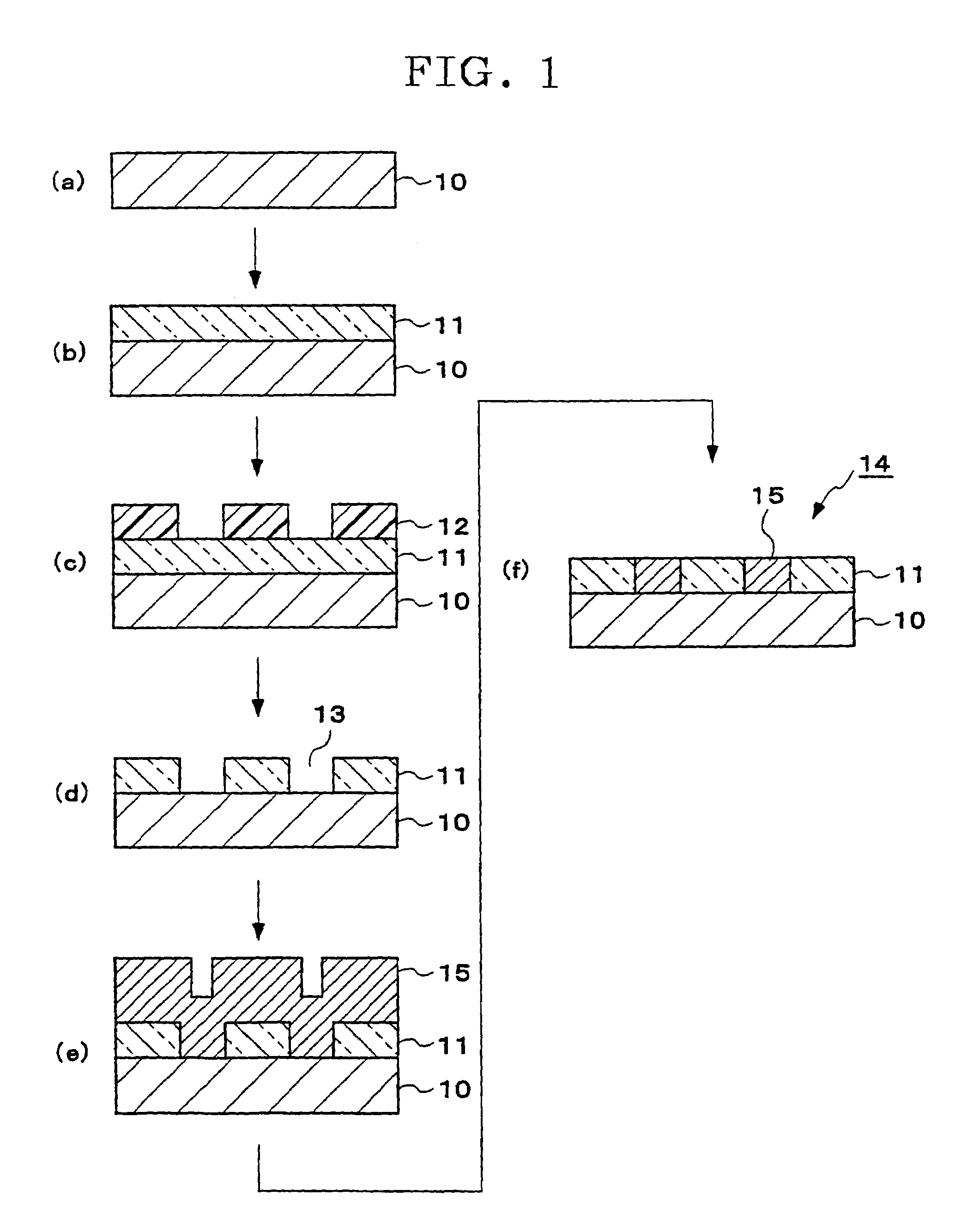

Method for manufacturing conductive element substrate, conductive element substrate, method for manufacturing liquid crystal display, liquid crystal display and electronic information equipment

InactiveUS20050186359A1High film strengthReduce etch rateLiquid crystal compositionsAdjusting/maintaining mechanical tensionLiquid-crystal displayActive matrix

A method for manufacturing a liquid crystal display which employs an active matrix substrate including a plurality of pixels arranged in matrix on a substrate and reflecting electrodes formed in the pixels, respectively. The method comprises (a) a laminated conductive film formation step of sequentially forming a conductive metal film and an amorphous transparent conductive film on a substrate to form a laminated conductive film and (b) a reflecting electrode formation step of patterning the laminated conductive film into a reflecting electrode, wherein the step (b) includes a first etching step of etching the conductive metal film and the amorphous transparent conductive film simultaneously and a second etching step of etching the amorphous transparent conductive film only.

Owner:SHARP KK

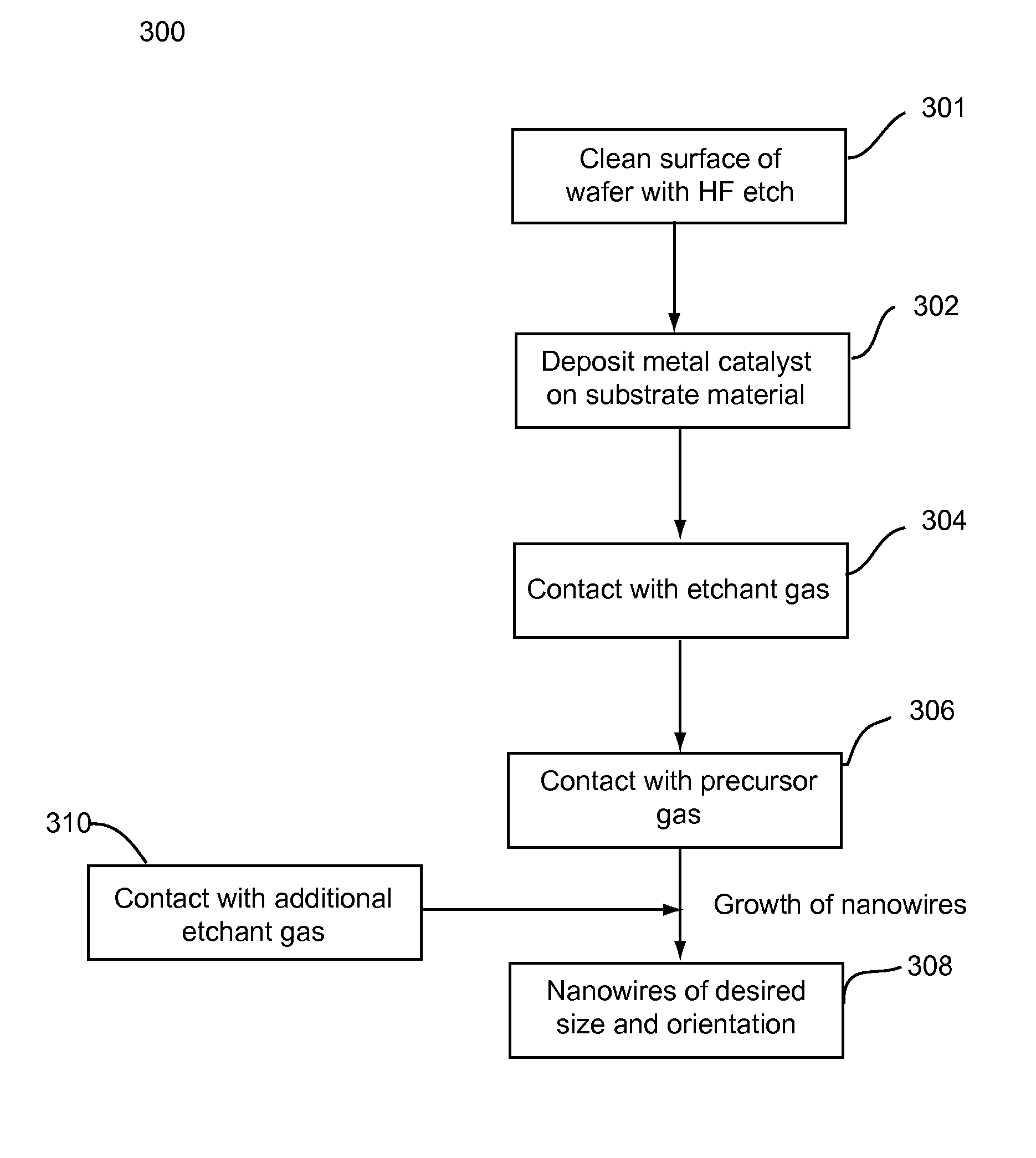

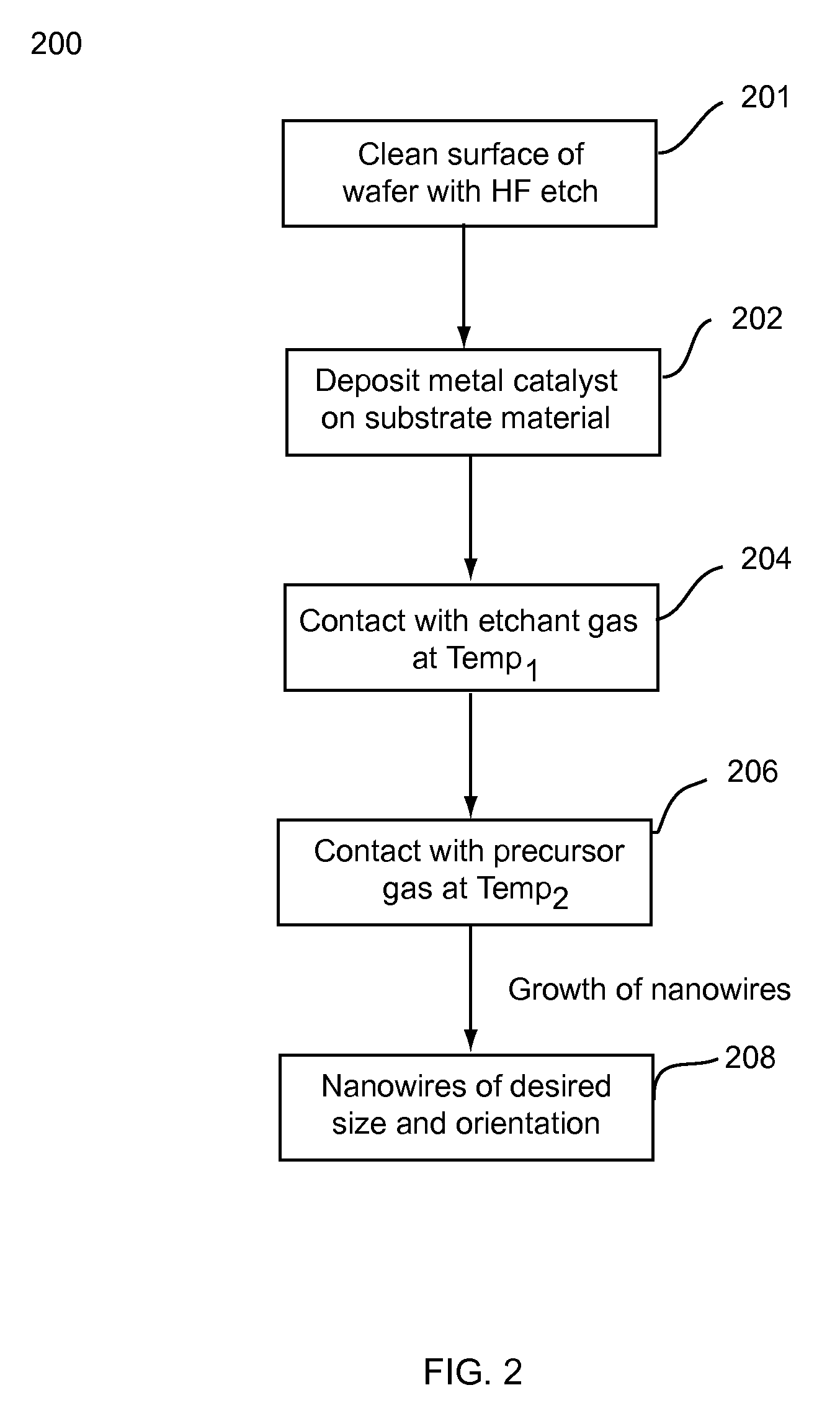

Systems and methods for nanowire growth

ActiveUS7776760B2Good ohmic contactReduce decomposition ratePolycrystalline material growthIndividual molecule manipulationNanowireAlloy

Owner:ONED MATERIAL INC

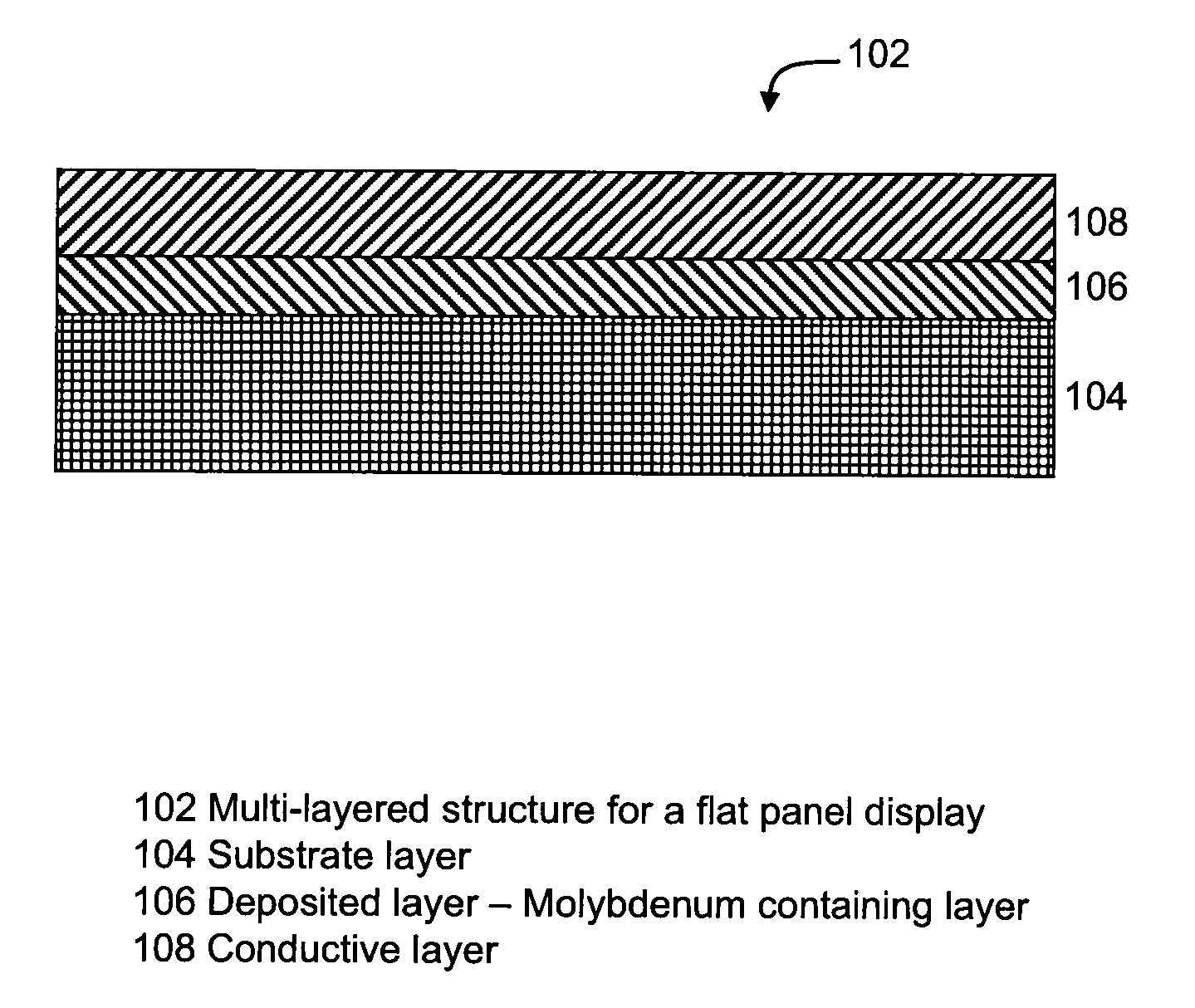

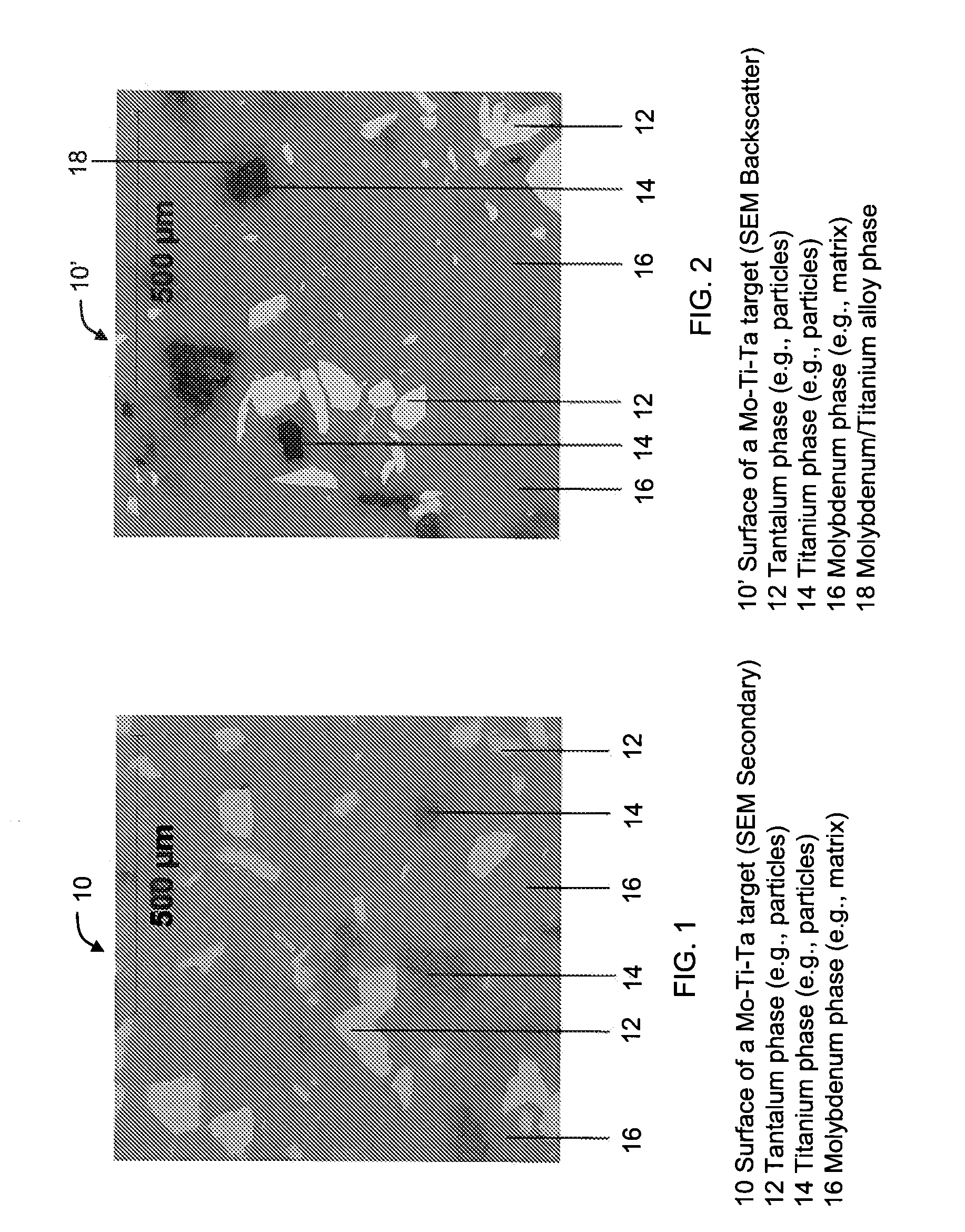

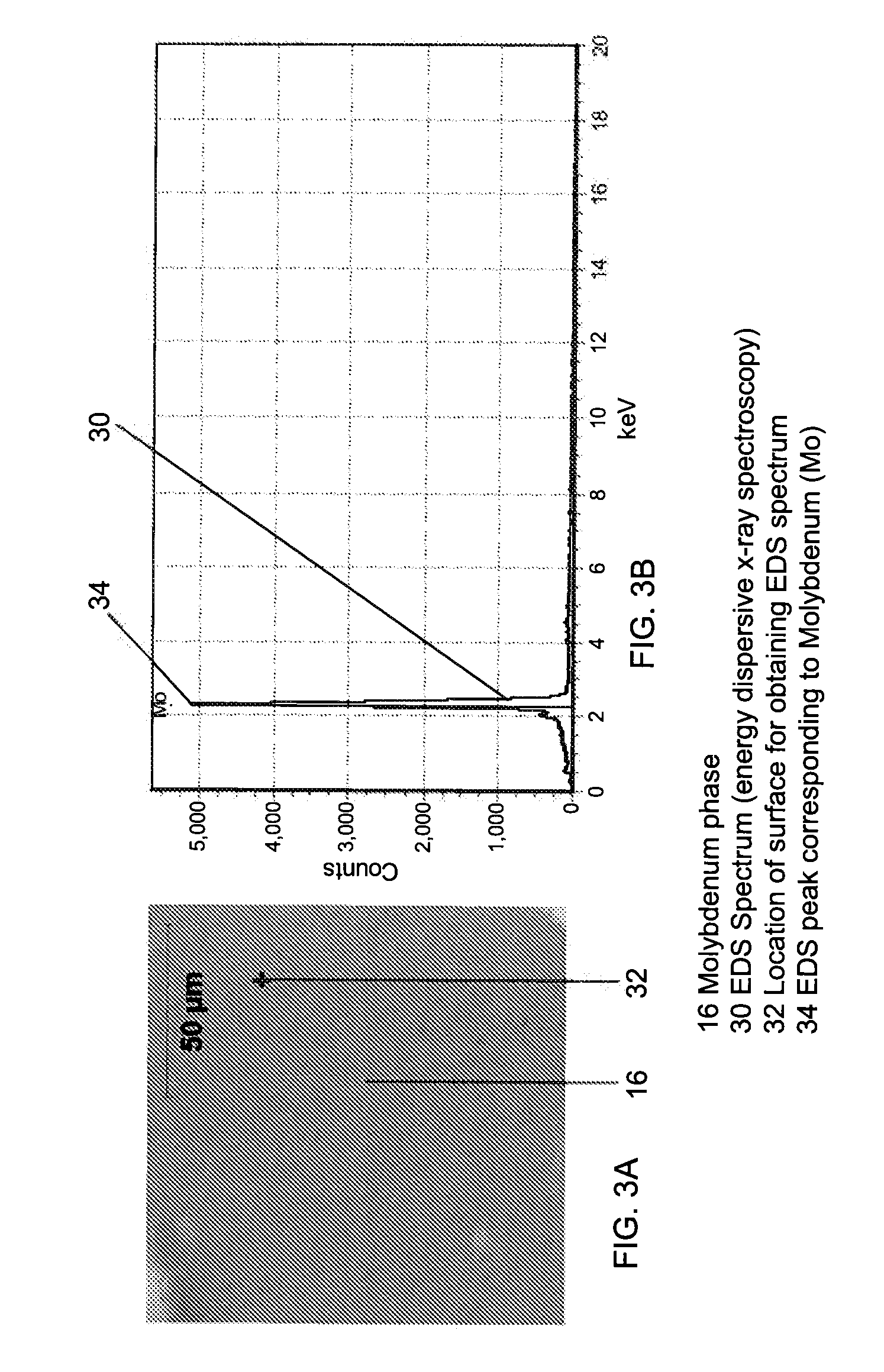

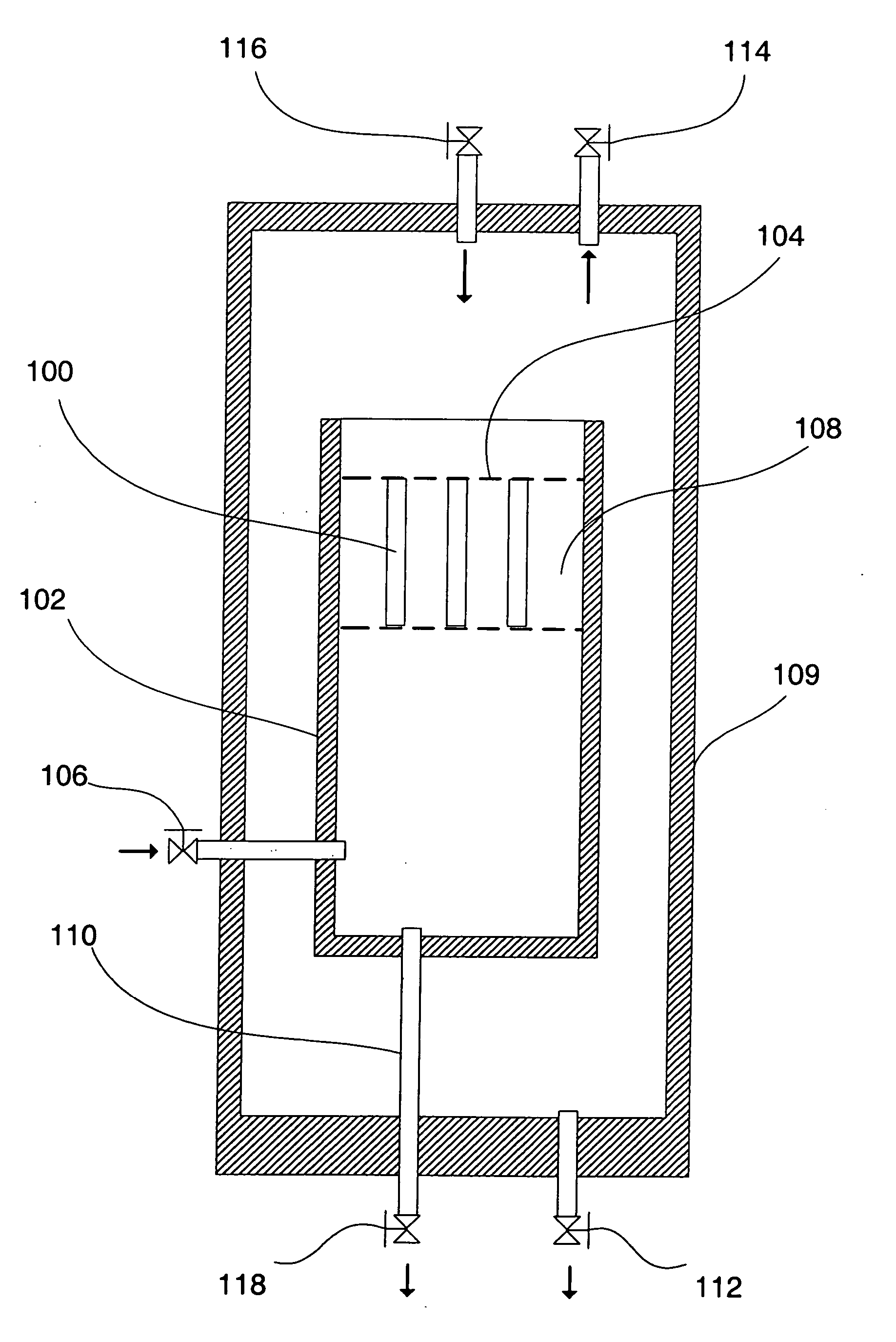

Molybdenum containing targets

ActiveUS20110117375A1Improve barrier propertiesLow resistivityCellsElectric discharge tubesTitaniumTantalum

The invention is directed at sputter targets including 50 atomic % or more molybdenum, a second metal element of titanium, and a third metal element of chromium or tantalum, and deposited films prepared by the sputter targets. In a preferred aspect of the invention, the sputter target includes a phase that is rich in molybdenum, a phase that is rich in titanium, and a phase that is rich in the third metal element.

Owner:GLAS TRUST +1

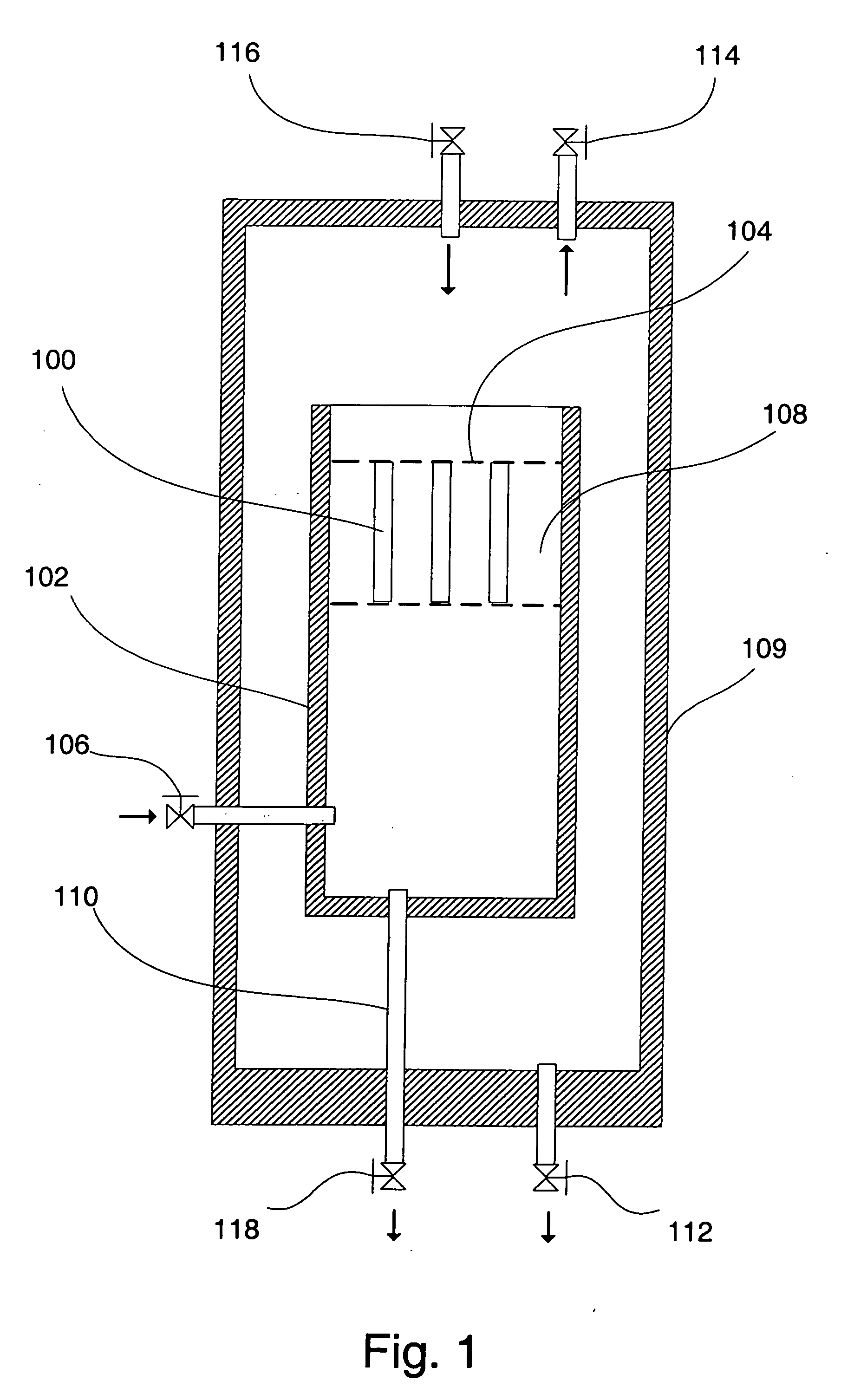

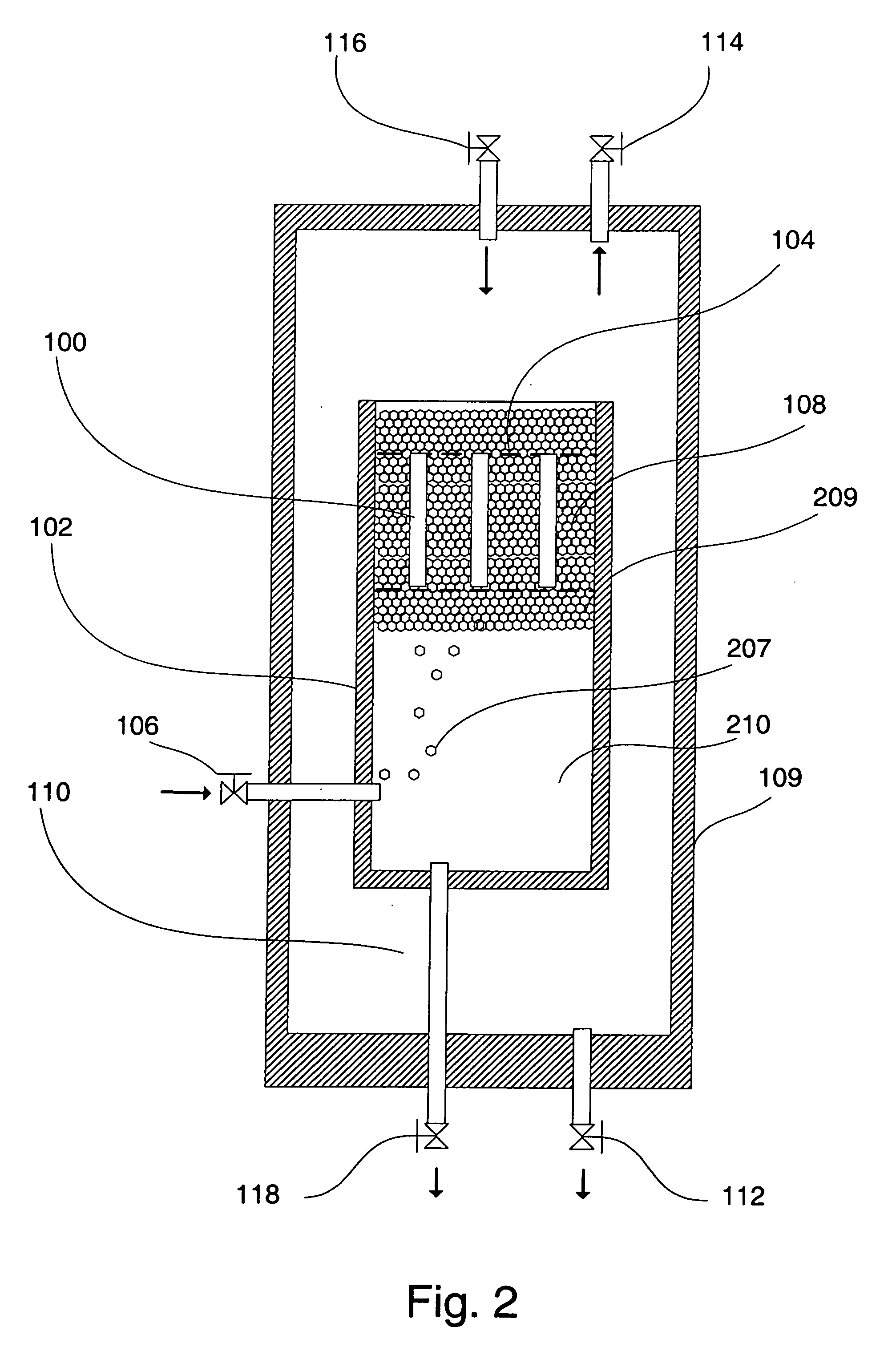

Methods for chemically treating a substrate using foam technology

InactiveUS20070135321A1Reduce the amount requiredLower operating temperatureInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemical treatmentHydroxylamine

The present invention relates to methods and compositions for treating a surface of a substrate by foam technology that includes at least one treatment chemical. The invention more particularly relates to the removal of undesired matter from the surface of substrates with small features, where such undesired matter may comprise organic and inorganic compounds such as particles, films from photoresist material, and traces of any other impurities such as metals deposited during planarization or etching. A method according to the present invention for treating a surface of a substrate comprises generating a foam from a liquid composition, wherein the liquid composition comprises a gas; a surfactant; and at least one component selected from the group consisting of a fluoride, a hydroxylamine, an amine and periodic acid; contacting the foam with the surface of a substrate; and, removing the undesired matter from the surface of the substrate.

Owner:EKC TECH

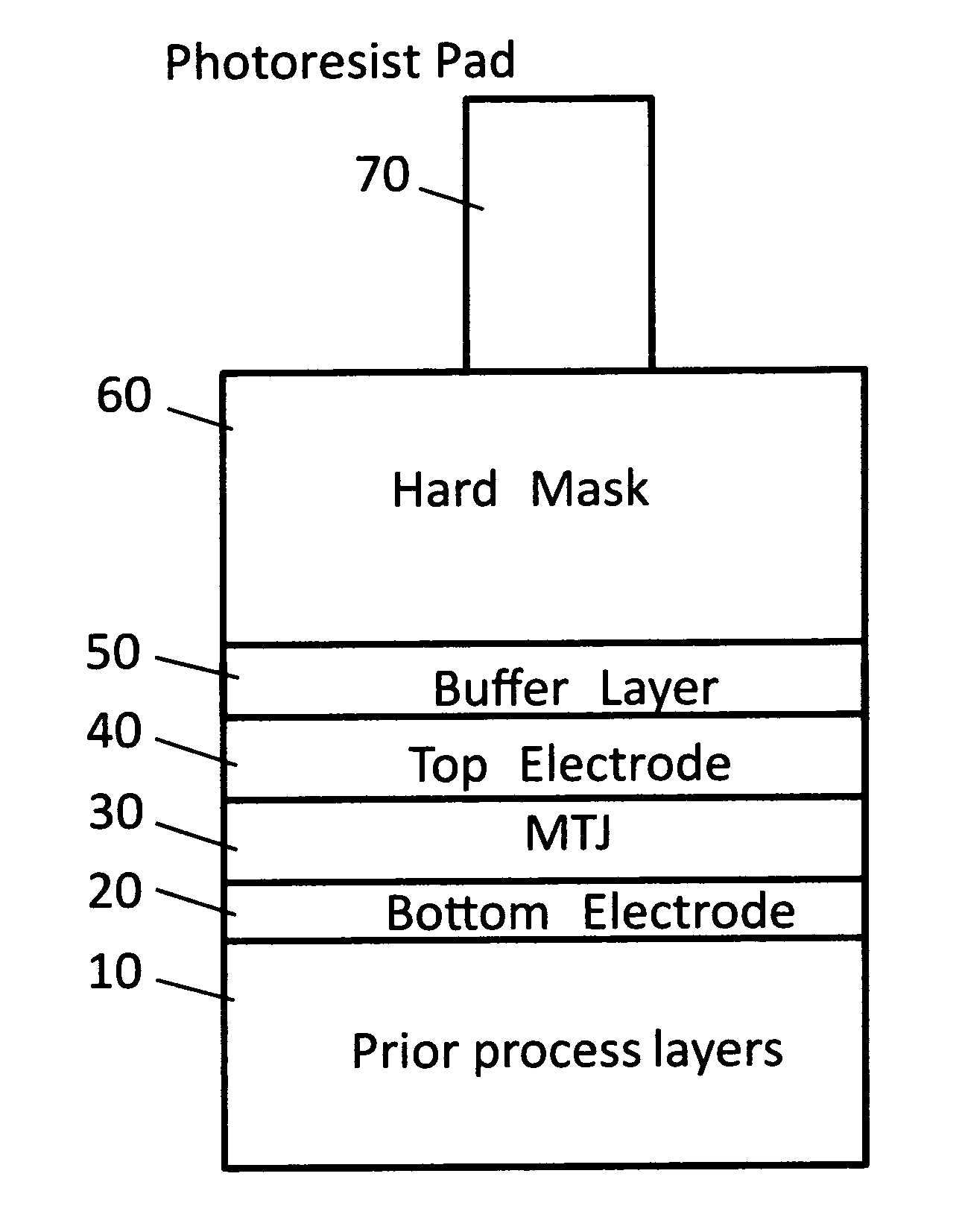

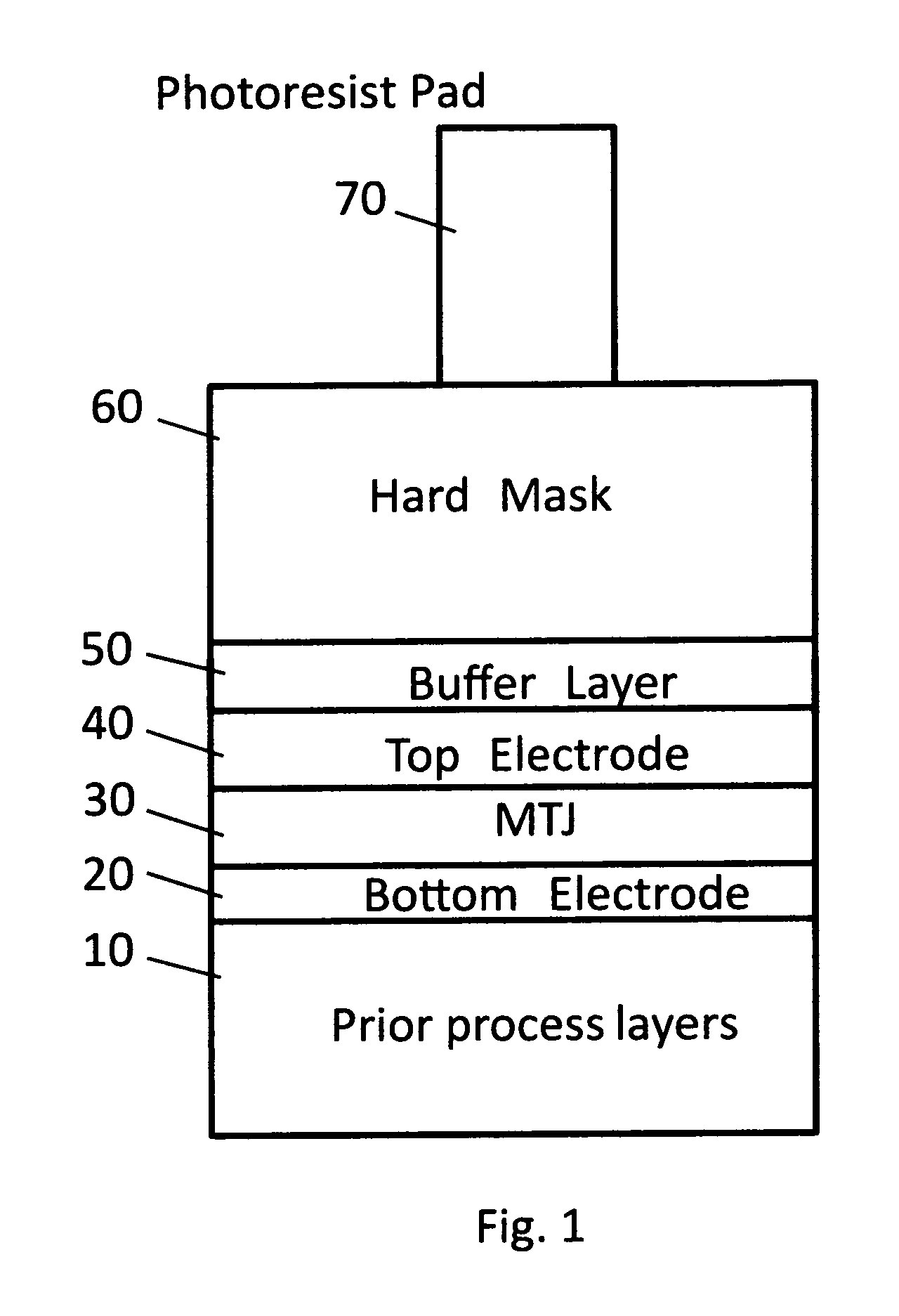

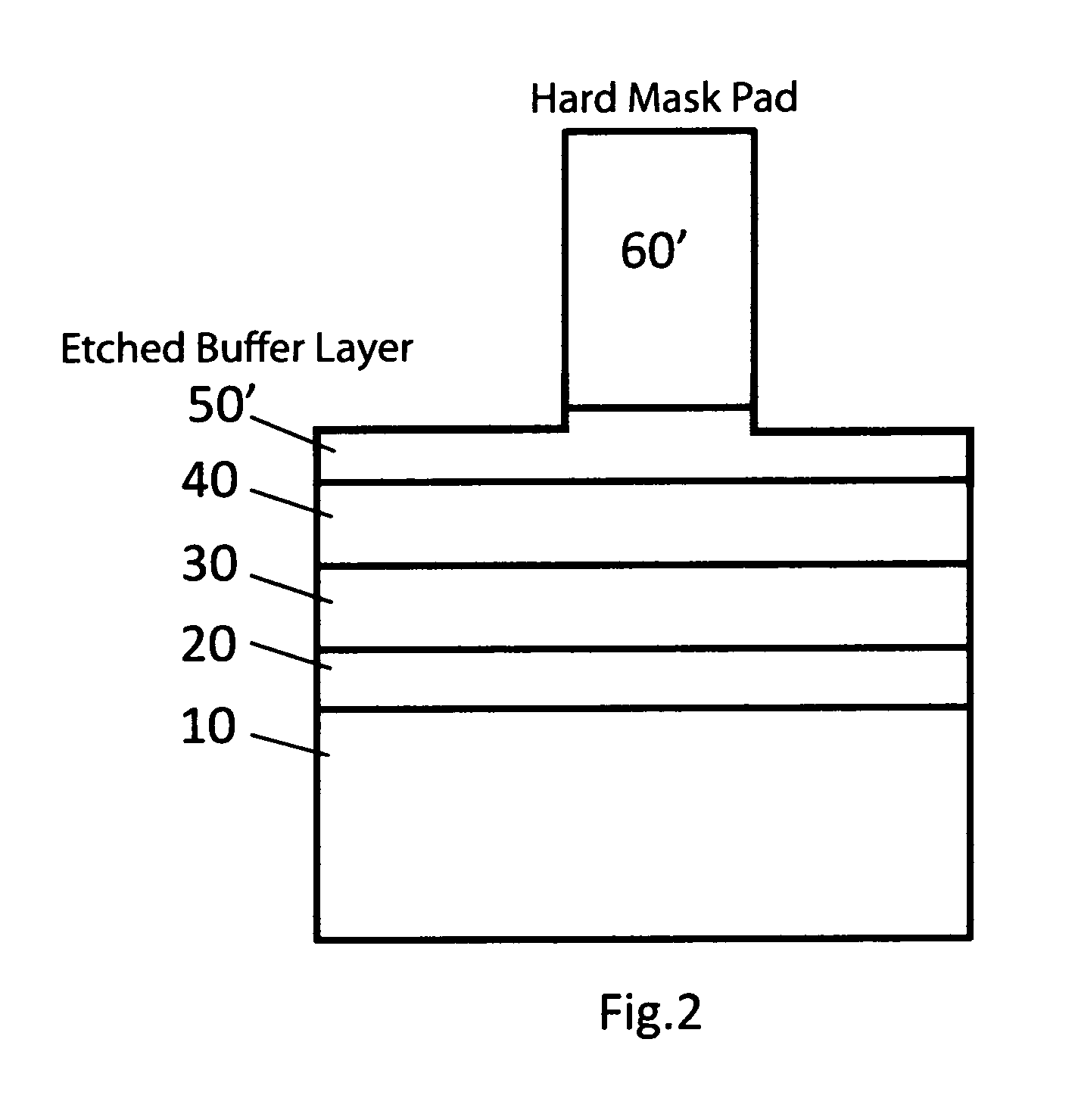

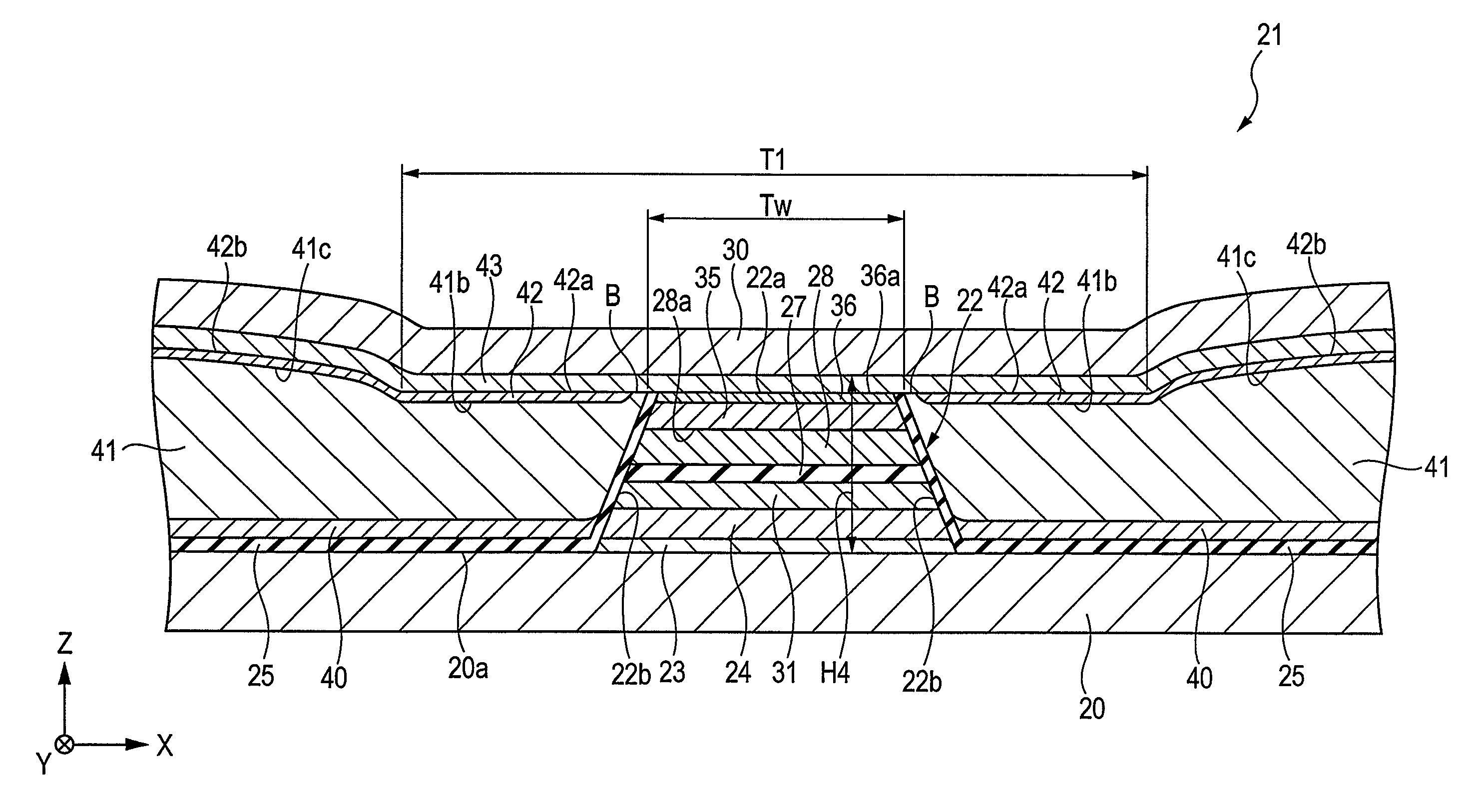

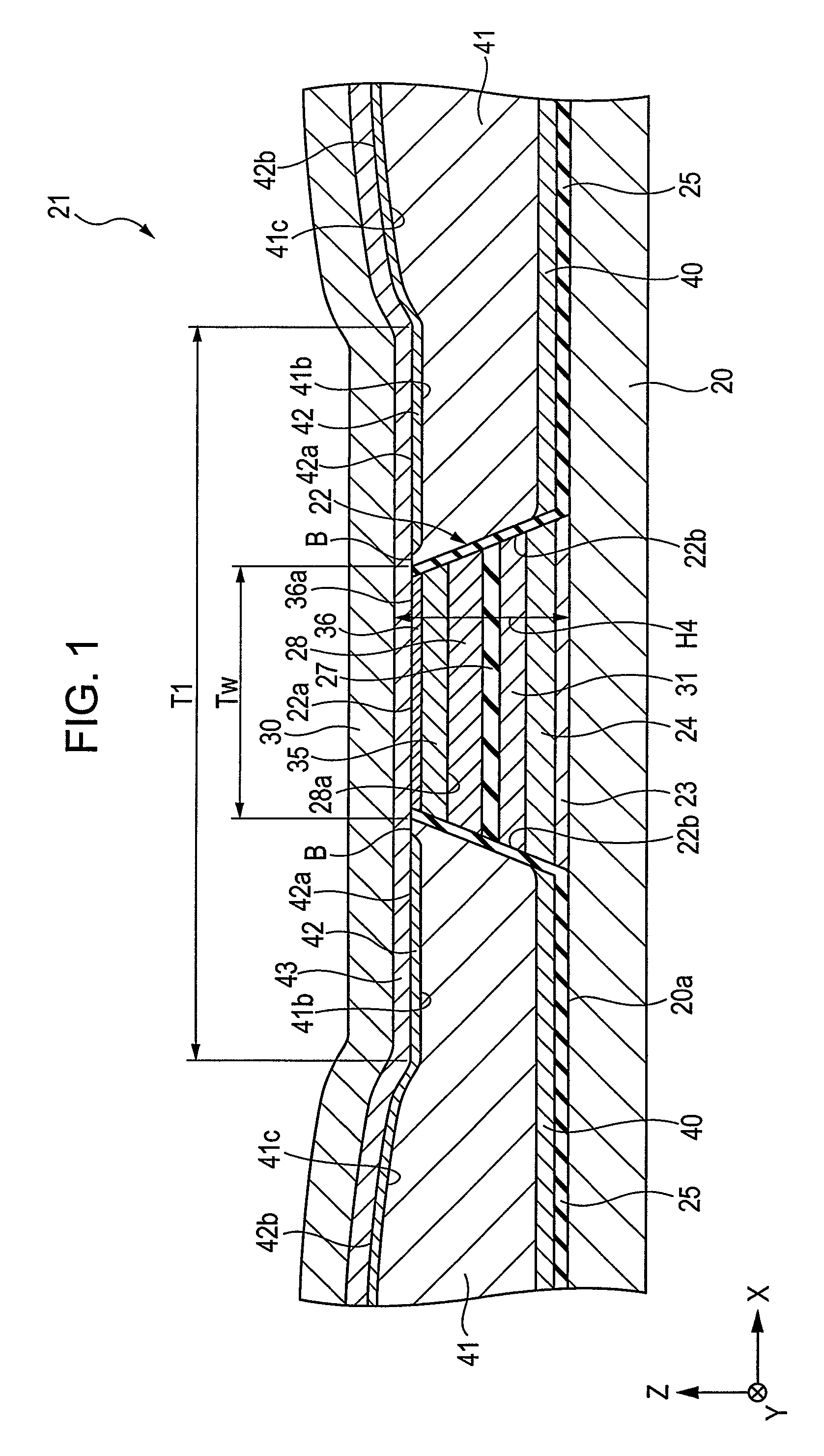

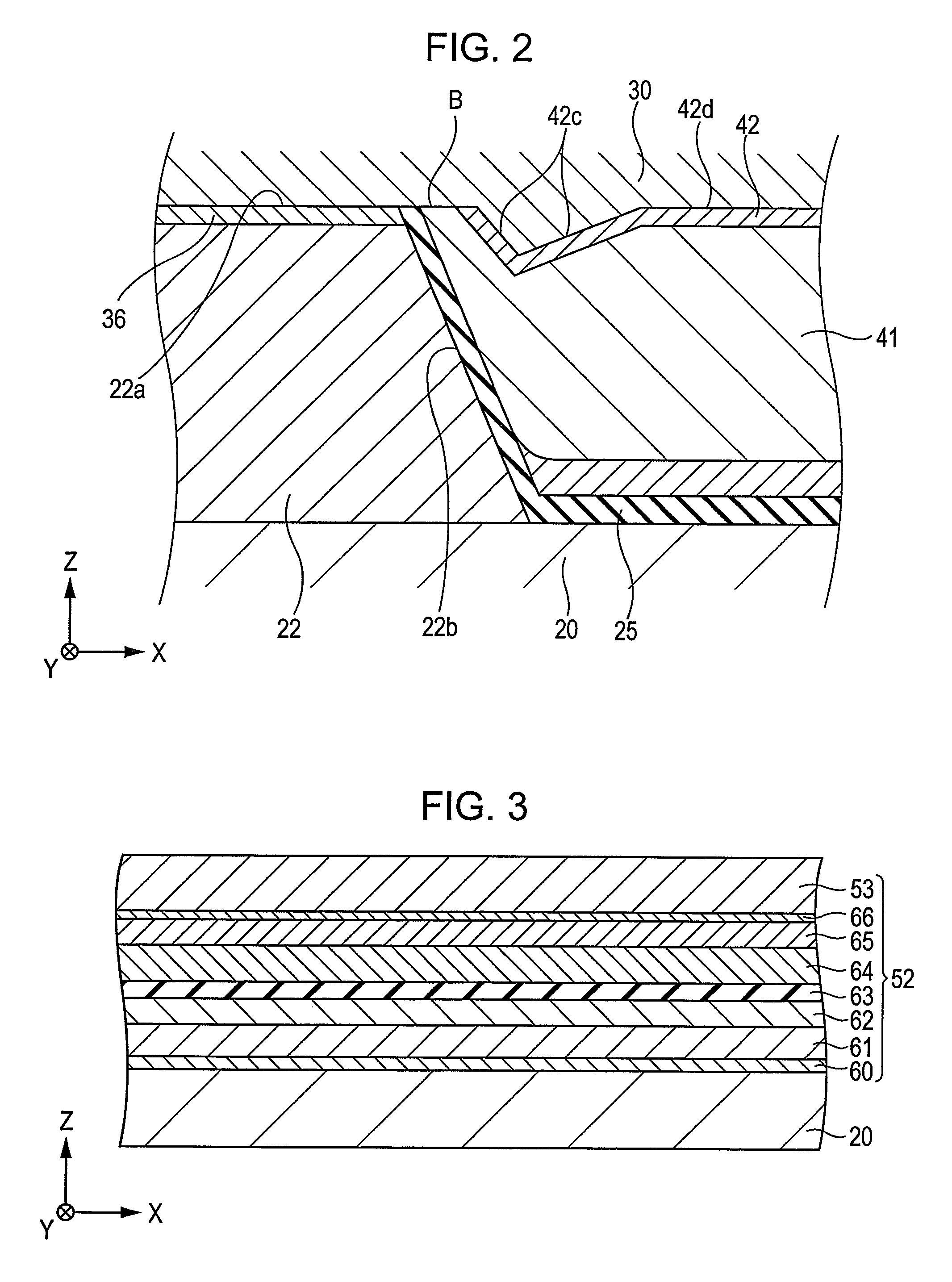

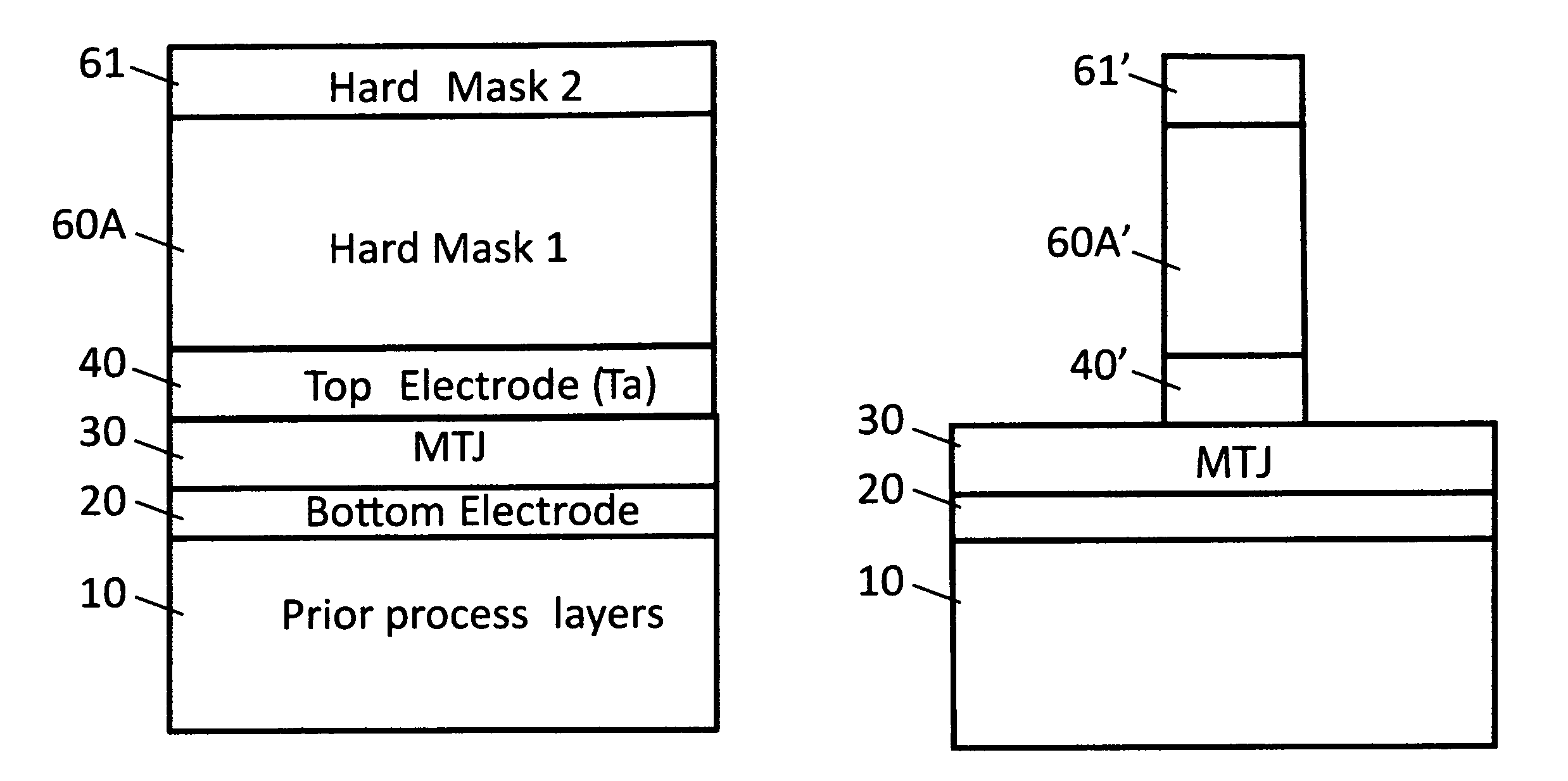

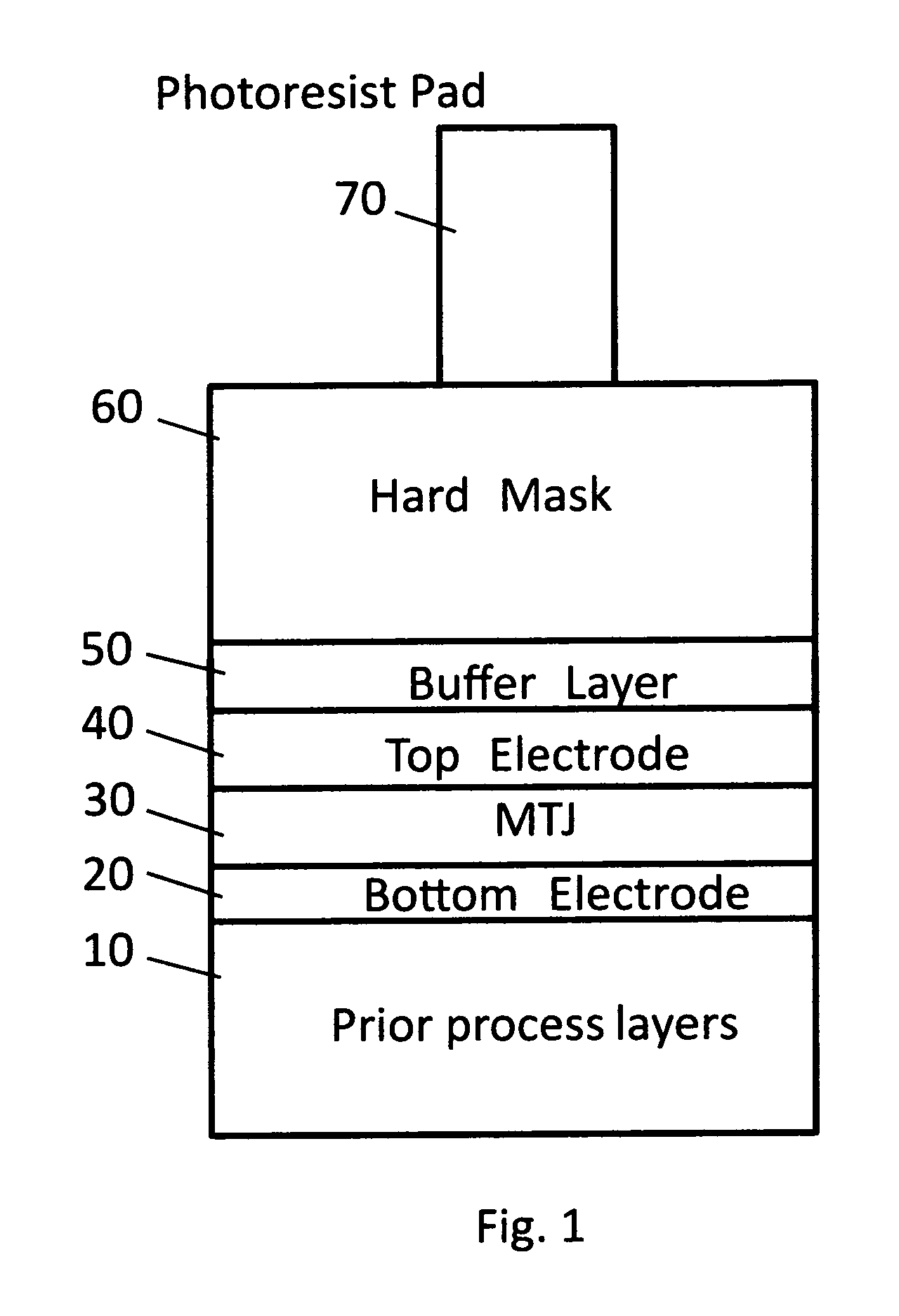

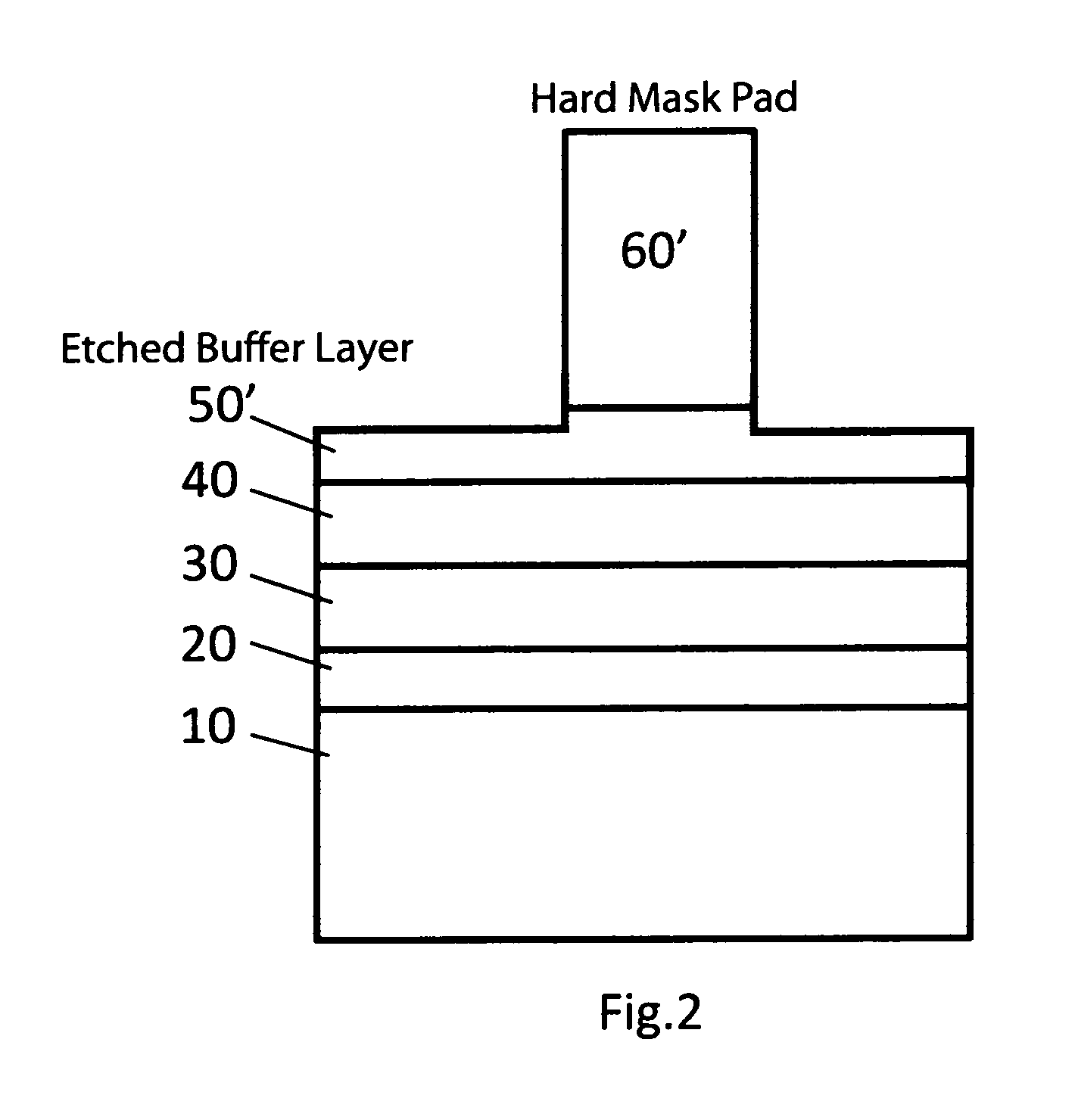

Mram etching processes

ActiveUS20130052752A1Good choiceHigh selectivitySemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentOxygen plasmaReactive-ion etching

Various embodiments of the invention relate to etching processes used in fabrication of MTJ cells in an MRAM device. The various embodiments can be used in combination with each other. The first embodiment adds a hard mask buffer layer between a hard mask and a top electrode. The second embodiment uses a multilayered etching hard mask. The third embodiment uses a multilayered top electrode structure including a first Cu layer under a second layer such as Ta. The fourth embodiment is a two-phase etching process used for the bottom electrode to remove re-deposited material while maintaining a more vertical sidewall etching profile. In the first phase the bottom electrode layer is removed using carbonaceous reactive ion etching until the endpoint. In the second phase an inert gas and / or oxygen plasma is used to remove the polymer that was deposited during the previous etching processes.

Owner:AVALANCHE TECH

Cleaning composition for semiconductor substrates

InactiveUS20080169004A1Efficient removalEtch rate reductionDetergent mixture composition preparationElectrostatic cleaningGlycerolCarboxylic acid

The present invention relates to a semi-aqueous cleaning composition used to remove unwanted organic and inorganic residues and contaminants from semiconductor substrates. The cleaning composition comprises a buffering system comprising a polyprotic acid having at least three carboxylic acid groups with a pKa value of about 5 to about 7. The composition also comprises a polyhydric solvent, such as glycerol. A fluoride ion source is also included in the cleaning compositions of the present invention and is principally responsible for removing inorganic residues from the substrate. The cleaning compositions of the present invention have a low toxicity and are environmentally acceptable.

Owner:VERSUM MATERIALS US LLC

Dry Etching Agent and Dry Etching Method

ActiveUS20130105728A1Efficient etchingHigh selectivityOrganic chemistrySemiconductor/solid-state device manufacturing1,3,3,3-TetrafluoropropeneProcess window

A dry etching agent according to the present invention preferably contains: (A) 1,3,3,3-tetrafluoropropene; (B) at least one kind of additive gas selected from the group consisting of H2, O2, O3, CO, CO2, COCl2, COF2, CF3OF, NO2, F2, NF3, Cl2, Br2, I2, CH4, C2H2, C2H4, C2H6, C3H4, C3H6, C3H8, HF, HI, HBr, HCl, NO, NH3 and YFn (where Y represents Cl, Br or I; and n represents an integer satisfying 1≦n≦7); and (C) an inert gas. This dry etching agent has less effect on the global environment and can obtain a significant improvement in process window and address processing requirements such as low side etching ratio and high aspect ratio even without any special substrate excitation operation.

Owner:CENT GLASS CO LTD

Novel method to deposit carbon doped SiO2 films with improved film quality

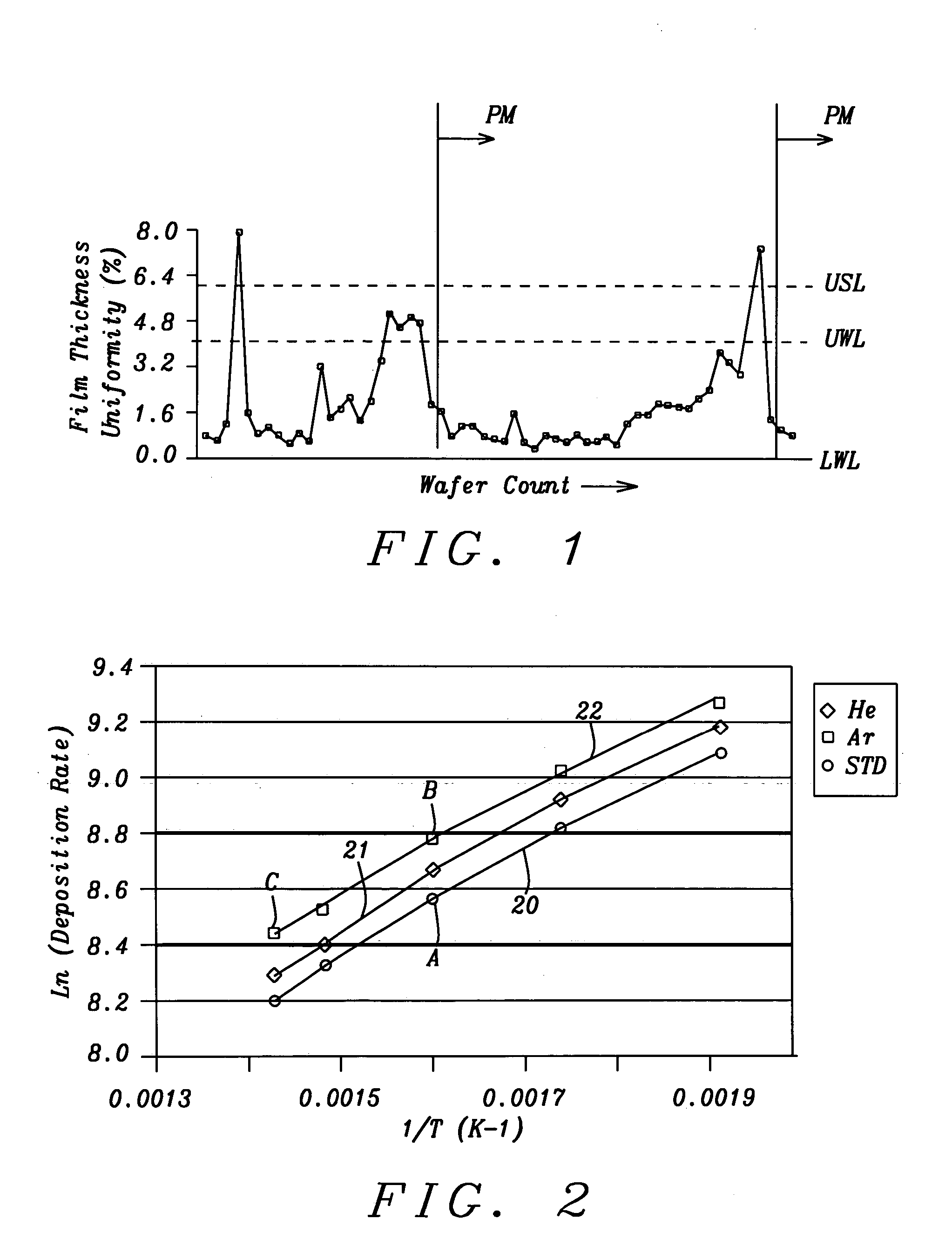

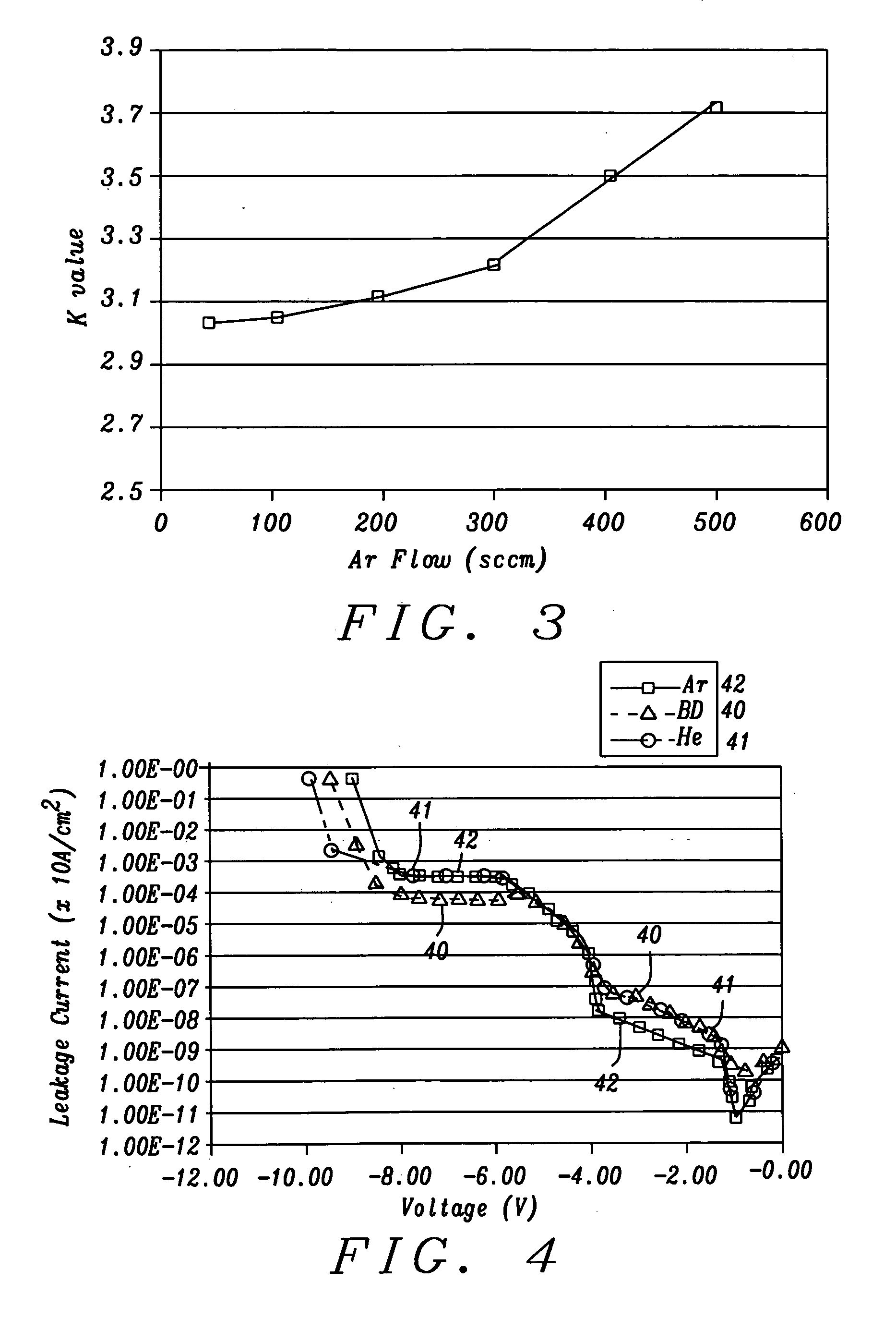

InactiveUS20050124151A1Increase deposition rateImprove film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal interconnectLow leakage

A method is disclosed for depositing a Black Diamond layer in a CVD chamber. Trimethylsilane, O2, and Ar are flowed into the chamber at 300° C. to 400° C. with an O2:Ar:trimethylsilane flow rate ratio that is preferably 1:1.5:6. The resulting low k dielectric layer is formed with a higher deposition rate than when Ar is omitted and has a k value of about 3 that increases only slightly in O2 plasma. A higher density, hardness, and tensile strength are achieved in the Black Diamond layer when Ar is included in the deposition process. The addition of Ar in the deposition maintains film thickness uniformity below 2% for a longer period so that PM cleaning operations are less frequent and affords a lower fluorocarbon plasma etch rate to enable improved trench depth control in a damascene scheme. A lower leakage current and higher breakdown voltage in achieved in the resulting metal interconnect.

Owner:TAIWAN SEMICON MFG CO LTD

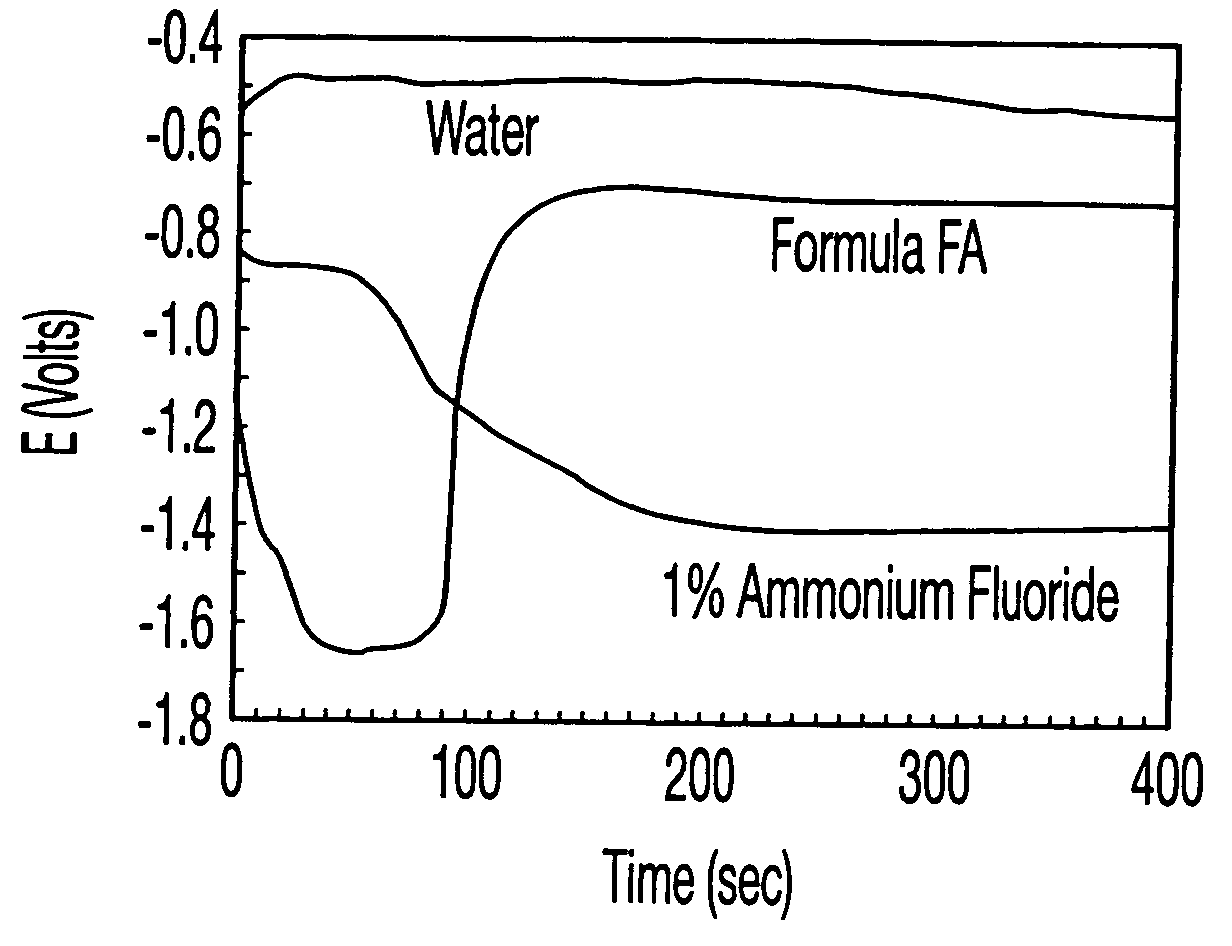

Forming a passivating aluminum fluoride layer and removing same for use in semiconductor manufacture

InactiveUS20060000492A1Enhance clean action and cleaning capabilityEffective temperatureDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventFluoride salt

A composition for the cleaning of residues from substrates can contain from about 0.01 percent by weight to about 5 percent by weight of one or more fluoride compounds, from about 20 percent by weight to about 50 percent by weight water, from about 20 percent by weight to about 80 percent by weight of an organic amide solvent and from 0 to about 50 weight percent of an organic sulfoxide solvent. The composition can have a pH between about 7 and about 10, alternately from greater than 8 to about 10. Additionally, the composition optionally can contain corrosion inhibitors, chelating agents, surfactants, acids, and / or bases. In use of the composition, a substrate can advantageously be contacted with the composition for a time and at a temperature that permits cleaning of the substrate.

Owner:EKC TECH

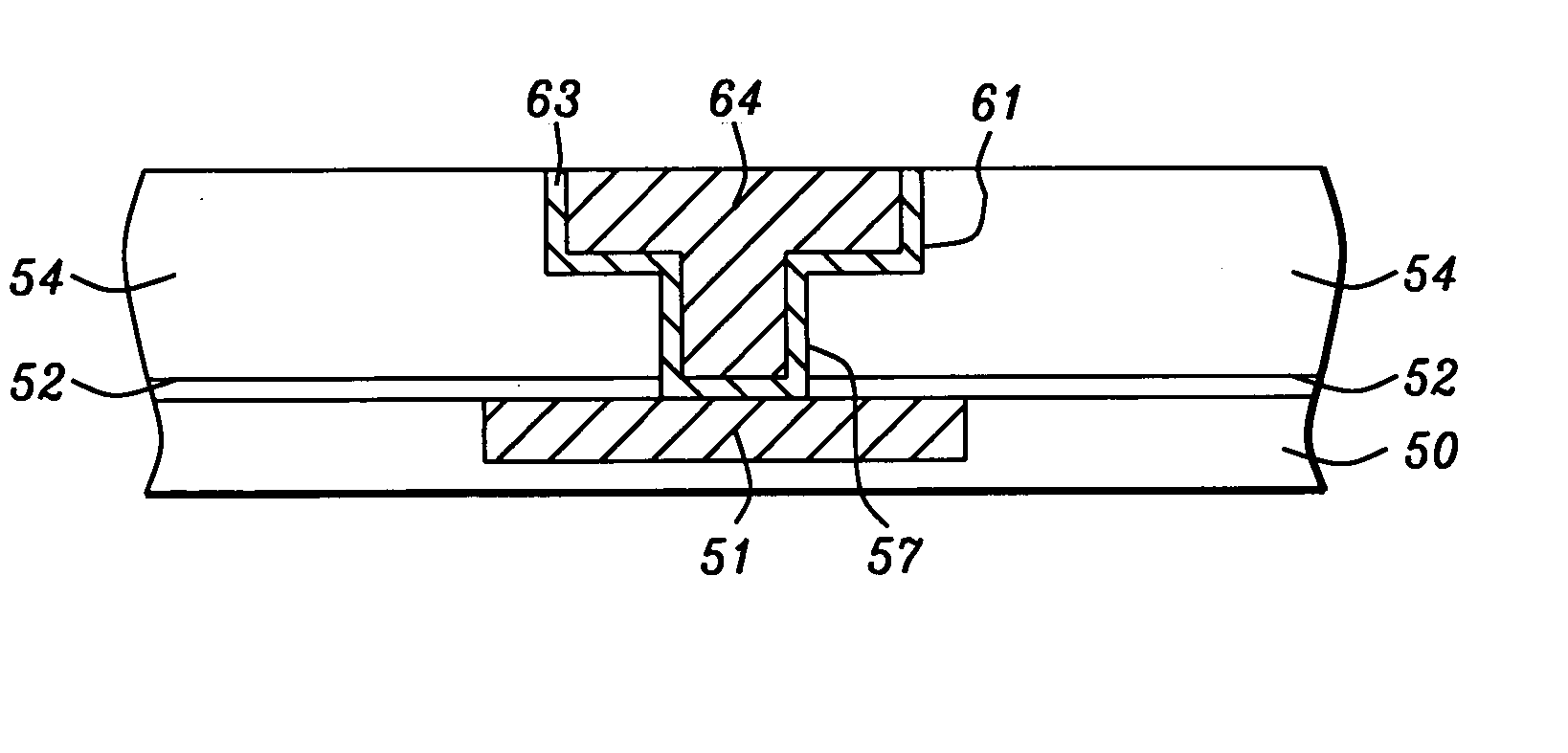

Magnetic sensing element having reactive-ion-etching stop layer and process for producing same

ActiveUS20060291097A1Reduce variationReduce etch rateNanomagnetismMagnetic measurementsReactive-ion etchingMagnetic layer

A magnetic sensing element including a laminate and a bias layer is provided. A first reactive-ion-etching (RIE) stop layer is disposed on a free magnetic layer. Second RIE stop layers are disposed on bias layers. The first and second RIE stop layers function as stop layers when layers on the first and second RIE stop layers are removed by reactive ion etching in a production process. Reactive ion etching is completed when the first RIE stop layer and the second RIE stop layers are exposed, the first and second RIE stop layers being disposed at almost the same height. Also provided is a process for producing the magnetic sensing element.

Owner:TDK CORPARATION

Abrasive liquid for metal and method for polishing

InactiveUS20050095860A1Improve reliabilityEtch rate reductionDecorative surface effectsSemiconductor/solid-state device manufacturingTectorial membraneFilm-forming agent

An abrasive liquid for a metal comprising (1) an oxidizing agent for a metal, (2) a dissolving agent for an oxidized metal, (3) a first protecting film-forming agent such as an amino acid or an azole which adsorbs physically on the surface of the metal and / or forms a chemical bond, to thereby form a protecting film, (4) a second protecting film-forming agent such as polyacrylic acid, polyamido acid or a salt thereof which assists the first protecting film-forming agent in forming a protecting film and (5) water; and a method for polishing.

Owner:RENESAS ELECTRONICS CORP

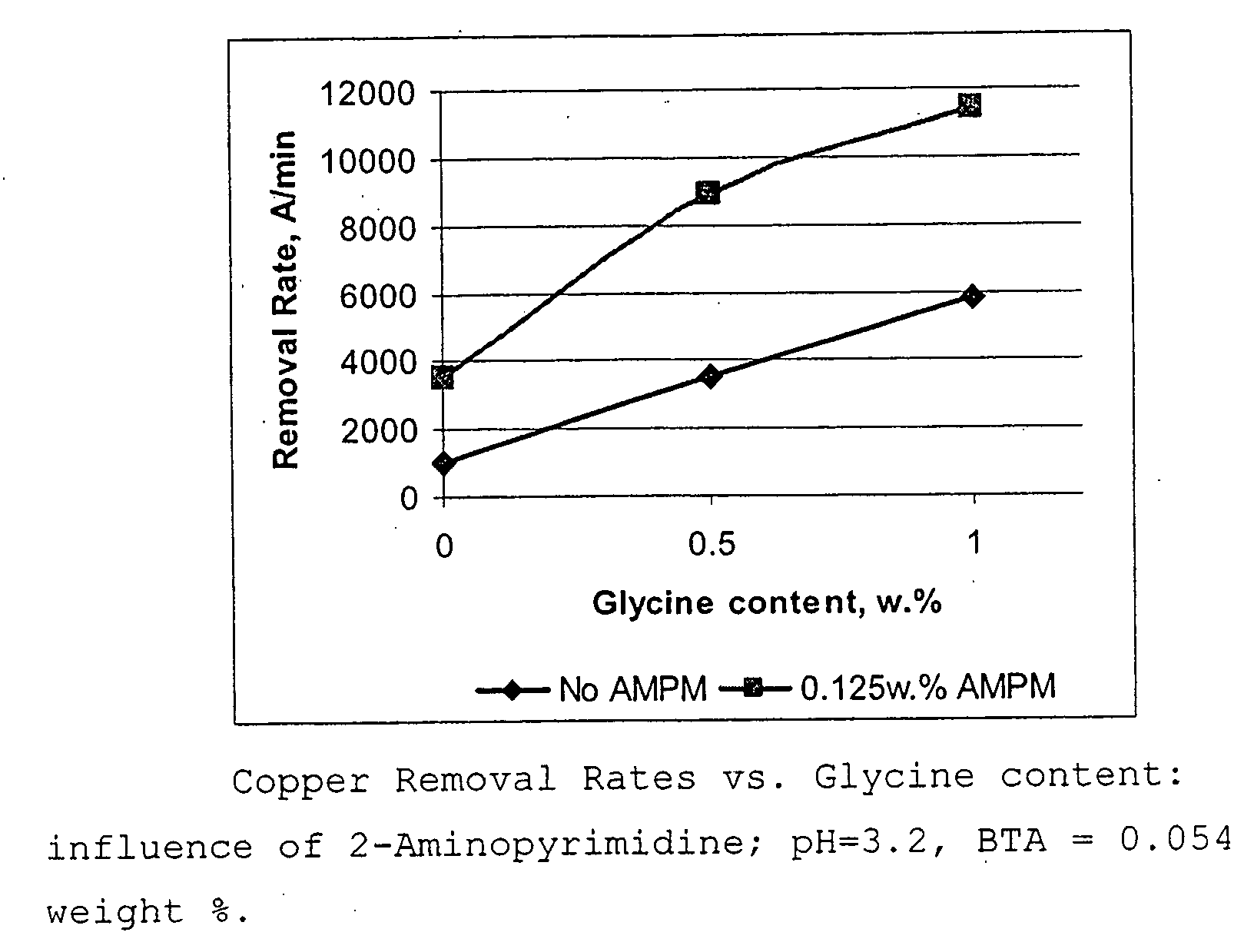

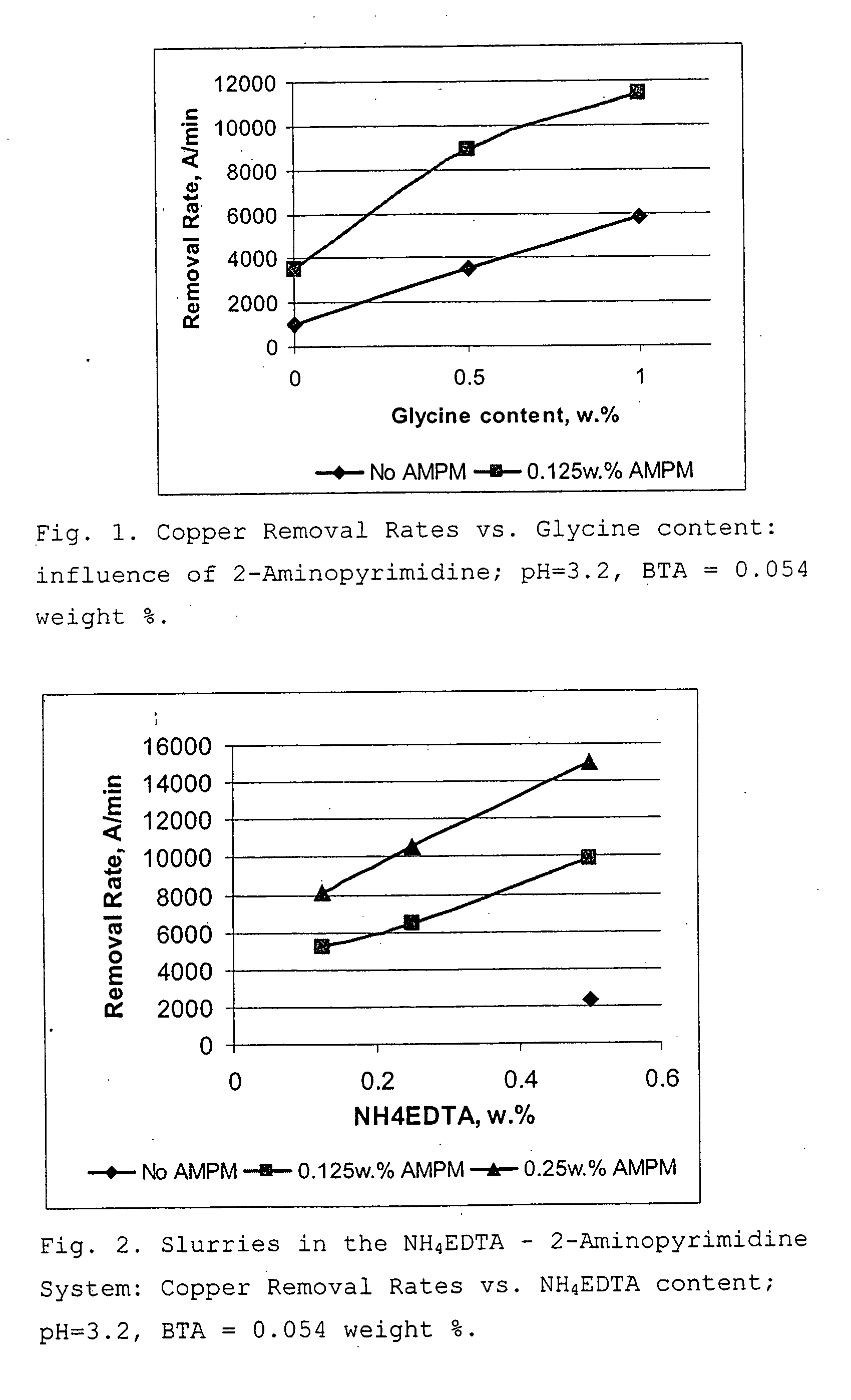

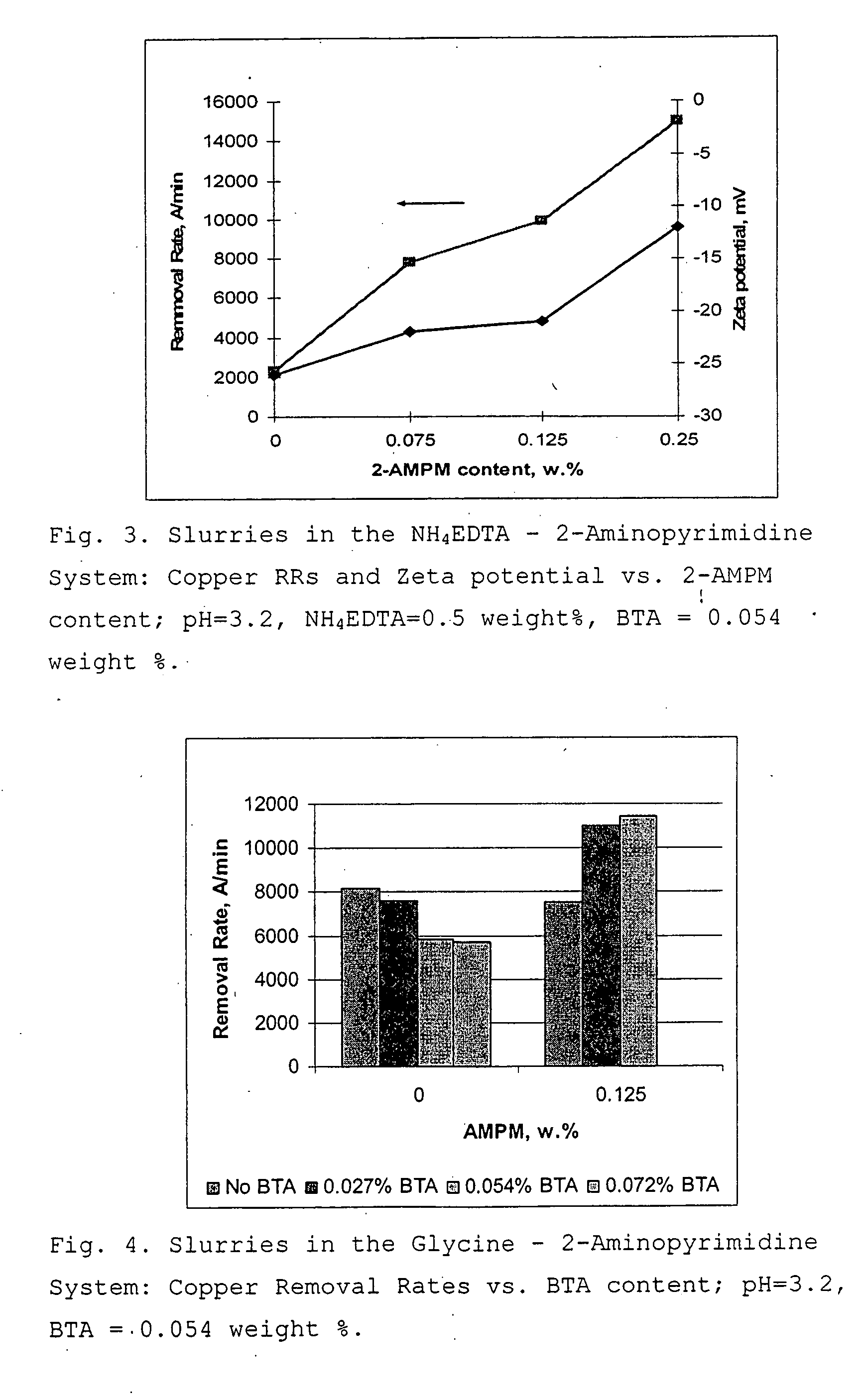

Novel polishing slurries and abrasive-free solutions having a multifunctional activator

InactiveUS20060163206A1High removal rateIncrease of copper removal rateOther chemical processesDecorative surface effectsSolution compositionCompound (substance)

The present invention relates to aqueous slurry / solution compositions for the Chemical Mechanical Polishing / Planarization (“CMP”) of substrates. In particular, the novel slurries / solutions of the present invention contain a multifunctional activator which provides increased copper removal rate to the aqueous polishing slurry / solution while suppressing isotropic chemical etch and dishing of copper lines.

Owner:PRAXAIR TECH INC

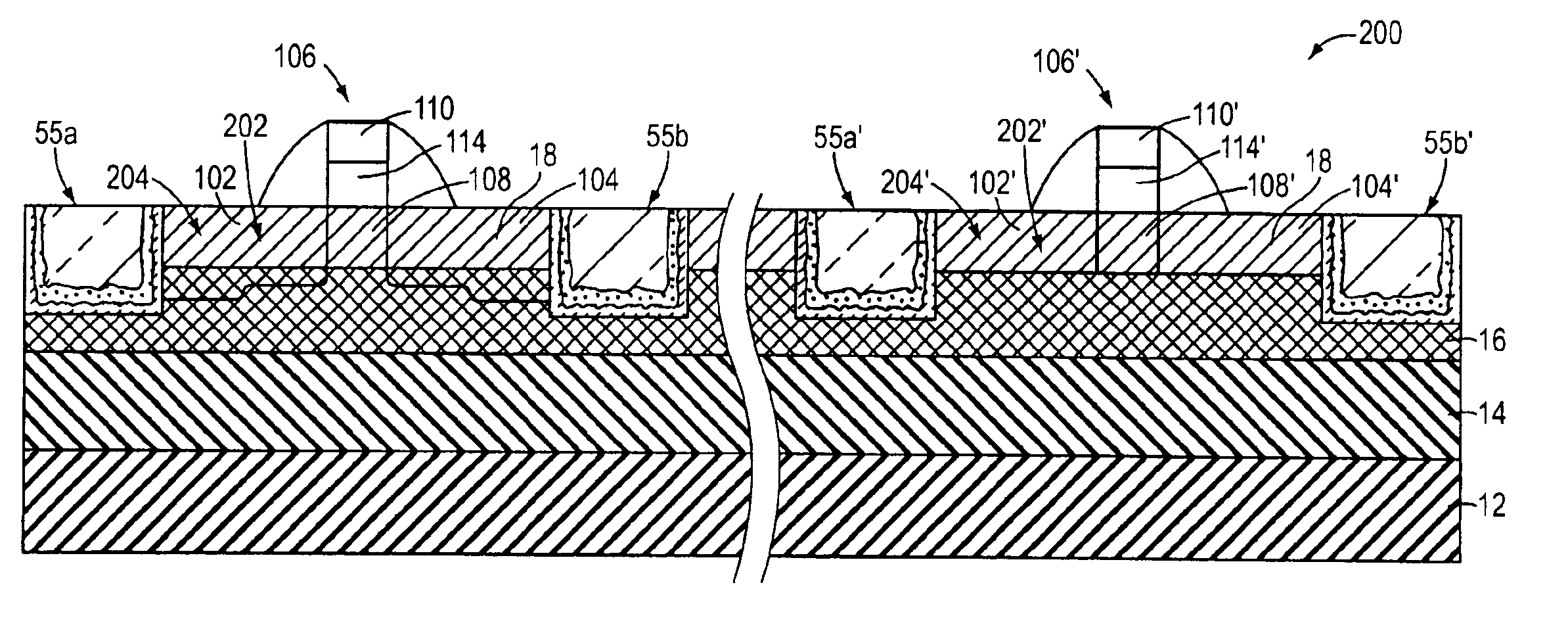

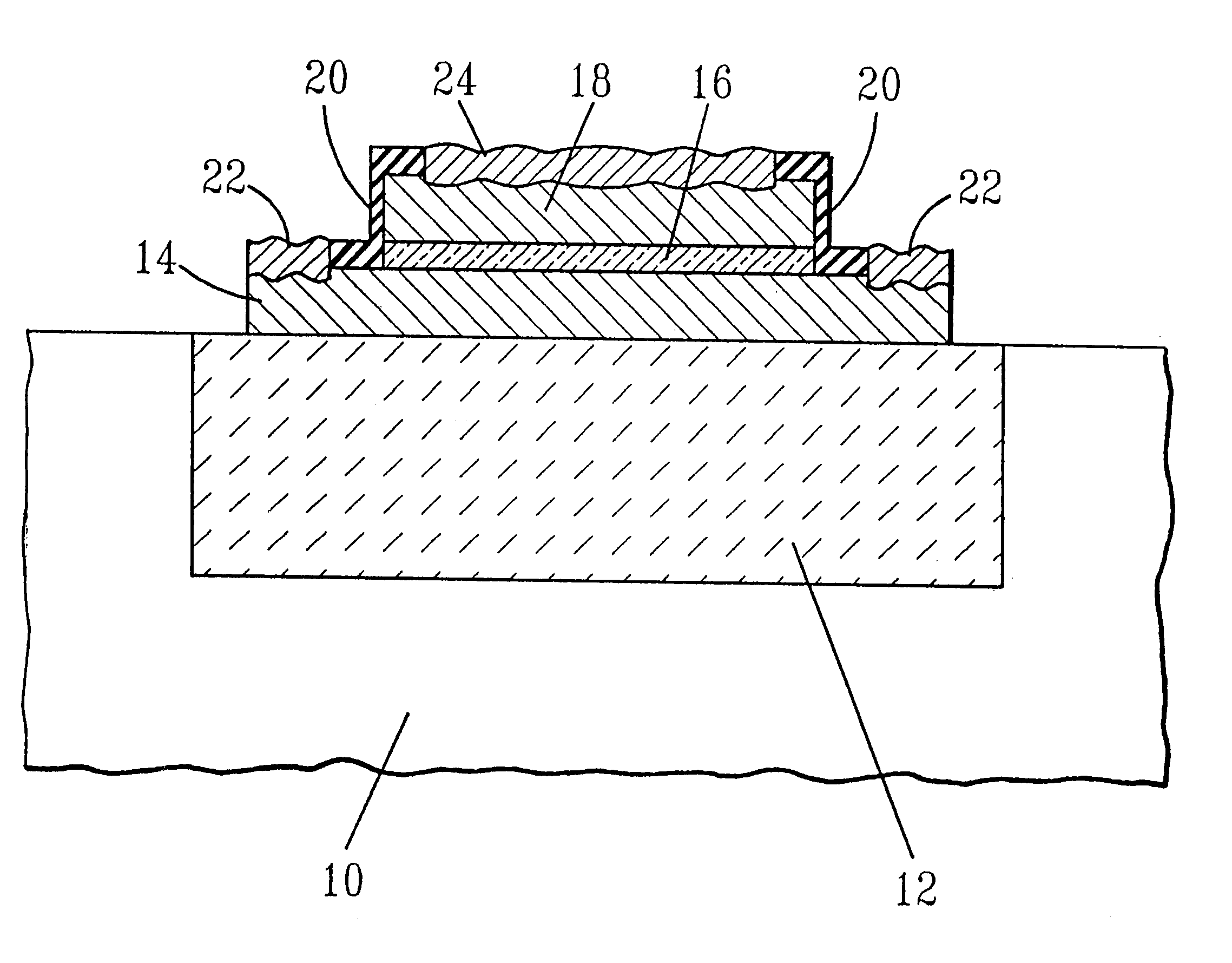

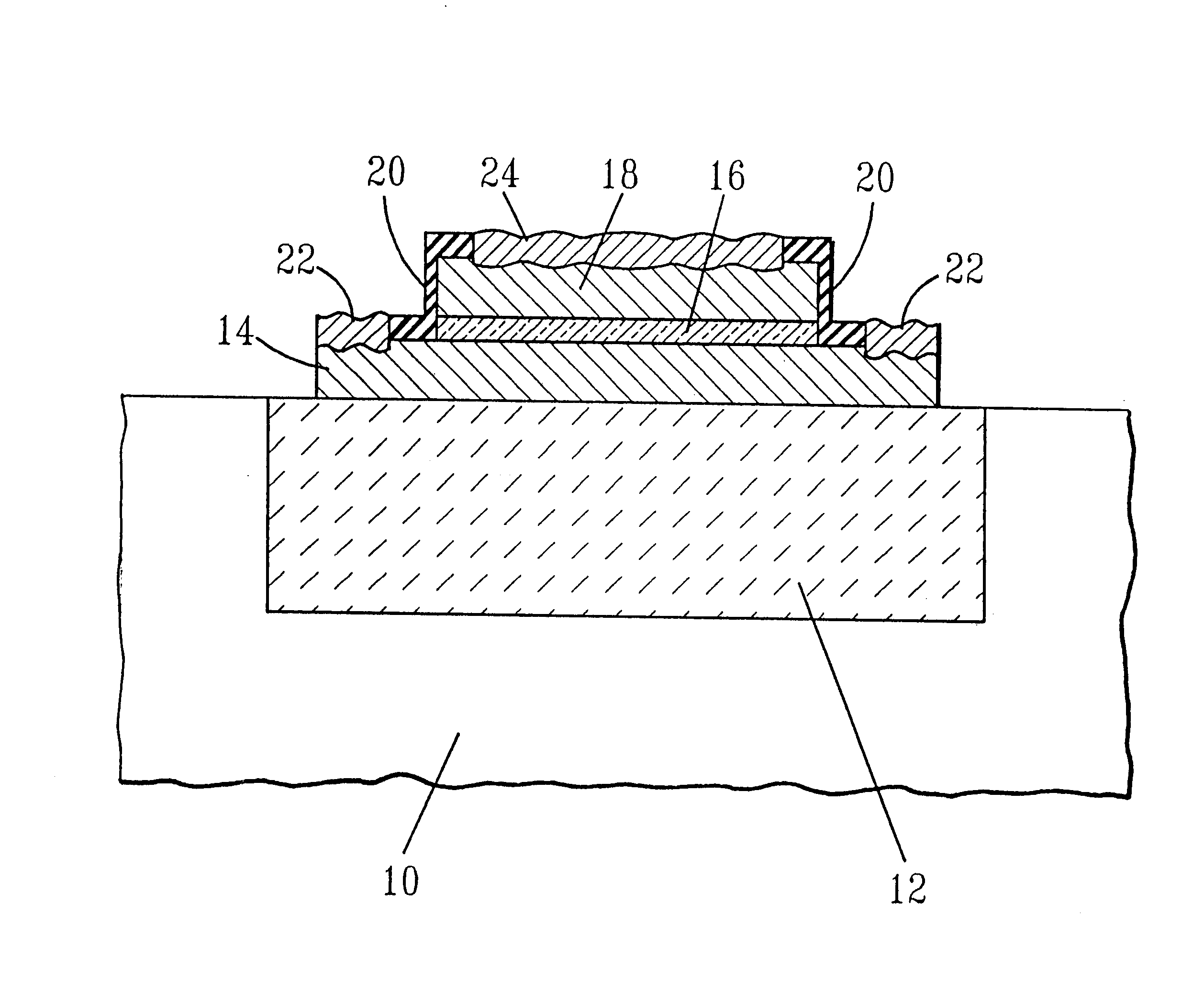

Semiconductor device and manufacturing method thereof

InactiveUS20060197230A1Improve throughputImprove reliabilityTransistorSemiconductor/solid-state device detailsEngineeringManufacturing line

A semiconductor device comprises a first insulating film formed over a semiconductor substrate, a second insulating film formed on the first insulating film, a contact plug made of a conductive material vertically penetrating the first and second insulating films and extending on the second insulating film, and a conductor film in contact with the upper surface of the contact plug and part of the second insulating film. This construction makes it possible to form minute via-holes in a mass-production line without increasing parasitic capacity, increasing the number of manufacturing steps, and generating defects.

Owner:FUJITSU SEMICON LTD

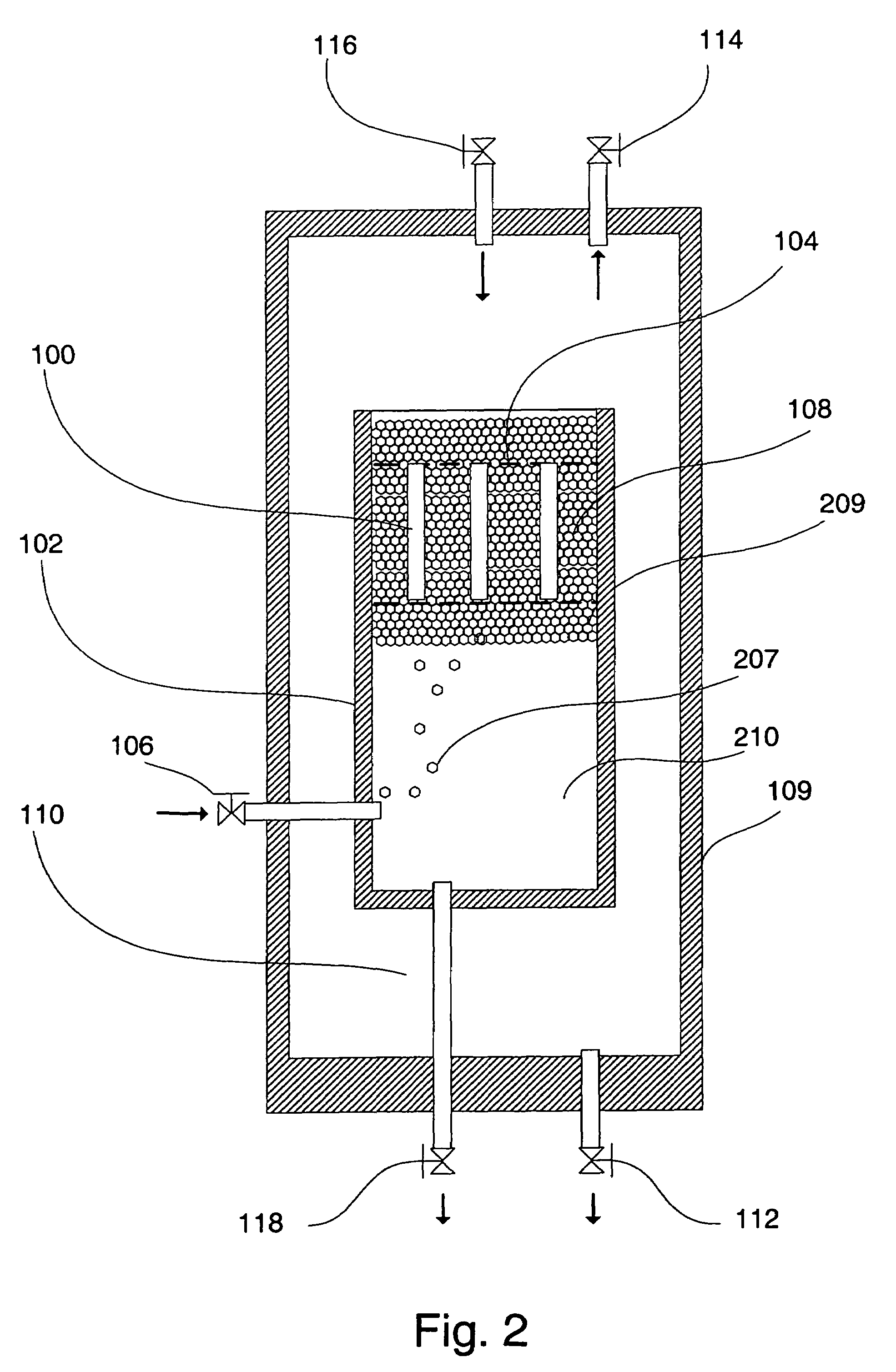

HTO (high temperature oxide) deposition for capacitor dielectrics

InactiveUS6218315B1Improve reliabilityEtch rate reductionSolid-state devicesSemiconductor/solid-state device manufacturingDielectricGas phase

Reliable HTO (High Temperature Oxide) dielectrics are provide by a rapid thermal chemical vapor deposition (RTCVD) process in which a low pressure and a high ratio of reactants, e.g., oxygen-containing gas to silane-containing gas, is employed. Specifically, the reliable HTO is formed by a rapid thermal chemical vapor deposition at temperatures of from about 500° C. or above, said rapid thermal chemical vapor deposition process being carried out at a pressure of less than 80 Torr and in the presence of at least one oxygen-containing reactant and at least one silane-containing reactant, said reactants having a ratio of oxygen-containing to silane-containing of about 25:1 or greater. Semiconductor devices such as capacitors and transistors that include at least a layer of the high temperature oxide of the present invention used as a dielectric material are also provided.

Owner:IBM CORP

Magnetic sensing element having reactive-ion-etching stop layer and process for producing same

ActiveUS7623324B2Reduce variationReduce etch rateNanomagnetismMagnetic measurementsReactive-ion etchingMagnetic layer

Owner:TDK CORPARATION

MRAM etching processes

ActiveUS8536063B2Good choiceHigh selectivitySemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentOxygen plasmaReactive-ion etching

Owner:AVALANCHE TECH

Methods for chemically treating a substrate using foam technology

InactiveUS7273060B2Reduce the amount requiredLower operating temperatureInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEtchingHydroxylamine

The present invention relates to methods and compositions for treating a surface of a substrate by foam technology that includes at least one treatment chemical. The invention more particularly relates to the removal of undesired matter from the surface of substrates with small features, where such undesired matter may comprise organic and inorganic compounds such as particles, films from photoresist material, and traces of any other impurities such as metals deposited during planarization or etching. A method according to the present invention for treating a surface of a substrate comprises generating a foam from a liquid composition, wherein the liquid composition comprises a gas; a surfactant; and at least one component selected from the group consisting of a fluoride, a hydroxylamine, an amine and periodic acid; contacting the foam with the surface of a substrate; and, removing the undesired matter from the surface of the substrate.

Owner:EKC TECH

Polishing compound for chemimechanical polishing and polishing method

InactiveUS7232529B1Highly reliable buried metal film patternsImprove efficiencyOther chemical processesDetergent mixture composition preparationTectorial membraneFilm-forming agent

This invention provides a polishing medium for CMP, comprising an oxidizing agent, a metal-oxide-dissolving agent, a protective-film-forming agent, a water-soluble polymer, and water, and a polishing method making use of this polishing medium. Also, it is preferable that the water-soluble polymer has a weight-average molecular weight of 500 or more and the polishing medium has a coefficient of kinetic friction of 0.25 or more, a Ubbelode's viscosity of from 0.95 mPa·s (0.95 cP) to 1.5 mPa·s (1.5 cP) and a point-of-inflection pressure of 5 kPa (50 gf / cm2).

Owner:RESONAC CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com